Deepwater Oil Spill - Sealing the Cap and Jet Pumps - and Open Thread

Posted by Heading Out on June 5, 2010 - 9:00am

There has not been much change down on the sea bed where Thursday evening BP were able to put a cap onto the short riser section coming out of the Lower Riser Assembly (LRA) that sits on the Blowout Preventer (BOP) at the top of the well. I have looked in a variety of places for information on steps forward, and did discover that there is a second assembly above the cap, that I had seen, but had not been able to recognize until watching the video on capping available at the Deepwater Response site. It is here that the methanol is sent down to the cap to make sure that no crystals form within the cap. So for those who wish to keep the right names for the right parts, take note. UPDATE: I have added a request to the end of this post.

And given that I was calling the cap the 7th generation LMRP when it was (as the big 4 on the side of the yellow structure showed) neither, means I need to take my own message to heart. In this post I am going to talk about the seal under the cap.

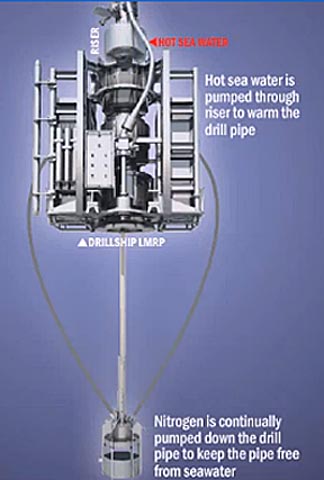

There are four ports on the top of the cap, that continue to allow the oil that is flowing into the cap to flow back out while the cap was initially positioned, and to reduce the flow according to BP's plans, until the system has been checked out to ensure there are no unforeseen problems. BP only slowly raised the flow rate up the pipe when they first started using the Riser Insertion Tool (RIT) starting out with a flow of around 1,000 barrels/day and then ramping it up, at the time reporting that flow ramped up first to 2,000 bd and then up to 4,000 bd. However they later rescinded the latter number and dropped the maximum flow level to around 2,200 barrels a day. Oil and gas have started flowing up to the drillship at the top of the riser where the oil is separated and stored, and the gas is being flared. (This was taken during the flare from the RIT operation).

However the flow out of the RIT was monitored, and higher rates have now been reported.

On May 25, 2010, at approximately 17:30 CDT, the RITT logged oil collection at a rate of 8,000 barrels of oil per day, as measured by a meter whose calibration was verified by a third-party. Based on observations of the riser, the team estimated that at least 10% of the flow was not being captured by the riser at the time oil collection was logged, increasing the estimate of total flow to 8,800 barrels of oil per day. Factoring in the flow from the kink in the riser, the RITTI Team calculated that the lower bound estimate of the total oil flow is at least 11,000 barrels of oil per day, depending on whether the flow through the kink is primarily gas or oil.With the full flow now being emitted through the single confluence of the riser and BP flows at the top of the remaining riser section on the BOP, a full estimate of the leak will, no doubt, not be long in being announced.

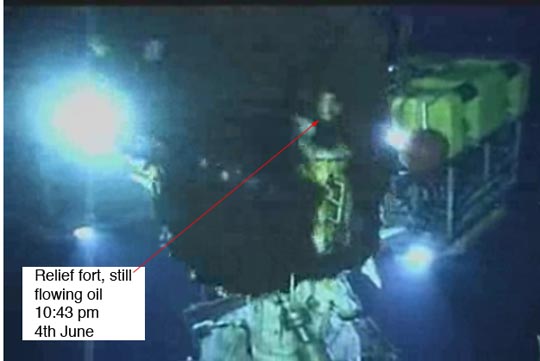

The high volume of flow means that there needs to be cautious progress in capturing all the oil and gas and sending it up the DP. However there is still a little communications conflict, since there were some reports that the taps bypassing the oil/gas would be closed later today, however at 10:43 pm the Enterprise ROV 2 was still showing an open port.

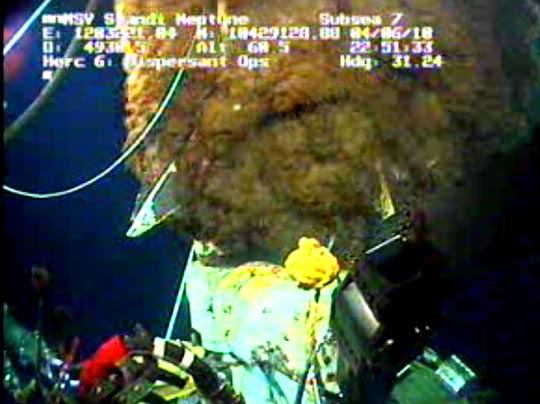

Oil was also leaking out of the bottom of the cap, which is, even when almost all the oil is being recovered, likely to be a good thing in small quantities, somewhat less than this.

Why is this? Well the way in which the Shear was used to cut the end of the riser and DP means that it is likely to be impossible at the present time to get a good strong seal around the chamber between the flow into the cap from the BOP and that out into the DP up to the LMRP.

When a stream enters a chamber through one port, and exits through another, both of relatively small size, then the jet will create a vacuum in the chamber, which pulls fluid from the surroundings into the chamber and carries it, with the jet fluid into the second port. I am going to embed a short video of a commercial down-hole video and am not endorsing anything but the animation shows you how the jet pump works. (And the flow in the Gulf is easier than that shown here ).

The reason that it is critical in this operation is that the fluid outside the cap is seawater. If the jet pumping action were to become too efficient as all the oil flowed from one passage to the other, then the “jet pump effect” would draw cold seawater into the chamber and the problem of hydrate generation and blocking of the flow path would be back to block the cap, as it did top hat. By not getting all the flow into the second pipe it should be possible to drop the suction in the chamber to the point that a little oil still leaks out (treated with dispersants) but the majority goes up the well. Getting this right should prove an interesting exercise. (But isn’t calculating this what the “best and the brightest” – Dr. Chu’s team - are there to do?) And it is not nearly as simple as it might at first appear, being able to capture almost all the oil, without getting the jet pump effect bringing in the seawater that would stop the flow.

Flow control is achieved, simplistically, with a valve at the top of the riser on the Enterprise. By adjusting the flow the valve effectively controls the pressure at the top of the riser and thus also at the bottom.

Incidentally in other circumstances jet pumps are neat tools. One of my students developed a high pressure one for use in lifting high-level radioactive waste out of nuclear waste storage tanks (you want to minimize water use, and do this by upping the driving jet pressure). Worked like a charm, when used in the real tanks. They are also used as remote inexpensive pumps in mines, lying in depressions where water can collect. The water collects, a float valve lifts and the jet flows, sucking the water away. As the water disappears, the float drops and the jet switches off.

Oh, and for those who have ideas on how to deal with any part of this problem, the Government is stepping up the ways in which you can get funding. The process goes through the Federal Business Opportunities Webpage where there is a Broad Agency Announcement on the subject. It would be more fruitful to contact them.

UPDATE:BP are slowly increasing the amount of oil taken up the drill pipe from the cap on the BOP. They have announced that they will give an update on the daily flows measured.

BP announced plans to provide a daily morning update on how much crude is being collected by their oil drillship Enterprise as the oil company struggles to contain the massive oil spill in the Gulf of Mexico.Although Toby and Bendal in comments have stated that BP have raised the flow rate up to the Enterprise to 6,000 bd, from the 1,000 bd initially ( which included 3 hours when the system was shut down) so far I can’t find a reference for this, so I would appreciate the help of readers in finding where these numbers are being posted so that I can make them available to the general readership, who often don’t read the comments.

