Tech Talk - The Coming Problems for the Alaskan Pipeline

Posted by Heading Out on August 28, 2011 - 4:57am

The original Prudhoe is a small village with a medieval castle on the south bank of the Tyne, in the northeast of England. It lies in a coal-mining region within five miles of Prudhoe Colliery, where there were, over time, an additional 157 mines and pits and five working seams of coal in the 1860s. Not in itself out of the ordinary, but by 1828 Prudhoe had given its name to a region in Alaska. The naming recognized Admiral Algernon Percy, the first (and only) Baron Prudhoe (after the castle), who later became the fourth Duke of Northumberland. (His dad, the second Duke, led the British retreat from Lexington after the initial battle).

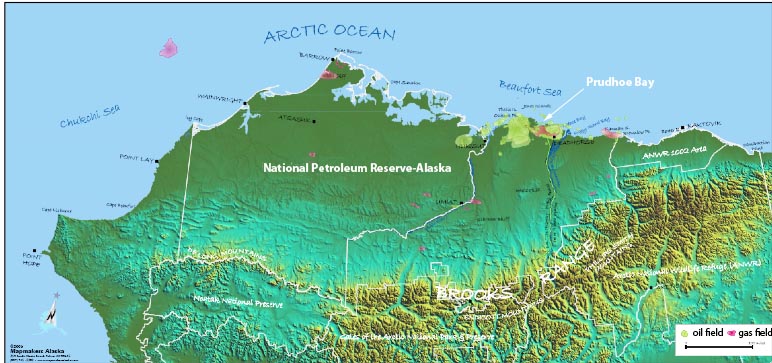

As with the region of Southern Alaska I mentioned last week, Prudhoe Bay would have faded into the obscurity of the original, were it not that oil seeps had been reported there by the Inupiat Eskimo. After the area had been prospected and surveyed between 1901 and 1919, President Warren G. Harding established the Naval Petroleum Reserve No. 4, a region now called the National Petroleum Reserve-Alaska (NPR-A) in an adjacent area of the North Slope of Alaska, that region that lies north of the Brooks Range. This led on to further exploration, and on March 13, 1968, the Prudhoe Bay discovery well was announced.

I am going to forgo a discussion of the development of the fields that were then discovered in Prudhoe Bay and its adjacent fields until next time, because the oil reserve in Alaska is only a reserve if it can economically be accessed. Otherwise, it is only a resource and the transition from one to the other, in Alaska, came about with the development of the Alaskan pipeline.

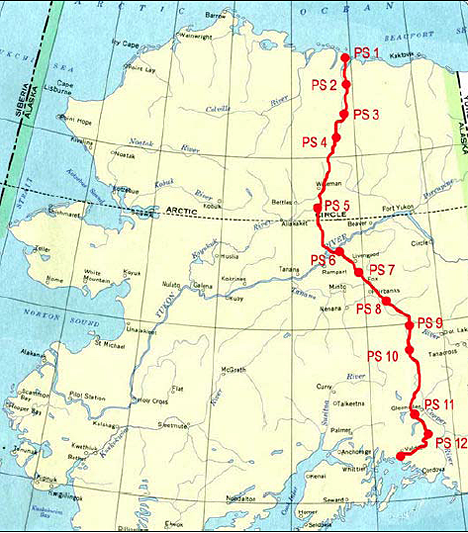

The Trans-Alaska Pipeline System (TAPS) is the conduit that makes it possible for oil to flow from Prudhoe Bay some 800.302 miles down to the ice-free port at Valdez. From Valdez it can be shipped by tanker (about 25 a month) to customer refineries further south.

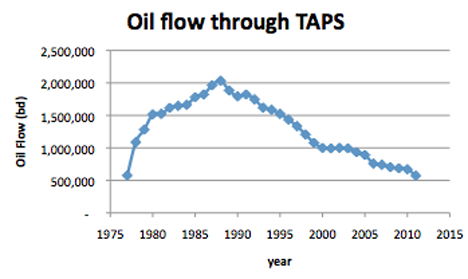

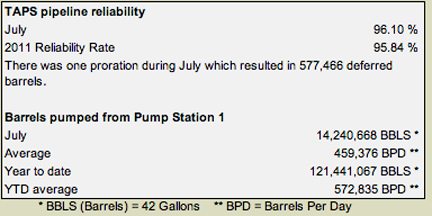

In July of 2011, TAPS averaged a flow of 459,376 barrels of oil a day, which is down from the average over the past year of some 572,835 bd. And those numbers are becoming something of a concern. While the pipeline produced about 15% of the national domestic production in 2010, the pipeline requires a certain flow level if it is to effectively deliver oil.

