Oil Well Pressures - What Brings the Oil Out

Posted by Heading Out on September 6, 2009 - 10:58am

Michael Lynch would have it believed that those who follow this site are relying purely on “anecdotal information, vague references and ignorance of how the oil industry goes about finding fields and extracting petroleum,”, so I’m here again proving him wrong. Here, on Sundays I give a little of the technical background so that those interested can understand more about the realities of production. The posts are a simplification of what goes on, but give enough detail that, hopefully, it is understandable (and if not then you should ask questions). The posts build on an original set of tech talks I wrote four years ago, but are a bit expanded. Interestingly four years ago Michael was spouting the same sort of stuff and getting it wrong back then too.

This post is going to deal with some of the problems that a driller encounters as he reaches the layer of rock (the reservoir) in which the oil or gas is being held. And what I want to talk about is something called Differential Pressure, but to explain that, I need to drag you back to High School for just a minute.

Let's, in fact, go back to Newton's Three Laws. And, for those who slept through that part of the Physics class in school, don't be too ashamed - I have seen the desk where Newton whittled his name, being similarly bored. Let's start with the first law, which is probably the most relevant.

Every object in a state of (rest or) uniform motion tends to remain in that state of (rest or) motion unless an external force is applied to it.

Except that I want to change external force into pressure (which is force divided by area) since it is the way we normally think of it. (Note: I added rest which is a special case of uniform motion since that is specific to the oil we want to talk about). In other words, nothing is going to move unless something pushes it. It is what does the pushing and what does the moving that this is all about.

And now our drill, is down through the casing, drilling the well open hole and using the circulating mud to carry away the cuttings as it continues to go deeper. I had stopped progress last week just before we went down to total depth (TD) of the well, or into the pay. And the reason I did has to do with this differential pressure. But first, the bit about how you calculate pressure.

As you go deeper into the earth, the rock at any layer is carrying the weight of all the rock vertically above it. For rough calculations we generally consider that this rock weighs 144 lb a cubic foot. So that 10 ft down the weight of the overlying column on a square foot would be 144 x 10 = 1,440 lb/sq ft. But through convention we reduce the area that we talk about to a square inch (144 sq in= 1 sq ft) so with this division the weight on a square inch would be 10 lb. A remarkable resemblance to the depth number (grin). This means that we can assume, as we go deeper into the earth, that the pressure on the rock increases by 1 lb/sq. inch (psi) for every foot we go deeper. This means that at 6,000 ft, the rock is under a pressure, from the rock above it, of 6,000 psi.

Now water does not weigh as much as rock, but can be approximated to roughly half the weight. So that, by the same argument, under water, for every foot of depth the pressure goes up roughly half-a-psi. So that at 6,000 ft under water the pressure is 3,000 psi (roughly twice the water pressure in the wand you use at a car wash). Now because we have increased the density of the fluid in the well (the mud) to help lift the cuttings out of the hole it weighs a bit more than water, but for the sake of working the example I'm going to use the half-psi measure for now. We are now at the point where the actual amount that it weighs becomes important.

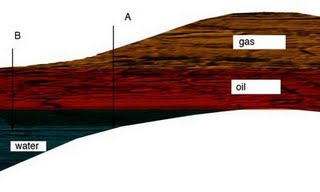

I have made a very simple sketch of the layer of rock that we are going to drill into. In order to trap the oil it is shaped into a dome, and the sketch shows a vertical slice through that dome, viewed from the side. It has a layer of oil in it (the reddish layer), but above that is a layer of gas that has diffused from the oil (brownish), and below it is water (bluish) which may have been there when the algae died and which has stayed with the remains as they turned into oil under the temperatures and pressures deep in the rock. Oil floats on water, and gas is lighter than oil, so we have the three layers. At the moment the well has not arrived and all three fluids are sensibly in equilibrium at the same pressure.

Now why do we need to know this before we reach our layer of oil-bearing rock? Well first let's go and interpret that first law a little more.

If a person on either side of you pushed you with equal force at the same time, you don't move, because the two forces balance out. It is only if there is one force, or if one of the two pushes harder, that you move. In other words, where there are a number of forces acting on a body, it is the size of the difference in pressures, and the direction of that difference, that controls the movement.

Consider, here we are drilling merrily away (and have cased the well near the surface, and hit no more fluids on the way down) and at 6,000 ft. we penetrate the rock that is capping the well, and enter the rock with the oil in it. The oil (in the rock) is at some fraction of the overburden pressure, since it is trapped in the rock, and for the sake of this example I am going to say that it is at 5,000 psi , the fluid in the well is at 3,000 psi, the height of the mud column.

There is a difference of 2,000 psi. We are drilling a hole some 6-5/8th inches in diameter. That has an area of about 34.5 square inches. The total force we have suddenly applied to the bottom of the well (bit and fluid) is thus (area x pressure difference) 34.5 x 2,000 = 69,000 lb (or 35 tons). Oops!

Sadly most catch fire and the rig is destroyed (there are more pictures of such damage at the EIP site). It's called a blow-out, and they still happen.

This is why we approach the oil/gas producing zone of the rock with caution. And bear in mind that the driller that is controlling the progress of this well is at the surface, trying to guide the bit at the bottom of the hole, with, historically, little immediate information to help.

Based on the surveys that brought the crew to the site in the first place he knows roughly how thick the layers of rock are, and probably what rock they are, but the only real information on where the bit is in that sequence, is from the returns (cuttings) that come out of the well, and there is the lag, we mentioned before, while those chips make their way up the 6,000 ft pipe. (This is why Measurement While Drilling [MWD] has been such a relatively recent boon to the industry (though not all rigs have it)).

By monitoring a number of pressure gages the driller can gain a sense of what is happening at the bottom of the well. If he senses that there is going to be a problem, then he can do one of several things, based on the way the well is set up.

The first thing is to increase the density of the mud. By making the fluid in the well weigh more, the difference in the pressure across that face is reduced, and the change in conditions is easier to handle. However weighting up the hole has the disadvantage that it becomes much slower to drill with a heavier mud (it is a poor bottom-hole cleaner among other things). And, if done during drilling, bear in mind that once the heavier mud is added to the well it won't be fully effective until it has had time to get down to the bit and then fill back up the annulus between the drill string and the casing all the way to the surface.

So that is an expensive and slow option. Let us take the game a little more interesting and say that there is a gas pocket above the oil, and that the hole is going to go into the layer at A. Gas will enter the well at the down-hole pressure, but as the bubble rises, that pressure is reduced, and the gas expands, pushing the mud above it out ahead of itself. Another potential source for big-time trouble. And this one (which is known as a kick in the well) happens much faster, so there is less time to react.

How do we handle this? The answer is to invert the problem. Gas or oil flows into the well because the well is at a lower pressure than the fluid in the rock. The fluid in the well is, initially at the pressure created by the depth, and by the weight (density) of the mud in the hole. However, if we put a restriction on the flow of fluid out of the well (such as when you put your finger over the end of a garden hose so that the stream becomes smaller and shoots out further) we can increase the pressure in the well.

For those who want to know why, if the same volume has to go through a smaller hole in the same amount of time it has to go faster. This means it has to be pushed harder. Bernoulli explained it, and there is an animation available that helps explain it.

