BP's Deepwater Horizon - More Insights Relating to DougR's Comment and Flow Rates

Posted by Gail the Actuary on June 29, 2010 - 10:30am

I thought I would combine a couple of shorter posts, relating to the same general topic--the issue of whether the Deepwater Horizon spill could be much worse than is being reported. I hope this isn't too confusing. The two posts are

1. Estimated Oil Flow Rates From the BP Mississippi Canyon Block 252 “Macondo” Well by Oil Drum staff member Art Berman, and

2. BP's Responses to Questions Raised by Commenter "Shelburn" by guest poster Shelburn

Neither of these authors find evidence that the spill could be much worse than is being reported. Shelburn asks readers what additional questions we should be asking BP.

Estimated Oil Flow Rates From the BP Mississippi Canyon Block 252 “Macondo” Well

by Art Berman (aeberman)

Estimates of flow rates for the BP Mississippi Canyon Block 252 “Macondo” well now range from 1,000-100,000 barrels of oil per day (bopd). Initial estimates were 1,000 bopd. These increased to 3,000 bopd and then to 5,000 bopd. Now the U.S. Geological Survey believes the well is flowing 20,000-40,000 bopd but other experts believe that flow rates may be as high as 60,000 bopd. Some have even suggested rates as high as 100,000 bopd, and others as high as 250,000 bopd. The purpose of this post is to provide a calibration framework for what flow rates are probable.

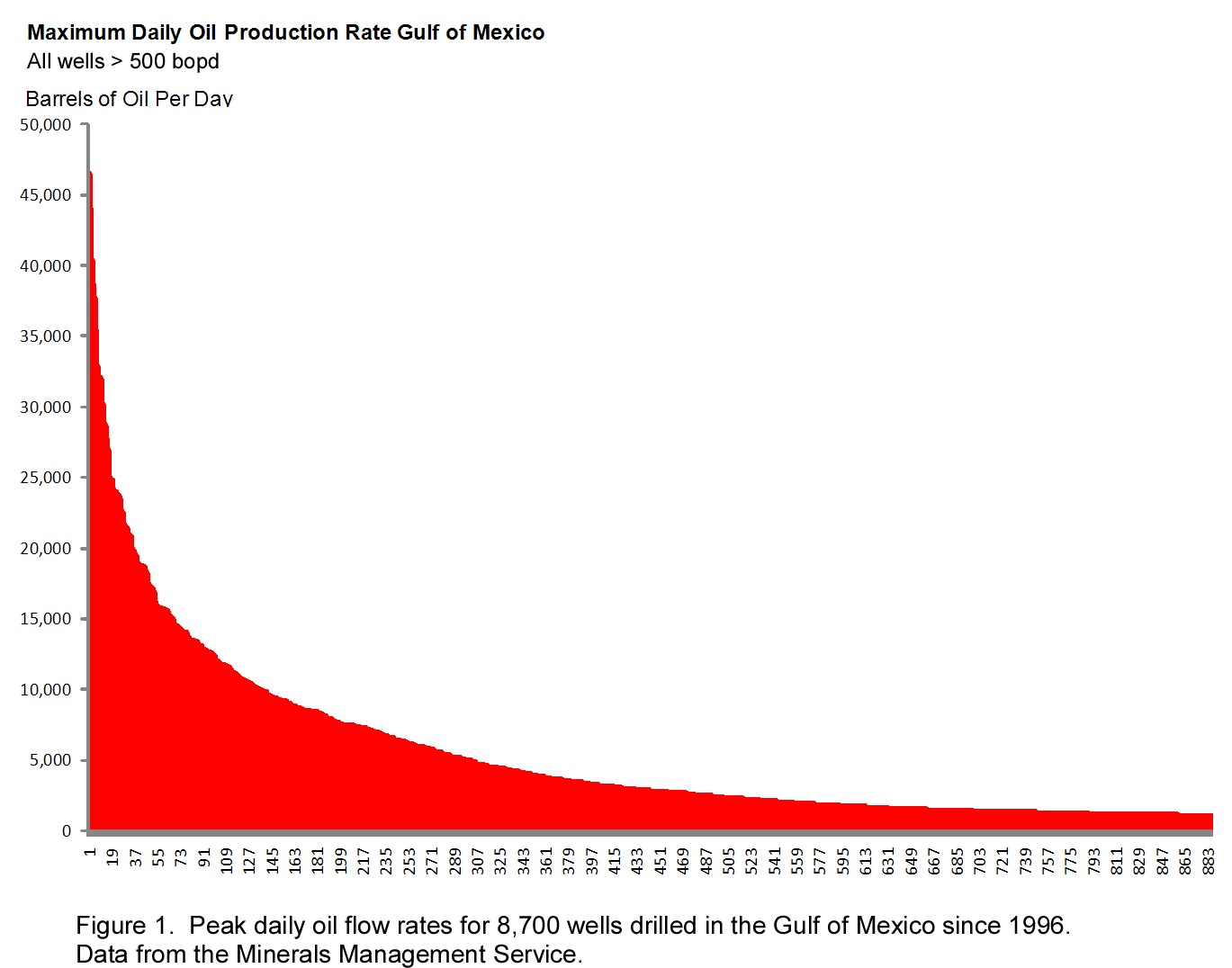

More than 8,700 wells drilled in the Gulf of Mexico since 1996 were evaluated using publicly-available production data from the Minerals Management Service (MMS). Wells in the deepwater Gulf of Mexico dominate the highest flow rates in this data set. Approximately 4,000 wells have been drilled in water depths more than 1000 ft, and more than 700 in more than 5,000 ft of water during the past 20 years. The Macondo well was drilled in 5,067 ft of water to a total depth of 18,360 ft below sea level.

Historical Context for High Flow Rates in the Gulf of Mexico

The highest flow rate for a single well in the Gulf of Mexico is 46,467 bopd (Figure 1) based on the daily average of the peak month of production.

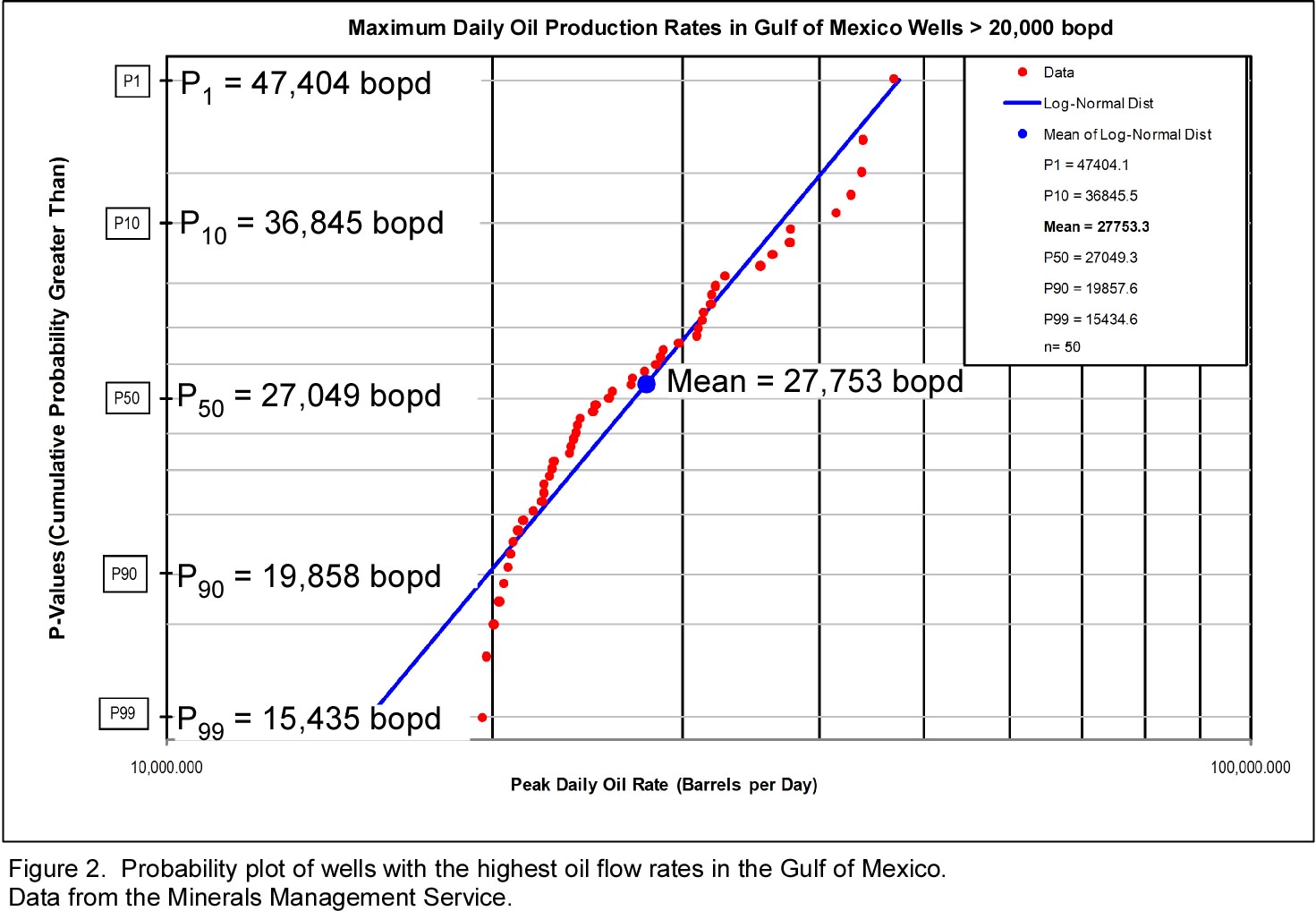

The mean of the 50 wells with the highest oil flow rates is 27,753 bopd . A probability plot (Figure 2) of these wells indicates that the most likely case is about 27,000 bopd (P50). There is a 10% probability (P10) that a well will produce approximately 37,000 bopd, and a 90% probability (P90) that it will be about 20,000 bopd.