Prof. Goose's comment:

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

bologgerian: I was cut off when I went to post this by the closing of comments on the previous post.

The worrying word here is: "Legitimate." Who defines it? BP? And what would be their motivation? Corporate survival? I can easily foresee forty years of litigation over that one word. And Hayward minimized the damages right from the start. BTW, I am not assuming they are dishonorable as officers of BP. Their highest duty as officers of the corporation is legally to their corporation. I'm just concerned they may have a conflicting interest with what's best for other people outside the corporation because of corporate survival; for instance, a conflict with the injured citizens of the GoM. The blow out raises an infinite number of conflicting values. Thank you for your responses.

"highest duty as officers of the corporation is legally to their corporation.

Well, what about morally, ethically? What about legal duties to the public - through laws and responsibilities?

I'm not really quibbling with your personal comments here. I am pointing to a wider problem within our society. Where we somehow have lost a sense of moral responsibility for one another. Where we believe that duty relates only to law. And even then, if one can skirt the law, it's become commonplace to do so.

Unless we return to a sense of common purpose - and I'm talking something which transcends national boundaries - we have become little more than squabblers over commodities or corporations or whatever can be weighed, measured, and stolen under the guise of "duty".

We have elevated corporations above the law and fostered a sense that it's ok for their officers to behave in ways that benefit an "entity" but harm society or the environment. There is something very insidious about this misguided acceptance of the "end" justifying the means. It's not better than the lame arguments put forth for why people were tortured for so-called "just ends".

You are right, but there is no objective way to determine legitimacy than through the legal system.

Not true at all.......

"legitimacy"

Has almost never been determined thru the legal industry. I would not give it the benefit of calling it a "system".

Only with Bombs, Bullets, or Blades, has "legitimacy" been established in the last 10,000 years. The "legal system" as you call it, is a joke beyound jokes in this day and age.

I say, take what is needed from BP, by whatever means, it's time to stand up to corporate criminals.

The life on this planet that cannot speak for themselves, deserve that those who do, have a backbone.

Look into the mirror and then go take a pill.

Wonder if he ever watched that movie Gangs of New York?

Now that was an interesting time to be living in.

break out the hatchets and knives, pitchforks and go for it

Can I presume legitimacy is determined by consensus inside a democracy?

My hope is that this international disaster, as well as ones in Nigeria, et al, will increase pressure for international ecological law, especially concerning global warming, pollution, starvation and then move to political stupidities like American, Israeli, Islamic, religious exceptionalism.

International democratic constitutional law is the only thing that will save a decent future for everyone, not just the pigs at the resource trough (some named above).

We long ago exceeded the useful parameters of the nation state, which doesn't scale globally.

In a sense don't we have an international ecological law now? Most of these companies are global in nature and can be held to the law of the country in violation, true?

That's not "international law" though, landrew. That's country by country law. International law would transcend countries as in the Universal Charter for Human Rights adopted by the UN. And the Geneva Conventions.

We need international laws for this ultimately, I would assert. And you're making a good point in addressing that.

"no (other?) objective way to determine legitimacy than through the legal system"

In the sweep of human history, war and survival have had a much greater impact on legitimacy than any system of law and law enforcement, IMHO.

I am not disagreeing with you. I'm just stating that since the East India Company was chartered in 1600 by Queen Elizabeth I of England that has been the standard of DUTY for corporate officer conduct. (For perspective, that was 176 years before the American Revolution.) To violate that duty as an officer, you would need to be brave enough to fall upon your own sword as the law stands today because the shareholders would strip you of all your worldly goods and toss you and your family out on the streets cold to start over with nothing. Find me a person willing to do that and you have not found me a corporate officer. "We" have condoned this concept of DUTY for 400 and 12 years. I am not defending this concept of duty. I am only talking about corporate reality today. The Resources War may change all this. But it ain't gonna be pretty.

I know you're not disagreeing with me. And thanks for helping me understand that there's a long history of "loyalty" only to company. And mind you, this is one I've debated with my own 93 year-old dad, a company-man through and through.

But still, should it not be instilled in all citizens that there are always higher duties, even ones for which one might pay a price? Martyrs have done so. Whistleblowers have done so. (And I speak as the spouse of a whistle-blower as well as having done so myself. Prices were paid. But a higher duty called.)

Actually in America corporations were originally highly restricted as result of the founding fathers' experience with the likes of the East India Company.

Jefferson and Madison's original bill of rights included an amendment blocking corporate expansion. It's provisions included:

Making it illegal for corporations to own other corporations

Making it illegal for corporations to give money to politicians or influence elections.

Placing time limits on corporate charters

Requiring corporations to demonstrate that they serve the public good to gain or renew a charter.

It didn't pass but such provisions were typically part of state laws.

American corporations didn't get the same rights to enforce contracts as citizens has until a Supreme Court decision in 1806.

They didn't get equal protection under the law (often called "personhood")until 1886 and Santa Clara County v. Southern Pacific RR. That decision maybe the most extreme case of judicial activism ever. Out of the blue corporations were given personhood by the court (sort of) in direct opposition to the intent of the founders. I say "sort of" because the decision doesn't give it to them- it is only done in the headnotes, and inaccurate summary written by a court reporter with close ties to the railroads. But judges read the headnotes and it came to permeate American law.

an earlier form of the corporation was the Limited - Ltd. in england... originally limited to a 40 year existence after which is was dissolved...

yes... we are nation of laws... but... as pointed out... since the late 1880's the laws have favored coproprations over the commons... ethics and morality are not admissable in court proceedings... and as we saw w/ exxon valdez judgement... a 500 MILLION verdict gets reduced to 5M...

corporations want the rights of people... but outlive people's individual resources esp. in terms of finance and lifespans... corporation can wait... litigate... and wait...

try getting a personal meeting with your elected representative in their office someday on ANY issue... i'm sure... BP's upper echelon's phone calls and letters get up the visibility chain far more often than individuals...

what's at the heart of the debate is... what is the TRUE cost of operating a corporation today??? corporations use common infrastructure... the water systems... the electric grid... the highway systems... the air and sea lanes... the courts... the interstate commerce protections... copyright and patents... intellectual property...

ALL of the commons - and yes the internet too - were created out of taxpayer funding directly or indirectly... NO corporation could build out it's own communications system... electric grid... or police infrastructure...

here's the litmus test... have ANY "free-market-milton friedman-ayn rand" ideologue - GO TO SOMALIA - and set up shop - there is NO government anything - after years of dumping radioactive and other waste into the waters off of somalia... the locals' way of life and survival was destroyed... now they pirate passing ships for ransom... they didn't just one day sit down and think it would be easier than fishing to start pirating ships for ransom...

the solution is simple... ALL corporate upper management and boards PERSONALLY sign for responsibility of their corporations' action on their watch...

OVERNIGHT... corporate behavior will change... the corporate structure is simply a method for those so talented and motivated to make lots of money in a short period of time... then get out... with wanton disregard for the consequences of the actions of the corporation in carrying out its "legal charter" of maximizing shareholder value...

squidd wrote:

here's the litmus test... have ANY "free-market-milton friedman-ayn rand" ideologue - GO TO SOMALIA

Neither Ayn Rand nor Milton Friedmand advocated anarchy. Both were advocates of a Constitutionally-limited government charged with protecting individual rights.

squidd also wrote:

the solution is simple... ALL corporate upper management and boards PERSONALLY sign for responsibility of their corporations' action on their watch...