What it means is that by adjusting the flow out of the hole, the driller can adjust the internal pressure, and thus "kill the kick," or if gets to be too much of a problem, “kill the well”. But it is not completely that simple. Bear in mind that there is all the drilling and rotating equipment on the rig floor connected to the drill pipe at the top of the well. None of this can stand much pressure. So we need to place another piece of equipment between the drilling rig, and the top of the well.

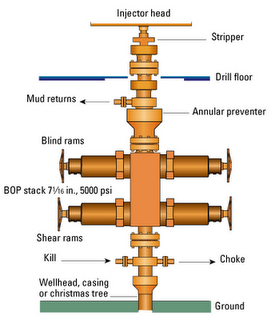

This is the Blow-out Preventer (BOP), which is essentially a ram that very rapidly shuts off fluid flow at the top of the well. These have to be well designed, since they are generally the line of last defense against a blowout, and when they fail as the pictures show, serious problems arise. They also form the basis for the well-known structures, often referred to as Christmas Trees that sit at the top of producing wells. By themselves, however, these aren't enough, since their main function is just to slam the door shut, before all the oil gets out and we have a gusher.

The more critical tools are the chokes on the well. (Below the rams in the picture above). There are generally several, both hydraulically operated and manual (in case the power dies) which are simply large valves that can be turned to increase or reduce the size of the flow path out of the well over to the mud pits. By adjusting these, in real time, the driller can control the well pressure, and thus the dynamics of the behavior at the bottom of the well. And after the rig leaves, an operator can adjust well pressure, and thereby the production from the well and its long-term performance.

If the operator is well trained (and you find drilling simulator equipment in Petroleum Engineering Departments so that students can understand how to do this (I last tried some decades ago) the well pressure will be controlled, so that any kicks can be handled, and the drill can now penetrate safely into the rock containing the oil/gas, which we call the reservoir, or the pay.

And you think the hard part is over?

Once the drill has penetrated through the layer, and the well has been completed, it is the controlled difference in pressure between the fluid in the rock and that in the well that will move the oil into the well, up and out into the pipeline. But we’ll talk about that when we talk about well completions and production in future posts.

As usual comments, questions and criticisms are welcomed. BTW if you're impatient with the speed of these posts, there is a lecture series on all this available from Rigzone, with videos. I haven't seen it, but I noticed it while looking for sources of pictures.

Hell HO....there you go again trying to send TOD into a coma. Just teasing as usual. I hope all the folks here try to make it through this thread. HO does a great job of supplying basic facts in as simple a format that offers useful knowledge. So many of the big headlines on flow rates, ultimate recoveries, etc, we discuss require this base knowledge. I appreciate how taxing the effort might be. I've looked into many a glazed eye trying to explain the same. Hang in there. HO has made the process a painless as possible.

Well HO. Your post has been up a few hours and no commentors other then my smarta**. Perhaps a lesson to be learned. Maybe you could resubmit it with a new title. Somthing like "Totally Naked Woomen Here" or "UFO's Finally Confirmed". Again, my compliments for your effort.

Well... maybe everyone's still in church. Yeah...yeah...that's the ticket!

Really folks. I know it rates up there with watching paint dry but it really is a good tutoring.

HO;

Once again, a very detailed but understandable description of an very complex process. And Rock, for what it's worth, I was fully intending on going to church this AM but got caught up in this essay, with it's attendant links. The video of the blowout on the ocean based rig was incredidble! I found myself thinking "And those guys (on the rig) get paid HOW MUCH to take that kind of risk?" Considering the sophisticated and expensive process it takes to get oil and natural gas out of the earth, it amaze's me that it has become such a routine thing that very few end users of that product (IE Joe and Jane Six Pack...folks like myself, that is) don't even give it a second thought. Of all the things that have to happen, and go as planned in order for me to pull up to the local QuickieMart and fill up my 12 year Ford Aerostar...this series is a real eye opener. Heading Out, again, thanks for all of your hard work. What I have learned by coming to this sight over the years never ceases to amaze me. In fact, I think the entire "Drill Here, Drill Now" crowd should be forced to read this series before putting one of those ridiculous bumpers stickers on their car.

Pete Deer

Dred,

How goes it?

Medic;

I am doing well, thank you for asking. Still participating as a minor cog in the giant wheel of the medical/industrial complex as a critical care/PACU RN in the local academic teaching hospital. I'm not sure how much longer the MIC will last given the machinations of a resource and credit constrained world, but I've been working on a local community garden and a few other operations that may allow myself and my loved ones to have a decent shot at living a fulfilling and meaningful life as we transition from our society of plenty to one that is not. That is, if the raging zombies don't get us first. Howse about you, eh?

Pete Deer

Dred,

2nd year med school. Cardio is my current system easy stuff after EMS and the cath lab. Harrogate, TN very rural med school I love it here. Thinking EM/IM dual residency but not sure.... Hopefully I can earn/save enough to head out west n get some land. Zombies don't scare me near as much as starving city folk. Zombies just eat your brains.

-matt

The devil fetch ye, ye ragamuffin rapscallions; you are all asleep.

HO,

Rockman you are not alone ;)

Thanks, yes we do read these,

You can bet that there is plenty of interest.The scarcity of comments is probably because most of us know so little about this subject that we can't even think of an intelligent question.

I am learning more in less time from these articles than any others since I've been reading this site.

Thanks!

This question may or may not be coming at the right time.

In other kinds of mechanical systems that are subject to breakage due to accident,sudden overload,etc, it is common to include a safety clutch or shear pins or bolts ,etc, that are sized to break before other more critical and expensive components are damaged.

Are drill strings so equipped and if so are there special hooks or rings or whatever included that make it easy or at least easier to latch onto whatever components are below the break and fish them out of the hole?

"Well HO. Your post has been up a few hours and no commentors other then my smarta**"

I think that is a tribute to the humility of folks here at TOD. I am well known for not being shy about commenting, sometimes making the error of speaking before I am really prepared and having to back out of a dead end argument of my own making (blush). But when it comes to the details of oil production, I will concede in most cases to the ones who know what they are talking about (and I consider myself well read on the subject compared to the population at large).

Oil production always makes me think of opera (I know, strange comparison but bear with me), it is an arcane, complicated, high risk venture in which the money has to be spent up front, and an amatuer commentator can easily argue that there MUST be some easier more direct way to do it. But the only way to get the beautiful effect is to do it the hard way. I am often at odds with the oil industry regarding motivations and overall philosophy, but I never question their ability, I am constantly astounded by what they are able to accomplish.

This creates another problem, that of having to defer to authority. If the oil industry says they can deliver the oil, I have to accept that they can (they always have) unless it can be proven that they can't. I will generally NOT bet against the oil industry.

RC

Never, never confuse the engineers with the management........

"Never, never confuse the engineers with the management........"

Point well taken in any industry. :-)

RC

Thanks for the kind words - this one is meant to get the basic ideas out, but as the following comments show, once you do that there are lots of follow on questions - thanks for helping with those.

Another superb presentation. Makes rocket science look easy by comparison! And we haven't even started on horizontal drilling (mind boggles).

Meanwhile that thing by Mike Lynch didn't exactly reek of sincerity.

This appears to me to be the same principle in which a mercury barometer works. The pressure air pushes the mercury up the tube, the tube is a vacuum so has had the overburden removed so to speak. The drilled hole is an analog to the tube under a vacuum. The overburden is an analog to air pressure.