There is no historical precedent for a single well producing more than 100,000 bopd. Among historical blowouts, the highest flow rates known are approximately 100,000 bopd at the Spindletop Field in Texas in 1901, the Midway-Sunset Field in California in 1910, the Long Beach Field in California in 1910, and the Lake Maracaibo Field in 1922. These were all open-hole completions drilled without casing or drilling fluid so they represent maximum unconstrained flow rates.

The BP “Worst Case Scenario” Document

An internal BP “worst-case scenario” document released June 20 has been mis-interpreted by some to indicate that the company believes that flow rates as high as 100,000 bopd are possible. The document states that the probable range is 5,000-40,000 bopd. It further states that the maximum theoretical rate is 60,000 bopd. It is important to note that these values represent unconstrained, open-flow rates that might be expected after removing the BOP from the well, and are estimated to be at least 10,000 bopd more than present flow. The 100,000 bopd rate assumes that flow is occurring within the production and casing and around the annulus. It again is an unconstrained rate.

The Most Likely Case

We know that the well is producing at least 25,000 bopd because that much has been collected in a single day. It is impossible to know the flow rate until the well is brought under control and rates and pressures can be measured. It is possible that the welll is flowing at a rate 25% higher rate than any well drilled to date (60,000 bopd) in the Gulf of Mexico, but it is not likely. It is less likely that it is flowing at 110% of the rate of the highest rate well so far (100,000 bopd). It is reasonable that it may be among the highest rate wells, and was initially flowing at 40,000-50,000 bopd.

BP's Responses to Questions Raised by Commenter "Shelburn"

by commenter shelburn

A few days ago Gail posted a copy of a comment I had made the day before as the main posting. It was titled, BP's Deepwater Oil Spill - Response to DougR's Concerns - and Open Thread http://www.theoildrum.com/node/6655 and http://www.theoildrum.com/node/6659

In that thread, as a side issue I took BP and the government to task for not releasing more technical information and listed about 10 hypothetical questions I would like to ask BP based on the content of the posting about DougR’s claims that the BOP was in immediate danger of tipping over and causing catastrophic damage.

I was quite surprise when yesterday Gail informed me that TOD had received a response, well, a partial response, to the list of questions. Below is the Unified Area Command response:

Subject: RE: Response to DougR's Concerns

Hello,

In your site's June 25 post discussing the Deepwater Horizon oil spill, http://www.theoildrum.com/node/6659 guestblogger “shelburn” asked a number of questions. We passed these on to BP and have obtained answers for some of them and thought you would like to share them with your readers:

Q: has the inclination of the BOP changed?

A: NoQ: Are you concerned about the structural integrity of the BOP, wellhead or LMRP?

A: NoQ: What are the ROVs doing when they are looking at the seabed?

A: There are a number of ROVs at work at the site so it depends on which ROV the viewer is referring to. As we prepare to set new equipment and flexible hosing on the seafloor, however, ROVs are often used for route planning. During those exercises the ROVs are used to scan the seafloor to ensure that there are safe and stable places to position equipment and flexible hosing.

Q: Is there any indication of seabed movement at the base of the BOP?

A: No.If you have any additional questions please let us know.

Sincerely,

Tech. Sgt. Alec Lloyd

Unified Area Command

Deepwater Horizon Response

I was surprised there was a response as, to the best of my knowledge, BP has not previously responded to any internet websites or blogs.

I would have hoped for a more complete and technically oriented response but at the same time am highly encouraged by the fact there was any response at all, and that they answered the most critical questions to refute the wild speculations by DougR that was causing considerable stress to Gulf Coast residents.

The most important fact is that there is no, absolutely no, evidence of washout, subsidence or leakage around the wellhead and blowout preventer (BOP). Without that all DougR’s his arguments fall completely apart.

It is interesting the questions they didn't answer. They dropped "casing" from the list of items of structural integrity. It is almost a clear answer that they are concerned about the casing integrity - no real news there for readers of The Oil Drum. Along the same line they did not respond to any other questions about downhole leakage. This is a list of my questions they did not answer:

Describe the “disk failure” at 1,000 feet.

Are you concerned about the structural integrity of the casing?

Describe the formation levels.

What are the current pressure readings inside the BOP?, the historical readings?

What is the little black box the ROVs place on the riser?

Personally, I was most interested in the historical pressure readings at various levels in the BOP and still hope that information will be made public.

I would like to thank BP for this amount of information they did release and encourage them to enlarge the information exchange.

To that end I would suggest The Oil Drum posters to compile a list of technical questions we would like to ask BP. Maybe through the comments section we could narrow down a list of 20 or so questions that The Oil Drum feels that BP could answer that would be most beneficial to transmitting factual data to the general public. Having watched the main stream media mangling of what information they are given, just possibly, having some technical information go through the Oil Drum “review process” would generate a higher quality of communication than we have seen to date.

We know that BP, for legal reasons, is not going to comment about what caused the original blowout or steps that were taken onboard the Deepwater Horizon, and for proprietary reasons they may be reluctant to discuss specifics of various formations. But it would seem that most other data, subsequent to the sinking of the Deepwater Horizon, would be available.

Editor's note: Comment moved here from Drumbeat.

Has no one here noticed?

http://blog.alexanderhiggins.com/2010/06/28/increase-leaning-bop-15-degr...

http://blog.alexanderhiggins.com/2010/06/11/confirmed-gulf-oil-spill-bop...

http://www.youtube.com/watch?v=9bWfI36pFec

I must have missed your response to shelburn's critique of your nonsense.

I notice two "404 not found"s and a six-minute YouTube video with nothing to bolster any claim of anything whatever. Perhaps you need some rest.

http://blog.alexanderhiggins.com/2010/06/28/increase-leaning-bop-15-degr...

http://blog.alexanderhiggins.com/2010/06/11/confirmed-gulf-oil-spill-bop...

Perhaps the link did not survive the move from the other thread. Look again.

Doug, you're a good egg and I share a lot of your concerns. BP's response to Shelburn is a pack of lies, period. That said, we'll have to wait on events. No purpose served by further discussion until they fail to kill it.

Avon says: "BP's response to Shelburn is a pack of lies, period."

Yes, it is, and why certain people keep beating this dead horse is beyond me. What's the point of posting BP's pretense anyway?

Not all expert opinion (opinion being a pivotal word) is here on TOD, there is plenty of serious discussion coming out of university lists, discussions that include people with duel affiliations of university and oil industry.... dougr's comments have been considered and taken seriously on several academic boards, especially in light of BP's silence. Strangely, only here have I read his posting/opinions ridiculed to the point of absurdity. Why does dougr have to be 100% correct on all counts anyway? Certainly BP hasn't. It's enough that he has offered alternative perspective while BP and the government were simply throwing out rose petals and looking to "kick ass." Like it or not, agree with it or not, dougr's perspective has been considered by a wide range of people with relevant expertise. By the way, I've read far more dire forecasts on other lists, but even so, those forecasts were followed by discussion without ridicule. One has to be suspicious of ridicule, I think... it usually comes with an agenda.

I also think Avon was correct in saying we simply have to wait, because in truth, I don't think anyone really knows for certain what to expect. And those with more information are not particularly forthcoming.

"Doug, you're a good egg......" This comes across as a pulp/paper mill comment. The initial smell and anything lingering is a real caught in the elevator **who-done-it**. If Ma or Pa works at the mill then it smells like bacon and eggs.

Dougr--

Thanks for your post from before.

Here, Avon has it right: We just are not getting any new information, and BP lies like a rug. So we will simply see as things unfold.

It is certainly a shame that we are getting no independent measurement of events in the GoM. I suppose that and BPs "ponies and balloons" show of Gulf clean-up in themselves really tell you all you need to know.

Recently, no less than Bill Clinton has gone on TV to soften up the public to the scheme of blowing up the well. He's backed off from Matt Simmons' implication that the explosion has to be nuclear--creating more wiggle-room, as it were. Somebody very big does not--or no longer--thinks the relief wells will work.

This is hardly reassuring, but does stand as support for your original post.

