I Sequester Carbon for a Living

Posted by Robert Rapier on December 19, 2008 - 10:53am

What Makes This Bridge in Sneek, the Netherlands One of a Kind?

Back in March, I left my job with ConocoPhillips to become the Engineering Director for London-based Accsys Technologies, PLC (my work is focused within the wholly-owned Titan Wood subsidiaries). I explained the circumstances behind my decision to switch employers here. I stated at that time that I would continue to focus my writing on energy and the environment, and not use my platform to start promoting my new company - even though it is focused on environmental technologies. I think it's fair to say that I have kept to my word. However, I did say that at some point I would write a more extensive article on exactly what it is that my new company is doing. This is that article, which ties into energy, the environment, sustainability, and carbon capture.

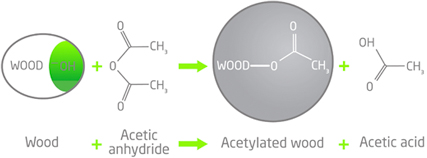

A Brief Chemical Tutorial

In a nutshell, Titan Wood chemically modifies fast growing softwood species like (but not limited to) Radiata pine in a way that results in performance characteristics that are superior to some of the best tropical hardwoods such as teak. It is important to note that the modification we make is at the molecular level; we do not impregnate the wood with chemical preservatives that can leach out into the environment. Wood treatment processes like Chromated Copper Arsenate (CCA) fall into this latter category, and can be a nightmare to dispose of, as they are classified as hazardous waste.

Following is a brief explanation of the science behind our process, in mostly layman's terms. Wood is a mixture of many different compounds, many of which are present as complex organic polymers (very long-chain carbon compounds). There are also numerous hydroxyl groups (OH) within wood. Think of a hydroxyl as 2/3rds of a water molecule (HOH, or H2O). Hydroxyl groups are very prone to attracting and releasing water, which is the primary mechanism by which wood shrinks and swells (and this of course makes paint crack and peel). Wood also naturally contains acetyl groups. An acetyl group is essentially an attached acetic acid molecule. Most of you are familiar with acetic acid, because you sometimes put it on your salad in the form of vinegar.

The Chemistry behind Accoya® wood

What we do in our process is remove a large fraction of those hydroxyl groups and replace them with acetyl groups. We call this wood ‘Accoya® wood’, and the properties are remarkably different than the unmodified wood we started out with. Dimensional stability, durability, and UV light resistance are all dramatically improved. Because Accoya absorbs less moisture, thermal insulating properties are also better. Further, Accoya is resistant to attack by termites, microbes, and fungi. Accoya is virtually rot-proof, and yet non-toxic.

Consider the implications. Instead of deforesting tropical rainforests for the highest quality hardwoods, we can essentially make them from fast-growing trees in northern climates. Wood that is grown via sustainable forestry practices and modified with our acetylation process provides a far more sustainable model for producing high-performance lumber. If the wood is both grown and used locally, so much the better.

How Accoya Sequesters Carbon

That alone is a pretty good story, but there's more. As we all know, greenhouse gas emissions continue to rise. The recently released World Energy Outlook from the IEA predicted that carbon dioxide emissions from coal combustion would rise from 11.7 billion metric tons in 2006 to 18.6 billion metric tons in 2030. The IEA further predicted that carbon sequestration applications will have limited potential to influence carbon dioxide emissions by 2030.

If we are to slow or halt our carbon dioxide emissions, we need a combination of lower reliance on fossil fuels, coupled with commercially viable carbon sequestration, or carbon capture and storage (CCS) technologies. But the problem with carbon sequestration technologies is that either 1). People can't figure out how to make money with them, so they aren't commercialized; or 2). The carbon sequestration is fleeting.

For example, carbon dioxide can certainly be captured from the stacks of coal-fired power plants. A number of technologies will suffice, but they will all add to the cost of electricity. Estimates are that carbon capture would add 25% to the cost of producing electricity from coal. Unless large numbers of consumers are willing to pay this cost - or unless governments mandate it (and therefore mandate that consumers will pay the additional costs), adoption of these sorts of CCS technologies will face strong headwinds.

What about the use of CO2 in enhanced crude oil recovery operations? There are some applications for this, but they are limited. You must still capture and compress the CO2, and then you have to get it to the oil field. Further, that CO2 is being used to produce more oil, which will subsequently produce more CO2. A similar situation applies to the schemes for using algae to capture carbon dioxide from power plants, and then turning that algae into biodiesel. While one could certainly argue that additional energy was produced for each CO2 molecule that was emitted (presuming the energy return is >1.0), at the end of the cycle the CO2 originating from the coal still ends up in the atmosphere.

However, I believe Titan Wood has a truly commercial carbon sequestration application. You know that when a tree grows, it extracts carbon dioxide from the air, converts it via photosynthesis into various biopolymers, and stores the carbon as wood, leaves, etc. Left alone, a tree will uptake carbon dioxide as it grows, but it will eventually die and decompose, returning the carbon dioxide back to the atmosphere. If you could instead take the tree and just bury it deep within the earth, the carbon would be sequestered. This is in fact similar to how all of the carbon in oil, coal, and gas got sequestered in the first place. Ancient plants and animals died and were buried, and the heat and pressure of the earth turned them into fossil fuels.

Of course one can’t make money by growing trees and burying them. So, what else can you do? You could build with wood, and that also sequesters carbon during the lifetime of the application. Because Accoya is modified to resist rot, the carbon can be sequestered for much longer. That’s appealing, but it isn’t the most compelling argument. In fact, you could make that same argument about wood that is treated with toxic treatments – it can sequester carbon for a long period of time (with the obvious negative of the chemicals leeching into the environment).

The really compelling aspect about Accoya is that the improved characteristics make it a viable replacement for metals, plastics, and even concrete in certain applications. You can take a fast-growing tree like pine, and modify it so that it can not only replace tropical hardwoods, but it can in some instances replace the steel in a bridge. That’s where the carbon sequestration potential comes into play.

Imagine that instead of making window frames out of plastic (which comes from a fossil fuel) or aluminum (which requires a lot of electricity to produce), you made them out of Accoya. Not only have you avoided carbon emissions, but you have sequestered carbon in a long-lasting application. (Window frames are in fact a major end use of Accoya).

Imagine that instead of constructing a bridge out of steel and concrete (both very fossil-fuel intensive), you made it out of Accoya. Again, you have avoided carbon emissions, and you have sequestered carbon. Note that neither of these scenarios is hypothetical. Accoya is currently being used in window frames, and a pair of heavy-traffic bridges is under construction right now in Sneek, the Netherlands. Kudos to the Dutch government for their foresight. The first bridge has been completed and is shown in the opening picture. (See this article for more information). Bear in mind that this bridge is certified to support 60 tons, making it the only wooden bridge in the world certified to support such a heavy load. That makes it the first of its kind.

(As an aside, in 1988 the U.S. Congress passed the Timber Bridge Initiative, to promote the use of timber in bridges. This initiative currently resides at the Forest Products Lab of the U.S. Forestry Service, but we have not yet been in contact with them regarding the possibility of building Accoya bridges in the U.S.)

What is the potential for carbon sequestration? I have done some calculations on that, shown below.

Carbon Sequestration Potential of Accoya

Per this reference:

According to analysis by JATO Dynamics, CO2 emissions in the top five markets dropped by 0.3 g/km in through the first seven months of 2007 compared to the same time last year. A volume-weighted average of new cars sold in the period yielded an average of 160.5 g/km for the fleet.

That means that the average European car emits (160.5/44 g CO2/mol) = 3.65 moles CO2 per km traveled.

The density of Radiata pine is roughly 500 kg/m3. According to University of Wisconsin Professor Emeritus Roger Rowell (and from other sources I have checked), carbon represents about 50% of that, or 250 kg/m3. In chemistry speak, that is (250,000 g/12 g mol) = 20,833 moles of carbon per m3 of wood, which is equal to the number of moles of carbon dioxide that were removed from the atmosphere.