Is this right?

Right on the money barrett. To carry on your analogy when we encounter a reservoir with lighter density oil/NG it acts like a bump up in over burden pressure. I know that sounds counterintuative but that's how it works. One of the very tricky aspects of drilling for large hydrocarbon reserves in the DW GOM is that the difference in mud weight (when you encounter such a zone) between having a blow out (too light MW) and fracturing the formation (too heavy MW) might only be 0.2 or 0.3 pounds per gallon...a very slight difference in other words.

One method to estimate the down hole MW requirements is to analyze electronic data sent from the downhole drilling assembly in real time. These measurements of the rock properties can be used to calculate changes in the bottom hole pressure. This was my job during the last 3 years before switching gigs recently. This is a big improvement from the old method of just "listening to the well talk to you". Then some times the message was "run like hell". Too late then to make adjustments. The new method is far from full proof but it's a big improvement.

HO,

I enjoyed reading this post, as I have appreciated reading your previous posts in this series. I agree that folks should have a basic understanding of the science and engineering of these processes in order to credibly talk about PO to others.

I say the same about other guest posters and their work educating about net energy, sustainable farming, and the like.

It would be great for TOD folks knowledgeable in various areas to create series of posts on how various power plants work (coal vs. nuclear vs. NG), how wind turbines operate, PV cells, CSP, electical grids, battery technology, etc.

Population dynamics, resource sources and sinks, and the financial system all beg for tutorials. I just read the test portion of 'The Crash Course' last night and thought it was a useful primer to the ideas of debt, money, and how the financial system appears to be based on the bedrock assumption of continual growth as far as the eye can see. A basic knowledge base of these things is essential to having a reasonable conversation about sustainability; it is the lack of this knowledge that fuels a lot of the partisan screaming that contaminates and even drives political discourse.

Perhaps all Congressfolks and their staffs (and the Executive and Judicial branches as well) should have to study these topics and pass an exam to demonstrate at least minimal acceptable levels of understanding before they go about and make policies which are often sub-optimal and counter-productive.

Technical explanations bubble up in Drumbeats here and there, but it is good to have a more formalized set of lectures to draw on.

Thank you for your great work, I am looking forward to more of these kinds of posts in the future.

MW

Thanks - to a degree it may be a question as to how many of my lectures you can bear to have me port over. (Grin) Actually in my class on power the other day I used the slides from the disaster at Sayano Shushenskaya that Euler Cruz and Rafael Cesario put up . If it doesn't go through (and I had a bit of a problem if you Google "Sayano Shushenskaya Cruz Cesario" it's the top link). They give a really good picture of how the mechanical side of how hydro power is generated, the electrical side took me a couple of lectures to get across. The steam cycle comes in the Thermo part of the course.

Sadly this was a real example of how badly things can go wrong.

I could not find the slides you mentioned, but I did look at some You Tube videos of the incident and the Wikipedia article about the Sayano Shushenskaya hydro station and a Wikipedia article about hydro power in general. My family and I toured Hoover Dam about 10 years ago, and saw the generator gallery. Very Impressive.

Well I just retyped in the four words "Sayano Shushenskaya Cruz Cesario" into the Google box, and now I get my post as the top hit - oh, well!!

It is the file that says "Accident at Russia's Biggest Hydroelectric " and it automatically downloaded into my Downloads file (I just checked and I have about 6 copies there) - so you might want to see if it did that.

Fascinating. For a while I owned an ETF (OIH) which was a compilation of many of the drilling support companies like Haliburton, Nabors,Rig, Schlumberger, etc. What was great about it was that I got the annual reports on all of these companies filled with pictures and descriptions of the technology they were working on. As an engineer, I found it amazing.

So here is a question. (maybe HO is holding out on us to keep us enthralled until the next edition)....Once you are approaching the pay, and have the borehole pressurized in expectation of hitting the pay, how the heck would you pull the string if you had to change a bit? Seems awkward and dangerous, to say the least.

marku -- I'll give HO a break and catch this one for him. The situation you're describing is typically a critical point. Ideally you're a little over balanced (MW pressure greater then bottom hole pressure) so when you pull out for a bit change the hole should remain static (not flow). While you're drilling the pump pressure adds a little more then the mud weight alone (effective circulating density...ECD). You loose that when you shut the pumps off to POOH (pull out of hole). But when you drill through a hydrocarbon zone an amount is liberated into the mud column and thus decreasing the effective MW (mud weight). This is especially true when you cut NG. So before POOH you C&C (circulate and condition) the mud to remove the hydrocarbons.

In addition we slug the pipe (pump down some mud with a little higher MW when we C&C). One potential danger is pulling the drill pipe out to fast. It can act like a plunger and cause a decrease in the effective MW and allow the hydrocarbons to enter the well bore. This, in turn, decreases the MW and causes more hydrocarbons to enter the mud column. Can quckly turn into your worse nightmare. "Swabbing" a well in such a manner is a common cause of blow outs.

One question some might ask is why not just put even heavier MW in the hole to just be sure. If the MW exceeds the BHP (bottom hole pressure) it will start to enter any permeable formations down there. The resulting LC (lost circulation) can lessen the weight of the mud column and cause a well flow. I once saw an operator loose 60,000 bbls of OBM (oil based mud) is this manner. At $120/bbl this can get expensive fast. It also inceases the chance of loosing the well or even having a blow out.

Sounds complicated but not too bad these days. Lots of computer power and better training in place. In the bad old days it was often done by the seat of the pants technique. As a result a lot of crippling and death. Not nearly so much now. Unfortunately bad incidents today can almost always be traced to human error. During the height of the boom last year I saw far too many hands lacking the experience/training for their responsibility level.

Wow, thanks for the answer, RM. As I expected, complicated and dangerous. How do you handle sealing off as you pull the string and bit up through the christmas tree? I have a hard time seeing how that works....

ROCKMAN:

Great explanation of that particular situation. Thanks for helping to clarify the details for all of us.

I look at core samples from time to time (in thin section, although no consulting work since February :-( but I'm an eternal optimist, so I know the work will come back), and it's important for readers to understand that each time a section of CORE is raised, the process you've described is repeated over and over, because core retrieval requires that the entire drill string be pulled each time that the core barrel is brought to the surface. Coring is most commonly done through/in stratigraphic horizons that are known or promising reservoirs, so there is commonly the need to deal with the pressure of the oil a/o gas That costs both time and money of course, but the payoff is an actual cylinder of the rock in which the hydrocarbon(s) are or may be present, and that cylinder can then be subjected to a variety of tests and analytical procedures that - in theory - will advance our understanding of the petrophysical properties of the reservoir.

BP's new Tiber field in the GOM is at 35,000 below sea level and under 4500 feet of water, so the rock depth is about 30,500. Would the pressure at the bottom of the hole then be 32,500 psi? Seems like something else may be in play to effect the pressure or how would the pipe casing withstand such pressure unless the diameter were quite small. Using 76,000 psi yield strength steel means a 6.5 inch inside dia pipe would need to be 2.77 wall with out a factor of safety (normally 2). My rough estimate of stress is only figuring the lateral stress, not adding in longitudal stress which would give a higher figure and put stress vector at an angle (not perpendiculat to the length).

