BP's Deepwater Oil Spill - Hitting the Well Annulus - and Open Thread

Posted by Heading Out on July 8, 2010 - 10:31am

This thread is being closed. Please comment on http://www.theoildrum.com/node/6708.

Work on the relief well is going quite well, as I have been noting. The Wall Street Journal is now reporting that BP is hoping to stop the oil spill through a relief well by July 27, ahead of its public target of mid-August.

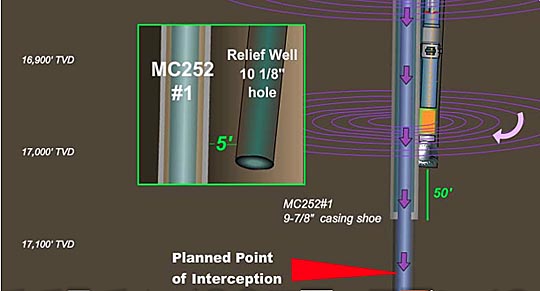

Trying to work out exactly where the relief well has reached, relative to set target depths is slightly complicated by the difference between measured depth of the well, and true vertical depth. To use just a portion of the final slide that Kent Wells used in his last technical briefing

If one uses this as a reference to the remarks made by Admiral Allen Wednesday, he notes that the well is within 200 ft of the initial intersection point, which is about 50 ft below the end of the lined section of the original well, which had been cased with a 9 7/8 inch liner. Below that level the well contains the production casing that was inserted into the well, but which was only cemented into place at the lower end. (The Admiral calls this the drill pipe – which is not the right term to use and which can be a bit confusing if you don’t look at the construction of the well). So let me just try and recreate a rough sketch of the area we are talking about.

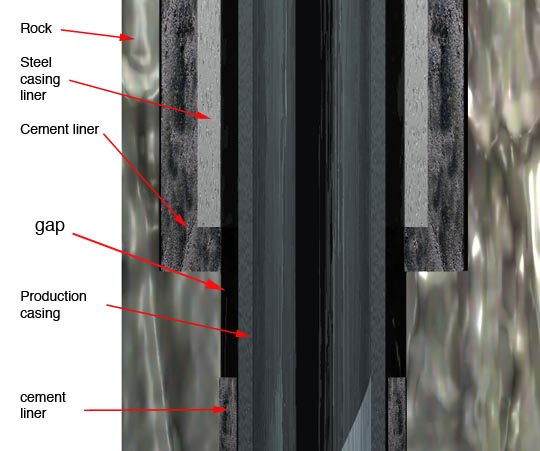

According to the Congressional testimony the bottom of the lined section of the original well ends at 17,168 ft, which is perhaps 100 ft below the level shown by Mr Wells. This is where the original well was lined with a steel casing, with concrete around and below it, as the original well was drilled. The gap between the steel of the casing and the rock is known as the annulus, and it is this that I show filled with cement in two places.

So if you look at the above sketch of a section through the hole at the end of the 9 7/8th inch segment, the lighter steel casing liner was installed first, then the cement was pushed down to the then bottom of the hole. The cement flowed out and back up the hole giving the sort of “L” shape that the top cement segment has in this section. The hole was thus lined with a cement and steel jacket, before the drill bit on the end of the drill pipe came down and drilled through the cement at the bottom of that section, and on down to the producing formation.

At this point BP could have continued a liner section for the bottom of the well, as they had just done for the segment of the well above, or they could install what is known as production casing. This latter is a long tube that will run from the bottom of the well up to the BOP. They chose to do the latter. Thus the production casing was lowered into place, and the casing section that I show runs the full length of the underground segment of the borehole.

However in installing that continuous tube, instead of filling the gap between the rock and the tube (the annulus) with cement all the way up to the cement above it, they only partially filled the gap, over the lower segment of the well. This left a gap of somewhat indeterminate length where there is no cement between the production casing (the Admiral’s drill pipe) and the rock wall.

With that situation in mind, let me return to the Admiral’s press conference Wednesday. In it, he said that the relief well is still around 15 ft from the original well and with about 200 ft to go to the point of intersection. At this point the well is being drilled in 10 – 15 ft lengths and then surveyed, so that the RW can hit the original well where intended.

The intention is

they'll go through a series of spaces, starting with what they call the annulus, and that's the area in the wellbore outside the casing, and then the casing is outside the well pipe.

They will check at each point on whether or not there is any hydrocarbons there and any pressure. And if there is none, they will attempt to actually apply mud to kill that portion of it. If they can go into the annulus and fill that with mud, and if that stops the problem, then they know the flow to the surface was to the annulus only. If that doesn't stop it and there's indications that there's product going up through the pipe, they will ultimately have to drill through the pipe and apply mud twice.

In other words, they will come into the well around the zone that I have shown with no cement in the annulus. If the well is flowing oil and gas into the space outside of the production casing, then it will be flowing up the outside until it reaches the bottom of the lined section of the well. The flow then moves into the gap between the production casing and the steel casing liner and works its way up to the BOP through that channel.

If that is the case, then the bottom of the production casing may be still sealed, and by just filling the channel from the point of intersection up to the BOP with mud, then the well might be killed.

On the other hand, if the bottom seal at the lower end of the production casing has failed (which might be why the initial negative pressure test showed flow) then oil and gas are flowing up the inside of the production casing, and filling the space outside the production casing with mud won’t stop the flow.

Thus the drill will then restart and drill through the production casing, to fill it, in turn with mud. Both operations will take time. As the Admiral noted

. . .if they have to pump mud up through the annulus and then go into the pipe and pump mud there, too, that's a period of seven, 10 days to accomplish both of those things. And if they have to be done in sequence because of the condition of the wellbore when they go in, it will probably take into August, . . .

And in the meantime, the seas are still not allowing the final connections to be made to the kill circuit on the BOP, to increase oil and gas collected, which in the last report was:

For the first 12 hours on July 7 (midnight to noon), approximately 8,330 barrels of oil were collected and approximately 3,925 barrels of oil and 28.8 million cubic feet of natural gas were flared.

• On July 6, total oil recovered was approx. 24,760 barrels:

• approx. 16,535 barrels of oil were collected,

• approx. 8,225 barrels of oil were flared,

• and approx. 57.5 million cubic feet of natural gas were flared.

Incidentally, it appears that the debate on changing the cap is still going on.

We are still reviewing the technical specifications that were provided to us by BP on not only that cap, but several other options. The procedures on how it would be done, the amount of time at which the well would be open for discharge of some amount of oil, and the weather window that it would take to do that, and that is all under review right now inside the administration, and I wouldn't want to attach a percentage right now.

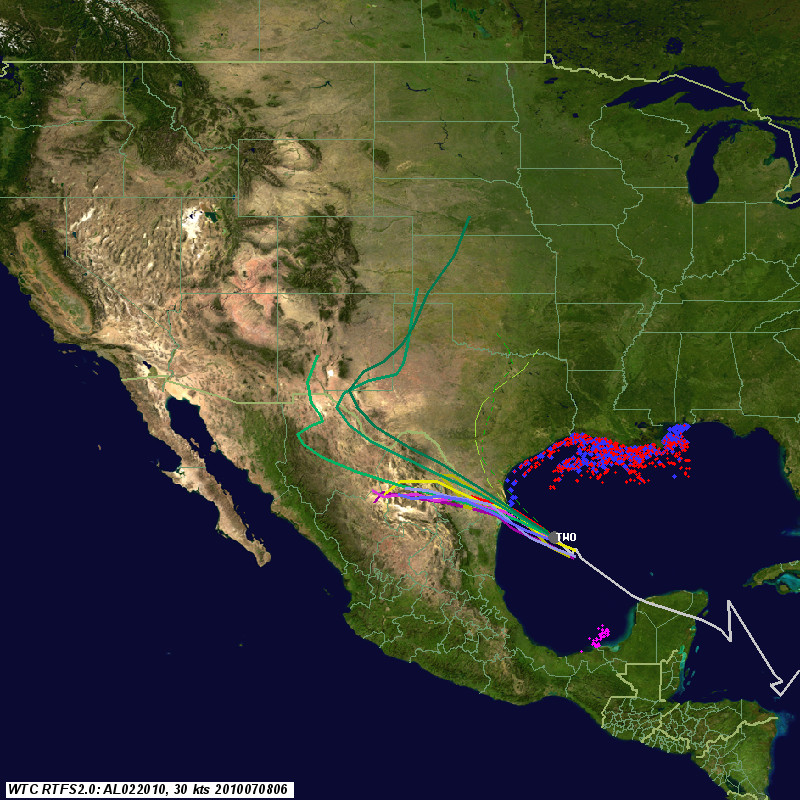

Chuck Watson has an update on the weather situation, and in particular Tropical Depression 2. He reports:

The National Hurricane Center started formally tracking Tropical Depression #2 last night. This morning it it doesn't look like much, although it might technically reach tropical storm strength before landfall. It is on track to follow in Alex's footsteps, making landfall in northern Mexico or far south Texas.