Our Arnhem plant has a nameplate capacity of 30,000 m3/year of finished wood (and the next plant will be much larger). Then the carbon sequestration potential from the Arnhem plant is 20,833* 30,000 = 625 million moles of carbon per year.

Put in terms of the average European car, that means that the output of our relatively small Arnhem plant could sequester the carbon emissions of 625 million moles/(3.65 moles per km) = 171 million km of driving. The average European drives around 11,000 km/yr according to this chart. This translates to sequestration of the carbon emissions of 171 million/11,000 = 15,545 cars per year.

I am not aware of any other technology that can make this claim.

Conclusion

I believe we have a good story in Accoya. I barely scratched the surface of the advantages, which extend to painted surfaces lasting much longer (more avoided emissions, and less fossil fuels for paint manufacture). Our plans at present are to continue to manufacture Accoya in the Netherlands, and to license the technology. The second Accoya plant is being built by our licensee, Diamond Wood, in China. The third plant will be built by our licensee Al Rajhi in the Middle East. Serious discussions are taking places with other prospective licensees around the world, including several in North America.

The nameplate capacity of our first plant in Arnhem, the Netherlands, is 30,000 m3 of wood/year. This output can potentially sequester the carbon emissions of over 15,000 cars per year in Europe. The total offset is equivalent to an annual distance driven of 171 million km. Note that this presumes that we have used Accoya in an application that normally uses metal/plastics/concrete, etc. It does not take into consideration the fact that our life-cycle-assessment (LCA) shows that the energy inputs into producing concrete, steel, etc. are also higher than for producing Accoya – nor that we are avoiding the harvesting of tropical hardwoods. In other words, I believe this should be a conservative estimate.

While I have given you the technical spiel, I am not the guy to answer questions about licensing, sales, etc. If you want some information along those lines, please contact Starla Middlebrooks (Starla 'dot' Middlebrooks 'at' titanwood 'dot' com) at our Dallas offices.

Questions and (My) Answers to Various Inquiries

People have asked me lots of interesting questions around the company and the product. One sort of funny story related to this is that at this year's ASPO conference in Sacramento, I escaped the talks a bit early to grab a quick bite, as I was on an evening panel session. A few minutes later, Bob Hirsch walked in and asked if he could join me. I was delighted, and thought I would get to quiz him about The Hirsch Report. Instead, he spent the next half hour asking me all sorts of questions about Accoya. We were joined by Kjell Aleklett, and he also wanted to talk about wood. After we finished talking, I reflected on how funny it was to have the three of us sitting there, all passionate about oil depletion and energy in general – and at a conference on oil depletion - and all we talked about was wood.

Anyway, here are some of the questions that seem to come up most frequently.

Q. Doesn't the process itself use a lot of energy? A lot more than say, planting a tree and waiting a few years.

A. No. When you grow a tree, like a fast-growing softwood, what happens? It either grows to maturity, eventually dies, and releases its carbon dioxide back to the atmosphere. Or, it is cut down and used in an application that results in it releasing its carbon back to the atmosphere in much less than 100 years.

What happens with Accoya is that you can make a harvest every 20 years and put it into a long-term application. When you put it into an application that is typically aluminum or steel, you have a dual-win: It takes less energy to make Accoya, and you have sequestered carbon where you would have placed steel.

Of course you also have a big benefit by using it for applications typically reserved for tropical timber in that you displace tropical timber with softwoods.

Q. Can Accoya eventually be cost-competitive with other treated woods?

A. That depends on what you mean by cost-competitive. Is it as cheap as arsenic-treated wood? No, but arsenic-treated wood is toxic and disposal is problematic. Likewise, there are similar issues with other cheap wood treatments like pentachlorophenol, creosote, borate, etc. Accoya is no more toxic than regular wood. There is no toxic residue from the treatment.

Q. Seems ironic. Other treated wood is less likely to be burned at the end of its structural life, so the toxic wood is actually more likely to sequester carbon for more than 100 years than is the Accoya, even if the toxic wood is otherwise worse for the environment.

A. No, as that misses two key points. You touched on one in your last sentence. The reason toxic wood eventually fails is because it has leached its components out into the environment. So it continues to decompose at the landfill, albeit at a slower rate than normal wood.

But the key point is this: The acetylation treatment not only makes the wood resistance to biological attack (as do toxic treatments), but it also imparts other beneficial characteristics to the wood, which is the real bonus.

Toxic treated wood doesn't become more dimensionally stable. A toxic-treated pine is still a softwood. An acetylated pine becomes comparable to a tropical hardwood. The durability and dimensional stability of Accoya exceeds that of teak. See here and here. Now you can go build bridges out of it, something you can't do with the toxic treated woods. Thus, the acetylation opens up new applications, so there is much greater carbon sequestration potential.

Q. So what's the catch?

A. The 'catch' is pretty straightforward. Accoya is obviously more expensive than untreated softwood. And unless customers understand the whole story, they may opt for a cheaper, but less-durable option. My job as Engineering Director is to make sure we are running our process in the most efficient manner, and therefore keeping our costs at a minimum so we can compete.

The other catch is that the market for building materials is presently pretty poor, as a result of the overall economic crisis and the slowdown in construction. So we are swimming upstream against that current.

Q. So are you saying that this is the solution to rising carbon dioxide emissions?

A. It can be a tool in the arsenal, but it would admittedly take a very large amount of wood in new applications to make much of a dent in carbon dioxide emissions. To make a bigger dent, we would need to start replacing more metals and plastics with Accoya (wooden refrigerators, anyone?).

Q. What are the growth rates for your softwood pine species?

A. Generally about 20 years, which is a much faster turn around than the tropical hardwoods.

Q. Are the freezing properties of wood changed (e.g. teak and mahogany do not handle freezing well when their moisture content is too high, compared with local (nordic) softwoods)?

A. Because the equilibrium moisture content of Accoya is much lower than other woods, we believe it should tolerate freezing quite well. But we are checking to see if we have any test data on file.

Q. Are the bending properties of wood changed in some manner?

A. Bending properties (MOE) are very minimally changed.

Q. Can wood be stained after your treatment?

A. Absolutely. Stained, painted, cut, glued – the same kinds of things you do with regular wood.

Q. What's the net carbon balance on your process? Presumably there's energy in the processing itself, as well as the harvest, transport, etc. That might be 5% or 50% of the embodied carbon in the wood, and that will have a huge impact on the actual potential for sequestration.

A. That is a very important question. We do have an LCA for Accoya, but I don’t believe that we have ever made that information public. We are in the process of getting additional LCAs that flesh out the carbon question in much more depth than the original LCA did. What the original LCA did was focus the energy to manufacture window frames versus competitors like aluminum and PVC. The conclusion was that it takes less energy to make Accoya than it does to make the competitors. But ‘less than a lot’ can still be a lot, so we are trying to go through and validate all of the energy inputs. Regardless of the energy inputs, if it takes less energy to make Accoya than it does to make a comparable amount of PVC, then the sequestration potential relative to the competitor is at a minimum the amount of carbon stored away in the wood.

The carbon issue is complicated by the fact that one can easily make choices that will impact overall energy inputs. When we built our first plant, capital costs were a concern. So, we used natural gas to produce steam. In the future wood waste could be used. In fact, I think I could design a process that could have zero fossil fuel inputs (into the actual process). It all comes down to capital costs.

Q. What is the typical mass of your material required in structural applications vs. the mass (of steel, etc) that is being replaced? That bridge looks like it used a LOT of wood.