We just are not getting any new information, and BP lies like a rug

Heh heh, I can see that BP is in a no win situation. If they answer any question that you don't like, they lie.. If they don't answer the question, they are stonwalling. If you like their answer, then spin it to the doomsday scenario.. What exactly is your purpose here?? Oildrum is obviously not a site that try to spin the doom and gloom.. And folks here seems to really try to get to the bottom of the technical issue. I thought BP up to this point has been mostly o.k. with their information espeically the technical info. A lot of schedule info are too optimistic but none of them are outright lie. I also try to catch Adm Allen briefing whenever it is available and he come across as having real command of issues. There are thousand of reporter and clean up workers in GOM now, it take a real conspiracy to lie about the condition without getting expose.

No reporters or clean up workers on the rigs, everyone else sworn to secrecy which is boilerplate for all of us who do contract G&G or drilling.

I don't know what Oil Drum is for. It used to be a forum to discuss peak oil. Rembrant Koppelar's monthly data was and is a must read. I like to keep tabs on megaprojects. All that changed (temporarily) on April 20. Drillers Club and gCaptain were redhot in the beginning, before BP was forced to spill their guts to the Waxman Committee staff. I played a role however small in demanding disclosure of BP internal emails and documents. Still waiting for the wireline logs.

Each of us comes here with an unique purpose vis a vis Macondo. Personally, I don't give a hoot about skimmers, beach tourism, oily air, seafood, sport fishing, dead birds, or gigantic underwater plumes. I don't care whether BP spins off its US refineries and runs off to Barbados with their remaining loot.

I care about deepwater E&P in the Gulf of Mexico. Until and unless the blowout is shut in, and the Obama Administration lifts their moratorium, we stand to lose rigs, crews, operators, finance, and a bunch of small service companies. That's the real unfolding disaster.

My purpose (waning rapidly) was to guage the complexity of RW operations and, in view of what I've seen and surmized, to warn people that this is going to take many months to kill several subsurface horizons.

I don't mind being proven wrong.

"Personally, I don't give a hoot about skimmers, beach tourism, oily air, seafood, sport fishing, dead birds, or gigantic underwater plumes."

Noted.

What's your motivation for promoting that particular meme? Is it just a simple case of inciting panic to somehow make yourself some money from your investments? Why does that seem to be a common theme among people pushing the wild doomsday scenarios? Well, except for dougr, he believes there are government agents following him as stated in an earlier comment.

You are just flat out making shit up.

Okay, we don't like each other. Irrelevant to the subject matter. Stacked pay is a reality. Lost circulation and stuck tools are undisputed, documented facts. I know enough about the trend to say that updip migration is possible. I believe there is seafloor venting about three miles from the wellhead.

This is no looming catastrophe, just means they will have to take more time, drill more relief wells and kill several horizons, in my opinion. Got it? An opinion. Not asking you or anyone else to agree with me.

BP has nothing to say to us. Nothing.

We want independent observations and measurements from people who aren't liars. We want those people allowed in to observe and measure.

If BP wanted a different outcome they could have told the truth. They didn't. Draw your own conclusions about that.

The US Department of Interior has fined BP $5.2 million for submitting "false, inaccurate, or misleading" reports for energy output on tribal lands in Colorado.

Upstream staff 30 June 2010 14:29 GMT

It was the first big fine levied by the Interior Department's Bureau of Ocean Energy Management, Regulation & Enforcement, formerly known as the Minerals Management Service.

"It is simply unacceptable for companies to repeatedly misreport production, particularly when it interferes with the auditing process," Michael R. Bromwich, the director of the BOE, said

Email me at dougrtod at y mail com will ya!

I'd be more worried if the bullseyes mentioned were the same ones. They aren't.

This shows the relative position of the two bullseyes:

The June 10 reading was taken at the Bullseye below the flex joint that connects the riser to the BOP (screencap from YouTube video):

Being mounted on top or below the flex joint is irrelevant. The Flex joint itself is a solid cast of forged metal.

It simply allows the riser adapter to swivel several degrees.

The Flex Joint is solid metal attached to the BOP.

The only way that would lean is if the BOP itself leans.

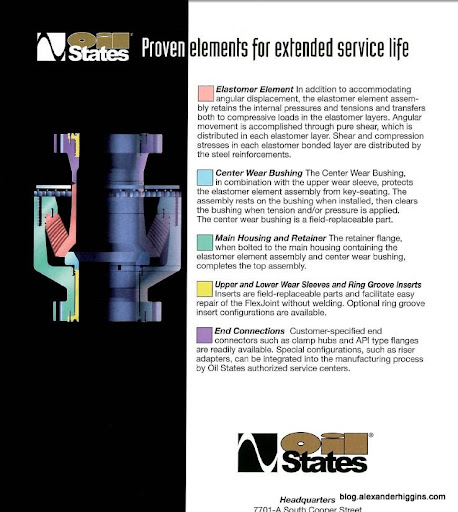

Diagram of the BOP

Cut out of the the Flex Joint

From the manufacturer's brochure:

Explanation of the the inner parts of the flex joint - shows the elastromeric element that allows for angular deflections of the end connectors

"The only way that would lean is if the BOP itself leans."

The specs reads that the flex joint takes the load. You've painted yourself into this corner (with DougR I might add) so how do you plan on escaping?

How much do you really know about the flex joint?

I have spent a good time discussing it with those who know the technical information.

The joint allows for the angular rotations of the shaft.

It is a solid casing attached to the BOP.

If this where a tensioner/joint slip system like diagrammed here http://www.freepatentsonline.com/6530430.html then it would make sense for the bullseye measurement to be off it where mounted above and below the joint.

Again this is a solid casing. The lean allowed comes from the elastromeric element inside of the casing which allows the riser shaft to move.

The specs read:

Refer to the diagram. The Elastor element is location inside of the housing and allows the shaft inside of the FlexJoint to move. The solid casing is forged metal and does not title on angles. Only the shaft.

What were the readings from the bullseyes before the blowout/fire/sinking?

Do you have any video/screencaps of the bullseyes before the blowout?

Was the BOP stack/LMRP/flexjoint exactly vertical, at 0*, when originally installed at the wellhead and up until the blowout?

And the top bulls eye is mounted on the part that is designed to move. so movement of the ball would be expected and not related to the bulls eye on the BOP assembly itself.

NAOM

He's playing semantics by dismissing anyone who says 'flexjoint' when referring to the bullseye mounted to the 'riser adapter'.

to Alex: the term 'flexjoint' applies to the base and the adapter. The adapter on top is an integral part of the flexjoint, they are not field-serviceable separately - it's one unit, and you know damn well that when someone says 'flexjoint' they mean the whole thing. There is a bullseye on the base, and another one on the adapter. You know this but are playing silly games to push a fantasy scenario. Stop it. You don't know what the reading was from the flexjoint base before the blowout, a reading from today is irrelevant. You don't know what the reading was from the bullseye below the BOP on the wellhead before the blowout, a current reading from that bullseye is also irrelevant without a comparative reading from before any potential damage occurred. And the bullseye mounted to the adapter isn't relevant to jack, since there is no longer anything hanging off the upper flange.

comfy --

right on ....no one has a datum for reference ...the pre-blowout readings are not known to any1 but BP....the idea for these bulls eyes is not to measure tilt from true vertical but to provide incremental leaning as observed over the drill program....I can confidently say no one in the history of drilling has ever known a true vertical BOP.....if we start measuring inclination from true vertical then every BOP in the world is suspect....except its not because these readings are meant to be compared against the datum established when the BOP is first sunk.....

No.. If the bullseye is mounted as shown in this diagram, which is where it appears to me that it is mounted then that part of the flex joint does not move.

Alex, you are reading the diagram wrong. The bullseye is drawn just above the tip of the upper red arrow, on the part of the Flexjoint that moves. The photo on the other end of that arrow is even more clear, the bullseye is clearly sticking out from the upper half of the Flexjoint, above the black skirt (the donut the upper half sticks up through) that covers the lower half.

If that is the case the diagram is wrong..

In fact you state so your self here: http://www.theoildrum.com/node/6644#comment-664348

The top bulls eye appears to be connected to the actuator assembly on the (presumably) EDS system attached to the part of the flexjoint that is supposed to move. Your arrow points to the top of the body of the flexjoint that is not supposed to move. Move the head of the arrow up about half way to the inlaid image of the ball for the correct position.

If the bullseye is mounted on the top of the Flex joint where the arrow is point (and that is my assumption) that doesn't move.

Alex, I think you've got me confused with aethervox or NAOM.

There is a small error in the drawing, the arrow needs to point a little higher. Everything above the tip of the arrow moves, right? You seem to be saying different, but I may not be understanding correctly.

Let's make sure we are on the same page. Look at the cutaway picture you posted at 6:31. It it shows two pieces, a lower one that is like a big bowl that bolts down to the LMRP/BOP, and an upper piece like a weird pipe that bolts up to the riser. The two pieces make contact in the middle in a ball and socket joint (with a big hole through it for the drill pipe), and the joint is surrounded by the brown elastomer which acts as a compression cuff around the joint. The ball and socket joint is what allows the top of the Flexjoint to tilt when the riser pulls on it. Is that what you are seeing?