The pipeline was built in the years from 1974 to 1977, and between then and now has delivered some 16 billion barrels of oil. At its peak on January 14, 1988, the pipeline flowed at a rate of some 2.145 mbd (the pipe itself contains some 9 mb of oil at any one time), though whenever it flows at higher than 750,000 bd, a drag-reducing agent has to be added to the oil to reduce turbulence.

However, as the flow declines, problems start to arise with the behavior of the oil. The oil comes out of the ground rather hot and enters the pipeline at a temperature of up to 145 deg F. But even though the pipeline is insulated and isolated to ensure that it does not have an effect on the ground that it crosses, some of which is permafrost, it will gradually lose heat as it makes the trip down to Valdez. For example, in 2008, when the flow was still 703 kbd, it took 13 days for the oil to reach Valdez, moving at about 2.6 mph. The oil was entering the pipe at 110 deg F, and was at 55.6 deg F when it reached Valdez. However, the lower the flow rate, then the slower the oil moves, and thus the cooler it becomes.

This first became publically evident as a concern last January when a leak at one of the pumping stations caused the pipeline to shut down. I explained some of the concerns at that time particularly stressing the problems with wax that starts to precipitate out of the oil at a temperature of 75 deg F, and ice that can form as the water starts to precipitate out and then freeze at 31 deg F (the water is slightly salty).

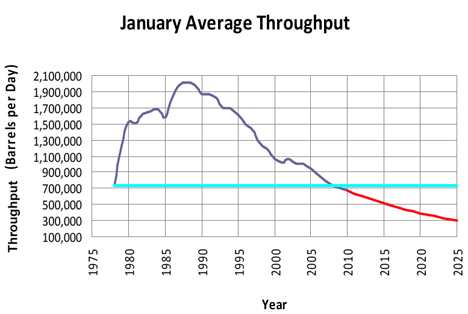

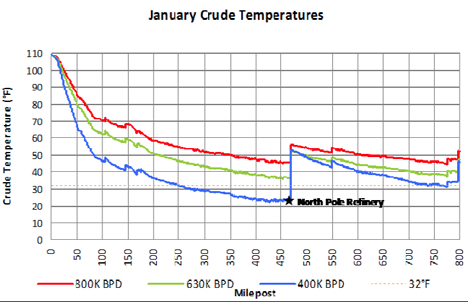

With these concerns on flow rate Alyeska has recently released a report on the consequences of the decreasing flow rates through the pipe, exploring these and other issues in more detail. The greatest temperature effects will occur during the winter months, and in preparing the report they plotted flow rates for January. The following section reviews statements and concerns in that report.

As I noted above, the average flow this year is below 600 kbd, which signifies a somewhat higher decline rate than that assumed, and that for July was below 500 kbd.

The declining temperature along the pipeline is offset at roughly the half-way mark by the withdrawal of up to 210 kbd of crude to feed the North Pole Refinery near Fairbanks and the re-injection of the residual fluids from that refinery, which enter the pipeline at 125 deg F. The loss in volume comes from the refined products, including gasoline jet fuel and asphalt, which are used for civilian and military use within the state.

(In what is, perhaps, an example of the Export Land Model, the refinery has grown in size, and thus demand from TAPS. It started at 25 kbd in 1977, shortly after the pipeline began to flow. It grew to 45 kbd in 1980 and was expanded to handle 90 kbd in 1985. It was then expanded to 130 kbd, and then, in 1998, grew to its current capacity of 215 kbd. ) However, the report suggests that only 35 kbd is retained at the North Pole refinery and 12 kbd at the Valdez Refinery. The volume removed does slow the speed of the oil in the remaining portions of the pipeline. Thus, at 400 kbd it will take 23.5 days for the oil to reach Valdez, with the speed falling from 2.15 ft/sec to 1.86 ft/sec after the North Pole Refinery.

When the pipeline was built it was assumed that it would pump a dry oil (without water content) and that flow rates would remain above 500 kbd. Neither of these conditions is likely to hold true in the future. The oil coming from the wells contains a small (0.35%) percentage of water with higher peaks, and flows are falling below 500 kbd at which level the water starts to separate out from the oil.