A. I have been asked that question now a couple of times. One thing to bear in mind is that there is a LOT of wood in the bridge, but a large portion of what you see is aesthetic. Your question would be relevant to the structural parts. I know how much wood went into the bridge, but not how much steel, concrete, etc. was displaced as a result. This is of course another very important question. If it took 3 cubic meters of Accoya to replace 1 cubic meter of steel, then the energy inputs for Accoya must be multiplied to compensate. I am not suggesting that this is the case, but I understand why the question is important. I am trying to find an answer for this question.

Q. Is this publically traded?

A. It is, but we have taken a beating just like so many other companies - especially in the building sector. We trade on the London Stock Exchange as AXS, and our current market cap is 234 million Euros.

Q. How does Accoya's strength compare?

A. The hardness slightly improves, and the strength is the same as the original wood. More information here. The real difference in strength would be noted as time progresses. Accoya would retain strength and the base Radiata would lose strength.

Q. What’s not mentioned is what happens to Accoya at the end of its life. Concrete and steel don’t last forever and both can be recycled into new buildings at considerably lower energy input when compared to extracting raw materials. Where does the Accoya sequestered carbon go when removed from service? I doubt it can be recycled to the same degree that can steel, and I suspect it will end up emitted one way or another.

A. I think the question remains theoretical for decades. We really don't know what the upper limit for the lifetime of Accoya will be.

Someone mentioned to me a couple of days ago that the Sneek bridge was designed for 80 years. So let's say that 80 years from now, the bridge is coming down. If at that point we are still dealing with the problem of carbon emissions, I can envision a number of schemes for recapturing the carbon in the wood. For instance, I can gasify the wood, turn it into acetic anhydride, and use that to acetylate a new batch of wood. I could burn it for process heat, displacing a fossil fuel. I could reuse it in a less demanding application. I could hydrolyze it to sugars and turn it into ethanol. I could gasify it and turn it into biodiesel. What I won't have to do is to landfill it as hazardous waste, which is the end fate of wood produced by many preservative processes.

So the question isn't whether it can be recycled. I think the answer is going to be dependent upon the conditions in place when we actually have to deal with the issue.

Q. Does the Accoya process change the thermal conductivity of wood as presently used up or down?

A. Thermal conductivity is lowered as a result of the process, which is especially desirable in door and window applications.

Q. Does using Accoya generate carbon credits?

A. Carbon credits, as I have found, are a very funny thing. While the regulations vary from region to region, for the most part the ones who can play are the ones who already emit a lot of carbon dioxide. As hard as it may be to believe, if I invented a machine that did nothing but extract carbon dioxide from the air and bury it in the center of the earth, you might be a hero, but you won't get to sell carbon credits as a result. On the other hand, the coal-fired power plant that reduces their emissions can sell carbon credits.

You can find answers to lots of other questions in our FAQ. Now back to your regularly scheduled programming (even though I think the subject matter here is topical).

Note: As always, if you spot any errors, please call them to my attention.

Increasingly popular is recycled plastic/wood fiber used in plastic decks. The advantage of this product is that it does not require any preservation/staining like pine, even arsenic treated pine. While it is more expensive up front, it is cheaper in the long run. Would Accoya be competitive with these recycled plastic products?

Would Accoya be competitive with these recycled plastic products?

I don't have any information on market analyses against recycled decking. We did come up favorable against PVC for windows in the initial LCA that we had commissioned.

Very intriguing. When will this be available on the US market? Anyone we can write letters to to move this forward?

The carbon issue is complicated by the fact that one can easily make choices that will impact overall energy inputs. When we built our first plant, capital costs were a concern. So, we used natural gas to produce steam. In the future wood waste could be used. In fact, I think I could design a process that could have zero fossil fuel inputs (into the actual process). It all comes down to capital costs.

This didn't quite answer the net carbon balance question; also please add in the carbon footprint of acetic anhydride to the LCA, if it already isn't there.

When will this be available on the US market?

We have been putting some into the US market, but I don't have details on whether it is going to be available for purchase. You can e-mail Starla (her e-mail is in the essay) and she knows all of those things.

This didn't quite answer the net carbon balance question; also please add in the carbon footprint of acetic anhydride to the LCA, if it already isn't there.

That's because the carbon balance issue is very complicated. Is the wood being sourced next door, or halfway around the world? Where is it being sold? Are you making your own anhydride, or are you shipping it halfway around the world? Lots of questions like that make the carbon balance question entirely dependent on the specific situation.

However, we sequester more carbon away than we use to make the product. Also, note on the anhydride that it gets chemically locked into the wood, and so is sequestered away as well. The other thing to point out on the anhydride is that we can make it ourselves, and if the economics dictated we could make it from wood waste.

We are in the process of having some more LCAs done to cover specific usages for Accoya. Hopefully this information will be widely available.

The other thing to point out on the anhydride is that we can make it ourselves, and if the economics dictated we could make it from wood waste.

How is your feedstock made now? Do you have any efforts underway at this time to determine the economic feasibility of making it from wood waste?

Any other beneficial products or feedstocks that you can recapture from your waste stream?

Will, we don't currently make anhydride from waste as the economics of doing so aren't good. I am working on multiple energy reduction projects however, and that is in the stack.

Could this treatment be applied to bamboo, and would it be advantageous to do so? (I am thinking of applications like wooden bicycles)

(Sorry DaveMart, didn't mean to tag this onto your thread, was supposed to be a new thread)

This statement is VERY important for everyone to understand. "Cap-And-Trade" is the equivalent being promoted (by industry insiders and Wall street brokers) in N. America, and it suffers exactly the same problems the author points out. It entrenches the incumbent emitters at the expense of any inovative alternatives, and is too complex for smaller entities to get involved with. FAR SMARTER is a simple carbon tax on all carbon fuels at source, which adequately penalizes incumbents and also doesn't discourage inovation.

We need to get LOUD about this quickly, people.

Carbon credits will rebadge themselves as deductions under a carbon tax scheme, plus the physical target will overshoot or undershoot.

That's the difference between "Cap and Trade" and "Cap and Auction" ... whether or not we create a "value in being a polluter".

Any time Cap and Trade is proposed, the fight to make it Cap and AUction has to be fought. This was done in the US in the Democratic primaries, but primary promises have a tendency to fade away after the general election ... its necessary to find ways to hold the Congresscritter's feet to the fire on this issue.

Cap and Auction versus Carbon Tax is whether you think its primarily a physical problem or primarily a problem in economic value. But Cap and Trade with free permits to polluters is giving a free ride to polluters based entirely on the fact that they have already been getting a free ride on the backs of everyone else for years.

Could this treatment be applied to bamboo, and would it be advantageous to do so? (I am thinking of applications like wooden bicycles)

Dave, we have been looking into that (bamboo, but not bicycles).

The light weight and toughness which make bamboo suitable for bicycles translate into a lot of engineering applications, so it is great that you are looking at it.

Here it is for bikes:

http://www.calfeedesign.com/bamboo.htm

Very intriguing.

Acetic anhydride. I imagine you could make that from apple juice, but I suspect it is really made from coal or natural gas. How much is actually used to acetylate the wood?

Cellulose acetate is pretty flammable, I believe. What is the flammability of the bulk wood product? What about the sawdust or shavings? Might it be unsafe to use under certain conditions?

Apparently you use some kind of giant autoclave to process the wood. That must take a lot of heat, though I suppose less than manufacture of Portland cement.

Seems like this would be a natural for the Pacific Northwest, if your claims are all accurate. But the long life of the product may limit its economic value! Out here on the coast we rely on the fact that wood rots, and so needs to be replaced. What will we do with millions of houses that will never decay, full of increasingly old people who almost never die because of increasingly effective medical technology? I see the makings of a new Zardos movie.

"Acetic anhydride. I imagine you could make that from apple juice, but I suspect it is really made from coal or natural gas."

Acetic anhydride is usually formed by carbonylation of methyl acetate(an ester of methanol and acetic acid).