I pointed to that comment thread because to make it clear what your where referring to.

Are we on the same page?

Same page regarding which parts move. Different page regarding where the bullseye is mounted.

This new picture shows the bullseye mounted on the (rubber?) skirt at the top of the Flexjoint lower half. The prior drawing and photo show it mounted on a bracket attached to the upper riser connector, a few inches above where you have drawn it here. If it was mounted in this lower spot, it could get crushed if the riser connector tilts toward it, right?

The upper bullseye is on the part that tilts, because you need to be able to measure the tilt angle.

OK,

This is what I am seeing as far as bullseye mounting.

Does anyone have a different shot of the top of the LMRP so Alex can see that he could pass his arm between the bullseye and the lower part of the Flexjoint?

edit for clarity

I may be wrong.. but I don't see any bracket. It appears to be mounted directly to the flex joint (part that does not move)

Also, if it where mounted via a bracket to the part that swivels... it would need to be several inches above the flex joint to allow for a 20 degree lean of the swivel.

I don't see clearance to allow for that.

In this link you can watch "BP Cleaning and Reading the Bullseye on the BOP", which toward the end has a closeup of the top Bullseye and it's bracket which is clearly attached to the flexible outlet pipe of the flexjoint. Then just to confirm this you can watch "BP getting the top hat back on" which shows a side end on view of the top bullseye attached to the flexible outlet pipe.

http://www.youtube.com/user/naula53#p/a/u/0/IRJCz2F6At8

It all makes sense. Bottom Bullseye to indicate verticality of wellhead. Another Bullseye at the top of the BOP but below Flexjoint to indicate verticality of BOP and a top Bullseye monted on flexible part of Flexjoint to indicate lateral loading on flexjoint from the riser.

Thank you for your pictures, diagrams and links, they are very useful.

Thank you for the video.

I stand corrected about the placement of the Top Bullseye. There is a definite depth perception / optical illusion in the cleaning videos and screen shots above.

Here are the corrections

Top of BOP Diagram With Bullseye Locations

Top of BOP with Bullseye Location Marked Screen Shot

No problems Alex. Here's a another video of the top bullseye. This time it is high definition, one of those that was given to the Flow Rate Technical Group.

http://www.youtube.com/watch?v=pdjEZodKZJA

Spot on Alex, that was what I was trying to get over earlier. In the video, above, you can see the parallax between the bulls eye and the joint. Thanks for updating the drawing.

NAOM

What were the bullseye readings before the blowout, Alex? Hello? Is this thing on?

Seriously, Is that a trick question?

http://monkeyfister.blogspot.com/2010/06/high-tech-bots-and-low-tech-sol...

You've been mislead, Alex. It has been reported more than once on TOD that the bullseyes are original on the BOP stack, not recent additions.

Regardless of the the reading at the point of origin... There is an increase of lean on the same bullseye below the flex joint of 1.5 degrees between June 15th and June 8th.

Added "below the flex joint"

Late to the party, alas. The photos from June 15 and June 28 are very curious.

It's a shame that Higgins obscured the photo with a red dot, but the screen shot from June 28 looks remarkably like the one from June 10, which is shown here: http://blog.alexanderhiggins.com/2010/06/11/confirmed-gulf-oil-spill-bop... . That is to say, the red dot is in EXACTLY the same position as the ball in the June 10 photo. This suggests that by Higgins' own photos, there is NO change between June 10 and June 28.

The screen shot from June 15 is harder to explain. Higgins says it's the middle level. I don't know what it means. Was the BOP momentarily more upright on June 15? Does this have something to do with mechanical loading? Or is there a fourth level that I don't know about?

I did find some evidence of change on YouTube.

The image on the left is from June 10. The date on the image on the right is illegible, but it was posted on June 18. They ARE both the same bullseye level. There is apparently a change from about at least 2.5 degrees to less than 2 degrees in 8 days. Of course, that small change could be in response to mechanical loading from the top hat.

As for the top level, there's no doubt that it IS mounted on the movable part of the flex joint, and Higgins unfortunately doesn't seem to have any idea what the joint does.

1) I did not obscure the video with the red dot. That was done by the OP. See my comment requesting the original video.

http://www.theoildrum.com/node/6644#comment-664598

2) The bullseyes you post here are the bottom bullseyes, not the middle bullseyes.

3) It is clear I do know what the joint does, see several comments and diagrams discussing the same.

http://www.theoildrum.com/node/6644#comment-664508

http://www.theoildrum.com/node/6644#comment-664518

I was mistaken about where the bullseye was mounted due to depth perception illusion. Again see my comment with the the latest BOP diagram with the correct locations of the bullseye location.

http://www.theoildrum.com/node/6644#comment-664584

4) Your images being of the bottom bulleseye and your are suggesting that the bottom bullseye is moving due to top hat load? Absurd. You are suggesting that the ~1.5 degree difference in the middle bullseye is from the same?

5) Your own bullseye photos here is here again supports that the the lean has changed by about .75 degrees between the 10th and the 18th, be that the data the image on the right was posted.

6)

This is not a clear picture of the BOP falling down. According to the bottom level, it "fell" UP, not down--and then by only 1/2 degree. At the middle level, if you take the data at face value, it fell up, then down again to precisely the same angle. Inconsistent, alarming maybe, but I'm not totally sure it's not just a piece of scuzz on the level, or perhaps a different bullseye level altogether. It would be nice to see the whole video.

I'm not so sure loading doesn't play any part in the tilt. The cap weighs some tons, and on top of that are a manifold and a mile of pipe.

Alexander, your blog has attracted a great deal of attention because of your live video feeds. You have built a huge story about sensational claims such as a tilt of 11 degrees and more, and failing fast. Considering that you don't seem to have a technical background and have made a lot of basic errors, maybe you should express a little less certainty in your blogs. Scaring people needlessly is really not in the public interest, especially if it turns out you're wrong.

If I am wrong then no one gets hurt.

If I am right then a disaster can be prevented

If that where the case it is likely that we would still be getting told there is only 5,000 barrels of oil per day leaking into the Gulf. It was my blog post that was submitted to NPR.. you know the rest.

I should stop sounding the alarm that oil as shown by USF, Roffs, and/or SkyTruth has been reported is either in/near or likely in/near places that Government refuses to acknowledge such the Florida Keys, Gulf Stream, and up the East Coast of Florida.

Ditto on the Florida Officials telling the public it is safe to swim in the water based on "visual inspection" leading to women and children swimming in waters on oil infested beaches, with a visible sheen in the water and skimmers collecting oil 50 to 100 feet off the coast while scientists and doctors warn against it.

Perhaps you are right, but then again "All that is necessary for evil to triumph is for good men to do nothing" Edmund Burke

Yes you are correct the top bullseye is clearly mounted on the outlet pipe ie the part that flexes. I would guess that the elastomer is now permanently deformed from having to act as the anchor swivel of the blazing DWH rig and then supporting the weight of the crimped riser. I wonder if it is still pressure tight?

"Has anyone here noticed?"

I did and I think many more did including UC and BP. I think they took a more tactful approach. My inclination after reading was; About half a bubble off.

From the author of the website I referred to above...a reasoned response:

While there maybe a swivel joint here, it appears that joint is for the pipe coming out of the top of the BOP and not the BOP itself.

It appears that the level is attached to the BOP and not the swivel joint.

It would also make no sense to me that BP would install a level on such a joint that could swing a few degrees knowing there was a lean on the blowout preventer and that the limit of the level was only up to 5 degrees.

It would also not make sense for BP to come back later to clean it and then measure it knowing the measurement would not provide an accurate measurement to any degree of certainty.

I wasn't referring to the BOP being a half bubble off. Personally I think there's lots going on down there that doesn't make sense to you.

How do you come up with swivel when the correct terminology is ***flex***? If there is a flex joint designed in the system then it should flex or allow for flex and it makes perfect sense to most here. It's possible the BOP is bent a few degrees. If the casing to the BOP was bent when the DWH sank and the sight glass shows the BOP leaning at 2-3 degrees upon first inspection after the DWH sank and BP does the same inspection daily for weeks on end and it still reads 2-3 degrees what could it possibly mean other than nothings changed in that area.

I haven't read you gloom and doom post because what you post here makes any additional comments irrevelant. Your attempts to instill fear come across as someone ill informed and demonic. I can't imagine your responses if you actually knew the truth.

Shelburn stated he agreed with your assesment of BP not being forthright on the information provided. Based on what you have stated if they gave you info they believed to be accurate and it turned out to be unfounded then you would probably accuse them of lying. Everything to you is lose-lose.

Angular movement, swivel, flex, you are arguing semantics when the concept is entirely the same.

It can be said that shaft / riser inside the FlexJoint is allowed to swivel.

The FlexJoint allows for the shaft inside of the casing to tilt.