More importantly for the Gulf, this system is a continuation of the disturbed weather that is keeping wave heights above 3 feet over the entire cleanup and response area. While waves don't interfere with relief well drilling until they are much higher (once in place, most platforms can function in waves over 20 feet, and some platforms can operate in up to 30 ft waves), the smaller waves severely restrict skimming operations and put a lot of stress on protective booms, breaking them, over toping them, and setting up longshore currents that move the oil in to previously untouched areas. In addition, the hookup of the Helix Producer to the existing capture equipment continues to be delayed due to weather.

It looks to be at least this weekend before things calm down.

Prof. Goose's comment:

New stuff in this introductory comment, 1 JUL 10.

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we brought online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read all the other previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all the comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. If you would like to catch up with what's been going on in the last few days, our IRC channel has been maintaining a FAQ, which is an open source log full of information, links, and such. Check it out: http://docs.google.com/View?id=dff7zmqz_7c6rdwsc9

6. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

7. Don't be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

8. Yes, HO and others have put up many counterarguments to the "DougR" comment. There are many many links, but the first one was here: http://www.theoildrum.com/node/6609. If you ask in the thread nicely, they will also point you to others.

A video from NBC news with reporters onboard the Discover Enterprise is posted at http://www.deepwaterbp.com

Continuing the discussion of potential downhole oxidation from the previous thread:

No free fluorine or oxygen downhole - others covered that nicely.

Polymerization is not likely either - what is needed for that is unsaturated hydrocarbons, and there aren't a lot of them in most petroleum reservoirs. The usual saturated hydrocarbons can be made to polymerize, but not with the garden-variety acids that might be used in downhole fluids.

If there was an explosion downhole, and I'll agree with Rockman that we don't have all the information by a long shot, it was most likely from physical changes resulting from pressure release on a supercritical hydrocarbon mixture.

I have some doubts any of the mixtures of hydrocarbons in the well (or any clathrates outside the hole in the sea bottom, mentioned in various other threads) are technically "supercritical." Once pressure is reduced by fluid moving into the well and then the sea or up the recovery pipes, yes, methane gas expands and various light compounds such as pentane become gases but I don't see any part of that as being poised to change phase yet unable to do so, as would be required for something to be technically called "supercritical."

Jumper - the mixture would have been supercritical before the pressure was removed, and the pressure removal would have allowed a very rapid, explosive in fact, transition to a gas phase. "Supercritical" means that the mixture is above its critical point, the point where the dividing line between liquid and gas ends on a phase diagram. Supercritical fluids have the transport properties of gases and the solvating power of liquids. But they change phases just like anything else when the conditions allow that.

I believe it's 30 degree API oil? The Gas/Oil ratio is 2300. Temperature should be less that 250 degrees F. I believe if this mix is taken to a PVT cell, it'll be shown not to be supercritical - it's a volatile oil phase. Did anybody see PVT reports or simulation results? I guess I can do one if somebody gives me the data.

I make it closer to 300 F. at TD but that's back-of-envelope stuff.

How do you get 300 F? I assume the temperature at the sea floor is 40 degrees F max. Then I took a normal geo-thermal gradient for the Gulf Coast, and I don't get to 300 degrees. Do they see really high geothermal gradients in that area? I haven't worked in really deep water, only reviewed work others did, and I didn't pay too close attention to the gradient asumptions.

Ah, my misunderstanding of the term. I assume this is correct:

http://en.wikipedia.org/wiki/Critical_point_%28chemistry%29

For others reading this, we are talking about only the light portions normally called "gas" at standard temps and pressures, certainly different from extreme downhole circumstances.

(edit: my poor old brain was thinking "supersaturated."

The wikipedia article is fine. The oil/gas mixture is a multicomponent system, so it's standard practice to use visual cell observation to define the critical point. Although today the pressure/volume/temperature simulation software is very sophisticated, we are missing the lab data to be 100 % on, this is even more so when there are super-heavy asphaltine molecules involved, and I believe this oil must have say 3 to 7 % asphaltines (just a guess based on experience).

So if you take this mixture at reservoir conditions, I believe you'll see a single phase, liquid with a volume factor around 2. I am saying this because I've worked with High pressure high temperature systems, and this is what we saw. As you drop the pressure, gas bubbles evolve, the gas will be very rich (loaded with C2-C7). But it is a volatile system. A supercritical system would not show a liquid phase, just a cloud that's neither liquid nor gas.

And of course there is no supersaturation as far as I know, because the system viscosity is so low. Supersaturation effects are seen in very viscous mixtures, where the gas microbubbles evolve but don't link up because the surrounding liquid is so viscous. At least this is what we see in crudes, I'm not sure about other types of fluids.

fdoleza,

I have a science question. I'm probably not using the correct terminology, so please be patient. The fluid in the pay/producing region is a mix of all molecule sizes from methane to what you term super-heavy asphaltine. You speculate that there might be several percent of the asphaltine in the original mix.

What is known about the physical properties of these asphaltines? Can they be dense enough to sink in seawater? You are aware of people writing about the 'oil hiding under the surface'. Could this be the result of a differential separation of the different molecular fractions leaving droplets of oil that have lost enough light molecules to become neutrally buoyant in seawater?

Geek7, I'm more of a generalist, and I have to be careful not to reveal confidential information, but here it goes:

According to what I read, quite a few reservoirs around the world, and some in the Gulf of Mexico, have asphaltic crude. This means they have a small percentage of very high molecular weight hydrocarbons in the overall mix. To make it even more vexing the crudes can be found at very high temperature and pressure, and contain a high gas ratio.

This is where it gets interesting, the crude is fairly light, but it has these super heavy molecules in it. These molecules are so heavy they do not readily dissolve, so you may think of them as tiny cannonballs floating in the crude. The key to flotation is slightly lighter molecules called resins (This is where the term SARA Analysis comes from, Saturates-Aromatics-Resins-Asphaltines). The resins hold the asphalt via polar bonds, and all of them live happy together until a hairless ape tries to remove it, and drops the pressure. IF the fluids are UNDERSATURATED, then the pressure comes down and the gas doesn't evolve just yet (eventually it does). As the pressure drops, the system density DECREASES, this means the stuff that floats in the oil tends to fall - and this is why pressure drop is a hassle in an HPHT asphaltic crude - until the bubble point is reached, at which time the liquid density begins to go up again.

What I did was put on my 3D glasses I use to look at kid's movies, and I derived by anal extraction that a 30 degree crude with this type of GOR should have about say 5 to 10 % asphaltines. That's only a guess, so please don't hold me to it.