Methanol is made from synthesis gas(a mixture of CO and H2). There's no reason except cost that you can't make syngas from biomass, old tires, whatever.

Industrial grade acetic acid is usually made from carbonylation of methanol.

I agree it sound real good as especially the lighter, fast growing wood rot way to fast. Interesting using

acetic acid. But how much/kg of wood do you need.

I build things of high performance wood, mostly plywood and epoxy so this is close to home. And it sounds like a real improvement.

You should try in your designs so you can be recycle the pieces into new structures, ect once the bridge, ect is no longer needed.

Here in Fla we have cypress that is about as rot

resistance as possible with 100yr old log cabins looking about 3 yrs old!! To take light pines, ect to do

.the same is a good step forward

As for larger wooden bridges we have many in the

US and should be online. Start with covered bridges.

And a large number of RR bridges all made of wood. Near me beside US301 across from the Hillsbrough State

park N of Tampa are several all wood bridges about the same size as yours built in the last 10 yrs or so.

I agree it sound real good as especially the lighter, fast growing wood rot way to fast. Interesting using

acetic acid. But how much/kg of wood do you need.

I build things of high performance wood, mostly plywood and epoxy so this is close to home. And it sounds like a real improvement.

You should try in your designs so you can be recycle the pieces into new structures, ect once the bridge, ect is no longer needed.

Here in Fla we have cypress that is about as rot

resistance as possible with 100yr old log cabins looking about 3 yrs old!! To take light pines, ect to do

.the same is a good step forward

As for larger wooden bridges we have many in the

US and should be online. Start with covered bridges.

And a large number of RR bridges all made of wood. Near me beside US301 across from the Hillsbrough State

park N of Tampa are several all wood bridges about the same size as yours built in the last 10 yrs or so.

Thankyou, this looks very interesting.

I read a science fiction story once about a future where essentially all technology was biological, i.e. all human artifacts were made from either living or once-alive organisms. I think possibly the only way out of our current bottleneck (the future a high-entropy wasteland) will resemble something like this.

Very interesting, have you considered "Accoya® wood" railroad crossties (or sleepers as you would say in Europe)? Even if unsuitable for heavy traffic applications like U.S. freight railroads, perhaps lighter duty applications such as rail transit would be feasible. There has been such a trend recently for railroads to switch to concrete crossties (and some steel, some plastic) and to replace older wooden culverts and trestles with steel or concrete. Many of those wooden structures had lasted a century, and had survived the pounding of steam locomotive drivers.

Very interesting, have you considered "Accoya® wood" railroad crossties

Without getting into details, yes, we have been discussing this quite a lot.

Your plant produces 30,000m3/year of wood, of which you say the carbon is 250kg/m3 which gives a total sequestered carbon of 7,500,000kg = 7,500 (metric) tonnes of carbon. Let's optimistically round that up to 8,000 tonnes.

The amount of carbon produced anthropogenically in one year is around 30 gigatonnes of CO2, or about 30x12/(12+16+16) = about 8 gigatonnes of carbon. I'll write that out: 8,000,000,000 tonnes. It's a lot. In fact, a million times more than your plant is capable of sequestering.

Now I'm the first to agree that we need every measure we can think of to reduce CO2 emissions to the atmosphere, but my question is whether you ever see this having a non-negligible impact on atmospheric CO2 levels - can it realistically be scaled up even to 100,000 plants (even if we do see wooden refrigerators as you suggest!) and if so, is the land area of forest likely to be able to sustain it?

Carbon Capture and Storage (CCS) technologies are indeed in their infancy but even at this early stage of relatively low adoption and little government support we already see storage facilities at the scale of 1 megatonne CO2 or 300,000 tonnes of carbon per year (for example at Sleipner in the North Sea). Admittedly, this is not yet enough to make a noticeable dent in atmospheric carbon levels but is nevertheless nearly 40 times more carbon stored per year than your process (and is more certain of guaranteeing storage security for longer).

You mention carbon credits - this or an equivalent carbon tax is exactly what is needed to kick start CCS. The reason the project at Sleipner exists is due to the Norwegian carbon tax which the operators of the plant avoid by reinjecting CO2 rather than releasing it. When governments can get themselves into gear on this issue and set up a properly operating system by which a price for carbon becomes well-defined and reasonably stable, then we will see CCS becoming economic and consequently more widely adopted.

CCS may not be "truly commercial" yet, but it is a large and useful addition to our armoury against global climate change. This process, though it seems like a great idea and may well be truly commercial, surely cannot reasonably be scaled up to be anything more than negligible in the context of global carbon emissions.

The amount of carbon produced anthropogenically in one year is around 30 gigatonnes of CO2, or about 30x12/(12+16+16) = about 8 gigatonnes of carbon. I'll write that out: 8,000,000,000 tonnes. It's a lot. In fact, a million times more than your plant is capable of sequestering.

Erica, those are numbers very similar to what I myself calculated.

A couple of things to note, though. First, our second plant that is being built in China is 10 times the size of the one in Arnhem (which is really a demonstration plant). The one in the Middle East will be similar in size to the one in China. We have had serious discussions with companies about building plants that are 33 times the size of our Arnhem plant. So we believe we can scale this thing up by quite a lot.

The second thing is to consider the alternatives. If you can choose to use wood instead of steel or plastic, you have lowered your carbon emissions and sequestered carbon in the process. Is that enough? Are any of our contributions enough? I bet you watch your own carbon footprint. Why? Paper or plastic? Does it really matter?

I agree with you that the scale of our carbon emissions is enormous. I have said before that people who think we will rein in carbon emissions any time soon really don't understand the magnitude of that problem. That's why I say it will take a combination of energy that has a low carbon footprint, and commercial sequestration technologies.

Re: Sleipner in the North Sea - apples and oranges. There, carbon dioxide that is co-produced with natural gas is reinjected. That amounts to a very small portion of annual carbon emissions, and this solution is only applicable in that specific situation. As I pointed out above, our process in Arnhem is really a demonstration unit, capable of being scaled and applied all over the world (and capable of soaking up CO2 from the atmosphere). So I would strongly disagree that Sleipner is a better example of a commercial CCS solution.

This approach could certainly comprise one of the much-discussed "stabilization wedges".

Hi B,

I'm not sure I follow. Like PO, mitigating climate change will require lots of silver BB's. RR's process seems like a wedge to me. Which of the stabilization wedges gets compromised?

I think you misread: "comprise" (make up) v. "compromise."

Maybe I should have said that Robert's technology could add another wedge. :)

B,

My fault, I did read it wrong. Thanks for correction. Your choice of words was quite appropriate.

Nicely put, Erica.

We have to stop UN-sequestering massive quantities of carbon as quickly as possible, but few have called for a moratorium on ff extraction (except for George Monbiot).

The moral hazard here is that someone will hear about this ingenious process and say "Hey, problem solved" without realizing the disproportionate scale of the problem.

That said, I am impressed with the technology and wish the enterprise well.

Could you give a bit more info on where and how the trees are harvested?

Two other applications which immediately spring to mind are 1) going back to wood pole for utility poles and street lights. 2) pilings used for docks and building foundations, used to be wood but now commonly concrete and steel.

Where/how are the trees grown? Timber plantations are notorious users of fertilizers, herbicides, insecticides etc etc (all of which require fossil fuels for their synthesis) and can be a serious source of pollution to neighboring ecosystems. Can you add these consequences to your equation?

That sounds a bit unreasonably negative. And to my knowledge, timber plantations are rarely if ever fertilized, sprayed for insects or weeds. What's your proposed alternative? Steel and concrete? Cave dwelling with only stone age tech?

Nothing negative about asking for transparent accounting. At first blush this sounds far superior to steel and concrete, but......if I get breast cancer from the 2,4D that contaminates my water supply or if more carbon is released in synthesis of the starting materials than is sequestered in the product, my enthusiasm is dampened.