The Casing itself is a solid cast of metal and does not move.

Why would BP install a level where it would be subjected to 10-20 degrees of tilting?

Odd question. Simple answer, they want to be able to measure how much it is tilting. Why? I'd say so they can tell if it is getting close to its maximum movement, and/or to tell how much the casing and drill pipe inside it are being bent.

The Flexjoint is a two piece joint just like your hip joint, as shown in the cross section you were kind enough to post, Alex. The Main Housing is the hip socket, the Riser Adaptor end is the femur, moving freely in the socket, with an elastomer cuff to keep things snug. Together they make the joint (hip bone connected to the leg bone...). The upper bullseye is attached to the adaptor/leg bone, as shown in the picture above in aethervox's comment; it indicates the degree of bend in the joint when compared to the lower bullseye.

I think we all have known that the bottom of the Flexjoint (the Main Housing) is solidly attached to the LMRP/BOP stack. Are you clear, Alex, that the top half of the joint (the Riser Adaptor with its attached bullseye) is the part that flexes? And that this upper bullseye does not indicate the tilt of the BOP?

Edit: Technically the upper half of the Flexjoint contains the concave socket, sitting on a convex rim in the main Housing, but the hip analogy describes the relative movement better.

"Angular movement, swivel, flex, you are arguing semantics when the concept is entirely the same."

No it isn't semantics by simple definition alone you are incorrect. If you think so ask someone (preferably of large stature)to take your hand and turn it clockwise a full 720 degrees. The flex joint could do the same if enough force was applied but much like the joints in your arm the intended design function would be destroyed.

"The Casing itself is a solid cast of metal and does not move."

The bottom flange of the flex joint is connected to the BOP and correct it doesn't move or to say the least it isn't designed to move. The top half of the flex joint does move and is designed to do so until worn or damaged.

"It can be said that shaft / riser inside the FlexJoint is allowed to swivel."

The drill pipe or casing moving through or being installed through the flex joint could swivel, yes I agree. The same could be said for the BOP.

"The FlexJoint allows for the shaft inside of the casing to tilt."

Varying by only a few degrees. But the primary function of the flex joint is to compensate for the flex, sway, movement and weight of the riser connected to the flex joint and extending to the drill ship or rig. The unit terminology and specs reference a flex joint for a specific reason and it isn't semantics.

Again.. the argument is over semantics.

Case in point take the "swivel chair" I am sitting on.

It allows my to rotate my body 360 degrees on a horizontal plane as well as lean up to 10 or 15 degrees on the x,y Cartesian plane.

Drilling industry specific terminology, per your argument, requires it to be called a flex joint.

To the average person the joint on a swivel chair accomplishes the same concept.

Continuing on with that analogy the flex joint is would be the base of the chair (flex joint casing).

I was arguing that the shaft coming out of the top of the joint is where the tilt/angular rotation occurs(the riser adapter beneath the chair).

It's called a flex joint because it's designed to FLEX.

My point isn't semantics and oil field brat made a similar analogy too(or vice versa) re; the hip joint. To the average person who has problems with reading comprehension yes your chair analogy may fly. Have you requested the 720 degree arm twist yet?

The swivel chair is called such because because that's what it does. The base is fixed or on casters and the chair base swivels on a bearing. The tilt forward and backward is controlled by a spring mechanism i.e. two separate features.

If I said it I didn't mean it (Missouri)......industry terminology is usually based on a specific feature, trait or characteristic. If it flexes then it's called a FLEX ?????whatever it happens to be.

There is nothing in the design of the flex joints that I have checked out to indicate the unit is designed for rotation but it is designed for long angular flex from the riser. I haven't read anything to support that it can't rotate. It's specifically designed to prevent the beveled seats from taking a keyed position. I imagine the riser rotating aroung the X-Y axis while the Z axis moves/flexes in the currents could make things a little interesting topside and at the sea floor.

My original point was to highlight your support of DougR's hypothesis and your continued effort to gleen information to support your theory of the BOP that is tilting more every day. In doing so you name parts to fit your theory. Your comments and questions are similar to those in the OJ trial; "Why would BP install a level where it would be subjected to 10-20 degrees of tilting?" I think there's a phrase that applies when asking questions you don't have the answers to in order to make your case.

A phrase? Are you implying I am begging the question?

I am not intending to offer proof of any question that is only evidenced by itself.

Do I misunderstand you? Unlike your implicit suggestion meant to indirectly suggest the idea that I have resorted to circular reasoning I am trying to use explicit process and procedure to state my claim based on reasoning (be it inductive or deductive) and then present the evidence to back it up.

I will then further refine my hypothesis as needed so that my argument or claims can be corroborated but to steal from your very own tactic the bottom line here is this all speculation, from all of us, and that includes your own speculation that the lean of BOP is not increasing.

AH,

Of course you are asking a question in which you have no answer or could you begin to answer. Clueless is the first thing that comes to mind. Your desire to create is over the top. Your field of expertise is believing what other uninformed people tell you to support your and DougR's hypothesis.

You have no explicit process or procedure. To prove your bullseye theory and chicken little the sky is falling pooh you bring out a diagram of a flex joint that you can't begin to accurately explain. You then have an Ah Ha moment after someone points to your many hypothetically incorrect assumptions based on ROV video snags in which you are cluless on the angle or orientation of the ROV.

I have posted in the past that I think the safeguard to prevent this from happening again (no there is no insurance for stupidity) is to drill more relief wells in conjunction with the exploratory well in case of a blowout. Happening again i.e. as in a WW gushing while we wait for a RW. It's been pointed out in many of the posts by the pro's why this fix has many flaws. This is one example of the lay persons view and thought process being corrected by the comments by the pros here at TOD. I accept this and have no desire to paint gloom and doom to support my theory. It's simple as education, experience and emphirical evidence/application over hypothesis. There is no logical need for the gloom/doom scare tactics.

I'm not sure if you understand me, do you? I didn't indirectly suggest anything. It was direct and your tactic as is DougR's is to ignore and deflect comments, facts or descrepancies in your logic. The problem with your inductive or deductive reasoning is your purpose is to make everything wrong, bad, faulty or catastrophic and therin lies the fallacy of what you state you are doing. You have chosen (conscious or unconscious) to overlook the good.

I never said the BOP wasn't leaning. In another post I stated the BOP was probably bent. I don't think the BOP is bent (possible, yes) but my intent was to reference the riser from the well head to the BOP. I was addressing the weight of the riser from the flex joint to the DWH drill rig and commenting on the force that was applied to the BOP when the DWH collapsed. The riser weighted approx. 290K tons and I don't know how much weight the flotation device supports but the BOP was subjected to extreme force when the riser collapsed and bent over. My point was to address the structural integrity of the BOP and how it's manufactured.

In regards to your comment that no one is hurt if you are wrong, you are again incorrect. You have no way of knowing the additional stress you may have placed on someone by your gloom and doom comments. Unfortunately this is the world we live in. The desire to know and be present is understandable but to take misinformation present it as factual is simply wrong.

It is both a sound and valid argument to say that if the lean had increased to x degrees and on another day it has increased y degrees that the BOP is falling. So yes I do offer the parts to fit my theory, parts that make my argument both sound and valid.

An increase on the bullseye is a decrease in perpendicularity which clearly is defined as falling.

In fact the term "Fall" could be used and it would still be sound and valid.

It would not be sound to say that the change in the bullseye measurement means the BOP will fall over because that implies that falling MUST lead to a "fall over"

None of this would be happening if we'd fought back and stopped them from poisoning us with all that fluoride in our water.

Help! Where am I? Not everyone, but quite a few folks here are making me feel like I've been dropped from an alien space ship into the middle of a Kos flame war. Can't we agree or disagree without calling each other names?

In the weeks that I have been watching the ROVs work, I have seen 4 separate bulls eyes.

Two are at the base.

The other two are attached higher up. Here's a diagram that shows where they are, one attached to the riser pipe, above the flex joint, the other attached to the top of the BOP. (Click on the image for larger size)

I have indicated the ball positions with a red dot, and will be happy to post the original video clips if requested.

Here were the positions of the top two bulls eyes on June 15.

I see very little difference.

The top bulls eye appears to be connected to the actuator assembly on the (presumably) EDS system attached to the part of the flexjoint that is supposed to move. Your arrow points to the top of the body of the flexjoint that is not supposed to move. Move the head of the arrow up about half way to the inlaid image of the ball for the correct position.

NAOM

Yeah, NAOM is right, aethervox. The upper bullseye is the narrow horizontal rectangle in the drawing just above the tip of your upper arrow. Thank you both for your clear thinking.

Where you say you see little difference

I clearly see an increase of over 1.5 +/- .25 degrees on the Bullseye labeled BELOW the FlexJoint.

June 15th - Lets call it 1.25

June 28th - Lets call it 2.75

Also... Are you sure the Top Bullseye is the same?

I can't make out the ROV coordinates but it appears that they clearly don't match up.

The thing that caught my eye is the your June 28th "Top" Bullseye has the ball to the right of the line while the June 15th "TOP" bullseye is to the left of the line.