There are several results from the lower flows of oil. As the above graph shows, even at the highest flows now anticipated (around 600 kbd) the temperatures fall below 75 deg F, and wax begins to precipitate out of the oil. Because this settles against the pipe walls it must be periodically scraped from the walls, and dumped at specially designed traps. At temperatures below 31 deg F, this mixes with ice.

Based on the nature of ice formation identified in the LoFIS, the HAZID determined that ice crystals will form in the pipeline stream while flowing at temperatures below 31ºF. The crystals can then combine with wax and add to the volume of debris pushed in front of a pig or, as seen in the flow loop tests, to be deposited at locations such as valves. Ice deposits could then accumulate at valves and potentially interfere with valve action such as the sealing of CVs.

and

Thermal analysis indicates that the critical throughput at which crude oil temperatures during normal wintertime operation decline through the freezing point of fresh water is about 550,000 BPD during the winter months, provided the heat from the NPR residuum continues to be available.

Further, in regard to the use of the pig

Movement of a pig in the pipeline following an extended shutdown was identified as a particular concern because the pig cannot be stopped and can push considerable volumes of ice, ice slurry, or ice/wax slurry through the pipeline and into instrumentation connections, pumps, strainers, as well as refinery off-takes, mainline relief valve branches, and the backpressure control system in Valdez.

It was noted that pumping stations were not designed to handle the high volumes of ice and wax that might build up in front of an aggressively cleaning pig.

The external temperatures through which the flow is moving obviously play a part in the thickness of the wax. The models that were run for the report illustrate the difference in volumes of wax generated, assuming 14 days between pig passes and comparing June with January.

At flow rates above 350 kbd, much of the wax scraped off the wall is assumed to be carried away by the faster moving oil, but at 350 kbd the flow may be insufficient and the wax may then agglomerate and build up in front of the pig.

The third issue of concern is corrosion. There is some evidence that this accelerates in the pipe when the velocity falls below a certain level, and this was discussed on TOD back in 2006. It was not discussed in detail in the report.

The final issue related to the behavior of the ground around the pipe. Where the pipe has historically kept some of this ground thawed, even during winter the fall in flow may now cause it to freeze and form ice lenses that then subsequently thaw and form voids (as was recently discovered with the Big Dig in Boston). While some movement (a foot) was allowed in the design, that will be exceeded if the flow falls below 300 kbd.

A reserve is only a reserve as long as it can be viably extracted, which includes the ability to access and utilize the oil and gas. Should the pipeline stop flowing, and there are credible conditions discussed in the report that may lead to such an event, then the remaining oil in the North Slope will be unavailable, as will that currently held in the NPR-A.

Under current conditions and without additional well development and a significant increase in oil flow, the data would suggest that the critical date will happen sooner than even this report has suggested (which would be when the flow falls below 350 kbd sometime around 2020). The Obama administration is interested in increasing production from the North Slope, but only after significant steps to ensure “responsible drilling” have been put in place. Concerned by a number of factors, Alaskan Governor Parnell wants to boost flow back to 1 mbd by 2022. To this end, and recognizing the problems of low pipeline flow, his new Commissioner of the Department of Natural Resources has put forward steps that could help implement that process, including a road to Umiat.

But that gets into the condition of the oil reservoirs north of the Brooks Range, and I’ll discuss those next time.

I was curious, how much of a problem if any is melting permafrost for this particular pipeline?

They did some intense modeling for the pipeline before it was installed, and it has had to deal not only with permafrost issues, but also earthquakes that have since caused the pipe to locally straighten, so that there is a fair bit of protection built in (remember that it has now been functioning since 1977). And even with the freeze:thaw issue I referenced there is an allowance for up to a foot of movement -though I don't think that reducing the flow will have much impact on melting the permafrost.

Everything you ever wanted to know about TAPS: 800 Miles to Valdez: Building of the Alaska Pipeline. Well, up to its going online, that is, this book was published in 1978. Entertaining read. I see 3 other books recommended by Amazon on the TAPS if you want to try something a bit more recent.

Recently I finished up Crude Dreams: A Personal History of Oil and Politics in Alaska, from 1997. Also a good read.

Another good read is The Great Land by Booton Herndon, 1971. It covers the very early years of exploration and ends with the building of the pipeline

I was surprised they allow such a high % of water in the pipeline. 0.35% amounts to 1750 barrels water per day into the pipeline.