That's a pretty declarative "asking for"

Timber plantations are regularly sprayed with herbicides. After clear cutting, but before replanting, most cuts are sprayed with herbicide to kill the "non-profitable" plants and allow the new trees to grow.

See:

http://www.eugeneweekly.com/2006/03/16/coverstory.html

I see. You have your mind made up already. So, for your POV, anything timber is out. BTW, some anecdotes in an Oregon local weekly are not scientific evidence. Surprises me to see it, because the returns are obviously very marginal for herbicide spraying forest cutting, but I guess anything's possible in the US.

I've done a lot of tree planting in Ontario, Canada in my youth, and never heard of such. Perhaps if locals planted trees rather than riding around on 4-wheelers protesting then the weeds wouldn't smother out the seedlings. 'Course no such thing as a weed either, eh?

Len;

There's nothing unreasonable about looking at their forestry inputs. It doesn't mean that they're 'Against' timber in the extreme, but clearly there are a wide range of lumbering practices, and this must be considered openly. I'm in favor of windpower, but it, too, can be done responsibly or not, it has to be approached more carefully than the blind rush that so much of our industrial development has exploded with.. with timber clearcutting often being the first stage in our expansions.

I would also be interested to hear what kind of polycultures are being used to keep these tree-farms healthy and uneroded.

I just finished Omnivore's Dilemma, and thinking about Joel Salatin's 'Grass Farm', I hope it's true that we can create and promote farming practises that enrich complex soils, pasturelands, woodlands and perhaps fisheries.

Bob

Your paycheck obviosly comes from the timber industry, so you will never understand things. Go to the town of Marcola, Oregon, and take a look at the Weyerhaeuser tree farm. Ask the people why helicopters are spraying their town with herbicices. Would a quote from the timber cos. themselves help you out?

http://coastalconcern.wordpress.com/2008/08/28/wheeler-oregon-residents-...

How about on the other coast?

http://www.wral.com/news/local/story/1088896/

Herbicide spraying is a common practice on tree plantations.

We have a neat poplar/wastewater reuse operation north of Seattle, near Marysville.

Great link, thank you. A fine alternative to the helicopters spraying hormones on Christmas tree farms.

Robert,

In section 7 of your FAQ is stated:

"Due to its lack of toxicity, however, Accoya® wood is not suitable for underwater use in a salt water environment."

This seems to imply that toxicity is required to be suitable for use underwater. Is this a typo of some sort or am I just too ignorant of the nuances of this application?

Very informative article.

What I am told on this is a copper treatment is the only thing known to stop the marine borer.

The wikipedia entry claims that teredoes can digest cellulose, but it is my impression (having had some of the critters in a saltwater aquarium about 4 decades ago) that they burrow into the wood only for protection, and filter-feed like the other bivalves. I believe there are even a few bivalves that burrow into stone.

Is the marine borer problem the only problem to marine applications? Is this a qualification only for stationary marine applications.

Older boat hulls use to be made of teak. So if this wood is comparable to teak then I don't see any problems beyond using it to make a wooden boat.

It would likely rot at the same rate. But I would think that there would be a cost advantage. Pine is much cheaper than teak.

Excellent. Linked.

I think it's a bit early for the authour to say that he sequesters carbon for a living. We need more data before we can believe him, and he has to clean up some messy calculations.

There are a few things the authour is not telling us in this piece. Most importantly, they are in brief,

- EU cars travel around 14,000-15,000km each, not the 11,000km the authour states, reducing the "equivalent to X cars' driving" number

- not all raw timber ends up as finished product, at best 2/3, and the rest will rot/burn

- the authour contends that forests once grown don't sequester any more carbon; this is true of continuously-harvested plantations, but forests left alone in diversity continue absorbing more

- the authour cannot give us figures for the emissions during timber harvest and processing, or for construction with the timber, so we can't say how much net carbon is sequestered; certainly it'll be less than the 250kg/m3 he tells us

In detail,

Distance travelled by cars in EU

You've overestimated the car-equivalent. This is because the chart you referenced gives distance travelled per person, which you have read as per car; there are less cars than people in Europe.

Car ownership varies a lot across Europe, from around 350 cars per 1,000 people in Berlin to 650cars/1,000ppl in Rome. The EU says that in 2004 there were 216 million, or 472 passenger vehicles per 1,000 people in the EU25. Thus, 11,000km annually per person becomes 23,300km per car.

This is probably an overestimate for passenger vehicles, since the original 11,000km you gave was just your eyeball guess from a graph. The underlying paper tells us that many of their figures are a bit of a fudge anyway. This book on infrastructure tells us the converging average in countries with a high rate of car ownership is 15,000km per passenger car annually.

As I discuss in driving is not a rational choice, in most countries passenger vehicles get driven pretty consistently 14,000-15,000km annually. The US is the exception at 19,000km. Fuel taxes, availability of public transport, culture and so on seem to affect whether people own cars, but once they own them they pretty consistently drive them 14,000-15,000km annually.

Anyway, 14,000-15,000km means that your 15,545 cars become 11,400-12,200.

Since this sequestration corresponds to, you tell us, 171 million km of driving, well if we divided that into the 216 million passenger cars in the EU25 in 2004, that'd be... not even 1km less each. So if everyone walked to the shop for that loaf of bread just once in a year, we'd get a reduction in emissions equal to your sequestered carbon.

The new plant you speak of is said in that article to have a "500,000m3 nameplate capacity", compared to to 30,000m3 one you spoke of earlier.

If 30,000m3 sequesters 171 million km of driving, then 500,000m3 will sequester 2,850 million km of driving. This is 13km per vehicle in the EU25 in 2004. So perhaps on a single day in each year everyone bikes to work... this will match you.

So I'm not too impressed with the scale of this sequestration method. It's just insignificant in scale compared to the problem.

Finished timber is a fraction of raw timber

You base the rest of your calculations on this figure. However, what you fail to mention is that not every last cubic centimetre of timber is used in construction. When you down a tree in your plantation, a fraction of that tree ends up in a bridge, but another fraction ends up as scrap discarded at cutting site, offcuts in lumber mill (eg you want square beams, the tree is round, or you need 0.2x0.2x6m beams so only the main trunk is useful, not the branches, etc...), sawdust, some is rejected as being not strong enough for the job, and so on,

The fraction of a tree which goes to useful building work is all you can count as sequestered carbon; the rest becomes paper pulp, is burned, left in the plantation to rot, etc. This amount varies a lot across the world depending on forestry practices. For example my country of Australia has sloppy forestry practices - we tend to plant the seedlings and then just leave them until 15 years later - and so our trees get lots of knots and splits and the like, unable to support weight, and are good only for paper pulp. Finished building product fraction = 0. Germany and Switzerland are well-known as being much better than this.

An excellent useful fraction, assuming a normal mix of building timbers, sizes and qualities, is 2/3. It would be a little bit more if you were making telephone poles, and much less if you were making framing timber for a house. But 2/3 is a decent figure for a normal mix of sizes etc. And so all your claimed sequestration figures must be reduced by 1/3 at least.

When you tell us that your plant can process 30,000m3, does that mean 30,000m3 of timber straight from the field, or 30,000m3 output? Generally a quoted mill's figure will be how much input it can process. So your 30,000m3 input is not more than 20,000m3 output. That leaves 10,000m3 to burn or rot and contribute to global warming.

Plantations don't sequester much carbon, but forests do

Yes and no. It depends on the kind of forest you have. Plantation forests have the ground kept clear for logging access and just one kind of tree species, so the material all rots as you describe. Old mixed forests with a variety of tree species and bushes and fungi and mammals and insects and heaps of worms and bacteria in the soil, in this case a lot of the material of dead trees ends up sequestered in the soil.

