Tech Talk: Coal mining - robbing the pillars

Posted by Heading Out on July 4, 2010 - 10:48am

In recent posts, I have written about room and pillar mining, where the miners drive tunnels through the relatively horizontal coal seam, until they come to the edge of the property. Depending on the accuracy and honesty of the mine surveys, they then stop. I mention this latter because, on occasion, miners who later worked in an adjacent mine, thinking that they have plenty of room, have worked close to the boundary on the other side, and suddenly, and often tragically, have found that they were too close. Water or gas that had collected in the old workings flooded into the new ones, with usually fatal results. (The Quecreek Mine Rescue was an exception).

Once the mine has reached the boundary, there is still a lot of coal left in the pillars. If the mine tunnels are 15 ft wide, and the pillars are 45 ft wide and the coal is 6 ft thick, then using a rough rule that a cubic yard of coal weighs a ton, gives that the original tonnage between the tunnel center-lines, assuming square pillars, would be 800 tons (20x20x2). The pillar left contains 450 tons, so that the initial extraction only removed 44% of the coal and 56% remains in the pillars. So, providing that the mine does not have major surface construction that would be harmed if the ground subsided, the miner might choose to remove some of that coal, as he retreats back from the boundary. (Although David Kuchta will tell you of times when folk were less fussy about worrying about the houses on the surface).

This practice is known as “pillar robbing,” though to get away from the negative picture that this raises, it may be called “pulling” or “drawing” the pillars. Essentially the miners will start at the boundary and work back towards the shaft, removing coal from the pillars in a systematic pattern as they go. And if you pull out the supports that hold the roof up, then that roof will collapse into the opening beneath it.

This is where there is some skill and forethought required in planning how to mine out the pillars, and to control the way in which the roof breaks. If the pillars are pulled properly, then the coal that is left, because some is, will crush sufficiently slowly that the miners can have enough warning to be out of the way, and it will control the way that the roof breaks.

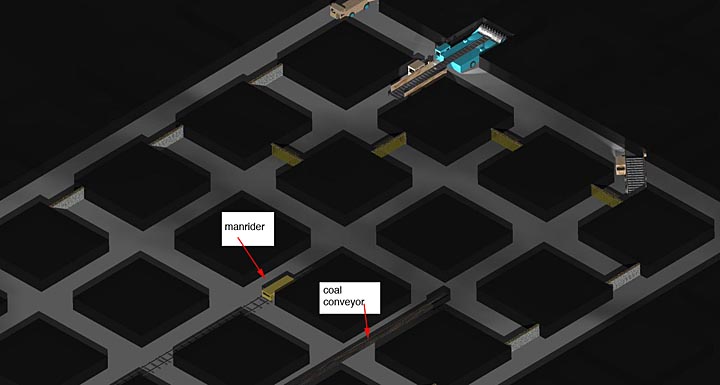

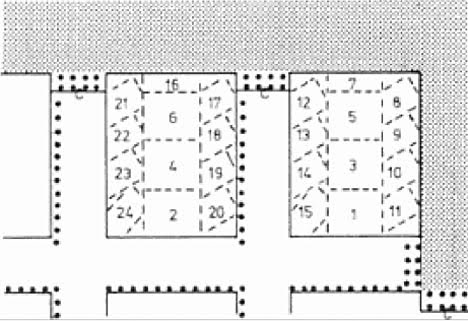

The process can be illustrated by first showing the layout I used earlier for the development of the mine:

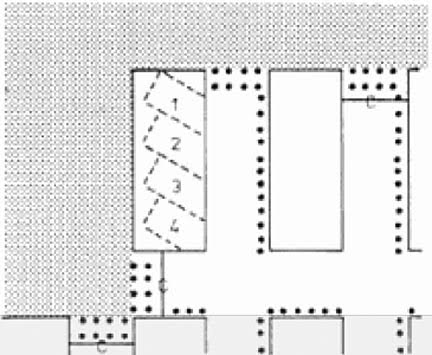

And then look at a mining plan after the mine has pulled most of the pillars from a section.

With 80% extraction the mine is now only leaving 160 tons of coal behind in the fenders or stumps. Fenders are usually the larger pieces of pillars that are left along the edges of the path the machine must move along, stumps are the residuals in the body of the pillar.

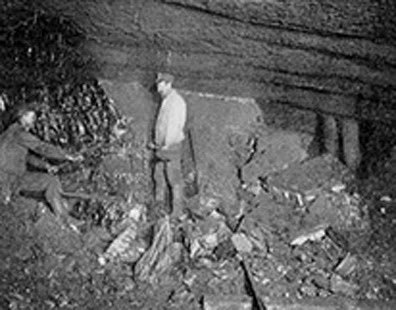

As the miner removes the coal, to keep the operation safer, while the coal is being removed, wooden props used to be installed that would hold the roof in place.

That practice, with the men under unsupported roof is no longer used. Now the coal is extracted using, increasingly, remotely operated mining machines, with the supports more closely located around the mining area and increasingly being hydraulic.