Keep in mind, Alex, that the top bullseye is on a part that moves every time the LMRP cap shifts.

We can go back and forth about the top bullseye being able to move.

Here is the middle bullseye, from the 15th and the 28th, side by side below the flex joint which show a 1.5 degree increase in lean.

These are the OP's grabs and there is a clear difference.

Again, Alex, you've got me confused with someone else. I haven't made any comments on red dots or metal balls. I was just trying to clear up confusion over the location of the top bullseye.

NP!

This is the last I will post on this subject.

Thank you for pointing that out. I'll amend that drawing.

Unless you know exactly what angle the ROV camera was shooting at in relation to the top of the bulls eye, as well as the spherical distortion of the lens the ROV camera is equipped with, I would not say, with any authority, that there is a clear difference. There may be a one degree difference, and I will keep watching for video of the bullseyes, as well as going back over the many gigabytes of ROV feed I have recorded, so I can get more data points to compare the images over time.

Also, credit, and a link to the photobucket page, for any of my photos and diagrams that you have posted or will post in your blog would be appreciated.

It would be appreciated. I am only after the truth.

I do disagree with the angle argument. That would not move the ball an entire line.

As far as the image, it is linked currently to the photo bucket image on my blog.

If you provide the page url you would like it linked to I will update the image on my blog to the corrected diagram and the page.

Also, you stated you would provide the original video upon request.

I would like it so I can get the original readings, specifically I would like the middle bullseye reading with out the red dot... but would like to post both videos on my blog.

Could you upload them to YouTube?

blog-blog-utube?

Lets take odds on how this turns out....

(edit) perhaps there was a silver lining to DougR's post with UC reading TOD and seeing it as a credible medium to address issues and concerns.

I would have liked a question about location, cementing, and any significance of the previous stuck and abandoned segment of drill pipe. Apparently the well was then sidetracked around that, and continued drilling downwards. That was mentioned here:

http://www.theoildrum.com/node/6579

See the word "abandoned"

(Note: That would be an entirely different section than the pipe remaining in the hole circulating out mud at the time of the accident; presumably the newer, replacement string is the only one now in the BOP package now.)

Shelburn asked for questions to pass along to BP. At this point, it is academic, but I am really curious about the phase composition of the flow. As I mentioned in some of my earliest posts, it is likely that at the reservoir pressure (I've been using 12,000 psi; can they provide better info?) that this reservoir contains a supercritical solution of gas/oil, as a single phase. So one question is:

What was the reservoir temperature and pressure measured before the blow-out?

Most of my other questions would be answered by the BOP pressure/temperature history that Shelburn requested. However, I'm assuming that deep inside BP, there are folks who were hip to the significance of supercritical solutions from the very first; they may in fact know the answer to this one:

At the beginning of the blowout, when flow rates were low enough that most of the pressure drop was due to adiabatic expansion up the drillpipe to the BOP, was the material reaching the BOP still a single phase, or had it phase separated in going from 12000 psi at the reservoir to ~8500 psi behind the BOP?

roger -- BP did get a wireline measurement (MDT) of reservoir pressure. Thatyielded 11,900 psi which is equivalent to 12.6 ppg mud weight. Not sure but I think i recall 185 degrees BH temp. But hopefully some one can offer the link to a BP site that has a good bit of this tech data posted. havne't seen any bubble point data but I suspect all the NG is in solution at reservoir conditions. I've seen NG concentration of 2,000 - 3,000 cu ft per bbl. Just a semi-educated guess but I suspect much of the NG is breaking out of solution by the time it reaches the well head.

Rockman: Look at the bottom of the casing schematic: 262 deg F

Good job FE...wasn't really trusting my old memory.

Thanks RM & FE. That (262F) temperature is consistent with the abnormally low reservoir temperatures seen throughout the gulf, and quite credible. It is also consistent with the 175F temperature I saw for behind the BOP inn early May. In principle, one can use data from the lab to find out whether there is a phase separation going up the drillpipe from the reservoir to the BOP...I suspect it was staying miscible at first, but at some point became two-phase flow.

Hi RR,

To add to the confusion I've also seen a credible 210 F stated on a wellbore schematic in a Halliburton presentation to the Energy and Commerce Committee on June 3rd.

A GOR of 2000 scf/stb and an oil API of around 38 together with a separator gas gravity of 0.78 suggest a border-line volatile oil to me (ie liquid phase in the reservoir with reservoir temperature to the left of the critical temperature of the fluid mixture).

Simple industry correlations suggest bubble point perhaps in the range 6000 - 8000 psi. At flowing pressures at the well head of 4400 psi or less, you would thus expect the gas to start breaking out some distance below the BOP.

Very good of Tech. Sgt. Lloyd and the UC to have responded (and to have recognized the excellent opportunity TOD presents to them).

If I had press credentials, my question might involve their replacement-cap options:

"Please discuss how you have chosen or will choose which new cap to try first-second-third; if you have made that call, what factors played into it? if you haven't, what don't you know yet that you need to know to decide? Thanks."

I think it was very considerate of UC and BP to push Tech. Sgt Loyd out front as shark bait. I'm guessing the Sgt. was the communcations correspondent. I think they missed an important PR moment. Answering NO in the positive to the questions they chose to answer and ignoring the remaing questions without as much as; we are uncertain, we don't know or we will follow up and respond later sheds a poor light on the questions they did answer. Answering, "What is the black box the ROV's place against the BOP" would have shown more credibility. Maybe they thought it was TMI but given that it's been a regular procedure I don't think it's purpose is ROV operator training. Given they answered at all says they are paying attention.

I think overshot is next up and it's should be ready soon. All the prior collection methods were stall tactics/kneejerk while waiting for processing capacity topside. Disaster prepairdness requires training and preparation and BP did neither. I don't think the USCG can crow loudly in this area either.

You with a press pass? You're kidding right! and I'm grinning.

All the prior collection methods were stall tactics/kneejerk while waiting for processing capacity topside.

it can be viewed as stalling tactic or interim solution. All these things we see on the sea floor and production capability take time to fabricate and logistic of moving stuff around also take time. I think a big part of the problem is that BP initial response miscalcualte the size of the spill and the impact (same for the UC initial response). Onc e they are behind, the only option they have is to catch up. Remember the first tophat, they had to reuse the cap from was used in a different well before. Now you have 4 or 5 different engineered top hat on the sea floor.

I'm familiar with the time involved in weldments. My stall/kneejerk comment was based on the fact that if nothing was done while welding was completed on the proper containment vessel then the screech would still be echoing. Yes I agree interim solution is another way to express the events. I would classify it as exceptionally poor planning. If the overshot weldment was sitting on the dock when the blowout occured they couldn't use it because there wasn't a vessel to process or store the oil. They needed to do something to pacify the public and media. Under estimating the flow was/is minor compared to BP's remaining screw ups. I am a layperson when it comes to this (oil) industry. That isn't necessarily true when dealing with the mechanics i.e. pipe, pipe connections, welding, pressure, pressure vessels etc.

To date nothing has been done by the oil industry, USCG or the federal government to prepare for a disaster like this. I seem to remember the last time La. and the gulf states had a disaster the comment was "let us know what you need after it's over/happened."

To date nothing has been done by the oil industry, USCG or the federal government to prepare for a disaster like this

yes, 100% agreed. But who has the foresight to see how big this oil spill can be? It is the same as asking someone to foresee the impact of 9/11 or earthquake in the bay area that collapse the bay bridge or ... You can fill in the blank on things that some government agencies or industry or individual seem to be ill prepared for.. The fact is that we cannot prepare 100% for any and all potential threat.. I am pretty sure one of the change after this spill is the spill response plan. Another change will be the safety protocol. May be some of the steps are mandatory now (circulating mud before cmt job, watch mud return etc. etc.).

Well, at least we got a little dialogue started now. Here's to more-n-better.

You with a press pass? [etc., etc.]

I do not keed. Almost majored in journalism and have palled-around with many local and a few national journos ever since. Heck yeah, I coulda been a contendah . . . if only I could write with a reliably-straight face a little more often than "rarely."

"An internal BP “worst-case scenario” document released June 20 has been mis-interpreted by some to indicate that the company believes that flow rates as high as 100,000 bopd are possible."

What is BP's answer to what is on the whiteboard at 6:43? At 6:35 you hear someone use these same figures.

The video is from NOAA

http://blog.al.com/live/2010/05/video_shows_federal_officials.html

What effect does the blowing up, burning, sinking of the DWH drill platform and the subsequent jerking around on the attached riser have on the BOP, well head, casing, etc?????

It has effects of deforming and stressing the structure. How many telephone poles have you seen break off a month after a truck hits it. Absolutely it is possible, but out of a million times trying it would stay up longer or fall sooner maybe 990,000 times.

Apples and oranges Tin

Better analogy might be taking a wire coat hanger. How many times and you bend it before it breaks?

Or a muffler. How long will the muffler last after losing a hanger clamp...oh, and the muffler is leaking?