That's why deforestation creates some 17% of our greenhouse gas emissions, because once we cut it down it rots and the carbon is no longer stored in the soil, not enough lives there to take up the carbon. If it were true that all dead trees returned their CO2 to the atmosphere and none was absorbed by the soil, then deforestation would not add any CO2.

A forest treated as a plantation does not sequester much carbon, but a forest treated as a forest does. You are probably thinking of "forest" in the form of plantation because this is how any lumber yard treats a forest - a crop to be harvested.

Carbon sequestered - carbon emitted = net carbon sequestered

This renders all your calculations of "carbon sequestered equal to X cars" utterly meaningless.

If we don't know the emissions it took to get the wood, then we can't say what the net emissions/sequestration are. Let's say the wood has 250kg carbon per m3, as you describe. And again remember that's only the useful timber, what happens to that? Burned, rotting, not processed with the preservant, etc - so it returns to the atmosphere. If 1/3 of every 1m3 is disposed of in this way, then you get just 167kg/m3 of timber input.

If your process requires (say) 50kg of carbon emissions to turn that 1m3 raw timber into 0.67m3 useful timber, then we have,

+250kg raw timber

-83kg discarded

-50kg emissions required to process timber, build structure, etc

= 117kg/m3 sequestered

Of course the finished timber/raw timber fraction is not known to us, and you specifically note you're not telling us the emissions required for processing, construction, etc. But we can say with certainty that the net carbon sequestered will be less than 250kg/m3 of raw timber input. The process may be carbon zero, carbon negative, carbon sequestering, we don't know.

Get back to us when you have a carbon LCA.

Conclusion

This appears to be a good and sustainable forestry practice; we don't yet know if it'll be a net sequestration or not. We need more information, and the authour needs to be clearer about the logging and timber processing methods, finished product fractions, etc.

Some very negative statements disguised with some easy quibbles about the obvious.

Any scientific references to back up that nonsense about "Old mixed forests"?

Perhaps you are unfamiliar with a website called www.google.com, it's most useful in discovering if someone's "nonsense" has any backing. But perhaps you just didn't know where to start?

Estimation of the carbon sequestration by a heterogeneous forest: night flux corrections, heterogeneity of the site and inter-annual variability

Long-term trends of carbon dioxide exchange above a mixed forest at Borden, Ontario

Global warming and terrestrial carbon sequestration

Comparing monocultures with polycultures or old forests,

Carbon sequestration in native rainforest tree plantations

"forest systems need to be managed to provide multiple production and environmental services, including carbon (C) sequestration, restoration of soil fertility, and biodiversity. Overall, traditional plantation monocultures cannot meet all of these new objectives"

Carbon return and dynamics of litterfall in natural forest and monoculture plantation of Castanopsis kawakamii in subtropical China

"The results of this study demonstrate that the natural forest has a greater C return through litterfall than monoculture plantations, which is beneficial to the increase of soil organic matter storage and the maintenance of soil fertility."

Old-growth forests as global carbon sinks [Nature magazine]

"Old-growth forests accumulate carbon for centuries and contain large quantities of it. We expect, however, that much of this carbon, even soil carbon, will move back to the atmosphere if these forests are disturbed."

Is that enough for you to begin your own researches?

Nonsense. Wood laying on the ground rots very quickly, releasing all carbon as CO2 and Methane. Doesn't matter how old the forest stand is, the trees all have a given life span. The author's process proposes to significantly delay the rotting and release of trees which would otherwise rot much sooner.

Period.

I hope you don't really think such a reply is really an effective refutation of all the links that Kiashu posted...

Aside from that, however, I can't resist saying that you've missed the forest for the trees.

To put it simply, it just stands to reason that an old growth forest, being an ecosystem that contains more living organisms than a tree plantation, is also most likely an ecosystem that contains more carbon at any given time.

Turn an old-growth forest into a tree plantation and you've released carbon into the atmosphere. Allow a tree plantation to return to being wild forest, and you've effectively sequestered a roughly equal amount of carbon.

I'm not an expert on the amounts, I'll leave that to the sort of folks Kiashu linked to.

A brilliant refutation. I'm sure that if you send it to the editors of Nature they'll publish it, and the Nobel Committee will create a new prize for contributions to biology just for you.

What matters is the net change in carbon storage, in the forest, plus in the product. We are not increasing the equilibrium amount of carbon in the forest. (That is also true of the mixed HW forest, although it probably takes longer to reach an equilibrium, and that equilibrium could well be higher). But RRs accola if the product lasts 100 years on average, would contain five times as much carbon, as the above ground part of the forest. Add in less than 100% for tree to accola, and the fact that the underground storage is (nominally) unaffected, and typically larger than above ground (roots, and carbon in storage). But even a conservative estimate would make the net carbon storage at equilibrium at least twice that of the forest alone. Of course this harveted forest will never be grown to maturity, so its carbon storage is going to be less than virgin forest. Nevertheless, I'd be very surprised, if this didn't cause net storage of carbon (and we have displaced other products, such as concrete/steel).

If this catches on it could be a useful carbon BB. Not a solution by itself. But it is doubtful any single method will solve the whole problem. Lets develop all the BBs we can.

A bit more from Kiashu's 'Nature' quote; part of Abstract from paper

(RR's technology seems useful: low maintenance long life construction materials that are non-toxic have to be real progress when we slide down the energy slope. But first priority: treat with utmost care the growing and harvest of trees, and defend the old forests.)

I posted this quote already on ToD in a different context.

I am getting questions faster than I can answer them, so let me hit a couple of points quickly:

Get back to us when you have a carbon LCA.

We do have one. I already stated that, and it verifies that our energy inputs are lower than competing aluminum, steel, or PVC. So if we choose to use Accoya over steel in an application, you would have a hard time arguing that carbon isn't being sequestered. You would essentially be arguing that the energy inputs into the process are greater than the energy contained in the wood.

A couple of other things to clear up. First, the 30,000 cubic meters is on an output basis. So the amount of wood initially in the tree is not a factor in my sequestration calculations. That is irrelevant. That covers about a third of your post.

If 30,000m3 sequesters 171 million km of driving, then 500,000m3 will sequester 2,850 million km of driving. This is 13km per vehicle in the EU25 in 2004. So perhaps on a single day in each year everyone bikes to work... this will match you.

This is the difference in what could we do, and what are we doing. Convince everyone to bike to work one day a year, and good luck with that. Meanwhile, we are selling a sustainable replacement for steel in certain applications, validated by one LCA (with two others in progress covering specific applications).

"energy" does not equal "carbon", as you know. I asked for a carbon LCA.

It's quite possible to have a net gain in energy while causing net emissions of carbon, or lose energy while absorbing emissions, etc. This is all about efficiencies. You've already stated that some lower-emissions methods were rejected because of financial cost.

I'd certainly be surprised if dealing with the timber caused more carbon emissions than the timber has carbon, but it's not impossible. And in any case it related to your calculation of sequestered carbon. Whether there are 1kg C emissions per 250kg C in the timber or 1,000 or more likely some number in between, it must be accounted for if you want to present us detailed calculations of "equal to X cars' emissions."

Had you simply said that it was a net sequestration, it wouldn't be a problem. But you gave us a detailed calculation of exactly how much would be sequestered. I was pointing out that the calculation was missing some important numbers.

Which means that there is some other timber left to rot or burn in the plantations. In a carbon LCA that'd have to be accounted for. Only counting the carbon once it enters the mill gates is like Italy boasting it's nuclear free when it buys nuclear-generated electricity from France.

If for example your finished product fraction was 1/2, that is only half the weight of the logged trees became a finished product, then the process would be close to carbon neutral (not quite because of the emissions in logging, processing and construction), but not net carbon sequestering.

Which is why I say that it certainly looks like a good and sustainable timber use practice, but it's not yet shown that it's carbon sequestering. So the title of the article is somewhat premature.