In 'past decades' the standard was usually 0.2 %. From this bulletin from Chevron, their standard, in the lower 48, is now up to 1%.

http://crudemarketing.chevron.com/posted_pricing_daily.asp

The problem with ice in the pipeline could be reduced but not eliminated by lowering the acceptable water cut. And surprise, surprise, surprise, adding heat to the oil/water mixture is one way of lowering the water cut. It only requires fuel, money and equipment.

Fine detailed article. The recent drop in output year over year seemed huge(19%!) and the reason was not well elaborated in the article. The remaining reserve amounts of oil are unknown and I have seen comments that suggest far more gas than oil remains. What is the chance that pipeline output would ever get back to 1 MBD, the bluster and rants of any AK politician du jour not withstanding? What with global warming leaving the north slope ice free for longer periods, one wonders if the oil could be transshipped by tanker. Alternatively one wonders if the refinery near Fairbanks could be expanded massively. Finally I wonder if the pipeline could be retrofitted or an additional pipeline installed in parallel to transport NG. Then again, highly doubtful given the low price for NG.

They need to convert the natural gas to DME so they can burn it in their diesel engines. rather then flaming it.

Or run their diesels on a gas-diesel blend.

By "flaming it" I assume you mean flaring the gas. This is not done, except for safety reasons, usually in emergencies. In normal operations, any gas flames you see above N Slope facilities are just tiny amounts of gas kept burning so the flares stay lit, should they be needed.

Aside from small volumes used for fuel within the oilfields, virtually all N Slope gas is re-injected into the reservoir. This is done to maintain reservoir pressure. If the gas were not re-injected, reservoir pressure would soon fall and oil production would rapidly cease soon afterwords.

I was a little surprised to see the current numbers, particularly since the flow rates were so much higher when I wrote about the stoppage last January. I was going to start writing about the reserves, and that 1 MBD today, but we had a visit from Irene and have only just got the power back.

Prudhoe Bay was as far west as Franklin could sail in 1826, when he tried for the Northwest Passage, he died on a later try. I am not sure that the associated costs relative to the benefits would likely justify putting in a tanker terminal up there.

To cut costs, they could try renting icebreakers from the Russians when they need them, or maybe get a discount if they top up another order:

http://www.barentsobserver.com/index.php?id=4940947&xxforceredir=1&nored...

Would it be possible to add a lower molecular weight component to the crude oil (e.g. Naptha) or even methanol (which can be synthesized from CO2 and H2, and both of which are usually available at an oil refinery)?

Methanol (even a small amount) would dramatically lower the freezing point of water to prevent ice build-up. Naptha should improve the solubility of the waxes and lower the viscosity of the oil. Perhaps the "North Pole Oil Refinery" could perform a cracking operation to create a less viscous crude??

I realize that the amounts involved are large, but rather than shut down the pipeline (or increase the chance of spills), some upgrading of the crude should be considered and/or some additives to improve the flow characteristics. Even a cracking operation to remove asphaltenes (which have to removed in any case) would significantly lower the viscosity, increase the flow speed and increase the temperature of the oil (faster movement to Valdez)?

What do you think?

Iwylie

The problem relates to the volumes involved, remember that the pipeline holds 9 million barrels of oil at one time. And you would have to send the methanol/whatever up to Deadhorse somehow.

What would be the practicality of running a smaller line from the North Pole refinery up to Deadhorse? A 6 inch line would provide enough for a 2% dilution rate. And for what it's worth, you get the material back at the refinery.

Does the pig, in the photo above, travel from left to right or right-left?

TIA

NAOM

To the left. The pipe is 48 inches in diameter, if I forgot to mention it. The pig I showed was one that I had taken a picture of, but there are specialized "paraffin" pigs to remove the wax, one of which is shown here .

Ah, thank you and for the link. The previous two photos are also interesting.

NAOM

Questions:

I guess injection of anything doesn't work as it will lower the temp of the oil and negate any change in viscosity? So, is it possible to shut it down ever? and then restart flow during warmer periods....say March-Nov. And/or is corosion a limiting factor? Do changes in pressure from a constant flow affect the integrity of pipe and welds?