Perhaps the casing can bear against the rock to keep from splitting open under such high stress.

Mark S. Bucol

overburden pressure (~1psi/ft) applies to unconsolidated rock. in consolidated rock, the normal gradient is generally 0.433 psi/ft, about equal to the pressure exerted by a column of water.

overpressured reservoirs such as the williston basin bakken and sabine uplift haynesville are overpressured because of the volume increase attendent with the conversion of kerogen to h-c, the reservoir fluids are overpressured because there hasen't been time for the pressure to dissapate.

the powder river and d-j basins are underpressured because erosion of the surface has removed enough overburden to allowed the deep rock pore space to expand slightly(on the order of 4e-6 vol/vol/psi). according to david love, the grand old man of wyoming and rocky mountain geology, almost the entire miocene strata that essentially burried the rocky mountains ended up in the gulf of mexico and off the east coast us by water and wind erosion, respectively.

Mark -- there's a long tech explanation for your answer but I'll try a short cut. It might not answer everything but it may help. The pressure in the rock is controlled by more then the weight of the rock. In the simplist model it's the weight of the water column at that depth that determines to pore pressure (pressure of the fluids in the rock). The weight of the rock is supported by the grain to grain contact of the rock particles. But certain conditions can arise were this vertical water column effect is interrupted. Much higher pressures can be encountered then the water column pressure calc would indicate. This "geopressure" anomaly can occur over just a few hundred feet. In heavily drilled areas these intervals can be well known. In more rank wildcats it can be difficult to anticipate.

Another diversion from the simple model. Many of the DW GOM wells are "subsalt": you drill through some thickness of salt before re-entering rocks. The density of salt is much less then typical rocks so it contributes much less overburden pressure. Last year I drilled a well that penetrated 24,000' of salt before getting back into the rocks. The mud weight we used at that point was relatively light...13.5 lbs/gallon. But I've drilled wells onshore Texas at 4500' that required 16.5 ppg to control.

High mud weights require strong casing for sure. But remember that the mud weight is the same (more or less) inside the drill pipe or casing as it is on the outside. Imagine a rubber ballon sitting in a tank with 10,000 psi. As long as the pressure inside the ballon is 10,000 psi it will survive just fine. Problems arise when circumstances allow a big differential between the inside and out. Let that difference get large enough and no steel can survive.

I have a follow-on question about the pressure vs. the capacity to withstand pressure of the casing material: How is this issue complicated by holes that start out plumb (vertical) but then bend to become more horizontal? Does the amount of force on the casing vary according to the casing's orientation ('straight down', '45 degrees', 'horizontal'? I use single quotes since these the definition of terms would depend on the reference datum planes used?

Edit: added clarification? to my question...

Sorry to wimp out on this one, but it is part of a later post where I get into horizontal wells, hydrofracing etc.

At this point, I don't know if you guys are still paying attention, but the answer is that your hydrostatic column is determined by your true vertical depth. Once you go horizontal, the pressure is constant. Most of the horizontal wells that I have been involved did not run casing in the horizontal section- at least later in the drilling program

Thanks for this post, I'm sure it took some time to prepare. I look forward to the next one.

Heading Out -

Another nicely done tutorial.

From viewing those pictures it appears that these blowouts can be rather sudden and quite violent.

I was curious as to whether the drill string itself can sometimes either get actually blown out of the well or bent and jammed within the casing during a full-bore blowout. It would seem to me that not only do we have the differential pressure at work here but also a great deal of upward frictional force from the high-velocity stream of fluid traveling up the drill string during a blowout.

Yes, some or all of the drillstring can be ejected from the wellbore in extreme cases. This leads to what is known as "raining drillpipe". First the drillpipe impacts the the crownblock, which is then knocked off with the collapse of the top of the derrick. The string then launches into the air and usually breaks the pin connections as they fall back to earth. There have been cases where the area surronding a rig resembles a pin cushion, with drill pipe and collars sticking end up in the ground. I have seen interesting photos of drill collars sticking in pickup trucks as though they are bugs in someones collection. Obviously this is a dangerous situation. The blow-out preventer is what is supposed to prevent this situation with use of the "blind rams" that shear the drill string(actually cutting the string in two) and seal the wellhead. The cases where this have happened have been generally from my understanding to usually be due to panic among the crew- the Driller is running for his life and forgets all about closing the Blind Rams.

What usually happens after drill pipe ejection is rocks blowing from the well bore and sand. Sand creates sparks and ignites the well. Depending on the situation this can all take place in a very short time. I haven't read all of HO's post but I am familiar with controlling pressures while drilling. The pressure is controlled by using mud weights as he discussed in an earlier post. The problem with estimating earth pressures is that there is a "normal" gradient, which can be estimated at the surface, and there is "abnormal" pressures with cause the problems as shown in the photos.

"Abnormal" pressure are created when a sealed reservoir (perhaps water only) has been uplifted within the rock column. It still has the pressure that it had at the previous depth. There are older ways to estimate the pressure using drilling calculations, shale density, gas detection, etc. These are still used however the newer MWD tools provide pressure while drilling and resistivity data that make "pore pressure prediction" a lot more accurate. In fact for those interested M. King Hubberts work on rock strength led to some of these prediction techniques.

It would be of interest to know the mud weight and type of mud that BP used on the latest announced discovery. With the mud weight and depth a good back of envelope calculation could be made on bottom hole pressure. Density of the mud at this depth would be significant and temperature of the returning mud would also be an issue. Most such projects however are "tight hole" and this type of information is guarded. Not only is knowledge of the resource proprietary but the technology in how it is accomplished often is as well.

frontier -- I was scheduled to be one of the pore pressure analysts on the Kaskida well but I changed gigs a while back. You're so right about the improvement in pore pressure estimation for the log-while-drilling data stream. Not foolproof by any means but much better then just waiting to see if you get kicked. Don't know what they encountered and can't talk about what they expected. But it has been amazing as to see relatively low mud weights used in some of these very deep wells. It's also shocking to see how low the bottom hole temps are compared to an onshore well. That's why the oil is still preserved at such great depths: still well above the cracking temp.

Rockman:

I didn't have much time yesterday when this discussion was going on. Your explanation on subsalt pressures makes sense and one that I have been thinking about. Particularly how at 35,000 feet the hydrocarbons would still be in the form of petroleum and not gas. "Back in the Day" when I was doing pressure prediction, we were using the "D" Exponent corrected along with Shale density - along with all the other parameters. One of the hardest concepts at the time for some to understand, was that shale communicated the pressure better than the occasional sand that was penetrated. We were taught at the time how to use short normal resistivity to calculate pore pressure trend lines in anticipation of the MWD tools that were being released at that time. Pressure While Drilling tools are available now, however it is still subject to calculation for valid answers. What other parameters are you looking at in terms of HPHT well's now?

Most of my experience over the past 15 years has been in subpressured, high loss zones as I discussed briefly. So it has been a while since I dealt with geopressured zones. Did some work in Green Canyon and the Tuscaloosa Trend back in the "good ol days".

frontier -- Pore pressure estimation has come a long way from the old days. LWD has made all the difference. I used the Knowledged "PREDICT" software suite. It uses the same equations determined decades ago when we used clear overlays on the resistivity curve. Now I can build models with sonic and density data too. In a lot of places sonic is a better tool the resistivity (mineralized shales are a big problem. With the power of Windows you just drag the normal compaction trend line around till you get a good fit on your historical MW data, etc. It's still easy to see the big PP jumps from the LWD but with PREDICT you can offer some sense of the slow changes. Of course, I still spend a lot of time watching the shakers. Not as meaningful in these days of PDC bits but old habits are hard to change.