The view of conservation or changes in people's day-to-day lifestyles as being impossible is not borne out by experiences. Here Down Under, for example, we have by a mixture of progressive pricing, advertising and regulation halved domestic water consumption in a couple of cities, greatly increased public transport patronage, and hugely reduced rates of smoking. So we can change people's behaviour substantially.

That does not mean it's certainly possible to change people's behaviour in all energy use, deforestation and so on. But it does mean it seems to be worth a try - amongst all the areas of transport, heating, cooling, cooking, food, and so on, it would be surprising if none of those could be changed.

Kiashu, first let me assure you that I appreciate the criticisms. If I can't defend my arguments against criticisms, then the arguments aren't good enough. Having said that...

"energy" does not equal "carbon", as you know. I asked for a carbon LCA.

You misunderstand. We do have a carbon LCA. The LCAs we are currently having done cover a lot of different "What if" scenarios. That's what I mean by going much more into detail on the carbon question. But for our current process, we do have a carbon LCA, done by EMPA:

www.empa.ch

Which means that there is some other timber left to rot or burn in the plantations. In a carbon LCA that'd have to be accounted for. Only counting the carbon once it enters the mill gates is like Italy boasting it's nuclear free when it buys nuclear-generated electricity from France.

I don't believe that is remotely accurate, nor a proper analogy. Timber that is left to rot or burn is timber that was previously carbon dioxide pulled from the air. So it makes no contribution either way. Your argument would be like saying that if I grew a tree and then burned it for firewood, there was a net addition of carbon to the atmosphere.

If you are harvesting from an old growth forest, then your argument is true, but it doesn't apply for us. The only thing that matters is the carbon that was ultimately wood going into our reactors, and the energy inputs it took to make and distribute the finished Accoya.

Whether there are 1kg C emissions per 250kg C in the timber or 1,000 or more likely some number in between, it must be accounted for if you want to present us detailed calculations of "equal to X cars' emissions."

Don't get hung up on whether it's 15,000 cars or 10,000 cars. That number was clearly for illustrative purposes. If I said "X tons of carbon sequestered", it's meaningless to most people. If I can put that in terms of cars or miles driven, it can start to give people a picture.

The view of conservation or changes in people's day-to-day lifestyles as being impossible is not borne out by experiences.

That's not my view at all. I highly favor policies that reduce consumption. However, you compared something that could be to somethign that is. This is like me saying "If the U.S. lowered their energy usage to Europe's levels, we could be energy independent." Or "airing everyone's tires up could save more energy than this or that." Those are certainly things that could be, but neither is likely to happen in practice. But that doesn't mean that we should stop trying, just that we also have to work with 'what is.'

And as I said in my reply to Erica, I certainly understand that magnitude of the carbon emissions issue. There won't be a silver bullet, unless we just run out of fossil carbon.

This sentence bothers me. Why doesn't it apply to you?

If you are arguing that using Accoya will have a globally significant carbon sequestration result, but you are not including in any of this that we will use less wood somewhere else, then you are essentially arguing that increased timber consumption equals increased global carbon sequestration. But increased timber consumption almost certainly means that, somewhere in the world, old-growth forest will be turned into tree plantation. Or worse, simply consumed. And that means that some amount of carbon is almost certainly released at the other end.

It doesn't matter if you yourselves only buy from good tree plantations, someone else on the planet will either devastate old-growth forest or else replace wood with the concrete and steel your customers gave up using. It's either a wash, or else the science of carbon sequestration in forests, and the fraction of harvested wood that goes into real use, and all the things Kiashu has brought up, are vitally important to the question of whether you are actually affecting global atmospheric CO2 concentrations.

This sentence bothers me. Why doesn't it apply to you?

Because it is irrelevant to the argument he is making - that I need to count against the process the wood that was cut down and not used in the process (since it will either rot or be burned). But since this wood was grown for the purpose of construction, etc. then the carbon that is released on burning or rotting is the carbon that was sequestered while growing. So it isn't a plus or a minus. It makes no contribution toward the sequestration calculation - which concerns how much wood was stored away versus how much carbon was used to produce it.

And my calculations are based on finished product - not trees standing in the forest. He wanted to shave off a third on the basis that he thought the 30,000 cubic meters was input, when it is output.

Hi Robert, I enjoyed your post. Have to agree with several posters though that, at least for the time being, the new product described will have virtually no impact on total carbon emissions. Certainly any process for decreasing carbon emissions is welcome. But a strong argument for products such as Accoya® wood is that it will help decrease the amount of waste in the world since the life time of the product is increased. Rot, rust and insect resistance are highly desirable attributes for any construction material. It must be noted that no proposed process for sequestering carbon dioxide is likely to even start to dent the amount of CO2 evolved by burning FFs. Burial of CO2 underground is likely to be too expensive, in the long run, for the consumer to ever be applied.

Has any thought been given to using this process in tandem with the Japanese process for steaming and compressing wood to give wood with very much superior strength? Your process probably would have to precede the Japanese process in order to get good penetration of the acetic anhydride but the high temperature steam used by the Japanese might start to de-O-acetylate the Accoya wood.

Lets look at accola as a modifier to global demand for wood. In an equilibrium system, annual wood demand is the total inventory of wood product divided by the average lifetime of the wood product. If we hold the total inventory of wood product fixed, but increase the lifetime of wood in use, we decrease demand. I.e. we can harvest less wood than before, because we don't need to replace rotten wood as often. Of course if the total inventory of wood product is held fixed, we have not increased carbon sorage in wood product (but we would have decreased demand, which should imply healthier forests). If instead we keep wood production fixed, but product lifetime increases the total carbon stored as product goes up. Either way we are increasing carbon storage, in either healthier forests, or in greater inventories of wood product. In all likelihood, the accola would lead to some of each of these alternatives.

Absolutely, the criticisms are not in any way meant to detract from what I think is an excellent idea - to use more wood in construction. Since modern building materials are generally created with large amounts of fossil fuel inputs, wood will generally be a great improvement on them in fossil fuel and emissions terms. I critique because it's always good to keep things rigorous. If I can think of it, commercial competitors, government regulators and so on will certainly think of it.

It's my understanding that slash heaps are often burned, making the methane issue moot.

The rest of your objections above are similarly flimsy. A stand of e.g. poplar is unlikely to serve just one purpose. Sections large enough for lumber will be sent to mills (which is where the arcs and knots will be cut off and rejected, not on the land), smaller pieces may be chipped for pulp, and the twigs and leaves may go for mulch. With the recent interest in bio-oil as an easily transportable fuel product, the non-lumber fractions could be pyrolized to bio-oil in the field and the ash returned to the earth. Chips for pulp yield fuel also, both immediate (the lignin-containing "black liquor" can be gasified) and deferred (waste paper is a perfectly usable fuel).

All of these displace fossil fuels using carbon taken from the atmosphere. Some of them sequester carbon for a while, depending on the lifespan of the product. None of them are the greenhouse disasters you imply.

Hmmm, not sure what happened with all those blockquote tags, that seems to happen a bit here. Anyway...

Slash heaps are often burned, but not always. In any case, the combustion is never total; if 4% of the material is left unburned, this potentially doubles the effective emissions.

Yep, plantation timber often serves several purposes. But just as often lots is wasted, and oldgrowth forests logged are largely wasted, too (a particular problem with Australian forestry practices).

It's certainly true that using best practice in forestry will mean that the net greenhouse impact is low. But it's also true that best practice is far from universal. In fact, of all timber logged, the vast majority is logged very wastefully. Most of us don't need to worry about that.

But a company offering timber products and wishing to claim "I sequester carbon for a living" does need to worry about it. You can't make a claim like that unless you can back it up by telling us about your forestry practices. Rapier's article was missing that half of the process.

Preview is your friend.

Not really. Anything left unburned from a slash-pile fire will be partially or completely pyrolized, and not digestible by bacteria. Thin layers of slash material will be aerobic, like fallen leaves and needles.