Maybe there are better analogies but the point is we should not be dismissive about the extent of the damage.

No and we should not, but my example gave a .01% chance and that is fairly significant to me. To me a 10% chance would not change anything from wait and see until relief well with containment and cleanup going full guns.

hello...stressed out resident here. won't anybody answer on the nuke power plants closing along the coast due to oil (crystal river)? also to bring up another question we have down here...my son/daughter-in-law are respiratory therapists at largest tampa hospital, they are woefully understaffed and struggling daily to take care of the usual problems. it will be pandemonium! will bp pay for additional medical staff if needed?

BP:

what are your plans to keep oil from further DESECRATING FLORIDA BEACHES

BP:

what are your plans to measure the PLUMES, WHICH EVERYONE KNOWS EXISTS, in order to track and deal with? we don't want them dispersed - we want them taken out of the water!

BP:

what are your plans to implement a decent and moral response to the american people? we do not want to see your tv/newspaper advertising, we do not care what face you put in front of the limited cameras, we do not want to see you on GOOGLE, we do not need your FAKE talking heads telling us what a tremendous job you are doing, we do not want to see you make fools of yourselves (and try to make fools of US)every single time you start talking! i would like to meet the person who thought WALRUSES LIVED IN THE GULF OF MEXICO.

BP is evil. There is no doubt. Nervousfromflorida it is up to the locals to help themselves. Work with your local officials and keep in touch with backup information sources like TOD. I will give you as much lead time as possible. I think by virtue of location, I may be on the edge of the sword here. If I hit the OH CRAP button, my first push will be here. So far, I have not turned the key that opens the door in front of the button.

THANK YOU FOR THAT!

To add to the chain of comments.

I just drive right on by the BP filling stations.

Its the right of the consumer to vote with his pocket book and I am most certainly going to do so. For the rest of my life as well.

Are you reading this BP? Or the BP shill in the crowd?

Passingby...means I pass them by

Its the right of the consumer to vote with his pocket book and I am most certainly going to do so. For the rest of my life as well.

And you will hurt BP but not filling your car with BP gas? Errrr... Do you know that most BP stations are not owned by BP but by independent business man who has nothing to do with the spill, the spill response and certain know nothing about deepsea drilling.. All you are hurting are your fellow neighbor who want to make a living...

Fruitcake,

Are you trying to tell me the big BP sign at the filling station has nothing to do with BP?

Its my choice to make and make it I shall and your observations will not deter me, and I hope many others, from voting with their conscience and their pocketbook.

Its come to the point that this is about all the freedom I have. What I purchase.

My small quiet voice protesting on a backwater website has zero effect on BP. My purchases will at least have some slight effect. Its all I can do to protest but protest I shall.

What is the name of YOUR GAME? To chasten those who would do such?

I would like to ask BP for the geology of the well and reservoir. And the question about pressure and temperature of the reservoir is a good one.

"...geology of the well and reservoir...

A couple of weeks ago I had questions on this subject that didn't get fully answered although my math was vetted and seems to be ok.

The Initial Exploration Plan submitted March 2009 stated that "conditions at the proposed drilling location have been evaluated on the basis of a regional shallow hazards survey and study conducted by KC Offshore in 1998....a shallow hazards report for MC252 AND MC296 produced by Fugro GeoServices, Inc in 2003; mapping performed internally in 2008 and 2009 by BP America...using a merged data volume (mosaic) reprocessed by TGS in 2004...site specific Shallow Hazards and Archeological assessment produced by CC Tecnologies..."

The document goes on to state that "the proposed wellbore will not intersect any faults between the seafloor and the depth of the the limit of this investigation at Horizon 6 or 5,328' below bml..." The depth to seafloor is give as 4992'.

The request to set plugs refers to resistivity bridging over at 12900'. 4992+5328+1000(mud, per TOD)=11320. MMS asked if there were any hydrocarbon bearing zones below 12900' in email of 3/10/10.

Do these facts mean that the geological data at the time of the well failure were only good to the 5328'bml? Did BP accumulate data as the well went past the limit approved? Why did MMS have to ask if there were "hydrocarbon bearing zones below 12900" if data had been submitted? Was that just a pro-forma question asked as part of a standard protocol? Does approval have to be granted for drilling to be implemented below the limits set by the initial plan? If so, it seems as though these documents altering the original site clearance narratives would have been examined during the hearings and made public.

If the well had gone wildcat, and this is a common industry practice in deepwater and ultra-deepwater drilling,that issue needs to be examined further as a regulation issue.

The initial exploration plan is available at www.gomr.mms.gov/PI/PDFImages/PLANS/29/29977.pdf and also at

http://www.scribd.com/doc/33620729/BP-Initial-Exploration-Plan-MC-252-29977

k3 -- the shallow hazard survey is one data set. It's used to determine what problems might exist before the drill permit is granted. This info is rather broad in character and thus doesn't provide great detail about the geology. But as BP drilled the well they acquired much more detailed info about the geology from logging info (wireline logs, log while drilling and mud logging). It's not so much that the MMS had to ask about hydrocarbon presence. The regs require BP to report any and all indications of hydrocarbons. Their presence determines how a well must be sealed. Yes...drill permits are depth specific. Drilling deeper requires supplemental approval.

Not sure what you mean by "going wild cat". Perhaps you mean changing the proposed TD of a well. The BP well was a wild cat (exploratory) well the day it started drilling.

Thanks, Rockman. I've been mulling over your answer since yesterday.

I’ve been thinking about what you said since you answered. In the last relief well thread, a figure of 18000’ for the total well depth was given. I’ll stipulate that 18000’ means below sea level and not mud line and will stand corrected if I am in error. That means they drilled 6680’ past approval level. Without permission. Or with permission but without the public knowing. Of course if the 18000’ figure is bml, we can add the 4992’. And the collapse was at 12900' and they were way past that when Macondo let go.

I think I’ve established I’m not a BP apologist, but I do not understand why the first question from the MSM, MMS and Congress was not “What the HELL were you doing down there?!!!” That absence of inquiry speaks volumes. All the people who were involved in DWH and who may be running similar scams need to 'fess up on currently accepted operating procedures. Based on the discussion of BOP failure rates in another thread, it appears that while BOP failure is a factor, the prime cause of the widespread and continuing death and destruction was going down there knowing the outcome of failure. I've been slow on the uptake with all this because it's mind boggling. I still can't believe what I think I see, which is why this is written at 5:49 AM.

BTW, I used wildcat in the sense of exploratory. I thought they knew what they were after when they went down there and were willing to take the risks associated with that local formation. Didn’t pay off too well, did it?

What makes anyone think BP would answer technical questions honestly that would have an adverse affect on their stock price? Seems kind of naive to me.

For details see the CEO of Bear Sterns before their collapse denying "illegitimate" rumors...

http://www.realscoop.com/content/ceo-bear-stearns-firms-collapse/

Of course they have to answer honestly ... if they give an answer.

However if they don't bother answering then you are stuck.

What planet are you living on? Hafle lied and dissembled under oath.

Art has done a great job of characterizing the flow rates of GOM. I've never seen such a comprehensive view before. But we also need to understand a unique distinction from historical flow rates vs. the BP well. The flow rate of any GOM was determined by two prime factors: its actual physical capability and self imposed limits set by the operator. Wells are seldom produced at their max capability for a variety of reason. But the underlying protocol is to not damage the reservoir or destroy the completion. Excessive rates can easily do either. A GOM well that has been produced at 40,000 bopd could have been able to flow at twice or more that rate if there were no concern about damage.

BP released a statement that they anticipated their well would produce at a rate of 15,000 - 20,000 bopd. That would be their max rate that would allow a stable completion. But such a zone could easily flow twice that rate or more if damage was not a potential problem. This is what makes the blow out so unique. It equates to what we would call an "open hole completion". A typical completion would have solid cmt covering the reservoir which in turn would be sealed by steel csg. Then a limited number of small (1") holes would be shot thru the csg/cmt. Anywhere from 6 to 12 such holes per foot is common. BP didn't indicate how many shots they would have used to achieve the estimated flow rate bit let's assume they would shoot the entire 60' thick zone at 12 shots per foot. Thus the 15 - 20,000 bopd would have come from 720 one inch holes. That would represent about 600 sq inches of flow channels. Or about 4 sq ft.

The original well bore had a 10" diameter. If you assume the hole hasn't enlarged beyond that initial diameter than the total area open to flow from the reservoir is around 150 sq ft. Or almost 40 times greater than would be open to a convention completion as described above. This greatly increased area is why open hole completions are made: to max flow capability in reservoirs with relatively low flow capabilities. Obviously the BP reservoir isn't such an animal. No engineer would ever propose opening up that much of such a reservoir nor attempt such high flow rates. But that's the very odd nature of the BP blow out: it's a cased hole. That adds great stability to the well bore unlike a typical open hole blow out. An open hole blow out flowing as this one is might have bridged over and killed itself long before now. In essence it about the worst case scenario one could dream up IMHO.