The asphaltines are indeed heavier than water, but they are attached to the resins. So it's not a simple story. What happens, I am guessing again, is that oil comes out, the dispersants make it break up, some of the light ends dissolve in the water or evolve as bubbles towards the surface, bacteria start eating the mid range hydrocarbons (they love C5-C6-C7), and this eventually leaves a mix of asphaltine, resin, and a bit of the lighter stuff. The mixture sinks in the water column, or never rises to the top anyway, and finds a water level (a thermocline?) where it floats and doesn't move much. The bacteria don't like to eat the heavier stuff, so they stop gobbling, and you end up with a "tarball". If this tarball also gets a bit of solid material (say dead plankton), then it's quite an exotic mix.

Now, if I were the Coast Guard I would be analysing the tarballs and checking their weathering, because I bet there's going to be tarballs from other sources (the usual suspects are tankers, seeps, and bad guys dumping oil by accident). And I got the feeling there will be wise guys picking up tar and dropping it on the beach at X and Y location to make claims and sue BP later. It sounds like a pretty good scam.

When it comes to the plumes, I've read they are less than 0.5 ppm. Not being a shrimp, I don't see much of a problem with that. But I do see a problem with the way they have been described by the media. I hate Fox, so I usually watch CNN, but they have been really terrible covering the story. The key to the right coverage is to discuss figures, and point out what could happen. They never did reveal the plume content was lower than 0.5 ppm - or show a water sample, because that water is crystal clear.

They SHOULD have asked somebody to take 0.5 ppm water, put shrimp in it, and see what happens to the shrimp. Although I don't know of anything useful that lives several thousand feet below the surface. The problem for the shrimp would be right on top, and that is really a concern. BP may have to buy off the shrimping industry for a few years, and we may have import shrimp to make up the losses. Which means there may be a good investement opportunity building shrimp ponds in Panama?

fd,

Bang on. I've never understood the comments around supercriticality of these fluids.

The parameters I've seen suggest a normal volatile oil as you say. Reservoir temperature (variously quoted as 210F or 263F in available documentation) will be well to the left of the mixture critical point, and temperature and pressure will drop substantially as the fluids ascend the wellbore.

There's a lot that we don't know about what led to the blowout. But it wasn't a reaction with oxygen or fluorine. That means that if there was an explosion, (note conditional) it must have had a physical cause. Could have been the pressure, could have been more than that. Depends on how much of an explosion it was.

You are right, much is unclear!

But I think we need to distinguish 2 different 'explosions' here.

The first is the violent ejection of the contents of the wellbore / riser, and I'd venture to say the mechanism is relatively well understood. Any free gas in the wellbore rises due to density differences. The ambient pressure is less and less as it rises and it expands. The process runs away as overlying fluids are expelled from the riser, the hydrostatic head decreases further, the gas expands even more rapidly. The evacuation of the sea water from the riser will have been VERY energetic, but I think there is no need to postulate unusual fluid properties to explain it.

The second is of course the ignition of the natural gas and rapidly following oil stream on the drill floor.

you are wasting your time, they either won't understand wtf you are talking about or wont believe you. .......i'm just sayin.

ik ya t'dts hap ?

ai ay tits d'hap !

I believe BP said that in an ideal world they could kill the well by the 20th-27th; "if everything went superbly". Still they expect that realistically it will be in August.

HO: Thanks for rough sketch! Its much better than anything I ever did on the back of an envelope or napkin. And, the light bulb finally went on in my mind. Thanks for helping me understand.

Where is the drill pipe that was left in the well?

If I recall correctly, the drill pipe in the wild well, the leaking well, extended down about 3000 ft, so it will not be present at the bottom, and not shown in the illustration.

is either:

*hanging in the BOP

*fall down at the bottom

*a part is hanging and a part is at the bottom

EDITED to say it has anyhow not so much of an importance for the RW bottom kill procedures

Thanks, that is what I was wondering. Would it be a problem if it was at the bottom.

drill pipe or any other pipe dropped in a well has the potential to collapse the casing at the point where the dropped pipe hits a liquid level.

Thanks HO for explaining that so even a 10yr old can understand.

Nice diagram, HO!

However, I don't see how oil can be flowing up the annulus. The "gap of somewhat indeterminate length where there is no cement between the production casing [...] and the rock wall" that you refer to is still several hundred feet above the oil reservoir, so isn't it unlikely that enough oil is going to be able to escape via this route to account for the vast quantities of oil we're seeing gushing out at the top? As long as there is an intact cement plug between the production casing and the rock wall at the point where it enters the reservoir, surely the prediction must be that the oil is flowing up the production casing?

Also, I'm wondering why they need a week to drill through into the production casing after having penetrated the annulus.

what you see there is the ideal situation, the well in this picture will be probably tight

in the WW the cement at the bottom of the smaller casing is not sealing (poor cement job)

the suface to flow from the annulus is not so small, without cement you will have like 38sq in (7 in casing 97/8 hole diam) (maybe even more due to the hol diam) true that a part will still be ocupied by the cement but think at the erosional forces and then you might accept that is not too much cement left there

Yes, but "intact cement" is the question. In previous threads, there have been comments from oil field professionals about how difficult it is to be sure of the cement job at the bottom of a well. And in particular, there have been questions about the cement job on this well. Whether the cement is properly in place, and doing what it's supposed to do, won't be known until the relief well provides some info.

There was cement ejected from the wellbore to the extent that there were pieces recovered on the deck of the supply vessel Damon Bankston that was being offloaded to. The size of these pieces have not been described however it is listed on the Transocean internal investigation that tests needs to be performed.

I think that there is only one place where one can conclude that cement came from and it would indicate failure at the bottom of the 7 inch production casing. In all likelihood the cement in that interval- if there is any left above the reservoir is mostly "rubble".

I agree that this is the clearest diagram and explanation of the situation that I have seen. Well done, HO!

It also makes it clear in my mind what a risky well design it was. Anytime you drill through a cap rock seal, you damage it. There will always be some degree of washout around the well bore through which fluids can flow after casing is set. BP put a lot of faith in the ability of the bottom cement plug to prevent fluids from rising not only within the casing, but around the outside of it as well. Unfortunately, it was a blind faith. As I understand it, the pressure tests that were run only test the integrity of the seal inside casing, not the seal around the outside of casing.

I now understand why the CEOs of all the other major Gulf operators testified to Congress that they would not have used this well design -- it's just too risky. A fully cemented liner should be required for all overpressured wells, IMHO.

What do you think?

I would run a fully cemented liner, with the number of centralizers required as per industry practice. The cement would be circulated to get returns to the top of the liner, which would have a significant overlap to make sure there's lots of cement for the formation fluids to break through should they try to do so.

If the cement column is too heavy, which depends on the frac gradient, then light weight cement should be used.

Once the cement is in place, a cement bond log should be run. If I had been in charge I would have asked for a third party verification on cement quality. I would have done the pressure testing to test the liner top with a packer and pipe set just above the liner top, not 3000 feet like they used. I would have put a stinger below the packer all the way down to total depth. If the test showed iffy data, I would have circulated with clear brine, as heavy as needed, bottoms up. Then pressure tested again, because brine tests better than mud. If the results were negative, then I would have pulled out, and gone in to squeeze the liner top. And I would have never circulate the well with light weight fluids unless it's to do a negative test, and for a negative pressure test I would make sure I have pipe to the liner top, with a packer set.

I guess the rig cost pushed the BP managers to do some very interesting and sophisticated things I would not do. For the record, I own BP and Halliburton stock I failed to sell because I thought the well was only making 5000 BOPD.