It appears that waste timber in Europe is a luxury that few can afford. Maybe Australia can follow suit? That would help the Americas and SE Asia get on the bandwagon.

Timber emits as much CO2 when it rots as what it took up during growing, so it nets out zero. Whats your argument then?

Regarding your comparison to the CO2 Saved by driving less, two things. First: Don't you think its a bit pointless to compare the CO2 savings of one pilot plant with all vehicle emissions in europe?

And secondly we need to do all we can to use less fossil energy and emit less CO2, so arguing that a method of CO2 sequestration isnt any better than driving less is again just contraproductive as we will certainly need to use all available methods simultanously if we want to turn this situation around.

No. It also emits CH4. See my comment above.

Perhaps, but it was the article authour's comparison, not mine. I was simply responding to that.

Absolutely! Which is the drive of my critique.

There is a tendency in many people to look at sequestration and hope that we can continue business as usual forever, but "let's just bury it." By overstating a particular process's sequestration potential, that encourages that wrong thought.

Likewise, by overstating the potential of reduction of consumption, of solar panels or nuclear or whatever, we also encourage the wrong idea that something is a "silver bullet". People tend to hope that they can continue their lives exactly as they've always lived them, and a single solution will without disruption or expense deal with all the problems.

We see it here a TOD all the time, posters become well-known for pushing nuclear, or personal rapid transit or whatever, and downplaying or denying the usefulness of any other approach. And it's not confined to TOD, but is quite widespread - it's human.

There actually is a "silver bullet," that is in the sense that there is one simple answer to the problem of increased CO2 in the atmosphere, and that is to stop UN-sequestering massive quantities of carbon in the form of ffs. But this doesn't fit the other usual meaning associated with "silver bullet"--that it be relatively painless (to "us").

Some good points, none the less if the acetylation process leads to a net gain in sequestered carbon the author would be within rights to make the claim he sequesters carbon for a living. Any model used to calculate the net value of carbon removed from the cycle at this point in time is lacking much in complexity and scope so any claims can not be taken as dogma--but we must start somewhere.

A point not adequately addressed critical to the calculation is the length of time it will take for all the carbon stored in acetylized wood to be released back into the atmosphere. Pie in the sky hopes that it will all be regasified or recycled in some other way do not mesh with generally happens on the ground with demolished wood product structures. They are bulky, long distant transport is expensive, reuse in less demanding applications is unlikely at a large scale in a market where labor costs are high. (I build commercially for a living so I know how the short term cost constraints shape projects.) To make any meaningful computation on the carbon being sequestered by the product requires the likely percentage of the wood that will eventually decay per time be subtracted from the amount of carbon which was stored in products originally per time.

All that said, this sounds like good innovation. Is the process patented? If it proves commercially viable in this market it will do well. Making unsustainable claims as to how much benefit the acetylation process brings are not helpful in the long run, they tend to bite you in the ass.

A point not adequately addressed critical to the calculation is the length of time it will take for all the carbon stored in acetylized wood to be released back into the atmosphere.

As I said, it's theoretical at this point. We know that the wood lasts above ground for more than 50 years. We don't know what the upper limit is. So, any carbon sequestered buys you 50 years for finding better solutions.

Is the process patented?

Yes.

Making unsustainable claims as to how much benefit the acetylation process brings are not helpful in the long run, they tend to bite you in the ass.

Claims are based on the LCA we had done by EMPA, as well as many years of independent verification by multiple outside labs. From our website:

Results of the testing are available upon request, so you can see that isn't just us making claims.

My point merely was that the greatest part of the wood will likely decay in time barring some phenomenal changes (we can hope) in the way materials get recycled from job sites. When talking carbon sequestering 50 years, 100 years and 200 years are all fairly short term but those differences could all be significant to the cycle we are dealing with.

Since the growing of the trees and eventual decaying of x percent of their end products will be an ongoing cycle it is of import to determine how much faster carbon is being sequestered than it is being rereleased if you are using carbon sequestering as a real selling point of the product. This is not theoretical. Of course if there is no reliable way to determine the eventual decay rate of acetylation processed wood other than gathering data in real time, coming up with real numbers becomes problematic. Marketers will look for the best case scenarios, decent science will require including all scenarios right up to worst case when rating the probable outcomes. Hence the possibly slightly coarse comment about getting bit, 'come back to haunt you' might have fit this forum better.

I in no way meant to impugn your product. As much as I love what I can do with reinforced concrete, wood is my first love as a building material. A better, cleaner type of treated lumber is a very good thing.

Increasingly, so is landfilling.

Landfilling of demolition debris is expensive enough that at least one startup, Ze-gen, is focussed on gasification of the combustible fractions and reclaiming metals. The mineral portions wind up as slag, which can be reused as well. Ze-gen has not yet released data on the efficacy or flexibility of the gasification process, but the chemistry is no mystery. Whether the syngas goes for synthesis of acetic anhydride or methanol or just gets burned for electric generation, it's displacing some fossil fuel. It may not be worth using Accoya for interior woodwork in a short-lived commercial building, but if Accoya can be used in place of e.g. steel roof members, substantial amounts of carbon would be taken out of the atmosphere for a significant period of time. If it can be separated upon demolition, it could be pyrolized just like wood and used for bio-char; that would continue to sequester about half the carbon for as much as thousands of years. The inseparable portion would become fuel or feedstock.

Accoya isn't the only new technology out there. It's worth keeping in mind that these things together can be more than their sum.

That's excellent.

Interestingly, here Down Under around half of municipal landfill inputs are from demolition and construction, the other half from homes.

On rubbish day, walk along and see how much stuff people are chucking out of their homes. Then think that it's about equal to the construction debris. All that rubbish every week. It's amazing.

If we could reduce that construction waste, and make use of it, that'd be excellent.

In Canada (and I think the US also) we have a MAJOR problem with the pine beetle. Could the wood that is infected with the pine beetle be used as a source for the Acoya process. If so, there is a lot of wood in Canada that needs a use.

Very interesting article, and a hopeful one also.

Don

Don, I want to be careful about how much I reveal, but we are very much aware of the pine beetle kills. In fact, I have some of this wood.

I agree, in Canada we need to be doing more (or publicizing it more) about the vast tracts of deadwood. We could make the best of a bad situation by sequestering a lot of that carbon before it rots, and I think this process just may be a perfect opportunity. Pyrolysis and biochar production could also offer some opportunities.

Robert I am curious about how deep the process penetrates the wood. Does it go all the way through a treated board or just some sort of surface application? Is there a limit to the board dimensions because of saturation issues?

Thanks for the article.

Jason, the process treats the wood consistently all the way through. Some wood species have very difficult to penetrate pores, however, and they can't easily be acetylated. So the process is not universally applicable.

Also, does the process work with denser hardwoods, such as oak or hickory? What about poplar, which grows relatively rapidly? And, has sawdust (form either soft or hard woods) been investigated, especially as a feed stock for a moisture resistant particle board?

E. Swanson

The hardwoods are very difficult to penetrate. Poplar and sawdust have both been done successfully.

If this process enables an increase in the use of wood as an 'engineering material', then so much the better. However, wood, in the form of large laminated wooden beams, has already found use in a variety of architectural applications, such as public buildings, modern churches, upscale residences, etc. As most of these are indoor uses where rot resistance is not particularly critical, I don't think the Accoya material is particularly applicable.

As far as the Accoya material providing a substitute for tropical hardwoods, I don't think one can make such a blanket statement, because such substitutions are highly application specific.

Take teak for example. It is used quite heavily in boat-building as decking material and various structural components. While teak has good rot resistence, what makes it ideal for decking is that it is hard, close-grained, well-wearing, and strong. Something like treated pine, even if 100% rot resistant would make for a poor substitute.