If by this you mean personal FINANCIAL responsibility, you'll simply never find anyone willing to take such a position. BP, for instance, has 80,000 employees. No in their right mind is going to put their personal finances at the risk of the actions of 80,000 people they cannot possibly directly control or supervise. You simply won't be able to form corporations -- or accumulate any significant amounts of capital for a business venture -- under such constraints, which will mean the end of capitalism and a return to the standard of living we had in about, oh, say, the 1750s.

But you will indeed succeed in eliminating these kinds of accidents. And you can enjoy an oil-free Gulf of Mexico for your entire 35 - 40 year life span, if you can walk or ride a horse to get there.

dude - did not say "anarchy"... said "no government"... that's what ayn rand's "atlas shrugged" depicted... in the woods... with a babe on each arm... the corporatists lived in world without restriction... the trains ran on time... planes didn't crash... even greenspan admitted his befuddlement with wall street's not policing themselves... gee... that's difficult to understand...

there's another scenario... wise guy... (my 40 y lifespan)... wouldn't matter to you... 'cept maybe is your family had to live in niger delta a month or year or so... but i digress...

OK... "under such constraints"... NO constaints everyone... tell the white house to DISBAND the joint ops center in the gulf... coast guard... GO HOME... EVERY public employee currently on the GOM response... GO HOME...

we don't need no stinkin' "constraints"...

Mr. "Member for

1 week 2 hours "

says... ALL IS OK with capitalism... besides... that latest vander sloot gibberish is crawling it's way accross the screen now...

oh... and that dead planet circa 2050.... hey... george bush opined it best... "we'll all be dead"...

now there's a "standard of living" we can all look forward to for our children...

squidd wrote:

dude - did not say "anarchy"... said "no government"..that's what ayn rand's "atlas shrugged" depicted... .

Hed, dude, "anarchy" means "no government". And that is not what Rand depicted in Atlas Shrugged. At the end of the book, one of its central characters is drafting a Consitution for a new government.

The rest of your largely-incoherent rant is straw man fallacy, inasmuch as I never advocated zero government response to this disaster.

There are two novels that can change a bookish fourteen-year old's life: The Lord of The Rings and Atlas Shrugged. One is a childish fantasy that often engenders a lifelong obsession with its unbelievable heroes, leading to an emotionally stunted, socially crippled adulthood, unable to deal with THE real world. The other, OF course, involves orcs.

"There are two novels that can transform a bookish fourteen-year-old's life: The Lord of the Rings and Atlas Shrugged. One is a childish daydream that can lead to an emotionally stunted, socially crippled adulthood in which large parts of the day are spent inventing ways to make real life more like a fantasy novel. The other is a book about orcs." — John Rogers

The Limited designation in UK company law relates to limited liability

of the directors. If the company goes bankrupt the personal

property of the directors is not taken from them. A condition

of this protection is that account and other data must be

published. If you want to avoid publishing your accounts

you can form a private company but then you incur total liability.

squidd: Do you mean all business organizations should become partnerships at the Board level? Who would serve?

I will advocate that idea. And, who cares? If no one would take responsibility (a word highly valued but little understood by libertarian capitalists) then screw it, no business. OTOH, why not partnership at the shareholder level?:

The so called free market is anything but free. It exploits the masses for the benefit of just a few, by appropriating the commons (land, food, fuel, metals...) under the hubris of ownership. As if land can be owned.

In real time, the only thing that creates ownership is adding labor to the commons. Your clothing that you created, either by earning a token for trade or by sewing them, spinning them, etc., is your property because of the labor you added. Value is created only by labor, not by time and money. Financial institutions as presently constituted are fantasy island creations that do not create anything of value, and steal real value from others.

Stockholders should be held personally responsible for the costs inflicted on the environment and on society by the corporation. Corporations should be taxed in accordance with the diminution they create in the commons, and in the public weal.

I am so tired of hearing from so called conservatives who don't know from up...

And, government is supposed to provide a framework, including limits, on unfettered human nature. By aggregating the power of the many, government is able to control greed, averice, lust, etc., by either taxing or making legislative provisions to control the same. Without any limits, we see what happens from 2008; just as before the Great Depression the economy suffered from periodic extreme bouts of depression and the masses toiled in squalor. Yes, the U.S. had greater freedom and greater wealth than Europe, but that was because we expropriated the land of the native folks and gave it to the white settlers. Once the land had been given away, sold or placed into trusts, those freedoms and that wealth began to change. Today most of the wealth of the U.S. is owned or controlled by a very few - our own 'landed aristocracy.' We have become increasingly polarized due to this concentration of wealth in the hands of so few - one of the converging crises that I see growing today.

We have been brainwashed, you more than most, into believing that our 'way of life' is somehow sacred, and 'annointed by God.' It is not. When we began our experiment in the new world, we stole the land and property of its residence, who held it in common. To make matters worse, we murdered most of those natives, and took most of the rest into slavery (Spanish style). Then we stole the inhabitants of Africa and enslaved them, and stole their labor, appropriating the wealth created by the work the did. In 1865, we ended slavery of human beings as property, but continued wage slavery by appropriating the means of production, and enslaving workers. During this period of time, those workers had little say about wages, they lived in company towns and purchased their foodstuff and clothing and everything else at company stores. The value they created through their labor was mostly appropriated by the "owners."

Later, we discovered that we could use coal and oil to do the work, again expropriating the commons (the natural bounty of the Earth), and for a while we have had fossil fuels to exploit as our slaves. There has never been a true sense of human family, of commonality, since the advent of the corporation and before, during the age of fuedalism. Soon, oil and fossil fuels will be running out - perhaps not in your lifetime or mine, but in the lifetime of our children and grandchildren. At that time, you and your ilk no doubt will reinstate human slavery since that is the only way to obtain wealth for you - by stealing it from those who labor, since you provide no useful service to humanity.

Excuse the rant. I sometimes find human stupidity unbearable. Especially the hubris of the neo-cons and libertarians, in their self rightous, moralistic, effete snobbery.

Enjoy your wealth.

zaphod42 wrote:

Enjoy your wealth.

I plan to.

I feel so sorry for people like you. Your education aborted your rational faculty, and then your teachers filled the resulting vacuum between your ears with stale leftist talking points that were refuted in the prior century. On cue, you regurgitate said talking points with all the understanding that a parrot has of what it says.

"SNEER

I plan to.

I feel so sorry for people like you. Your education aborted your rational faculty, and then your teachers filled the resulting vacuum between your ears with stale leftist talking points that were refuted in the prior century. On cue, you regurgitate said talking points with all the understanding that a parrot has of what it says.

end SNEER"

There, I fixed that for you.

No, I am broke and out of work, things changed with the new administration

and now the thing with BP, seems to ensure that work will be very spotty at best for me over the next several years. The real shame of it all is I don't have that many more years that I will even be able to. Already had one back operation and had to change my working habits.

We were working on the house, but all that is stopped now. At least we managed to get the garage closed in before we had to stop, but the floor and the walls are still undone and the ceiling. No government checks here.

Hey, nice condensed course in realistic human political economy! (I put human in there because the Randistas keep forgetting we're not all John Galt)

I would just add that the expropriation of the commons has now moved to air and water, which is sort of threatening, and may be that last mistake the artistocracy cannot help but make.

Pitchforks is a-coming, there's hanging tonite!