Mike -- I don't have a strong opinion as to whether all the flow is going down the annulus and then up the csg or just up the annulus. But in either case the oil has to move thru the annulus from the reservoir to reach the surface. So the flow volume potential is the same up the annulus as it is down...same cross sectional area. Exactly where the cmt is still intact isn't clear to me. Just my guess but I think most is going down the annulus to the bottom of the production csg and then up. But it could be flowing 100% up the annulus and it would look the same coming out of the BOP IMHO. The big question is whether the annulus between the production csg and the other liners is open to the BOP. I haven't seen any definitive info on that possibility. Also I don't think they've commited to breaching the production csg until they determine the conditions in the annulus. I won't be surprised if the stop driling for a day or two after they cut the annulus so they can evalaute what's going on.

Rockman, I doubt the formation fluids are u-tubing through the liner shoe. The liner is run with a collar to take the cement bump plug, so unless they forgot to use a plug, there's solid cement between the collar and the end of the liner (It's not a good idea to set the collar right on bottom, they should have a little bit of pipe just below). The likely flow path is up the annulus.

Evidently they had a channel, and as the well blew it eroded a path. I've seen videos showing how a wormhole erodes (using a sand box placed inside an MRI machine), and it's a real eye opener. Can't discuss the exact details because the data is confidential, but I think it's safe to say a channel will erode, and at the rates we're discussing, the channel will erode to exactly the size it has to be, in this case it should be a flow path on one side of the liner, wide enough to flow 50,000 BOPD/140 MMCFD at downhole conditions, and that's a pretty big wormhole. It's like a gazelle's speed, the gazelle evolves to run just as fast as it has to.

Unless BP was using cardboard, the liner should be OK, because the pressure OUTSIDE should be a bit lower than the pressure inside (due to the dynamic pressure loss), but not enough to make the liner burst.

I'm assuming the fluids are coming out of the liner top into the casing and then flowing up.

But I haven't read all the threads and blogs they post here, sometimes I get very busy and don't have the time to keep up. So maybe I'm missing something.

I also saw a video showing cracks on the sea floor, which tell me it's possible somehow the BP enginers managed to set uncemented pipe up hole, which got parted and dislodged from the casing hanger and shoved up into the BOP. So they lost seal up hole as well? Or i didn't interpret the video properly. This is really weird, just a theory to explain why the blind rams didn't work. And I sure wish the Kent Wells briefings weren't so simple. They must have lawyers looking over everything to make sure it's sanitized.

Fd - I am pretty much in agreement with you, but I think it would be a little more clear if you would use the term production string instead of liner, since they in fact ran a long string from top to bottom rather that just a liner covering just the open hole. I know the terms are sometimes used interchangable, but earlier posts on TOD have explained the the differance, and for those without field experance here the term liner might be confusing in this context.

I take it you believe they ran a 7 inch casing all the way from TD to wellhead? But that wouldn't make sense for a well like this. If they ran it with a single cementing stage, then this is really odd. Do we have a drawing showing a 7 inch CASING run from TD to the wellhead?

there is no engg case for running this mechanical setup other than the increase the longevity of the well....so really a financial case can be made for this string ...

this size string was used commonly in timbalier bay (plenty of wells in vermillion blocks have the same) and other shallow areas back in the days where some operators would run dual (i've seen triple string completions every now and then) .....even now small operators like maritech (part of tetra) are still flogging dead reservoirs by running co-mingling permits

how this makes its way into a DW exploratory well is weird and frankly knowing what do now about such mech setups a little wrong

fd -- They actually ran a tappered string with 7" on the bottom and 9 5/8" (?) on top. I don't have the profile handy but I bet someone will toss it out in a moment.

Here you go rockman:

http://www.energy.gov/open/documents/3.1_Item_2_Macondo_Well_07_Jun_1900...

Thanks FE...saved that booger this time.

It was a tapered string of 7 and 9 5/8 . I don't know if that is odd or not, but I believe that not runnin a liner contributed to the problem. I am no expert on pressure testing and casing hangers, but I don't see how you can test the back side (annulus) of the cement job with a long string.

Also they did not use a lock down ring on the casing hanger for some unknown reason,

Fd - One other point I would like you to comment on is the fact that they only circulated enough including the cement job to get bottoms up to the wellhead not counting loss of 18 bbls during the process at some point after running casing. In other words 18 bbls short of bottoms up.

I thought the 7 inch was a liner, because 7 inch is too small for a well expected to make more than 10,000 BOPD (4 1/2 inch to 5 1/2 inch tubing is what I would run in a well like this). But to run the 7 inch by 9 5/8 inch tapered string without a two stage job sure sounds a little risky. It's better to run the two stage job, and then monitor the 9 5/8 inch by outer casing annulus with a permanent readout just in case.

I have had a lot of discussion about this problem, because an annulus pressure problem in an HPHT well, when a lot of casing is left uncemented can collapse it downhole, and that can be a real problem.

I suspect their outer casing must have been something big, say a 16 inch casing. So, they had hydrocarbons leak up to the top in the 9 5/8 inch by 16 inch (?) annulus, these put downward pressure on the uncemented casing, and upwards pressure on the casing hanger. If the tensile load split the casing, and the hanger wasn't locked down, it pushed casing up into the BOP, and the shear rams couldn't cut through it. At that point they had flow up the annulus at the wellhead, and they had a column of lighter fluid in the riser, which the hydrocarbons blew right out of the well.

So where does the cement come from? The hydrocarbons start flowing up the channel in the 7 inch by 9 5/8 inch tapered string, and as they flow they erode the heck out of the flow path - they bring up sand, cement, whatever gets in the way, and this makes it way to the surface.

So if they are lucky BP has a parted production casing shoved up, and an eroded annulus flowing 50,000 BOPD. This means the relief well has to tap the flow wormhole in the annulus between the casing and the formation wall.

Once the relief well has tapped in, I would pump mud to start increasing column weight and slow the well flow gradually, but I would also hook up a boat to the kill line and be ready to pump down, because it may be a lot easier to rock it with the final kill coming down rather than going up, this would allow them to use the relief well as a safety valve to avoid parting the formation. Once they put a cement plug down the original well, as I mentioned yesterday, I would pump enough water in (say 5 million barrels) to flood out the reservoir area around the well. I may even consider pumping in a lot of resin to plug the reservoir up, then plug the relief well half way, drop a staintless steel flask with holy water, and then pump more cement on top. That should keep the devil down there.

I get the holy water part, but not this part:

I'll see if I can find your quote from yesterday...

do a web search on "oil-halliburton-cement-052010jpg" It's a diagram of the well.

There is a production liner that starts at 9 7/8 at the top, then steps down to 7" down hole.

Here's an early diagram from nola.com .. the final full well depth liner/casing tapers from 9 7/8" to 7" ...

http://media.nola.com/2010_gulf_oil_spill/photo/oil-halliburton-cement-0...

and another well schematic

http://1.bp.blogspot.com/_udSTgadqhFc/S-uAQp9p7jI/AAAAAAAABbg/hQCGgca2Se...

from the earlier TOD post on the Congressional testimony on the well design.

http://www.theoildrum.com/node/6462

FD:

I for one, appreciate your comments and welcome you to the discussion.

Guys- for accuracy purposes it was 9 7/8 x 7 not 9 5/8

I know - odd size.

hey..it was between 9" and 10"..right? Close enough for a geologist.

unless the 7" is collapsed or parted. i ran across a wellfile a few days ago where there was a "gap" in the casing. how the he11 does a gap get in the casing ? maybe a joint came unscrewed ?

clearly something went wrong.

True elwood. I've confirmed gaps a couple of times. I seem to recall they aprted at the collars both times.

The Times-Pic on moratorium developments:

Today in a 5th Circuit hearing, Interior will argue that the 5th should lift Judge Feldman's stay and reinstate the original moratorium. But a more interesting story explains that some folks call this a "red herring" since Interior's already-promulgated new rules impose a de facto moratorium anyhow. Highlighting my favorite of them:

Elsewhere, the paper reports that locals such as the St. Tammany Parish president blame dispersants for the tar-ball invasion of Pontchartrain.

this is a defacto moratorium for sure. It amazes me how the federal government finds such creative ways to thwart oil production, and then thwarts cleanup initiatives at the state level.

creative ways to thwart oil production

captbob, do you believe that's the gummint's goal? Why? What would be in it for them? Seems to me it's a (large) knock-on effect of their need to clean up the mess MMS left and do what they can to ensure we don't see DWH II anytime soon.