Rockman makes an important observation about reservoir management and constrained flow rates. Looking at the highest flow rate wells in the GoM, it is clear that rates increase and decrease during the first several months suggesting that engineers are attempting to determine optimal flow rates.

On average, however, in the first 6 months of production in these highest rate wells, monthly decline is about 15%. This means that, assuming the BP DWH well was initially flowing at 60,000 bopd its rate for Month 3 (that we are now in) should be in the mid-40's.

Yes indeed. An interesting article but I'm afraid that statistics for observed production well rates are not a good analogue for the flow potential of this wild well flowing up large tubulars.

This probably reveals severe intellectual limitation on my part, but the following statement is unintelligible to me:

"A typical completion would have solid cmt covering the reservoir which in turn would be sealed by steel csg. Then a limited number of small (1") holes would be shot thru the csg/cmt. Anywhere from 6 to 12 such holes per foot is common. BP didn't indicate how many shots they would have used to achieve the estimated flow rate bit let's assume they would shoot the entire 60' thick zone at 12 shots per foot. Thus the 15 - 20,000 bopd would have come from 720 one inch holes. That would represent about 600 sq inches of flow channels. Or about 4 sq ft."

I can envisage a vertical hole intercepting a horizontal reservoir. But I am not sure how to envisage "cmt covering the reservoir" and "sealed by steel casing." As I understand it, cement has been squeezed out of the end of the hole, but then what? Does the cement form a glob filling the space between the top and the bottom of the reservoir, or what? And then how is this glob of cement "sealed by steel csg."? Is a hole drilled through the cement and then the hole lined with csg.? If so, I can see shooting holes horizontally through the casing into the reservoir. But if that is not it, I am lost.

Any clarification would be appreciated.

I had the some of the same thoughts as Lucretius. I was thinking before replying so as not to ask too obvious a question. What the hell...

Visualizing this, following the description in the last paragraph, the 10" well bore casing is poking in to the reservoir a distance of 60 feet, and doing the math that gives 157 feet of surface area (the inside of the cylindrical pipe). But to get flow from those 157 square feet wouldn't there have to be holes punched through virtually every square inch of the cylinder? Without any holes punched for production the largest cross sectional area such a casing could present to the reservoir would be the 10 inch bore, assuming it was completely open at the end, or some constricted section of it. That 10 inch bore is one half a square foot. So rather than getting an evenly distributed flow of fluid and gas across a 60 foot path, this well is getting all the flow from a single point or area of the pipe.

I take it then that distributing the uptake of fluid and gas across a larger area of the reservoir improves the character of the delivery and the life of the well. But isn't the maximum delivery possible a function of the 10 inch pipe, so long as it remains structurally complete?

Hi Luc, HK,

A little misleading I fear.

The simplest way of completing a reservoir is not to set a final casing at all; the naked wall of the wellbore is open (an open hole or 'barefoot' completion) and reservoir fluids flow into the well and up the rest of the production string to surface. This is very rarely done for reasons I can explain if needed.

Much more common is to set a final casing string across the reservoir section. You are right, as it stands there is no way for the fluid to flow into and up the well since the casing is cemented in place and has a cement plug at the bottom left over from the cementing process.

For this reason the casing is perforated using shaped charges with a particular shot density as noted by RM. The holes created are very small (like the diameter of a pencil) but the charge punches a tunnel 20 inches or more into the reservoir rock. A perforated completion in a sandstone reservoir can in principle perform just as well or better than a completely naked wellbore; believe it or not, in a well designed job there is no additional pressure drop at the wellbore due to flow into the tunnels and through the small holes in the casing. (A common concept in the industry is 'skin' which describes this additional pressure drop, and skin values of zero are not uncommon).

Part of the reason that the Macondo well rate is high compared to the production well rates listed in the article above is that production wells are generally designed to flow up a production tubing which is set inside the production casing. You would never flow up the casing itself, or its annulus. Production tubings generally have a smaller id and create a larger frictional pressure drop for the fluids on their long journey to surface.

An example would be the Thunder Horse completions which are I believe designed for max flow rates around 50,000 b/d using <6 inch production tubings. A handy diagram is here :

http://www.bp.com/popupimage.do?img_path=liveassets/bp_internet/globalbp...

Thanks! I understand about the delivery in production being done through smaller tubing. I was thinking from the perspective of the present, as Rockman described it, and in the context of off the chart suggestions from the fringe that the volume could be 100K bpd. Yes, lots of these details are covered in other TOD posts and I have read many, not all. It's a handy conceit to imagine one could grasp all the concepts and understand what is going on simply by reading. It's what's available.

hk -- I don't have the charts here but you can put 100's of thousands of bbl of oil thru a 10" pipe if the pressure is high enough.

Lucre, With a little searching thru previous TOD posts you can find detailed info to your question. But for now, Think vertical, the cement (cmt) surrounds the casing vertically from a pre determined depth down thru the oil producing zone. this forms a seal/ bond with the surrounding rock and anchors the casing in place.

When the well is ready to start production, the casing (and cmt) is 'perforated' (horizontally) using shaped explosive charges @ the above mentioned 6-12 holes per ft. thru the zone to start the well flowing,

Hope this helps some.

Cheers

I believe the reason to spread the flow through pipe wall perforations is to protect the fragile surrounding porous rock from fracturing, and to spread the flow over a range of vertical layers; I assume the permeability of the rock is higher horizontally than vertically, in most cases.

Here you go L. We’ll go step by step. The reservoir is relatively flat and 60’ thick. The drill bit cuts a vertical hole about one foot in diameter. The drill pipe is removed and steel casing with a 10” diameter is run thru the reservoir to the bottom of the hole. They then run the drill pipe to the bottom of the hole and start pumping cmt which goes up the space (annulus) between the csg and the reservoir. A cork (packer) around the drill pipe stops the cmt from going up the inside of the casing. So now going from the center of the production csg outward you have the steel csg and then the cmt and then the reservoir. After the cmt hardens they can do a “conventional” completion: they send a perforating gun down the csg on wire line. The shape charges in the perf gun blows those 1” holes thru the steel casing, the cement and into the reservoir. The cmt isolates the reservoir from other rocks exposed in the annulus. Then they can flow just the reservoir contents up the csg.

In the BP well, at the moment, it looks like the cmt didn’t harden properly before BP removed the heavy drill mud from the csg. The reservoir pressure (11,900 psi) pushed the wet cmt back down the annulus with the oil/NN following it. Thus the entire section of the reservoir is flowing down the annulus and back up the csg. This is the 150 sq ft. Compare this area to the 4 sq ft of reservoir that would have been open to flow as I described in my conventional completion model.

So the cement is gone, pushed out of the way into the surrounding rock? That's the missing piece. I get it. Thanks

Rock,

Cool. Thanks.

Thanks to Gail for the excellent lead articles. I hope a lot of people in the media will read them.

It is easy, when you have lots of folks with knowledge willing to write them.

More questions for unified command:

RE: riser segment that was cut from he top of the BOP.

1) In an image taken by a ROV, there was a figure-8 object visible in the riser. Was that two pieces of drill pipe, or a single crushed segment of liner?

2) If it was drill pipe, is there a theory to explain why it appears there are two segments side-by side?

3) If it was liner, where is the drill pipe, and how much of the liner was ejected though the BOP?

A related question ...

after the riser was cut off and before the containment cap was placed on the LMRP/BOP, it appeared that two distinct flows were coming out - different in apparent color and density. What paths do you think the flows were taking? through the drill pipe? the annulus? a liner?

Some time ago a reporter asked Kent Wells what was in the riser... drill pipe? crushed liner? etc and he replied that he didn't know but was curious to find out. It seems that no reporter has asked the obvious followup question now that the kinked segment of riser has been raised. I know it has been taken to NO for the ongoing investigation, but I find it hard to believe that no one on the lifting vessel took a look inside.

And, fwiw, shortly after the Q4000 began flaring oil & gas, Wells said that he estimated the flow to be around 35,000 bopd. First and only time I've heard a BP guy actually volunteer a flow number estimate.

i would like to throw a few questions towards the TOD question pool...

1- I can understand the particular mechanical setup used in this well was aimed primarily at increasing the longevity of the well but then why include rupture disks in the setup.( both are conflicting decisions )

2- the particular rupture disks used here -- at what pressure were the disks to activate and bleed pressure

3- the BOP pressure history

4- pressure readings during top kill and the top kill attempt after pumping the bridging agents (a significant divergence in both can help get an idea of downhole conditions)

5- the caliper log ....i understand it won't be released in its entirety ....but maybe they can tell us the avg dia for the last section or more importantly the last 500'

6- the sand cut of the fluid being produced topside.

7- how big is the concern with integrity around the csg hangers

8- they ran an approach on this well where mudcake is used to provide structural support at the wellface before cementing (not the best of approaches at best and most operators won't use this but given the problems they ran into in the last section maybe a justification can be made considering the dia in the last section)...did they run a under reamer prior to cementing and what did the return indicate at that point.

9- there was a significant event around 17500' +/- . A little detail of this would be nice