(sung to the tune, appropriately, "Shrimp Boats is A-Coming)

I have to admit that the founding fathers had more vision than those who followed in many areas.

Ideally, you would have small to medium sized business only. The only larger entities would have to be CO-OPs. A co-op can be large enough to engage in activities requiring a larger size corporate entity, without the enticement to grow ad infinitum. A corporation that is owned by a limited number of shareholders (current common practice) tends to strive to grow without limits as this increases the return for each investor. It is not good for the consumer and society at large as it merely reduces competition, and increases the bureaucratic complexity and makes it basically as inefficient a a government entity without the same requirements for transparency.

A CO-OP, on the other hand, once it is large enough to accomplish it aims does not see an increase in payback with increase growth for its shareholders (a.k.a. employees) as the returns are divided among more employees. Indeed, excessive growth will result in higher administrative overheads which will reduce the net advantage to the members of the CO-OP. There is therefore an incentive of growth to a steady state, without the stakeholders feeling it is not doing well. As long as their products move, even without growth, they will feel their business is successful.

Compare this to the current paradigm, where a company that doesn't grow, sends the shares tumbling. It doesn't matter that the reason they don't grow anymore is that they are the only provider of their category left on the market (a sign of success if you ask me). The lack of growth itself will be perceived as bad. I believe CO-OPs are the way to go in a sustainable future.

The flow of history looks to move one way in this country and it will be just as difficult to reverse it as it would be to reverse the flow of the BP blow out in the GoM. 50 revenue hungry places to shop for a corporate charter.

We live in a society that operates by rule of law. There is a process which goes back 900 years to the Magna Carta which defines what that law is. The ways which that law may be changed are outlined by the Founders in the Constitution.

Corporations, despite your statement otherwise also operate under that rule of law. If it were not so BP could just walk away from their spill.

Individuals likewise operate under that rule of law, or otherwise pay severe consequences. Part of that is the duty of a corporate officer to make decisions in behalf of the stockholders of the company he works for. If that were not in place he would be free to make decisions for his own or other's benefits. This is what got Enron and Worldcom in trouble - their executives were ignoring their obligations to their shareholders. Some of these executives are now in jail.

People may make the statement that a higher ethic applies. Fine. But that ethic also applies to the duty to follow the law. And individuals may have very different views of what that ethic is. It is not the duty of anyone to act on someone else's view of that ethic. It is however their duty to follow the law. We cannot hold anyone accountable to a higher ethic BECAUSE THAT ETHIC VARIES FROM PERSON TO PERSON. Law though is constant across the society.

If citizens don't like the way a corporation behaves it is their duty to CHANGE THE LAW.

While you present an idealized case and argue for it, it does not work that way in real life. The 'law' is broken, circumvented, and ignored on a regular basis - by corporations as well as individuals. Prosecution for an offense is selective, and the more powerful the offending party is the more politics is involved in the law's application. This is not unique to the US of course - it is true more or less everywhere - but there is a tendency here to pretend that 'equal justice under the law' is the norm in this country - it is not, and this is a fact of life.

BP is of course in trouble - despite their considerable economic and political power. The rig accident and the gushing oil (the offense) is clear for all to see - there is no way to hide it. They will absolutely pay a price, and have already. Will 'justice' be done? That is an entirely different question and won't be easy to answer, even years from now when most of the legal dust has settled. There will be (and is) public censure - some justified, some not - and economic, social, and environmental consequences - many of which may not be immediately apparent. This is not simply a legal matter.

Personally, I care much less about the strictly legal questions than I do about what lessons society will learn, what changes in behavior might occur. I think this aspect of the accident is more important.

As oil extraction will continue I would hope that the industry as a whole would take more seriously the problems that drilling in the ocean specifically brings with it. Accidents will happen, and there needs to be development of effective technology and strategies mitigate the problems created when a well blows out underwater. There really is no excuse for being caught flat-footed by this - this was not a bolt of lightning out of the blue.

As a society that depends on fossil fuel energy to maintain its way of life, we also shouldn't be surprised that our addiction has consequences - for the environment as well as those people directly affected in this case - fishermen, people who work in the industry, tourists, and the general population of consumers who will be indirectly affected.

Shelburn had a nice post explaining why we shouldn't denigrate those who are working on our behalf (as a society) to fix this difficult problem. It is a hard lesson to see that we can create so serious a problem and not have the ability remedy it without a few months of hard work - and to know that the remedy will not fix the environmental damage that is occurring - that will take some years and is mostly out of our control.

While the oil industry in general, and BP in particular, should feel embarrassed about the behavior that led to this happening, should feel responsible for 'fixing' it, it is not just 'their problem' - it is our collective problem, our collective failure that is on full display here. Risk was undervalued, safety sacrificed for economic expediency, regulations not enforced or subverted, and society looked the other way and pumped their gas.

We should all be ashamed, we should all do better - it is certainly within or power to do so.

Yes it is true that our system of laws does not function without warts and blemishes. In some sort of absolute scale you could say that it is a very poor system and needs to be improved greatly.

It is in fact the worst system you could have.

Except for all the others.

"Yes it is true that our system of laws does not function without warts and blemishes."

Nicely understated...

The problem is not the system (a system in no way unique to the US), but has to do with human nature. The statement you made above "We live in a society that operates by rule of law." is generally a cloak trotted out to justify some selective application or another. In this country, as elsewhere, you most generally get the justice you can afford. The main differences from country to country are the nature of acceptable deviations - the social norms, if you will, of the law's application.

Incidents like the well blowout are a special case because the most direct evidence cannot be hidden and the scale of impact is very large.

I am fascinated that the two replies above me, by wrb and Speaker to Animals conflict with each other! To my mind this keeps the topic alive.

Moral dilemmas are important to look at. And corporate personhood creates huge moral dilemmas. Civil rights groups broke the law in order to demonstrate that laws were morally wrong. Gandhi advocated civil disobedience as a means to change laws. And Martin Luthor King followed Gandhi's path.

I'm simply questioning the status quo. As Speaker to Animals assures me it is my moral duty to do!

speaker to animals is not interested in human law , as a kzin

why should he?

now if we had a Pak Protector, then look out!

Forbin,

hmm, some would argue that the Puppeteers are behind the whole thing .....

or maybe just some luck

A respect for the Earth and our children and future generations *should* be instilled in everyone at a very early age, but it would require the widespread adoption of a new secular religion to accomplish that. There's no real likelihood of that happening any time soon, even though the fate of humanity may depend on it.

A deeply-felt reverence for the Earth and for our future -- there you go, I almost said "collective future" -- is pretty much the polar opposite of what we've got now. It wold take a really big disaster, far larger than the Gulf oil spill, to accomplish the needed mind-switch. People would have to get to the point where it was not only undesirable, but actually impossible, for us to continue down the path we're going now, before there would be real change in the right direction.

Of course the Native Americans and other "primitive" cultures in various parts of the world have made reverence for the Earth a basic element in their tradition. But we've cast that off, in favor of material well-being and short-term gain (sanctified by the "law"). We've got the religion of "grow or die" now.

Years ago I remember seeing an article in 'Outside' magazine about the State of Alaska, and the author described a mock "Seal of the State of Alaska" as something like this: a shield with 4 quadrants, showing a tree, a mountain, a river, and a bear, with the motto "Chop it down, dig it up, fish it out, shoot it". That's so us.