Thanks in advance

The article I wrote in January was written in part because of the serious problems that arise if the pipeline is closed for more than about two weeks in winter, at the flow rate then pertaining. At the time they were so worried about this that they restarted the flow before they had the pipe leak fixed (it was at a pump station and the oil could be captured easily). At flow rates below 500 kbd they only have 9 days. (ibid)

At the risk of sounding like an optimist, i think the TAPS and other pipelines in the north have a long future ahead of them. The TAPS runs through some truly vast coal fields and coal pipelines of similar length have already been built. Could the TAPS be adapted to transport coal slurry, or twinned with a pipe dedicated to that purpose?

The use of coal pipelines has had a very limited success, and while there have been successful experiments with making the coal into coal logs to float down the pipe as a way of filling most of the volume while not wetting the coal, the big issue is with the amount of fluid needed for the transport medium. Most coal pipelines have been quite small in diameter (less than a foot IIRC) and a 48-inch diameter coal log boggles my imagination.

Surely if the wax precipitates out, it narrows the x section of the pipe, so the oil in centre flows faster and therefore loses less heat? You might need bigger pumps with a narrower pipe though.

The problem is that the pipe is not a long straight bore all the way from Prudhoe to Valdez, but instead goes up and down and has zig-zags to help cope with ground movement. Thus there are low spots where debris can collect, corrosion can occur etc. These are often in really inhospitable parts of the geography. And thus there are problems of fluid control, which is why they now send the pigs (some of which are instrumented) to monitor the pipe very regularly to ensure that there are no unanticipated problems. But life being what it is . . . . .

As a footnote perhaps, John G. Kneiling PE was an industrial engineer in practice around the time of TAP design & construction. Kneiling worked up a substantial body of technical information, cost/benefit over long term, for railway instead of pipeline. He included some hopper-type railcars for fast load-unload, etc,

Kneiling's work can be found by searching his name, with "Professional Iconoclast" attached, as he was a columnist with that moniker for TRAINS Magazine circa 1970. Certainly, railway might have a greater role in the Oil Interregnum!

I have looked at extending the Alaskan RR north of Fairbanks and it appears quite doable and economic till one gets into the Brooks Range.

If a viable path could not be found through the Brooks Range (nothing immediately apparent), I would suggest a new, smaller pipeline from the North Slope and a transfer to rail inside a mountain.

Do a TBM drive through the mountain and a second TBM cavern inside. A pipeline in one end, rail the other and transfer the oil inside the mountain - out of the weather.

The flow rates when the 48" pipeline is no longer viable are also when Alaskan oil demands will absorb a good % of the production#. So rail some oil to the North Pole refinery and perhaps a new refinery. The remainder could be exported from a new, low volume oil port near Anchorage.

The rail extension would have other economic value, such as exploiting other resources and some tourism.

Best Hopes,

Alan

# Alaskan oil demand is around 125,000 b/day today, but on an upward trend.

Had to look this up: TBM = Tunnel Boring Machine. Have always agreed this would be a good way to extend the life of NS fields, if it can be done economically of course.

KLR

Jet fuel from the Koch brothers North Pole Flint Hills refinery of course doesn't all get burned in Alaska. Anchorage airport shoots for 600 landings of big air cargo jets a week. The air carriers do no like to overfly Anchortown as they must displace revenue generating freight with deadhead fuel to do so, but the fall in jet fuel shipments from Flint Hills have forced some overflights. Sea going tankers are now carrying some jet fuel into Anchorage to make up the shortfall.

H.O.

Thanks for the excellent key post H. O.

Luke

I spent (wasted) some time looking at the topography of the Brooks Range.

East of the TAPS pipeline, a north flowing river and a south flowing river are separated by about a half dozen miles - and there are ridges and valleys between them. A single tunnel may be required at that point for part of the distance.

I was unable to judge the grades up each river valley, but I assume that they are glacial type fjords and the slope of these are typically less than 2.2%. Grades > 2.2% can be lowered by moving side to side in large radius S curves.

So I am more optimistic about an economic rail extension to Dead Horse to extract the remaining oil.

Best Hopes for Leaving Little Oil Behind,

Alan

Hi Alan,

Don't have any good grade numbers for you but the ramp up to the Brooks from both the south and the north approaches is gentle by highway standards (unlike the road maybe fifty miles either way north and south of the Yukon River bridge).

Here are a couple of shots I took from near the top of Atigun pass last summer. They give some idea of the topo inside the pass.

The Brooks Range rises very suddenly when approached from the north. South of the range the valley is quite long and gently sloped.