Rockman, thanks for the update on how you do it these days. I have some friends who have been hanging out on the deepwater rigs, but I passed on that duty. It's good to know that they are putting that data to good use. I had a good taste of the Gulf in the 80's, enough for me. Shale Density from a bromoform/neothene solution was problematic, besides being a little dangerous if you broke the column. You are wise to keep an eye on all the old parameters, since your MWD hand may be watching a movie when his downhole sensor craps out. All of this happens around 2 AM in the morning- I'm sure you know what I'm talking about.

I did most of my recent(15 years ago) logging work on horizontal wells in the Williston- totally different. Later moved to MWD- mostly positive pulse directional and natural gamma. Then went to the "dark side", Directional Drilling. Like a lot of guys I have been severed from my obligations which allows me to comment on here occasionally.

Maybe when HO does his horizontal essay, I can pitch in.

Frontier -- I've been drawn to horizontal geosteering for a long time. Geologists seldom every get that much control of drilling ops so it's fun. Unfortunately I didn't get as many gigs as I would have liked. But did to geosteer four wells for Exxon up in your neck of the woods in the Powder River Basins. Sounds like you got sent to the house. Hope things break for you soon. Best wishes.

OFF TOPIC Frontier -- Not sure this is your cup of tea but Rig Zone has a posting for a N Slope well site gig.

Thanks for the heads up Rockman, but I think I'll pass. I'm trying to re-enter a different field now that they've given me a chance. If it doesn't work out, I'll probably do some contract directional work in north louisana when things pick up a little bit. Yes it was a good excuse to get rid of troublemakers like me. From some of the calls I've been getting from the guys who stayed it may be just as well since they are sure enough working them to death. 0 Days off and going from one rig straight to another. They have money but no sanity.

I think you would have had fun up in North Dakota. At least before the recent boom. The wellsite geologist had almost absolute power in calling the shots, whether to steer up or steer down in the zone. He can overule the directional hands, even the company man. Maybe not the geologists in the office but often they would agree as well. One time we drilled a 5k foot lateral and I had told the Company Man at about 3k that he had drilled low and out of zone- he blew me off. We got to TD circulated out samples. The office called him to pull back to 2500 feet and sidetrack. Total MD was about 14,000 feet. He was pretty pissed at me. Like I said "troublemaker".

Drilling the curve "back in the day" was interesting when we didn't have gamma. Trying to look through oil-based invert samples for formation tops was a challenge - especially when you are sliding 100% of the time. That is pretty much done for you now with TVD corrected gamma and p-rate. Landing the curve is a much easier proposition.

I could tell you great stories about looking for dinosaur bones in that country as well. I have one in a small museum in Marmarth ND. One time I made a deal with the local paleo club- they would show me their Cretaceous hadrosaur site and I would show them my Ordovician samples at the Rig. That was a good time.

Looks like I am going to head south this winter to see how things go. Maybe catch some redfish.

I know what you me about us trouble makers. I've been known to comment without considering the politics involved. Here's one of my short stories about PO'ing a companyman. The landing (Hartzog Draw south of Gillette) should have been a snap given we were just 300' from an offset well. Yet my correlation showed we were coming in 20' off. Made the adjustment in the nick of time. Turns out they would shoot the ground elevation and give that number to the direction company to draw up the plan. But then they would scrape off or pile up on the location and not reshoot the elevation. Tried to explain to a young companyman who predictably blew me off. So I went to town,rented some survey equipment and made the adjustments myself. My Exxon geologist caught hell from the boss engineer back in Houston. Fortunately he understood my prior explanation and jumped right back in his face. Obviously I wouldn't ever be asked to work for that drillign dept again but the satisfaction was well worth it. There's always another gig down the road. But the chance to tell a coman to eat sh** and get away with it comes along so rarely.

frontierenergy -

Thanks for the explanation.

Wow, the scenario of 'raining drill pipe' sounds like something out of a second-rate action movie! If I saw such a thing on the screen, I'd say it was too far-fetched to be believable.

Looks like when you're drill a deep well, things can turn to shite in a matter of seconds. The guys operating these rigs must be a special breed.

"The guys operating these rigs must be a special breed."

No just desperate or crazy - mostly both.

Most hands that have been hurt or killed during my years in the business came from a split second inattention to detail. Lucidity is a survival skill.

HO-thanks for sharing. Awesome and valuable perspective even for outsider like me. Appreciate the role of safety, too.

My thanks, Dave, for these tutorials. I get the impression you must be a great professor, with such understandable discussions of fairly difficult to understand subjects.

I thought the blow out pictures you linked to were pretty spectacular. This is one of them, from Energy Industry Photos.

Here's a smattering of brainstorm questions. Feel free to answer or not in future posts. Don't waste your time composing a direct reply, as I know my questions are random, disordered, and I don't know what I'm talking about. As an outsider, I'm still mystified by the magic.

You are drilling into a pressurized self-sealing balloon. Could you have a subterranean blowout when you broke the cap? Gas is slippery stuff and could just bubble out above the cap rock and escape. Yes?

Make sure you tell us how you get pay from two different reservoirs of different pressures from one well.

I read somewhere about a well in the Gulf where the rock (salt?) was so soft, the bit began to sink without input of horsepower. So they pulled the bit, changed their shorts, and moved away. What's up?

Are there ever unpressurized oil reservoirs that pay? What significance does under over pressure mean? I know what it is.

You make this subject sound so simple and intuitively obvious, but I imagine the learning curve was tough. Can you cover serious mishaps that might not have been front page news? Not just a history, but a insiders view of terror on the drill pad, or what keeps driller's wives up at night, especially the ones that were significant learning events even if no loss of life. I understand blowouts, but are there other things that could destroy a reservoir? I learn from other people's mistakes.

Old days, drill to blowout. Wait until pressure drops, then cap it. How have I damaged the reservoir? Is it true that with modern simultaneous primary and secondary development, tertiary is significantly reduced or insignificant?

How have recovery rates changed through time? How have recovery percentages changed through time? It seems to me that high rate and high percentage are mutually exclusive, are they? Could we gain a significant amount of production by mandating reduced rates? Do we lose a significant amount of production by pumping full blast? Or just pull production forward?

High cost fields (offshore, arctic) die. Old onshore fields have rockers. What happens with modern onshore (small, low cost) fields? Could somebody buy a new, small, low cost field and keep it as money in the bank, or would it degrade somehow? Could I have a spigot in my garage sorta thing? Isn't there a field in Texas managed for long-term production owned by the Hunts? Gettys? I think it was developed for 100K bbl/day for 100 years or something like that. Yeah, I know that's 3.6B bbl recovered. It must have been smaller than that, but it was real.

So you've found a field. How do you decide how to develop it? Where to produce, where to inject, how fast, etc? Not details, just interesting, significant alternative methods.

Did you cover seismic etc? Feel free.