I don't believe in religion. I would much rather see people's behavior governed by an understanding of natural law and the altruism that arises from that. Religion gets wound up in questions of faith and acceptance of rules that are based on that faith.

Unfortunately history shows us (and even modern times show us) that this faith can easily be manipulated and twisted to cause much suffering. In reality faith is a lousy foundation to use for building civilization.

It is much better to base one's beliefs on objective reality and the laws that arise from study of that.

As Laplace said to Napoleon when he asked why there was no mention of God in his magnum opus on celestial mechanics, "I have no need for that hypothesis."

And thus I think we should consider those words when we develop our own personal ideals. And our civilization.

I'm not in favor of any current religion either, and don't believe "blind faith" is the right vehicle for the improvement of our society. What I was suggesting was a "secular religion" that really amounts to a deeply-held (and deeply-felt) belief in the sanctity of Nature, our home the Earth, and the paramount importance of keeping it a fit place for our children and future generations to live in.

In order to succeed, this belief would have to come "from within" each person, and not be imposed from above, either by the State or some sort of elite priesthood or aristocracy. But it would have to be taught, basically to children at an early age, and the question is "how" and "by whom" can such things be taught? How do you instill a transcendent belief in the sanctity of Nature to billions of people, equally, and all at once? How do we get past the point where, inevitably, the first people to adopt such views are marginalized and "wiped out" by those who do not?

I`m hoping that MOther Nature will take care of this problem. It just takes time for the economics to work out.

For example, govts will not have the money to treat and filter and pump water. Then people who receive water services won`t be able to dump garbage into landfills and burn it in incinerators because the costs to clean the water are too high.

Plastic will be too costly. I will have to buy my rice from someone local who sells it out of a big barrel and I bring a bowl and fill it. Producing garbage will be too costly eventually. Transporting the rice from far away will be too costly. So I will support local growers. The highway system will become an expensive and unused thing so it will be taken down and the land used to grow food.

Oil allowed us to PAY for disposing of the industrial wastes we produced. That is OVER now although we haven`t realized it yet. That is what the financial crisis is about, in part.

Basing one's "beliefs" on "reality". Pray tell, how does "reality" tell you to believe? Faith is not just about religion. You are using your "faith" all the time - it's just not visible to you. Your very argument about "belief" and "reality" is an assertion (assumption) you've made. At some point we all fall back on assumptions. And those "assumptions" are things we believe in. Morality, for example. "Reality" - the material world of facts - says nothing about morality.

You've got an interesting "assumptive world" from which you're operating. No need to assume God. But the assumption of "no God" is also - an assumption. An assertion. A belief. The faith you choose to hold. Along with many other values you choose to hold.

Just Wondering, above me, has set out a beautiful example of what I've just described.

I don't make or need any assumptions or hold any beliefs regarding the existence or lack thereof of God, Supreme Being, Flying Spaghetti Monster or similar deities. What I accept as evidence cannot possibly decide the existence of these beings.

My personal philosophy is based on the principles of methodological naturalism. That means simply whatever explanations I accept for the way things work are made without reference to supernatural beings or phenomena. This is what Laplace meant when he said he had no need for that hypothesis.

These explanations may or may not be objectively true, however there exists a method for deciding their truth. This is the power of this philosophy.

As far as naturalism and morality goes, I disagree strongly that naturalism does not lead to morality. In fact there is some pretty good evidence that what we call morality is based on the structure of our brain as determined by our genetic code. We just have this tendency to wrap it up in some cloud of 'faith' or "religion" which is unnecessary.

Take a look at the nature of this site. It is all about morality based on naturalism.

Ok, so "reality" does not tell you how to decide. You've place your faith in this method.

Thanks, that helps! You believe in a method.

Have you read Joseph Tainter`s The Collapse of Complex Societies?

He says in effect that when energy declines it becomes both undesirable (no longer economic) AND actually impossible to continue down the old path and that is why collapse ensues.

Yes, great book! Jarrod Diamonds Guns, Germs and Steel is another great book. I didn't really care for the follow-up. We need a system of economics or we perish I guess is the end rule?

The entire point of incorporating is in most cases to shield individuals from formal responsibility.

Not really.

The purpose of a corporation is to shield investors who have no influence in the operations of the corporation from any liability that exceeds the amount of their investment.

For example - I own 100 shares of Transocean stock. Obviously, this investment give me no influenmce whatsoever as to the operations of the company. If transocean were to go bankrupt - my only risk is the amount of moneu I paid for those shares. Otherwise debtors could come after my house, cars, bank accounts etc.

This 'shield' is necessary in order to capitalize business. If this shield were not in place them people like myself would never dare to invest in a publically-held company.

Activated05b

That is NOT obvious.

As a stockholder of Transocean Ltd, you at least have the right to attend the annual general meeting and ask to speak. You can submit petitions to the Board of Directors with greater authority than other citizens. etc. e.g.

Transocean Ltd. Shareholders Approve Proposals at Annual General Meeting

You can also call the company to uphold its stated commitment to responsibility. e.g.

I can - and do - vote my proxies.

However - I simply cannot afford to take the time off of work and incur the expense of flying to and attending the meetings. And even if I were to attend - my influence is limited to the proportion of shares I own.

BTW - unless I see a real reason otherwise, I typically vote against retaining the current board of directos and senior management at companies I own stock in. My theory is that even a competent board need to be 'kept on their toes.'

I'd venture to guess most corporations in the US aren't publically traded for starters. The primary reason for forming corporations is very much to shield the individual, actual human from liability, and in many cases from taxation. Hence the LL in "LLC."

Most corporations in the US are 'Schedule K' corporations. The purpose of a 'K' corp or an LLC is generally twofold. First it shields the owner's personal assets from liability claims against the corporation (Dr's Offices are one of the most common examples here) and in addition it shields the owners from 'double taxation' in that the government taxes the profits of the corporation then places an additional tax on any dividends paid by that corporation.

I think you mean "S corp". The reporting schedule for shareholders' income or loss of an S corp is Schedule K. The corporation itself is called an S corporation.

The purpose of that shield is to encourage the formation of corporations as a means of engaging in the investment of capital in the pursuit of profit. If people were not shielded they would not invest is these pursuits and we would not have a capitalistic society.

The shield is not unlimited thought. This is why corporate officers who engage in some types of criminal behavior go to jail.

How often to corporate criminals go to jail?! That's pretty rare.

What you are describing here is called an 'ethical delemina.' This situation occurs whenever a person's legal and moral obligations conflict. In this case the senior management at BP have conflicting obligations - any action taken to satisfy one set of obligations will result in compromise of the other set.

And corporate officers do not act in order to benefit an 'entity' - they are legally and morally obligated to act in the best interests of the _people_ who own that entity (the shareholders). In effect the corporate officers are trustees of the money entrusted to them by everybody who invested in the enterprise.

Here is an example of a similar situation I face in my own life. My parents had a messy divorce several decades agow which resulted in my mother owing a significant amount of money to my father - which she never paid. A few years ago she had a stroke and as a result I was required to take over management of her affairs. The legal documents involved require that I manage her finances in her best interests. As a result I had to determine that I would not may my father the money he is owed so I can preserve it to cover her medical care and nursing-home fees. This is despite the fact that from an ethical viewpoint - that is really my father's money I am spending.

Sometimes there are no good answers.

Corporate officers may be "legally" obliged to benefit the corporation and shareholders. Under current law. But morality transcends the law. For example, laws may change. But your moral compass may continue to point you in certain directions - which you hold dear, which you perhaps might die for.