Most of the heat energy in the oil is being lost before milepost 150. The temperature differential is significantly higher in these sections. Double insulation of the first 150 miles of the pipeline seems it would allow significantly lowered operating volumes without temperature problems. The report mentions improving insulation as an option, but doesn't develop on the subject very much. Reducing temperature loss before oil enters TAPS also seems important.

sounds like they may have to install oil fired boilers every so often to heat the oil back up.

tap into the pipeline for fuel and then wrap some steam lines around the pipeline.

2001

Oct. 4 60 hr, 30 min (down time) Bullet puncture at MP 400.

I was just checking one of the links in the article The one other down time longer as I can make out was for an 7.9 earthquake which was about 6 hours longer. It doesn't stand thinking about, its frightening 15% of America oil supply off line because some hick from the sticks fancies a bit of target practice. I wonder how long it would have been down if he who had done it had have had a middle eastern outlook, a political agenda and a RPG.

Multiple proposed locations are in the report.

Another strategy is to use some of the abundant natural gas at Prudhoe Bay and preheat the oil before injecting it into TAPS. 145 F is hardly the upper limit for hot oil.

Perhaps dewatering the oil is a viable strategy in conjunction with heating is a viable strategy.

Best Hopes,

Alan

Dear Mr. Heading Out:

Does anyone think that oilsands output from Alberta (yes that Dirty Stuff) or any other refined product (choose one), could be shipped over on a new rail link via Ft Nelson BC CN Rail terminus and then on to Ft McMurray or Upgrader Alley near Edmonton...essentially a newer version of the 2005-7 Al_CAN Rail link project

It might help solve the problem of low temp and low flow all at the same time.

I think California and Asia could use the supply (I've heard)....

Helps relieve the burden of risk for supertanker spills off the BC Coast (and Alaska Panhandle too).

Plus remove the uncertainty of the financial viability of the TAPS and the future of State revenue streams.

Plus the value of the North Slope...as I wanted to point the decline curve flattens out over time and during that "time", of say 30 years, I figure the North Slope holds another $80 Billion worth of oil

Just curious.

Bitumen from the Alberta oil sands is already being shipped from Northern Alberta to ports on the Gulf of Mexico by rail, and the volumes are rising fast because of the difference in oil prices.

The track is already in place to haul oil from Northern Alberta to anywhere in North America, all that is necessary is to build the tank cars and loading/unloading terminals at each end. CN Rail has lines extending from Canada's Northwest Territories to the Gulf of Mexico, and the Pacific and Atlantic Oceans, so it is keen on the concept.

From Alaska's perspective, what is missing is a rail link from Alaska RR's lines in Alaska, across the Yukon, to CN Rail's lines in Northern BC. This would cost a fortune to build (it crosses the biggest mountain ranges in North America), so somebody (e.g. the US government) would have to subsidize it....

Terrific piece.

I am trying the extrapolate from this report to the results once the NPR-A is producing (as Obama has agreed to do).

896 million barrels is the estimate after preliminary drilling. I assume that this is OOIP.

First production in 2017 or 2018 and full production by 2020 seem reasonable (to me, any better guesses ?). Hard to guess production rates (permeability, how many wells, etc.) but 125,000 - 200,000 peak b/day seems within reason.

I am not aware of the characteristics (API, wax content) of the NPR-A oil found in the test drilling.

I assume that the new oil pipeline will cross the coastal plain and connect with TAPS within 100 or so miles south of Prudhoe Bay. A new line through the Brooks Range seems uneconomic.

Even heavily insulated, the oil will cool by the point of injection into TAPS.

It seems likely that supplemental gas heating of the oil will be needed, either at Prudhoe Bay or where NPR-A oil is injected into TAPS.

"Later" ANWR oil will also be injected inot TAPS. At some point, before all of the North Slope oil, on and offshore, is recovered, TAPS will go the way of all carbon steel.

The replacement may be a new pipeline (likely smaller), a rail extension (likely combined with a new short pipeline) or an Arctic Ocean port with seasonal shipping.

Just thoughts about the future,

Alan

If they use a seasonal ocean port, wouldn't they have to find some way of keeping the oil warm until shipping season? Or would they let it freeze in tanks and reheat it?

Or shut down production for X months/year. X being smaller as it gets warmer.

Alan

Alan:

The 896 million is technically recoverable, I write about this in the next post in the series.

Cheers

Dave