Are you in the "we don't need no steenkin' rules" camp?

Of course rules are required- and there are lots of good rules. This has created the need to review and tweak the rules, but not to create such an onerous regulatory environment whereas it become next to impossible to profitably drill offshore in the USA, which I think is indeed the (misplaced) agenda of this administration.

create such an onerous regulatory environment whereas it become next to impossible to profitably drill offshore in the USA, which I think is indeed the (misplaced) agenda of this administration

So . . . Obama was just funnin' us at the end of March when he announced the expansion of offshore drilling? I mean, I know he has a good sense of humor, but that sure didn't sound like "I kid" fodder to me.

you mean this reversal of his campaign pledge?

"The plan, which needs congressional approval to be implemented, would permit drilling off the coast of Virginia, as well as end a moratorium on drilling 125 miles from Florida's west coast."

Do you think this administration is friendly to the development of oil production in the US?

Do you think this administration is friendly to the development of oil production in the US?

Yes, my understanding is that they believe domestic production will be a necessary tider-over until the era of renewables sets in in earnest.

Which campaign promise do you believe that breaks?

If they actually mean to shut-in production then they are REALLY stupid as GOM oil production is 25-30% of TOTAL USA oil production. You CANNOT make that up from on-shore sources. I'm sure domestic wells could produce some amount more for a short period, say 5% for 3 months and unless they open the Strategic Petroleum Reserves (as GWB did) there is NO WAY we can keep overall production where it is today.

If mean new wells there will be some impact, but it's hard to say how much right now. The big impact could be that the drilling rigs will leave and it can be years before they can get back as they will be deployed elsewhere under long-term contracts. So effectively this could shut down GOM drilling for several years and net new production to make up for depletion wouldn't occur meaning the downslope of the peak oil curve hits sooner.

Renewables are a laugh, that's just more money being thrown at a technology that 1) needs time to mature, labs don't produce break out tech overnight even with more money 2) many people have studied this issue and renewables won't fill the gap for about 30 yrs. You can't just stick out more windfarms and if you grow more Corn/Soy/etc. for biodiesel & ehtanol as that's land taken out of food production increasing food prices AND gas prices. Double-dip here we come!! I'm wondering if the whole Administration is either idiots or want's us to suffer badly so they can step in and solve it with MORE Government. Probably some of both.

The problem I see with past MMS regs and enforcement, which will only be worse in the next itereation, is that they focus on paper accountability and expect that if the forms are right then all will be well with the world, that nothing will occur which was not thought of in advance and included in the forms. Judgement is not involved. Two things happen, neither is good: 1) Industry has no respect for the regulators and just goes through the motions, and 2) Industry becomes contaminated by the same view of the world as a perfectly predictable place with no room for judgement - and thus tolerant of lack of judgement.

Glen -- Sadly much of my 35 years in the oil patch supports your statement. I don't know if the tolerance for lack of judgement is pervasive but it certainly does exist to some degree IMHO.

Lack of respect for regulators? Here a very common joke offshore: "Let's see...it's Friday so we may be having our unannounced MMS inspector showing up today." Friday is typically seafood day on the rigs. And also the most common day of the week for surprise inspections, which, coincidently, often happen around lunch time.

That is one of the most thoughtful and well articulated statements about government regulation I've ever read. If "industry" had a better reputation for honesty, it wouldn't be quite so laughable to suggest that the best approach to regulation is a collaboratively developed set of guidelines, iteratively reviewed.

This is far afield, but not too. Here in RI, we had a terrible fire at a "night club" called the Station, killing 100 people. It was, like our topic here, an engineering clusterf@*# of epic proportions.

In response, the state legislature passed knee-jerk, strictest-in-the-nation fire codes. They've been an unmitigated disaster for development and will likely get reviewed next year. With luck, the review process will be inclusive - as the original legislation was _not_ - and generate a collaboration between safety, city planning, developers, etc.

But, ah, I am ever the optimist. Perhaps I should think about Mel Brook's line as the Governor in Blazing Saddles when he learns of the sacking of Rock Ridge and killing of the sheriff:

What are drilling safety rules like in the North Sea? Are these new rules stricter than those enforced by Norway and by the UK?

den - I was hoping someone with more specifics would answer you. But you're stuck with me. I've heard for years the N Sea regs were tougher...especially Norway. But I don't have any details to offer.

I was thinking about the North Sea today reading about 6' seas docking clean-up boats.

If there was an event like this in the NS, would there every be a day calm enough for skimming?

I lived on the beachfront of the NS and seldom ever remember seeing a calm day.

I think you're being a bit harsh! I've been out on the North Sea when it's been as smooth as glass for weeks on end. Admittedly I've also been out there in 8 meter (25') seas :)

Sometimes, high seas can work to your advantage in unexpected ways. See the following article on the Braer disaster from the amusingly named Shetlopedia.

http://shetlopedia.com/The_Braer_Disaster_%28Oil_Spill%29

When the oil tanker Braer foundered on Shetland in the winter of 1993, storms pretty much stopped dispersal attempts and a major disaster was expected. The storms however did a better job of dispersing the oil than we humans, and things turned out a lot better than they might have done.

Here's a picture of a workboat supplying a rig in a "smooth-as-glass" day in the North Sea.

http://privat.bluezone.no/bloody.peasant/144699-rigwave.jpg

lotus, I might ask if you are in the camp of putting incompetent people in charge of an offshore rig? How many ways can this incident be dissected? Is there anyone out there that believes human error was not the prime cause of this tragedy? Even Rockman, in his most foul mood after learning of the Blue Bell factory shut down, and on withdrawal for an extended time, will attest that this tragedy was easily preventable with existing regulations.

I might ask if you are in the camp of putting incompetent people in charge of an offshore rig

Heh-lo, EDM, where did that come from?

Sure looks like cascades of human error to me -- which the regulatory system we had not only countenanced but participated in. They've all got to do some serious socks-pulling-up to do, Interior as much as the drillers.

The CEO Certification, in my opinion, would be a show stopper if I were in that position. A CEO can not control every aspect of the process of offshore drilling involving hundreds of people. The CEO can certify that those people have attended training sessions, the equipment meets specs or industry standards, equipment is routinely tested according to some schedule, wellbores are constructed to industry standards etc but not that no problem will ever occur, which is what the regulators are looking for.

If these certifications are so great, how about the President certify we will win in Afghanistan, that we will find Osama, that he has no marxists in his administration, that none of his appointees are crooks, that his appointees have read laws before objecting to them etc.That's how ridiculous the certification is.

I would spool up my operations and move them to another country where the risk-rewards are more favorable.

how about the President certify ... that he has no marxists in his administration

Now, EDM, I love antiques, but that one passed its sell-by date nigh onto 60 years ago.

I haven't clicked through to read the directive yet, but how, exactly, is "certifying all safety equipment works properly and all well designs are safe" any tougher than promising that "the equipment meets specs or industry standards, equipment is routinely tested according to some schedule, wellbores are constructed to industry standards[,] etc."? Seems to me this rule stops the buck where it belongs.

"but how, exactly, is "certifying all safety equipment works properly and all well designs are safe" any tougher than promising that "the equipment meets specs or industry standards, equipment is routinely tested according to some schedule, wellbores are constructed to industry standards[,] etc."? Seems to me this rule stops the buck where it belongs."

any equipment with moving parts can and do fail. Sometimes they fail on test, but not always. If your standard is "never fail" then no oilfield equipment can be certified to accomplish that. Shut down the industry forever is the only solution for that requirement. What does "all well designs are safe" mean? This was an exploratory well. No one knows what will be encountered in an exploratory well for certain. If a well is designed for every and all contingencies, it will not be economically viable or, in many cases, even drillable. I can assure you of that. There would not be enough casing sizes made to guarantee a well I have to certify, under penalty of jail, is safe per your definition.