Is there property anywhere in the world that you could identify that has huge amounts of oil/gas locked under it that isn't marketable? I thought about buying a farm in WV. Turns out that it is in a new drilling play. I wanted the farm, but the drilling kicker would have been nice. Then again, if I refused, could my gas be legally sucked out by neighbors? On that subject, discuss OK vs. TX historical oil production (OK said super straws ok, I think), plus international significant differences. I have my eye on land with 30' of bit. coal under it (gassy) that has no mineral rights value. If the surface rights were to drop, I might buy it. Are there opportunities with oil that are just sitting out there? This coal field is well known. Nobody cares. My feeling is that oil was sucked out, gas is being sucked out, but coal was bypassed. Please input.

I went to NAPE and looked at well logs and seismic from all over. I looked knowledgeable and kept my trap shut. I've pulled production history on wells and fields. Hey, I'm not going to quit my day job, but I'd like a primer so I could impress the groupies.

I'm speaking out of my Rumsfeld, so don't bother directly correcting any of my totally off-base assertions. I left them in there because you need to know that even a knowledgeable and relatively logical audience has a bunch of dust bunnies upstairs. Thanks for shining a light.

Cold Camel

Thanks for the comments - I am trying to keep these down to relatively short posts and thus have to break the topic up a bit, which also forces choices as to what I cover next, and this tends to drag out the explanation. But, as you may have gathered from some of the discussion above, there are a number of different bits to this puzzle and I am trying to get the basic bits out before I go on to the more technical discussions that will come later.

Regarding "subterranean" - this is called an "underground blowout" and it occurs when the combined shut in pressure and mud weight hydrostatic pressure factures the formation. Some of Hubbert's work was in this area in estimating when the formation would break down. Typically after setting casing(mulitple casing string wells) and after drilling out a few feet, a "formation integrity test" is made to find the estimated break point by shutting the pipe rams and slowly pressuring up with the rig pumps. Watching the pressure carefully the break point can be found. Knowing this pressure and calculating the equivalent mud weight give an indication of maximum pressure that can be exerted, i.e. maximum mud weight.

An underground blowout in certain cases can cause the gases to escape around the wellhead- even if the blowout preventer is closed. Offshore this is a very dangerous condition as it aerates the water surronding the rig. Escape capsules sink and those who try to swim away sink - even if they have a life vest. I believe in most cases these tend to "bridge over" and the earth collapses and seals itself. It's not a subject that I have tended to dwell upon.

Conventional wells are produced through multiples zones by perforating them as need arises. Better zones first, weaker zones as needed.

My personal theory regarding future missed production zones will involve going through old mudlogs and looking for shows that were missed in later evaluation. The reason being is back when the bulk of wildcats were being drilled, mud invasion into the zones blinded many lesser productive zones to the geologists. I know that mudloggers have seen shows and later evaluation showed nothing on elog and committment to shoot sidewall cores is expensive. Unfortunately mudlogs are famously unreliable and that would have to be considered.

Regarding subpressured zone- that is pretty much the name of the game in land US operations which requires underbalanced drilling technology. This requires using water as the drilling fluid and air injection at depth to reduce the hydrostatic pressure. Also sometimes "stiff foam" and even crude oil itself has been tried as a drilling fluid. Nitrogen has been used as well, since it is inert. All of this is difficult as well since you still have to maintain hole integrity. Otherwise you get "stuck". Maybe HO can describe this sad scenario sometime.

This is what an underground blowout looks like:

http://www.youtube.com/watch?v=rhZKUYVXM78

Great answer Frontier

Just a thought. How many 3 Way Cats would it take to clean up all the unburnt hydrocarbons to EPA reg's from the blow out.

Does any body know how long the blow out last for ?

Thanks Frontier, but that video will give me nightmares and I don't work on rigs. I assume the drillers must have done something wrong, if not, I don't want to know. That was Lucifer, straight in the eyeball.

Cold Camel

Camel –I’ll take a shot at some:

A subsurface blowout (your subterranean) is always a potential problem. Seldom deadly but often very expensive. Besides loosing a volume of oil/NG yo typically loose the hole. Killing an underground blowout can also be very expensive.

Two pays with different pressures: you isolate the two zones with different stings of casing/production tubing. This is often done (a dual completion) even when two zones start out at the same pressure. Over time a pressure differential can develop as one zone depletes faster then the other.

Drill bits sink w/o horsepower: called drilling off and it can happen in any rock besides salt. Various causes. In the case you describe if it scared the pooh out of them then it probably means they drilled off into a much higher pressure zone then they anticipated, If the mud weight isn’t sufficient the rocks will literally explode out of the bottom of the hole because hey are under such high pressure.

A bloody learning curve for sure. In the bad old days there were no OSHA fines or big lawsuits. And replacing steel and bodies was relatively cheap. Very different now. Safety is a very big issue for any number of good reasons. And yes…I helped carry the body of a young boy off the drill floor once. Enough said about that. Loosing drilling mud into an oil/NG reservoir will destroy its productivity in the immediate area but I’ve never heard of a case of field-wide reservoir destruction

Recover rates etc: always improving the process. But there will always be a maximum effective recover rate that does affect not only ult recovery but also the life of that particular well. Pull a well too hard and you’ll draw the water to it faster then it would have happened normally. And you an almost never fix such a screw up. But this will always be an issue: the battle between maximizing immediate cash flow vs. ult cash flow. Companies in financial trouble will always be tempted to risk it even thought hey almost always loose. Engineers might argue against such actions but the man who signs the paychecks will always have the last say. But when it goes south the partners will set their attorneys loose on them. As far as mandates in the old days in Texas the sate set “allowables”: specific rates a field could be produced. This was often done as much as to control prices (yes…we were the OPEC of the 1950’s) as it was to max recovery.

The small US independents rule the world of small onshore fields. The big companies can’t begin to compete because of the overhead factor. Even a field that once produced 200,000 bopd and recovered 350 million bbls of oil is still producing 100 bopd now. The small 1 or 2 man independent makes a good living at this rate (especially when oil hit $147/bbl last year). But that’s because they do the labor and thus not have to pay expensive engineers and geologists. This is what separates the US oil industry from almost all other countries: private ownership of mineral rights. Without these small businessmen we wouldn’t be producing half the oil we are today. Collectively these folks produce more US oil then Exxon and all the other big operators combined.

Develop a new big discovery? Hire those expensive engineers and geologists I mentioned above. No alternatives. But there is an interesting subplot many outside the oil patch don’t realize. The service companies (like Halliburton, BakerHughes, etc) supply a very big chunk of the manpower on such projects. Add to that the big numbers of consultants such as myself and the required manpower for such projects just doesn’t exist as employees inside the company. I’ve worked on DW wells in the GOM that cost $200 million and of the 145 souls onboard only 2 were company employees. Drilling operations are the extreme situation but it’s not much different in the office. This has system has developed for a reason. When things went south late last year the first to be cut are the third party contracts. Then the consultants. We’ve recently reached the employee layoff phase. Such is life.

Seismic, especially 3d (very high density coverage) is GOD!!!! It rules the oil patch like never before in history. Has led to many discoveries (like Tiber) that weren’t even dreamed of 15 years ago. Very expensive upfront cost but has also caused thousands of wells to not be drilled. If you can’t show the potential on the seismic data it’s very unlikely anyone will drill it.