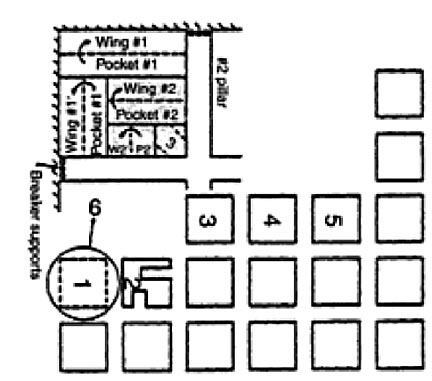

Pillars can either be mined very simply, by cutting into the side of the pillars left in initial mining:

In stronger coals or where the roof is better more of the coal can be removed.

The reason that the props are located close together at the edges of the remaining rooms, is that the roof layers above the area will start to break after the coal is removed. By establishing the props along the edge of the pillars the breakup from the previous coal removal will be stopped at the edge of the existing pillars.

The roof breaks into fragments as it falls, and will bulk into the space left by the coal removal. This bulked up rock provides some support to the roof overlying the area where the coal is then removed in the next sequence of mining. And so the process retreats.

It is not as effective as getting all the coal out, and can lead to more difficult problems at the surface than an alternate method of mining called longwall, and we’ll come to that next. But pillar robbing requires a great understanding of the geological conditions before it can be safely carried out. Unfortunately when this is not the case then we get disasters such as that at Crandall Canyon.

Can the pillars be replaced with Ice pillars?

Yes, but I think there would be difficulties when the ice melted.

We remember the Springhill mine as a very deep one where, sadly, they did not use ROVs.

What if, at intervals down the mine shaft, there were pressure gates? (For a non-vertical shaft, these might be revolving doors.) Between each two neighbouring gates, the mine is pressurized with gas to the same pressure as in the rock. Where extraction is not occurring, the rock is impermeably lined.

I would expect this arrangement to be immune to rock bursts and cave-ins, so one would not lose one's ROVs even in a very deep mine. Plus, no coal pillars would be needed; it would all be one big gas pillar that would not impede the machines.

(How fire can be domesticated)

Well, no more people in the mine then. You would either need to be in a pressure vessel, or on a gas mix, and need a very long decompression time. Remote would be much easier, I would think.

Gas pressure would likely be above human physiological limits. Also there would be gas leakage through the rocks. Don't forget that you would need VERY strong horizontal containment too.

NAOM

EDIT: using pressures from Macondo we could be talking 5-10 times maximum depth even using exotic breathing mixes.

naturally the ice would not melt instantaneously. It only has to be there long enough for the coal to be removed then they let the roof collapse. Perhaps a mixture of saw dust and water( pikecrete) which melts much slower.

Of course the trick is how to make it in place.

The only way to keep operations inexpensive (and for most of coal mining history it had to be cheap to be competitive) is to keep everything very simple, and while using coal waste to pack into the spaces where the coal has been removed has worked, even that was too expensive in the long run and is no longer used.

I was quite impressed by the coal mine machinery at the Chicago Museum of Science and Industry when I visited many years ago.

http://www.msichicago.org/whats-here/exhibits/coal-mine/

I wondered what happens at the surface as the rock below is going to fracture from the controlled collapse of roof. Is the result a landscape for which drainage of water from the surface is enhanced? Would that not cause more problems for surface vegetation and thus for those who depend on farming or logging that land at a later date? Could the resulting drop in the water table or pollution of the water prevent some other uses of the land, such as housing based on wells for water supply, thus making the land useless?

E. Swanson

I used to live in a big mining area in the UK. Until they mined it all of course.

There was a huge amount of subsidence and the UK nationalised industry had to pay to have many many houses repaired including making good walls and complete replacement of lath and plaster ceilings which seemed to be particularly vulnerable. My home at the time was thus refurbished.

That is now some 55 years ago. All our services were mains services - no wells. There were frequent breakages of the mains water supply which ran in cast iron pipes.

I don't recall any other specific effects regarding soil drainage and such. The local farm land just carried on as usual, as did the small allotment gardens in the area.

Looking forward to your discussion of longwall mining. When I first learned about longwall mining, it sounded terribly dangerous in comparison to room-and-pillar mining. But I was missing one step in the evolution: if it's a choice between longwall and the pillar-robbing techniques described in today's post, longwall looks like a no brainer, safety-wise.

Would it make sense to reenter an old pillar mine with longwall equipment?

Not really, the roof control would become more complicated, as would the ventilation of the working area. Longwall evolved from room and pillar and I will discuss that next.

Seems to be very little interest in coal on TOD considering the small number of comments. Is anybody with current technical knowledge about coalbed methane wells willing to post here?

Thanks for posting this series. It's very interesting and quite informative.

Greetings from Port Townsend,

I've expended considerable effort to learn more about the m/v A Whale.

The Great American News Machine has been a miserable failure in providing useful information.

In my opinion, while we appreciate Mr. Su for making an attempt to create an oil skimmer,

a tanker is the wrong tool for the job. Those slots are too narrow, unless the Gulf were as calm as a mill pond.

At any rate, I invite you to evaluate the information I have presented at:

http://www.oil-electric.com/2010/07/mv-whale-demystified.html

Robert in Port Townsend.