By the way, do you even know what a CEO does every day? Do you think he/she studies a drilling report every day and several times a day for every will drilling in the Gulf, and injects himself/herself in every decision?

In fire protection devices you have a listing service such as UL or FM factory mutual that tests and lists things like sprinklers and fire suppression panels. Does the oil industry do the same thing? In other words perhaps the BOP is already "listed". Does the oil industry have codes like the NFPA codes which the company can say "look I did it according to such and such code"?

How many oil field engineers are professional engineers. A PE as I understand it is a very broad test that the state makes them take. Does that mean that a PE may not know anything about oil wells?

"Does that mean that a PE may not know anything about oil wells?"

Yes!

It does not seem that this argument is reality based. Codes like the NFPA codes and government regulations do not require that nothing ever goes wrong. Codes specify, generally, the minimum standards. If I built a house to the codes it would be a piece of $hit. It might be nominally safe, but I wouldn't want to live in a house built to minimum standards, would you? I have to install woodstoves using the fire and building codes as a minimum guideline, so that if the operator does everything wrong then there is still a pretty good chance that the house will not burn down. My butt is on the line on every installation.

I am assuming that industry standards and government regulations for hydrocarbon drilling are just like that. If everything is done just to meet code which is a minimum standard then any corner cutting is asking for trouble and crosses over the line from "human error" (an almost useless phrase) into negligence. I'd rather have Rockman drilling a well up to his much-stricter-than-minimum standards, than XYZ company drilling to regs with lots of contrary pressures and incentives to corner shave. If we as citizens don't demand something better than minimum standards both in the industry and in the regulating agency then we are just throwing the dice all over again.

Obama is so wedded to BAU I think you can rest easy about him wanting to get as much hydrocarbon as is reasonable wherever it is found within the tolerance of the electorate... which may mean that ANWR is out, but not necessarily. We will have to defend Mother with our voices and not depend on him or any other POTUS.

PE's are tested per discipline in engineering, my father was an Mechanical, Electrical, Civil PE (actually had a 4th but I forgot discipline) which means he passed the test for each of those and had 7 years experience in the field. However he would on not known anything about well drilling, at least not to the point of signing off on them but that was not his area of work. I lot of the engineers in the engineering industry are not PE's, but graduate engineers, but the lead discipline engineer (a PE)on their project is responsible for reviewing and signing off on their drawings. Multiple PE's held is considered a little unusual.

Right now, I only need one hand to count the number of PEs I know working as well engineers. It has not been a requirement until recently. NTL 2010-N05 (released a month ago today) made a PE certification required for all casing and cementing programs in the Gulf. I was planning on getting mine anyway once I got the required experience, just to have it, but this has cemented the decision.

The API (American Petroleum Institute) creates most of the technical industry-specific standards for the industry. Other standards organizations such as ISO, ASME, ASTM, etc, are used where applicable as well.

Most PE's I've ran across in my career have zero knowledge of the Oil Business. And a PE isn't easy to get either so increased demand on a small set of resources means higher salary. Wouldn't it be better to develop for API to stand up a program to get something like an API certification in Cementing or such? PE's the deal in things like Cement would likely be in the Structural or Civil Engineering areas. Sounds like another stupid Gov't reg that no company can really meet.

PE stands for Punning Engineer?

When I took and passed my PE exam back in 1988, the questions were limited to civil engineering fields only; surveying, hydraulics, traffic, waste management, etc. I suspect if I had been testing for a PE in ME or ChemE the questions would have been appropriate to those fields. Oil well drilling would fall under what field of engineering, I wonder? It requires knowledge from a lot of disciplines; geology, mechanical, chemical, civil and electrical.

There is a Petroleum Engineering test. Then you'd be a PE PE.

Bendal says:

For information about the current fields covered by the exams, see

http://www.ppi2pass.com/ppi/PPIInfo_pg_myppi-faqs-oth.html

and for information about the petroleum engineering exam, see http://www.ncees.org/Documents/Public/Pet%20Oct%202007.pdf

The latter link contains a list of topics that looks pretty exhaustive.

Speaking of links, there is a good gulf oil spill web page at the American Petroleum Institute's website at http://www.api.org/Newsroom/safetyresponse/index.cfm

Nothing is really "safe". Nuclear plants can fail, airplanes can crash, and you can get killed laying in your bed from a meteorite.

It is just some things are safer than others.

What they need is a quantitative measure of the safety requirements . . . e.g., the frequency of a spill of over 1 million barrels of oil < 1.0 E-6 per year per well (or better yet, a log-log curve of frequency of spills versus size of spill). Once that is done, safety engineers can use probabilistic risk assessments to assess risks of drilling, optomize the design, and demonstrate the goals have been met. See the writeup at http://en.wikipedia.org/wiki/Probabilistic_risk_assessment for a discussion of this methodology which has been applied in the nuclear and airline industry.

Once we know "how safe is safe enough", one can figure out what is needed in the way of redundancy of BOPs, BOP rams, controls, training, and the like to resume drilling.

The business of "how safe is safe enough" really isn't a technical question . . . it is a political question. One must weigh the risks of drilling with the consequences of spills and the benefits of domestic oil production.

Unfortunately, our political leaders are hopelessly inadequate to even begin to address this.

James, you hit the nail on the head. Thanks.

I'm no engineer, but I think the term used in the profession is "factor of safety".

Now I'm curious. What exactly is it that a CEO does all day? Look at quarterly reports and play with himself? If the person in charge cannot get control over all of a company's tentacles, does that not demonstrate that the company has become "too big to succeed" and that, say, changing a culture of negligence and corner-cutting is close to impossible? The detachment of management from the day-to-day concerns of operating a business may be necessary to an extent, but we've all seen what can happen when this idea is taken too far and management simply fails to pay attention to concerns raised by engineers and safety personnel, caring only for the financial figures. The next step after that is a failure to properly account for small but nonzero risks of catastrophic failures...

The solution is competent line managers. There is a huge difference in line managers from company to company. I doubt seriously that a CEO from the largest oil company in the USA reads a daily drilling report.

For high investment or high risk/high payoff wells I would bet he does, at least a summary and the costs but he can get more if needed. If he has $100M+ on the line for a well and has made promises to investors of discovering a big new find he better know what is going on in general.

Having competent line managers who will tell the truth and who understand they CAN and MUST tell the truth is also important.

I worked in an office very close to a "CEO". The day is a mixture of meetings and reading time (I'd say 60 % meetings, 20 % reading, 20 % individual discussions with people or using the phone). If the guy knows how run things, he has staff or departments write briefing memos, usually one to three pages. Issues regarding engineering design practice and procedures are handled by a "Chief Engineer" or its equivalent. A large company has one high level type Chief Engineer who is more of a figure-head, and Chief Engineers for the different specialties, plus Chief Engineers on location (say a Chief Engineer for a major project, or for a subsidiary in Indonesia). The CEO doesn't get involved with the work the Chief Engineers do - but he has to make sure there are documents which describe what a Chief Engineer has to have under his belt to become a Chief Engineer, and what testing or certificates the guy has to have. This means on a periodic basis he has to meet with his "Chief Chief Engineer" and review the current org chart, and make sure the Chief Engineers are suited for their positions.