A partial answer: in Texas we have the “Right of Capture”. As long as I don’t drill within specific legal limits of your property I can drain FF off of your lease. In La. It becomes a technical legal battle decided by the state. OK I don’t know.

NAPE (North American Prospect Expo): I was there too. You remember seeing a guy with a beard rolling around in a wheel chair? That was me recovering from double knee surgery (too many years running up and down rigs). My new small company was one of the very few buyers out there. About 300 hundred companies there trying to sell drilling deals they’ve spent many years and billions of $’s generating. And maybe 4 or 5 buyers. We’re owned by a man who made his fortune trading equities and commodities. He wants to spend around $300 million with the drill bit over the next sevral years. A simple commodity play: buy low and sell high next time prices spike (5 or 6 years in his estimation). We’re buying these deals at bargain basement prices at a time when drill costs have fallen by almost 50%.

All in all Camel…very astute questions. And shut up for a while. I’m a two-finger typer and I’m worn out.

i dont think "rule of capture" and voodoo pv economics are fully appreciated in explaining the dismal historical recoveries from oil reservoir, especially in 'merka.

Thanks Rockman, turn off the tap, my brain is full. The rest of this reply is social.

I was at NAPE in 2006. It was crazy. I paid extra for the Bjorn Lundberg talk, where he says oil is unlimited. I so wanted to jump up and say, "Do you think these guys are stupid? You are talking to oil GODS here! If they can't find a single elephant, who the heck can?" But I didn't. I'm with a bazillion Texan oilmen, but not a single one raised an eyebrow at Lundberg. I was just flummoxed ... all hat.

I am glad you are finding profitable opportunities today. Back then everybody felt they were sitting on gold, and surely wanted it. I asked silly questions like, "You are asking $50 per barrel in the ground before it is drilled, how are you going to make that pay?" I really wanted in.

I had done my homework on Syntroleum, so I stopped by the booth and asked the chief some questions. I know he was a BMOC because 4 guys came over with him to listen to my questions. This guy and his henchmen can't get a single zinger past me. Their dream is a GTL barge, but I think LNG, pipe, and local use leave them no market, and tell them why. They can't come up with anything to prove my logic flawed so I move on.

I stop by the big boy booths where I'm totally out of my league. They're not selling nuthin. Why did they come to NAPE with their $200K+ booth if they've got nothing to sell? Can't they put that money in a hole somewhere? I couldn't find anybody with something interesting to say. It's Syntroleum all over again.

I'm a hick from Alaska. I was willing to put down money, at a minimum buy stock but there was nothing point nothing on the floor. Of course, you make a fine living on nothing point nothing, but that still doesn't change the equation. We are going to get squishified right certain.

Cold Camel

Thanks for the great tutorials.

After oil has been hit how much mud/oil mixture does the driller have to deal with (obviously to some extend a function of the depth of the well, but are there other factors involved? How is the oil separated from the mud?

Thanks,

WeekendPeak

If everything goes well very little oil is visible in the mud. There maybe some gas-cut mud but this is ran through a "gas buster" that seperates the gas from the mud. Sometimes it may take a while getting the well under control as it is shut in and bled off through the choke line. This is kind of like shaking a pop bottle, then slowing bleeding off the pressure with a little twist of the cap slowly a little bit at a time.

Underbalanced horizontal wells may have oil flowing continously from the wellbore.

Interestingly it is often a bit more complicated than even that, with some gas perhaps being mixed in and perhaps water - enough complexity that I will have a post on GOSP's and such down the road a bit.

As I said, if everything goes well. Sometimes it takes a while to condition the hole at TD to get ready to wireline log. If it is a long logging run, there is a lot of gas and oil invasion into the hole. This is primarily because the mud column is static- circulating the mud adds an equivalent circulating density that helps hold it back. This ECD is usually in the neighborhood of .3 pounds per gallon, but hydraulic calculations can give a good idea. Sometimes it takes some time to circulate the gas out before another logging run can begin.

Regarding the mud quality - this is usually directly in relationship to the attention of the derrickhand. Mud Engineers take the credit, but it is the derrickman who is key to getting it right. Yes you can have light gas cut mud, heavy mud spots, high solids, all in the same mud system.

HO and Rock, interesting stuff. I wudda thunk that since rock is normally strong, and permeability low, that any pressure diffs would soon be equalized once a small amount of fluid has flowed. But the experiences with blowouts say otherwise. Or is it just often true that HC bearing rock is usually pretty weak. Presumably you gotta worry about pressure diffs all the way down. What if the pressure gradient varies significantly with depth? Do you get instances where a mud weight which is enough for one depth, is just way to much- or too little for another? Are these cases where you just gotta give up?

EOS -- what you describe is a common occurance. When MW requirements for a deeper section exceed the fracture gradient of the shallower rocks you set a string of steel casing over the shallow rocks to isolate them. The cement at the base of this casing string is tested to ensure it can withstand the higher MW. This is a big reason why deeper wells cost so much. In DW GOM wells the cumulative costs of these multiple casing strings can easy exceed $60 million. Some of those wells have as many as 6 or more different casing points. A true DW nightmare: not designing the casing program correctly, spend $150 million to get to depth (like 30,000') only 1500' short of your objective and not have a sufficient hole size to set another string of casing. You'll just plug and abandone that hole and do it right the next time. That's a bad day.

Enemy:

I'll add my 2 cents' worth here: I've looked at hundreds of thin sections of drill core over the past 24 months. This has included some world class reservoir rock (the upper Jurassic Arab-D zone in two fields from the KSA, and the lower Cretaceous Thamama Group from an onshore Abu Dhabi field) and some far,far lesser reservoirs as well. The evidence to support broad statements such as yours above is elusive. There is commonly much petrographic heterogeneity of any rock from the real reservoirs in real oilfields. Sure, some fields are relatively homogenous, at some scale, and it can be true that the rock in a given horizon overall is strong, with a low permeability. But in my experience, a given rock that is a good reservoir might be strong, it might be weak, it might be of low permeability overall but with a few super-K zones that more than offset the low zones, or it might be very porous to the point of being vuggy, but with limited permeability.

Until the reservoir rock is carefully examined and its porosity and permeability are quantified, its petrophysical properties cannot be described in general terms such as "normally strong" or "usually pretty weak." It would sure be nice if we could do so, and it would make petroleum engineers very happy, and their jobs much easier, but real rocks are incredibly variable, and without methodical examination, they are not readily pigeon-holed into this or that category of mechanical strength, or porosity and permeability.

Petrographer,

Could you send me an email (in my user profile)?

Thanks.

JB

Some claim that CO2 burial as part of CCS will require gas tightness at over 650 bar or say 10,000 psi internal pressure. Presumably this will be discussed in a much awaited TV show to be aired in Australia tonight http://www.abc.net.au/4corners/

Note on the trailer Obama says it will work but the Chinese guy says it won't.

With the West Atlas blowout in the Timor Sea some claim 3,000 barrels a day of oil is being lost along with a large amount of gas. http://www.news.com.au/perthnow/story/0,27574,26034570-2761,00.html

The West Triton rig on its way to divert the blowout has been hampered by a snapped tow rope. I want to see just how close the rigs will be when this operation starts.