I think you put your finger on it when you pointed to the "moral dilemma" aspect. Thus, even corporate officers, as indeed any one of us (as you have described in your own situation) may find themselves between a rock and a hard place, when it comes to making moral/ethical decisions.

For example - at any point in this chain of mismanagement that led to the blow-out - had there been a corporate officer who simply refused to go along with a directive - out of concern for the environment or for the safety of workers and so on, even if that person had been over-ruled and fired, would we not hold that person out as hero, trying to hold back the tide of a greedy corporation, flagrantly flouting best practices, heedless of the common good for society?

One thing that I find ironic is our own biases that corporations seem to owe us - but we have no obligation to them in return. When we talk about 'the good of society' we are really saying: 'what benefits me.'

During my years in the military there was a leadership concept that was drilled into me: 'Loyalty works both ways.' In effect if you want somebody to be loyal to society and work for the good of society even to the dettriment of their own interests - shouldn't society have an equaly obligation of loyalty in return?

How do we prevent corporations from taking the institutional attitude of: 'We care as little about you as you care about us?' due to how we treat them?

Please give examples of what you mean. That would be helpful. How am I to be "loyal" to a corporation whose shares I do not own, whose products I do not buy? Even if I do own or buy, I am free to divest myself of those. So... not sure what you mean. Your leadership concept would seem to apply to people who work for a corporation - as those who are "in" the military. But perhaps you can explain.

One question: Who defines and decides what is "the common good for society?"

Well, here's the rub. Give me 10 people and I should be able to identify at least 11 opinions on what the moral and ethical responsibilities might be, and how they ought to be weighed in those many hard cases where You Can't Have It Both Ways. So we end up looking to the law because all else turns to fuzzy mush having no existence save in the eye of the beholder. The world is too big for it to be otherwise.

The days of living in tiny and relatively isolated and tribal (sometimes in a loose sense) villages, and intuiting the responsibilities - and pushing out into the woods anyone who intuits "wrong" in the eyes of the chief bully - are over. Seven billions do not constitute a tribe or a family and cannot be expected to function thusly. They constitute something else, something new that has never been seen in full before, something only hinted at by the historical Roman, Chinese, Moghul, or even British empires.

(Emphases added.) That overarching conceptual we hardly existed until a century ago, except rarely as the violent imposition of a royal we. That common purpose, except as imposed by the royal we, was without existence beyond the tiny tribal village.

Nor do I see that "we" have ever reified it beyond that. Nowadays, with a great (over-) abundance of both real and sententious "diversity", what could possibly be the "common purpose" for which "we" would be conscripted into marching in lockstep, and, and amidst the "diversity", who are the "we"?

Common Purpose. Ok, let's turn to the Declaration of Independence:

Looks like a sense of "common purpose" undergirds our whole society and has done for centuries now. Sorry to be the bearer of this news.... which you may have forgotten.

Seems this part was forgotten a long time ago

The government has a perfectly rational way to assess your attitude.

It's called informed voting. There is no fault, and no blame, to be assigned except to the foolish citizens who are so busy living their little local lives that they willfully ignore the larger society.

It's OUR fault we don't vote intelligently!

Even more so since the internet now gives us the tools we need to inform ourselves.

If we don't, we deserve the laws and government we have.

VOTING IS THE BOTTOM LINE OF BLAME.

We have elevated corporations above the law and fostered a sense that it's ok for their officers to behave in ways that benefit an "entity" but harm society or the environment.

As others have so ably said in the thread, the fact that 'We, the People ...' allowed corporations that are granted privileges by government, to also acquire rights as a Man before the Bar, is leading to the destruction of our constitutional Republic. I know this is not the venue to pursue that line of investigation, but it should be brought to fruition in the near future, or I fear our children will have no future with freedom.

You always give great questions, and thoughtful commentary. Thank you, TheraP.

There does seem to be a problem with the incentive structure.

I'm sure BP is doing all they can to stop the leak- it is in their interest.

Their self interest, when it comes to clean up and compensation, is less clearly aligned with doing right and it is congress's fault. With them having to pay for all clean up that is done but their liability capped so they won't have to pay for the consequences of inadequate clean up there are doubtless lawyers and MBAs in the company who believe that since their highest responsibility is to their stockholders that they should scrimp on clean up and fight all claims for compensation.

What I'd like to see is the government step in and compensate everyone immediately and then collect from BP. But both the right and the trial lawyers would hate it so there is little chance that congress would authorize it.

The government could possibly throw more resources at clean up and protection and collect later for

Hi wrb,

I sense your frustration.

There is some good news. First, BP's liability is not capped. I'm assuming you are referring to the 75 million. That has been agreed to by BP under oath before Congress.

Second, BP has a substantial claims program in place and Congress is putting pressure on them to continually improve it. (Check the liability hearing on C-Span) By the way, for the government to step in would basically require the process to start over and we would lose a month's work.

As far as compensating everyone immediately, I think you feel the rate of response needs to be improved, not that everyone who walks through the door is handed a check without having the documentation first. Situations like this bring out the worst in some people and a small percentage who come in are there to scam the system. Again, it is the process that needs continued improvement, I doubt the government could run a substantially better claims operation.

The government is not shy about billing BP for money they spent on BP's responsibilities. The first bill went out in the mail last week, if I remember correctly.

All that said, yes, BP will not spend more money than they feel they have to. There will be areas of legal disagreement. I expect most of those will not see the light of day until after the well is killed and the public's attention moves on. That is when our government has to be held accountable for following through with all the rhetoric they have been putting out to date.

We saw with the Valdez and Bhopal that these things just drag along for years and years and people's lives are wrecked while waiting for too little too late.

We can approve drilling permits with an apparent 5 minute turn-around time http://online.wsj.com/article/SB1000142405274870449020457527895278400867... but there's every reason to believe people will lose businesses and homes and have medical bills racked up from this long before seeing a penny from BP.

The drumbeat in America is always for more regulation for the little guy and less for the big guy. There's always the assumption that industry can police itself, but the average schmo is a welfare queen. I can't see holding up pay outs on claims for everyone because 1% or 5% or even 10% might be scams.

Fix the court system then. Bhopal especially dragged on because of the ridiculous nature of the Indian government and bureaucracy.

Why would Union Carbide insist on the Indian government forcing it to make good by the community?

"We'd love to do the right thing for the disabled villagers, but their government's legal system makes it hard for us to battle having to pay them until so ordered." Well that's a heck of a way to operate day to day.

I am in the medical field, and therefore cannot comment with any authority on the mechanics of oil well drilling on land, much less in 5K' of water. But I do have experience in regards to incorporation, purposes of LLC (within the medical community) and cost of doing "medical work" in the current climate of CYA against litigation. Hence that is why so much money is spent on a lawyers retainer fees and PR.

While is it fair to say that incorporation is done to protect the shareholders as they do not have say in how the operation of the company is done, that is not, IMO, the primary reason. And here is why. LLC, utilized by most professional persons (remember corporations are legally persons) who's nature of their business puts them in harms way for a litigation barrage (such as lawyers, medical personal, BP, etc), intend for that LLC to be a barrier to the person's own private wealth. The typical medical malpractice policy covers up to a million, and there are no funds available beyond that, regardless of the damages awarded.