My guess is this where BP failed, Tony Hayward is a geologist, and from what I gather he has been somewhat of a high flier who didn't really have to worry about nuts and bolts - evolved to be more of a wheeler dealer and likes to go to Davos, meet with Putin, and talk to bankers. So the emphasis within BP was to focus on the money side, and the international relations side, and less on the engineering. This was discussed by a panel created after they had an explosion at Texas City, when they killed something like 15 people. Thus BP, if it survives, needs to change its emphasis, what one may call a serious culture change. It is likely to make less profits and be less glamorous, but it should get better results if they do worry about engineering things properly, and their managers are picked with the right pedigrees. Can't have poodles trying to serve as watchdogs, that's for sure.

I think that points to the reason why Schlumberger, (in my mind, at least), has the reputation it does. They do what they do, and do it well. (those more familiar, correct me if I'm wrong.)

Beyond Petroleum was, (again, in my opinion), a lap dog for political agendas, while doin' what they do: produce oil, at profit, for their share holders. The high flying political shenanigans, (green tech, carbon trading), is probably a big part of their epitaph.

The CEOs I have met generally are interested in decisions that affect the company's structure. Should we get into business XYZ? Is ABC a company that we are interested in acquiring? What can we do to improve gross margin by making partnerships with others? Should we get out of this business? Are we spending too much / not enough on R&D.

The decisions of this type can and do make or break a company.

Unlike apparently all of you, I've been a CEO in a past life. The CEO spends his time on STRATEGIC issues, what you're describing are TACTICAL issues. A CEO who wastes his time in tactical is in charge of a company that won't last long. Also as a CEO I almost never overrode a decision made by an underling, even if I completely disagreed with it. My reasoning was simple, I had hired that staff to make decisions FOR me, once I started overriding decisions, I get to make ALL decisions from then on. After a company is publicly traded everything changes. Now 40% of a CEO's time is spent dealing with shareholders and analysts. Sarbanes Oxley has only made this worse, now another 20% of his time is spent on accounting issues, leaving 40% to deal with strategy, sales and positioning for the corporation. Those strategic issues often deal with financing venues: Banks, strategic investors and bonds. The other job of the CEO is chief salesman for the company, and establishing the position of the corp in its market. Ultimately the biggest deals require the CEO's personal imprimatur, usually just to convince the buyer that the company is very serious about the deal and will put everything behind it. There's lots more, but I think you get the drift. Micromanaging by CEO's will NOT solve ANYTHING and will just succeed in driving about $1 trillion in market capitalization from the valuations of oil companies, this while they struggle madly to deal with the OBVIOUSLY IMPENDING tragedy of peak oil, soon to cause gas lines at a (non) filling station near you.

The notable exception to this rule is Steve Jobs, who's been known to sit in design reviews of PCB designs. BTW, Apple recently surpassed the market cap of Microsoft, which has been drifting since the loss of Bill Gates, who also was involved in tactical decisions.

Disagree entirely. Steve Jobs couldn't design a circuit to save his life (that was Woz' job). Gates was a competent programmer, but didn't keep his chops, it is almost impossible if you're not coding at least 6 hrs a day, and even with his 20hr days Bill couldn't stay on top of it. I knew both men a LONG time ago, Steve is there to provide what he calls, "taste". Bill is there to kick butt and take names.

There's a scene in the movie "Patton", where George C. Scott gets to a muddy intersection and personally steps in to direct traffic until the jam up is removed. Some would say he was acting tactically, but in reality he was stepping in to make decisions that those on that intersection didn't feel empowered to make. When you have a command and control structure (military by definition), those at equal ranks can't navigate competing interests. Someone with higher rank needed to step in and take over. While it was an interesting piece of cinema, I highly doubt Patton was a stupid enough general to step out of his jeep (where he could get run over by a truck) and direct traffic himself. If he were in that situation, he could assign one of his staff (colonel most likely) to coordinate.

The printed circuit board meetings where Jobs is present mean he is showing management focus to deal with any problems and is implicitly telling his staff that those problems are getting the highest attention. He would only be there if the project is substantially late, over budget or incredibly important to the company. Having multiple friends at Apple, I can tell you he is NOT present at 99.9% of those meetings.

Getting back to the Patton example, it is entirely possible in a company where you have VP's from different divisions and no clear seniority versus each other that they will back their own group instead of working for the common good. That's when you need someone higher up the food chain to referee.

Very interesting, Widelyred.

What is your persepctive on the chain of command on the rig? Do you see any problems with the decision making process as it relates to this disaster. Not the actual decisions, but the process and chain of command, and the interplay between BP and TO?

Syncro, I posted a couple weeks ago about this. The bonus structure at BP is skewed towards profitability and therefore cutting costs. As competing VP's push for "their" projects to go forward, they dice the costs in their budgets so their projects will get approved. When the stinky stuff hits the fast spinning object, it is up to those lower down the food chain to try and salvage "their" bonuses (think bonus trickle down theory). That's where the corner cutting begins. It really isn't a question of whether this would have been a monster well, with tremendous profits for the whole company. The metric they are measured against is how the well is doing against BUDGET. If they beat the budgeted costs, they are heavily compensated. If they miss, they just get the paycheck, but some of these bonuses can dwarf paychecks. So on the one hand, you could pad your budget, but your project will never get approved, or cut your budget to the bone, but sweat out problems in the field. Macando was a month or so behind schedule and at least $30-40 million over budget when the disaster hit. As someone who roughnecked his way through college, I can say that offloading the mud to the support vessel was the killer. When they needed to pump tons of mud back down the hole when it kicked, it was 130' below them on another ship. That offloading saved BP about 12 hours, or $500K. Not doing the wireline with Schlumberger saved them about 12 hours, single casing instead of double saved a few million plus days etc etc. Looks pretty stupid in hindsight don't it?

Chain of command would have gone something like, "Joe you want that bonus don't you? Think there's anyway to cut corners on this so we can all cash those big checks?" TO isn't really involved, they're just waiting to be told what to do, and sometimes how to do it. The interplay of saying "NO" to the customer, when TO is essentially captive to BP as far as total revenues are concerned (biggest contractor to the biggest operator in the GOM) means no go. And let's not forget there was a PARTY on the ship that day, to celebrate TO's wonderful safety record!

I agree with you 100% on the bonus motive. But that approach may have helped generate the higher profit ratios BP enjoyed, before it met its demise, anyway.

The casing saved from $7-$10 million accoding to BP e-mail.

You raise a point I have not seen raised before. There has always been something about off-loading that mud that really bothered me. i could not put my finger on it, but you do:

As someone who roughnecked his way through college, I can say that offloading the mud to the support vessel was the killer. When they needed to pump tons of mud back down the hole when it kicked, it was 130' below them on another ship.

The only problem i see is that it looks like by the time they figured out what was happening, it might have been too late to pump mud. It was shut it in or be killed by that point. Maybe not, though. I don't have the knowledge to judge.

It does help put in perspective how far ahead of the game they were rushing those last days, from no bottoms up, no CBL test after the negative pressure failures, or earlier, displacing the riser before the top plug was set, pumping mud off, no monitoring returns. Based on their conduct, the well was already sealed, but it wasn't.

What stuns me is they ran one red light after another until they ran into that big truck called reality. One warning sign after another and just carried on with the next step as if nothing was wrong. At least after 2 or 3 warnings pause and check but they just went right ahead regardless. Maybe they cut $10 million dollars but just a check at any of the stages when they were indicating there was a problem would hardly have made a huge dent in that. If the check said 'BAD' the choice would be fix or carry on. To fix would cause money, yes, but to carry on would be to lead to disaster with massive cost in money and in lives. I really cannot get my head around it.

NAOM

p.s. widelyread, where were you roughnecking, Wyo or CA?

Red -- I guess that depends on the CEO. Over the last 35 years I’ve consulted for a few dozen companies. At least half of them failed. And without exception each company had senior management very focused on strategy. And every one failed for the same reason: failure at the tactical level. So many times I’ve sat in the big conference room and listened to all those grand strategic plans. I got to calling their approach “management by goal”. IOW: This is what we plan to achieve. And please don't bother me with the details of how we'll do it. Of course, never used that term to their faces. Always a great plan with no concept of what it would take at a tactical level. I won’t take up space detailing this foolishness. We’ll just use Tony as an example. He might have had some of the best strategic plans ever developed in the oil patch. And how much market cap has been lost due to what appears to be a bone head mistake by one of BP’s lowest management levels. But we’ll leave Tony alone. He’s been beat up enough.