Boof -- A suggestion when you watch the presentation. In 34 years I've never seen anyone even hint at the prospect of FF, water, or any other substance migrating from one layer of rock to another THRU THE EARTH. Virtually all incidents of leakage I've seen were a result of migration up an existing well bore. Commonly a result of casing or cement failure. In the bad old days the regs were very loose or non-existant so there were many problems. If the regs and enforcement are good there is little chance of problems beyond human error.

HO

Interesting article thanks. And also thx to Rockman for further commentary.

Maybe you intend to cover this in the future but it would be interesting to learn a bit about what happens once the pressure difference drops to zero. Presumable you then need to create a difference by either pumping (sucking) or forcing via e.g. water injection? Assuming that's the case then what is the influence of reservoir depth on level/cost of recovery? Are deeper wells more difficult in this regard as the oil has to be pumped/forced through a greater height? Or is the process height independent?

TW

Watcher -- I suspect HO will have a more detailed explanation coming. In the meantime, yes, "artificial lift" is the general term. It's utilization/efficiency is depth dependent. The two most common approaches are sucker rod pumping and gas lift. In SR pumping most have seen the cricket pump jacks. The vertical movement of a rod lifts the oil a few feet at a time by dragging rubber cups up thru the tubing. It's that constant up and down movement which brings the oil to the surface. By taking the weight of the oil off the producing formation for even those few seconds aids in the flow of the oil out of the rock. Pump jacks might run 24/7 or just a couple of hours a day. No benefit in pumping any faster the oil can flow out of the reservoir. As basic a technique as it sounds and has changed little over time. Not too useful in very deep/offshore wells. Gas lift is often preferred but requires a source of natural gas. Imagine a string of casing with a second string of production tubing inside of it. Natural gas is pumped down the area between the casing and the tubing. Valves set at specific distances down the tubing allow the NG to enter the production tubing carrying the oil. This aerates the oil column and reduces it effective weight. As a result the oil will move more easily to the surface. Here the oil and NG are separated and the NG is repressured for reinjection. Mechanically much easier to deal with then sucker rods (they eventually wear out/break and require a work over rig to repair). Of course, gas lift requires a NG source and compressor but tends to need less maintenance. A third option is an ESP: electric submersible pump. Run down hole on an electrical cable and pumps the oil directly upward. Useful in some situation but readily suffers from a variety of mechanical problems. A fourth less common method is the PCP: progressive cavity pump. A very simple design: it's a screw-like rod sitting inside a rubber sleeve. Sucker rods are used to rotate the screw and the oil is lifted by the basic Archimedes method. Such designs have been used to move water into crop fields, etc for centuries. Very useful when there's a lot of sand produced with the oil or if the oil is very thick. Sand can tear up an ESP quit quickly.

Apart from the discussion on the draw rates, one point sticks out clearly. You can't really tell how much oil is underneath from the basic premise. All the head pressure is derived from what is above the "top" of the reservoir and not from what is below. This may need to be pointed out more clearly and early on. After all, we know that the oil people have the technology to get at the stuff that is down there (don't forget that Exxon had record-breaking profits for corporations the last couple of years, this after all is essentially free money that we are talking about - in inflammatory terms of course). That to me is not really the interesting part, instead its that we all don't understand how they estimate what is below. I realize that much of the estimates are then gleaned from watching the equilibration of pressures and changes of flow with time, so as the oil redistributes through diffusion and drift we can get successively more accurate "feels" for the ultimately recoverable for a reservoir.

If you were diving down a 10,000 foot water well it would feel the same as if you went that far below in the ocean. You couldn't tell the difference until the well started depleting.

So my point is that we more or less know the pressure exerted from above since this is fairly well characterized as they drill their way down, but trying to decipher accurately how much is below seems to be a much more interesting and challenging topic. Thus the question, is this a valid discussion topic to elaborate on?

It seems that the industry needs to start to move away from conventional drilling and look more closely at the closed loop systems out there.

Then you are already in a 'well control' drilling mode alowing much better control of the BHCP as well as pore and fracture gradients.

Some of the newer systems allow for formation strength tests and pore pressure tests in real time without the need to pull the drill string. Now actual pore pressur measurements instead of deterministic measurements.

The biggest 'kick' I was involved in was N.Sea, 1984 6 lb pre gallon underbalanced at 15000ft. We drilled into one of the now known gas /condensate pockets, 14000 psi at surface.

Just a little bubble!

Web --Right on! You hit the big uncertain nail on the head. Even when we have all the data the interpretation of future production rates and recovery is just that: INTERPRETATION. In some situations we can make a pretty good guess. In some dynamic reservoir situations it can amount to a wild a** guess. Then add the secrecy of the KSA et al and we can really be stumbling in the dark. I know it can be daunting for those without a petroleum background but so much of the basis for opinions on PO rest in filling in the blanks on Ghawar et al. It's worthwhile IMO that we continue to remind ourselves about not being too certain of some of the "answers" we experts throw out.

p.s. "free money" is not inflammatory in the oil patch. It's comfort food to make up for times like today when the lack of capital is crippling the industry. Ten's of thousands of more would have been laid off by now had it not been for the revenue bump last year. But those monies are running out fast for the small operators.

I am becoming more and more convinced that uncertainties in estimates also leads to these huge speculative bubbles that we are seeing. This leads to the feast or famine on earnings. If everyone knew the amount of oil predictably recoverable, the prices would stabilize -- albeit likely high of course. But this may prevent the squeezing of the smaller operators, since the biggies can handle the bubbles and collapses much more effectively.

So, as a bottom line, not knowing stuff, or preventing the dissemination of knowledge helps them. As you mention, just look at SA.

Yes, of course, filling in the blanks is what keeps us interested :)

Web -- Long ago I made a statement that few outside the oil patch could appreciate: the late 70's oil price spike did more to damage the oil industry then any other single event. The absurd escalation in drilling and the subsequent crash put hundreds of FF companies out of business. The spike and bust last year didn't have quite the same effect. The boom didn't last so long. But the capiatl sources have run away from the industry as if there were no tomorrow. Obviously the crash in all the other segments of the economy certainly contributed to this turn. The lack of investments in the oil patch today is a non-news item, of course. But sure as the sun rises tomorrow the media will jump all over when prices spike again

I'll give a simple example on porosity and a rough estimate on resulting oil content in the next post but one, and then, back in 2006 I put up two posts on Abqaiq ( here and here ) which I can also resurrect some time in the future, and which sort of answer your question.

Thanks. I am extremely interested in transport mechanisms. Dispersive transport in porous materials has math that will make anyone go MEGO in a matter of seconds but I think there is a chance to make some headway in our fundamental understanding.

Permeability, and predicting fluid paths can be a real pain I have been significantly wrong more than once and discovered in the process the importance of viscocity - but more of that in the posts. (Sorry, just came out of a meeting on this very thing).

HO -- Great point about viscosity (the thickness of the oil and it's resistance to flowing). There's a series of coastal Texas oil fields with very high viscosity water-driven oil. After 50+ years of producing the oil/water contact (seen in new infield wells) is nearly unchanged even when drilled on 40 acre spacing. Yet most fields recover 45 - 50% but it took many decades and billions of bbls of water pulling the oil out one molecule at a time. I know very few geologist/engineers that understand this dynamic. Unfortunately the new vertical wells seldom payout. Many times I've pitched the idea of redevloping this 1.4 billion bbl residual reserve horizontally but typically see only blank stares looking back at me.

again HO, hat tip to you. Great series.