Both the UK's constitution and the USA's constitution were founded on the proposition that there are higher transcendent laws that supersede the Constitution, the King/President, Parliament/Congress, and subsidiary laws. When transcendent law is breached, then the people have the right to interpose, and even change the government as needed. e.g., as Archbishop Stephen Lagdon led the Barons to impose the Magna Carta (1215) over King John, and the US Founders issued the Declaration of Independence against King George III & Parliament. They appealed to:

@David L Hagen

A small point: Neither "God" nor "creator" is mentioned in the U.S. Constitution.

If the Founders were so insistent upon founding our nation as a religious one they'd have surely put something about Him in there, no?

The Constitution carefully avoids enumerating the exact moral platitudes the "Creator" expects, and then goes on to obviously leave morality to the informed consensus of the populace.

Unfortunately, as time went by, the citizenry became complacent and shoved that nasty and time-wasting "informed" part under the mattress, where it now sleeps.

That would be the bed we're sleeping in now.

All the high-flying ideology about revealed morality is bunk. You want to find morality, look in the genome, and cultural anthropology.

It's the best we can do, and it's actually all we need.

God isn't dead. It never existed.

Question: When changing from one cap to another can the oil already in the riser be retained or must the siphon be re-started?

On flange mating: Can a tactile "snapshot" be taken of the rough surface / bolts / cut pipes etc. as when a dentist fits a crown?

On Relief Wells: How long from successful interception to completed plug?

Takes me around an hour to read each page so please forgive me if I'm a bit out of kilter w. current discussion or have asked questions already answered.

The well provides the head pressure to fill the riser. The reservoir will continue to flow oil with pressure until the natural gas cap is depleted. I think think is determined by the structure of the reservoir. Not all reservoirs are of a continues gas cap. There have been many knowledgeable articles written here on that topic. Some pertain to water injection to re-create head pressure.

Why's it called a syphon then?

I don't think it's a siphon in the traditional sense, because what we normally call a siphon works via gravity because a liquid generally tries to seek it's own level, so as long as the outflow end is lower than the level of liquid in a container, the siphon will work.

In the case of this well, while gravity is involved, the upward flow works because oil is roughly 80% the density of water, so if the bottom of the cap is open to the sea -- even if the opening is small -- the water will try to push the oil upwards, until the weight of the oil in the tube balances the water pressure.

So if you have a tube from the bottom to the ship above, the water will naturally push the oil upwards. If you continue to replace the oil as the well does, then the water keeps pushing on the column of oil, but the water never gets into the tube because the pressure of the column of oil balances the water pressure.

Simple experiment:

1) Take a spray bottle, remove the plastic tube from the spray head and wash it out (or get a clear soda straw)

2) Get a clear glass a couple of inches shorter than the tube and fill it with water, nearly to the top

3) Pour a little cooking or olive oil into another glass

4) Using the tube like a straw, suck oil into the tube until nearly to the top, then plug the top with your finger (I did this by putting my finger in my mouth along with the straw, then put my finger over the top when I tasted the oil).

5) Keeping your finger over one end, put the other end of the straw/tube into the glass, all the way to the bottom and remove your finger from the top.

The oil will begin to drop in the tube, coming out the bottom, but the oil will eventually hit a level in the tube that will be 1/2" to 1" higher than the water level (depends on the height of the glass. I used a 4" glass, so the oil was about 1/2" higher.

This is the principle that's at work here, but replace the cooking oil with crude and the fresh water with seawater, and then scale it up to work in 5000 feet of water.

Thanks Dave. I knew all of that already, learned it at school. Also I'm a washing machine repairman. I wasn't asking what a syphon was. Also I read it in a previous thread where you posted it! I was trying to answer landrew's post in which he suggested the oil goes up due to well pressure.

Anyhooo... None of this answers even my first question.

So I'll pose that again. But I dunno' why bother? Nobody has time to read this stuff. Nah, never mind. It doesn't matter anyway. Oh, go on then, I'll put it another way..How long does it take to swap from one cap to the next? Does the whole syphon have to be primed again?

"The reservoir will continue to flow oil with pressure until the natural gas cap is depleted."

An extended area of water-filled rock connected to the oil reservoir will also allow oil to flow with pressure. However, in my limited experience to these deep water reservoirs, they often seem to have fairly limited aquifer support.

I have seen comments that this oil was undersaturated (though not by much): If so, there should have been no original gas cap. The GOR derived from the published gas and oil recovery volumes yesterday seems about right for a 'normal' oil at the depth and pressure of this reservoir, and certainly indicates no gas cap is exposed in the well.

If the reservoir indeed lacks a primary gas cap and strong water support, then pressure and production rates should decline rather quickly ('quickly' is only a relative term though - 50% or even 100% per year is still a lot of oil into the Gulf.)

Thanks for the more detailed info:) I was very uncertain of any water flow in these deep reservoirs? I have asked Rock to give a more detailed view with his deep water experiences. Would you think this well in Miss. 252 would be similar to that of the lower boundary of Gahwar in KSA? With multiple gas caps and changing fault lines within the same reservoir?

Sorry about that double post. I will add instead, BP will map the edges of this reservoir and determine sites of either water or nitrogen injection to increase flow rates.

Yesterday while watching the video from Enterprise ROV II, I could see the 'fins' at the bottom of the cap. It appearred that the cap was still 'floating' above the riser. Does BP plan to 'hard land' the cap onto the riser assembly? Why didn't they plan a larger rubber 'sleeve' to go over the jagged cut of the riser?

Did you notice that the fins are no longer translating w.r.t. the BOP today?

The technician is confused about the cap not being on the sea floor already.

This video from May 31 shows (not as clearly as desired)

the LMRP cap #2 (side number 4) on the sea floor as of May 31. It's to the left of LMRP cap #1.

One can barely make out that it's yellow, and the 4 vent valves and 2 methanol ports are just fuzzy dots.

http://bp.concerts.com/gom/subsea_staging_area.htm

I saw it being hooked up Thursday.

http://www.theoildrum.com/node/6539#comment-639723

Considering the velocity of the oil that was shooting out of the cut (mangled) riser pipe after shear job, I can see the reason for "jet effect". With the present "cap" over the riser flange some oil will reverse direction and head downward and out the around the bottom edge of the barrel shaped part. This oil would then escape past the seal, but it would shield the flow from seawater intrusion.

My main concern is the small size of the new collection pipe going to the ship's LMRP. I have heard that it is 6" ID, which seems too small since bouyancy and expanding gas will be means to push oil up the pipe. Right or wrong?

A Housekeeping Suggestion

The last thread was shut down with just 120 comments (and the start of an interesting discussion on oil metabolism increasing the GoM Dead Zone via oxygen depletion).

Why not an all bold letter post/ announcement that a new thread (with a link) has opened up but allow continued responses on existing debates ?

Alan

My suspicion is that it's to do with distributing server load. If you're synthesising the page from a database, you're probably reextracting each comment from the database (N database access for each user/page refresh). If the page is accepting changes, to a first order approximation (ignoring, eg, invalidatable caches), you've got to do this from the master database, whch only runs on one server, because you don't know if something has changed (an edit, etc). If the thread is frozen, then you can safely make a copies of the database and put them on each auxilliary server you've got. So there's probably a limit on "active articles comment length" that won't bring down the main server.

(NB: I don't know if this is how this particular software works, but it'd be a reasonably common architecture.)

Let me first start off with saying I'm an engineer familiar with fluid mechanics (civil engineer), but in no way familiar with the complexities of deep sea oil drilling. Looking at this cap though, it appears to me that there's no place inside it to help reduce the turbulence before it enters the riser to the ship above.