Let’s talk about another oil man. He started a new oil & gas operation a year ago. It's one of about 40 different companies he owns 100% (he hates screwing with partners/investors) Strategy: put oil/NG reserves in the ground with the drill bit and then in 4 or 5 years when the markets peaks again he'll sell out and go away. Same old simple strategy: buy low...sell high. Did this with another little oil company 25 years ago and flipped it for half a billion…back when that was a lot of money. Does he pay attention at the tactical level? You have no idea. He knows every thing that goes on at the lowest level. And if he doesn’t like what he sees it get changed. Not next month…not the next day. It’s fixed before the sun goes down. You succeed he’ll reward you generously. You take foolish/dangerous chances that risks the family's money (they are private, you know) and he’ll fire you on the spot and personally walk you out the front door. Pay attention at the tactical level? No one (from senior VP to beginning secretary) comes to work for any of his companies until they meet with his wife and pass muster.

So how has being focused on the tactical level paid off for him? He’s a self made multi-billionaire netting a little less than $80 million a month. Guess no one ever told him a CEO can’t make a bucket load of money focused on the tactical. About the only time his folks collectively BS about strategy is during their Wednesday company catered lunch. And everyone eats together...clerks to senior VP's. Not really much need for the chat though. His strategies were set years ago. They focus solely on the tactical implementation of those strategies. Well..maybe he just got lucky. Perhaps he should reconsider his approach this summer when he's out cruising on his new $70 million sail boat.

Tony Hayward runs a company with 80,000 employees. Sitting down to lunch with all the employees would take a large football stadium.

The CEOs that you are thinking of are entrepreneurs, something very different from a CEO hired by a board of directors.

It's real simple. My CEO doesn't talk to my gauger...I do daily. My gauger does something stupid that significantly damages the company I get fired on the spot. That's the type of tactical control I speak of. Again, a CEO can devise the best strategy ever seen in his field. But if he doesn't assure it's implemented properly at the tactical level then he is THE failure IMHO. IOW, who else in the company has more authority to see business is taken care of properly? I know strategic planning. As critical as it is it takes a very small percentage of the time. You show me a CEO who spends half his day modifying his strategy and I'll have little hope for his future. My CEO set his strategy in place over a year ago. It hasn't changed since then so he's spent zero time on STRATEGY since then. It's been 100% implementation. It's the proper application of the strategy that determines how successful the company will be. The only difference between an entrepreneur and a board selected CEO is that if they both destroy the company the entrepreneur loses his ass and the CEO may walk away with a nice golden handshake (I've seen that more than once first hand). But both are charged with the same responsibility. Same job = same process IMHO.

Don't want to seem harsh on all those CEO's out there but the great majority of company failures I've seen firsthand happened because upper management was not realistically connected to the bottom end of the pyramid. Perhaps that's just unique to the oil patch. But I've never seen even one company falter where the top dog wasn't on top of the details daily. In fact, I can't recall one such company that hasn't prospered in difficult times. In the mid 80's during the worst of times when oil was $10 and NG less than $1 I had one of the most financially successful drilling programs in my career. And that was due, in no small part IMHO, to a CEO who often sat on the drill floor drinking coffee next to the driller. And this was the CEO of a public company who was hired by the board. And the board expected no less from him.

The way I look at this, is the CEO has the vision. He/she hires people to help make the vision a reality. I've not yet been a CEO, but I've definitely learned what visions I can make reality, and which ones to walk away from, (the ones where I can only envision myself suffering trying to achieve something not achievable by me. Not sayin' the vision is unattainable, just I know when I'm not the one to make it happen).

A simple example? A woman I know asked if I would paint her door red for her. I knew a) this woman has a vision, and will not settle for less than perfection. b) every time she saw so much as a brushstroke on that red door, (it was to her office), she would think of me, and that I didn't deliver exactly what she wanted. I told her I wasn't the person for the job. The (completely competent and talented) woman who took the job told me, after her third re-sanding/painting of the door: "passing on this job was the smartest thing you ever did".

I still work (volunteer, really), for the woman with the vision. Because I believe both in her vision, and her ability to make it a reality.

Rock, I respect what you're saying. Perhaps I never made myself clear enough before, it is because I have a very clear idea of what strategy means. I used to play chess at about the 2000 level. At that level it is always about strategy and position. A tactical player can mop up those below him, but he's stuck when he faces me for the same reason I'm stuck when I face a truly strong position player. Of course a strategic player uses techniques that look (to the unwashed) like tactical moves, but they are always part of a bigger picture. I'm sure R. or H. in your story has the same thing going on, to me it is strategy, but of course he knows where all the pawns are and what they're doing, so did I. Remember, the object is to capture the king, not this or that valuable piece, no matter how tempting, unless they're on the path to winning. Likewise valuable pieces can be bypassed if there is a better path to victory (and it fools the competitors too).

At the end of the day, your "flipper" is selling his company to a BP or Exxon, he really isn't playing in their league, he's just the farm club supplying the "talent" upstream. Not that that's a bad thing to be, I'm sure he'll enjoy his boat more than Tony enjoys HIS.

And I do appreciate your experience red. But how well does your chess strategy work when your opponent throws a cup of scalding coffee in your face and steals the chess board? LOL. I'm sure you get my point: have you ever had any of your good strategies ruined by poor implementation? Probably had. I'm not knocking strategic planning. Just saying it ain't worth poop if the top dogs don't push it (indirectly or otherwise) down to the grass roots. But maybe that's the difference in my experience and something unique to the oil patch. BP has lost tens of billions in revenue and perhaps $1 trillion in market cap probably due to the poor implementation of the corporate strategy by some guys who made less than Tony spends on his company car and driver every year. Could any of the shops you've run been potentially destroyed by a mistep of one of your clerks? If Tony and the other oil patch CEO's didn't realize they were living on a razor's edge controlled by some bottom rung blue collar workers they do now. I'm sure I've gotten a tad overboard with my opinion but remember where I spend many of my days: watching operations first hand that can make or destroy a company in just minutes sometimes. And leave more than a few grieving widows behind.

It is written by Son Shoe, "A Sawyer is worth the board".

Hail Son Shoe, a mighty profit and wielder of numba 14 Thom Mchanns.

It's Tony Hayward's job as CEO to set BP's direction, to make sure that the people who run its operations follow that direction, and to listen to those people to make sure the company stays on track. Eisenhower was responsible for 50 times as many people as Hayward is. He made sure that his generals made sound tactical decisions and that he was in the loop for the big ones.

When is the next law suit stating that the government officials regulating oil drilling in the gulf cannot be retards?

EDM -- Different folks handle risks differently. My owner signed his certification ass away to the feds a few weeks ago. You either believe you're going to make the best effort possible or you don't. But I agree: many CEO's know they don't have the top to bottom control we have in our company. Most probably have to look at a list to know the names of the folks they are pledging to trust. Our owner doesn't: he looks into our eyes every day. And we all know what we have to do to protect him as well as the hands on the rigs.

"Different folks handle risks differently."

Very true.

I need to get off my soap box but need to make one more point. I worked for a large Company that took regulatory compliance very seriously. In fact, there was zero tolerance on non compliance.

You probably remember back when the first certification requirements from MMS came out regarding the testing of safety devices. In my company, before the Division Manager signed his name on the periodic certifications, there would be a gathering of people in the conference room. In front of the division manager would be a computer output about 6 inches high(old style large computer paper) listing every safety device offshore, date tested and results etc and a signature sheet for his signature.