Would it work better if the cap had a mushroom shape to it above the initial throat over the riser? The larger volume between the riser and the current oil outlet would dissipate some of the turbulence and increase the draw of the pipe leading to the surface. Or would that kind of design create some other problem (formation of hydrates, etc) similar to what happened to the initial larger structure?

For that matter, would it be possible to retrofit the larger cap structure they gave up on earlier with heating and antifreeze devices to keep the hydrates from forming? That would at least increase the capture of oil flowing from the pipe, assuming they kept it clear.

I also think its worth to ask why the first cap was just forsaken without some trial of Methanol injection and/or additional heating.

In general a lot of things happening here are quite disputable and BP does not publish information for people who are more familiar with engineering and does not tell why they do things so and not others. I think it is their duty to inform accuratey also about technical details.

duh, couldn't be engineered/ manufactured in situ

First cap as in "the coffer dam over the end-of-riser leak"?

Huge internal volume, no ports to add methanol IIRC.

They'd have had to drag it back to the surface, and even so, how would you fill it with methanol?

n.b. the RIT I think also used the "fill the drill pipe with nitrogen to flush all the water out" trick.

There's no way to purge such a huge volume box with nitrogen.

First cap as in "LMRP cap #1" - it was designed to seal on the flat surface of a diamond wire saw cut. When the diamond saw was abandoned, so was any hope of use it's seal. So they just picked up it's neighbor waiting on the sea floor - LMRP cap #2 was designed to seal around the edges of the flange.

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

Bendal, I also feel a solution might be possible based more on elimination of turbulence. However, it would be contingent on the ability to transport larger volumes to the surface, ie big pipe and big pumps. Not having the information on what the possible pumping configuration could be, there is no way to know if this idea would work, but, I don't see the hydrate formation happening in the seawater as the oil and gas flows unobstructed. So I would suggest a large funnel which would let the oil and gas and hydrates and seawater come to equilibrium and then the mixture flows or is pumped through a *smoothly filleted* transition to pipe. Some hydrates would not necessarily be a problem in a smoothly flowing system perhaps. I'm thinking a large cylindrical foundation on the sea floor, seawater entry slot, then large funnel to pipe.

At any rate it is a complete mystery to me why cap #4 has no provision to even attach securely to the flange it seems! As others have said they have a perfect (more or less) round flange edge to seal to! And there are no tightenable dogs or clamps or as others have said giant bungees, nothing. Seems odd.

Hi all, may I say what a fine thread this is and very informative, thank you all.

I was watching a feed late on the 3rd of June (GMT so mid day of the 3rd in the Gulf I think) before the cap was lowered onto the BOP. There was a large disk on the pipe between the cap and the LMRP. While I was watching it was attacked by an ROV and the washer/seal at the centre was pulled out. A new washer was put onto the pipe and I went to bed. I've had a look about and can't find an explanation as to what the disk was and what they were up to. Can anyone enlighten me?

Thanks

Fingers crossed this works! For the Gulf and BP.

must have been something to keep the whatever on location on the new riser, ROV kept pushing it back in place when it moved as riser descended, and when it was dropped, ROV got another and replaced it.

There was speculation earlier that the disk was in place to deflect the rising plume of oil & gas away from the LMRP.

From the OP: "...By not getting all the flow into the second pipe it should be possible to drop the suction in the chamber to the point that a little oil still leaks out (treated with dispersants) but the majority goes up the well. Getting this right should prove an interesting exercise. (But isn’t calculating this what the “best and the brightest” – Dr. Chu’s team - are there to do?)"

I should certainly hope the only direct involvement of the only science and engineering people on the planet outside of BP's team who have direct contact with them and some influence upon them isn't just to run some numbers to tweak what BP is already doing.

I would hope that we would have multiple teams of people working on solutions independently. By "soultions" I mean ANY workable plan to keep the oil contained or corraled, in addition to focusing on the point source of the pollution. I would hope they would also be looking at ways to divert the point source of the flow which might not have anything to do with the current top hat method.

Hi quizmasterchris,

The engineering group does have multiple teams workings on other options. As soon as a viable idea is identified a team is assigned to it. There is no waiting to see if the current effort fails before they get started.

They are also several steps ahead on the current solution. While we see what is in place, they have already projected ahead to what adjustments may need to be made and the engineering and fabrication is well under way, if not already completed.

PriorityX do you have some urls to good sources for information on the relief wells? I'm particularly interested in the casing design, the wellhead lockdowns, and the estimated depth for the final intermediate string.

Hi ov,

I'm assuming you are looking for the actual Well Design documents that BP must submit to MMS for approval. I'm not aware of any way to access them via the MMS website. I do seem to remember someone mentioning they found some BP documents but they contained only the header page and no detail. Not sure if they were Well Plan documents.

I did find the BP Regional Oil Spill Response Plan for the Gulf of Mexico if anyone is interested. It is a huge PDF document, almost 600 pages. The area of most interest is appendix H near the end of the document. That is where they discuss worst case response. Well, discuss, is probably not the best word to use. Basically, the response seems to be the same for all size spills. A list of resources available :-(

BP Regional Oil Spill Response Plan - Gulf of Mexico

Further thoughts on sealing:

(Low tech is required because: fast implementation needed. Gives time to hi-techies to work on better ideas.)

So 1.Lift cap.

2.Place soft* "doughnut" seal over flange.

3.Lower cap.

4.Hold down with upscaled "bungee" cords.

No, I am NOT joking.

*Edit: "soft" at the pressure down there?

Alternative:Porous (sponge) so not compressed by pressure of water.But once compressed by bungee pressure and siphoning force pushing down on cap, pores will close.

Sorry about this. I'm an ideas person. Please forgive me for wishing to share them / bounce them off others.

Now that they have cut the bent riser off the BOP - why can't they start pumping mud and cement down?

1. no top to riser anymore to hold mud in

2. and even so, casing below BOP is unstable (see previous posts and main commentary) - could blow out everything

Old school, but material called Oakum is a wonderful thing.

http://en.wikipedia.org/wiki/Oakum

Good stuff. Bet those young techies haven't considered it yet.

What's this super oakum, and how does it act at 2500 psi?

Interesting idea, in a way that is what they are doing in trial and error. I am not convinced that a fixtured bolted connected is really a good idea. If there is a hydrate block or surge in gas pressure at that point. I think they would want to pressure relieve at that point. With still so many unknowns about casings, bop and gas flows I would have doubts. They will most likely adopt your idea (or theirs) in time. Most of this will be shaped by the success of the relief wells the first choice of permanent containment. I think this question of a bolted connection is interesting in itself. Any others have comments on that topic?

Thanks for reply.

I said flange but I said nothing in that post about undoing any bolts. Leave it as it is and use doughnut and bungees as I said. If problems arise, take a couple of bungees off! PS: I recently posted another idea for pressure regulation around seal.

It's surreal to know that in 50 days, as a country, we have the ability to effectively deploy, co-ordinate & supply in the field one million military personnel, 15,000 tanks & vehicles, 4 carrier fleets and an entire air force. We can fly into space on a daily basis, and landed on the moon 40 years ago. Yet when it comes to an oil leak, it's all ad hoc and a robotic crimper. It can't be possible.

That's because as a country--for better or worse--we have 234 years worth of experience in exporting combative forces, and have it fine tuned to an art not seen on this planet since the days of Hannibal and Ghengis Khan. That is NOT the case with fighting an out of control well 1 mile down on the ocean floor.