BP's Deepwater Oil Spill - Capping the Riser - Part 1 (Cap on, but leaks) - and Open Thread

Posted by Heading Out on June 4, 2010 - 7:00am

Please transfer discussion to http://www.theoildrum.com/node/6572.

This post describes what leads up to Heading Out's statement at 10:06 PM that they have the cap on but it has not gone down far enough to generate the seal, and so there is a lot of oil still coming out from under the cap.

The vertical section of the riser was cut, using a Shear, at 9 am Thursday morning.

The oil and gas are rising vertically, from the top of the riser, the drill pipe (DP) and the saw cut in the side of the riser (just down from the top of the shear)

At 8:30 pm, the ROVs maneuvered the latest version of the “top hat”, variation 7, of the LMRP over the top of the LRA. As the new cap was lowered into place, it was surrounded by clouds of oil and gas, making the actual progress of the event somewhat difficult to follow. The new variation had been finished yesterday, to accommodate the changing upper surface of the remnants of the well.

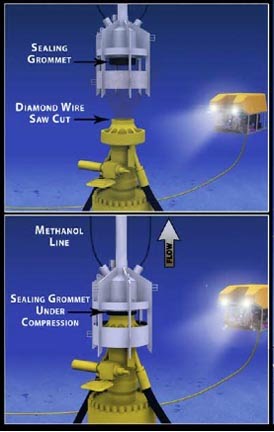

The Lower Marine Riser Package (LMRP) was first connected to the riser, and to a methanol feed that would help, between them, to inhibit the formation of methane hydrides when the gas came into contact with the surrounding cold seawater. It was then slowly lowered to the site, and across into the fountain of oil and gas, and down over the top of the riser.

The initial attempt halted after a while, and by 9 pm the situation was, for while static. The cap was sitting apparently on the rubber seal that had been designed to fit between the LMRP and the flange, but the amount of oil that was leaking out of the bottom of the LMRP was still a considerable amount, even though some of the flow was also being bypassed through ports on the LMRP that could later be closed.

The question now arises as to whether the LMRP could be lowered sufficiently that it could seal to the flange surface, since it was no longer possible to get the seal needed on the upper surface of the riser, given that it had been distorted by the Shear which had cut the bent riser away.

There was a pause, while the engineers had a bit think for over an hour. Looking at the cloud of oil coming out, it does contain small white specs that could be either methane hydrates or drops of the dispersant. And now, at 10:30 pm, there is a little more action.

For those who may not remember, this was the initial plan as it was proposed.

So far it is not quite as simple as the sketch would suggest. But I will put this up, and then update, as changes appear.

At 11:12 PM Central Time, we received an e-mailed press release with a statement from National Incident Commander Admiral Thad Allen that the cap was in place.

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

New regs going up...

Found this on drillersproboards:

http://www.stb07.com/downloads/increased-safety-measures-mms-ocs.pdf

"Auto's" summary of the doc:

"

The Secretary recommends a series of steps immediately to improve the safety of offshore oil and gas drilling operations in Federal waters and a moratorium on certain permitting and drilling activities until the safety measures can be implemented and further analyses completed.

Summary...

Recommendations and Key Components (with implementation plan

Blowout Preventer - (BOP) Equipment and Emergency Systems

Order re-certification of subsea BOP stacks (immediately)

Order BOP equipment compatibility verification (immediately)

Establish formal equipment certification requirements (rulemaking)

New Safety Equipment Requirements and Operating Procedures

Develop new BOP and remote operated vehicle (ROV) testing requirements (immediately)

Develop new inspection procedures and reporting requirements (immediately)

Develop secondary control system requirements (emergency rulemaking)

Establish new blind shear ram redundancy requirements (emergency rulemaking)

Develop new ROV operating capabilities (rulemaking)

Well-Control Guidelines and Fluid Displacement Procedures

Establish new fluid displacement procedures (immediately)

Establish new deepwater well-control procedure requirements (emergency rulemaking)

Well Design and Construction - Casing and Cementing Establish new casing and cementing design requirements - two independent tested barriers (immediately)

Establish new casing installation procedures (immediately)

Develop formal personnel training requirements for casing and cementing operations (rulemaking)

Develop additional requirements for casing installation (rulemaking)

Enforce tighter primary cementing practices (rulemaking)

Develop additional requirements for evaluation of cement integrity (immediately)

Study Wild-Well intervention techniques and capabilities (immediately)

Increased Enforcement of Existing Safety Regulations and Procedures

Order compliance verification for existing regulations and April 30, 2010, National Safety Alert (immediately)

Adopt safety case requirements for floating drilling operations on the Outer Continental Shelf (emergency rulemaking)

Adopt final rule to require operators to adopt a robust safety and environmental management system for offshore drilling operations (rulemaking)

Study additional safety training and certification requirements (rulemaking) "

"Study Wild-Well intervention techniques and capabilities (immediately)"

I guess this is as close to Figure out what else we're missing which might cause the next disaster as we're likely to get...

DAMN! Just read a part of an article that said that there was a simulation run by CG and oils (?) in 2002. They knew THEN that we didn't have the tech to clean something like this up! I'll see if I can find it and post a link.

Found it...buried in this ABC news article:

http://abcnews.go.com/Blotter/bp-oil-spill-oil-rig-blast-bp-refused/stor...

This is just like New Orleans, where the simulated Hurricane “Pam” foretold what would happen with Katrina several years later. One could conclude from our mistakes that we never learn from our mistakes.

As a previous manager said "There are lesson available to be learnt, but never lessons learned"

You know... this is such an indictment! And it goes far, far beyond just the oil industry or any one issue that we are confronting as a society and as citizens of the whole world. To think that people KNOW that more needs to be done. And that they COULD do more - but that we must "wait" for LAWS to mandate that? That is just so, so sad. That is, as I have already said, an indictment.

Honestly, this is one thing that worries me about our future on this planet. That many good people, people reading and posting right here on this blog, are doing things to try and conserve resources, to live more simply, while others are grabbing everything they can - law or no law!

I realized the gravity of this the other day on a thread related to "peak oil" and how to cope with that. And I suddenly thought that even if thousands and millions of us "conserve" resources and find ways to live simply, unless we find ways to forestall and end war, we are simply "saving resources" for the wealthy, the greedy, the powerful - to wrest from our heritage!

It's like the $$$ surplus we had in the year 2000. But then came years of war and of plundering the treasury. And now we're in financial pinch. Well, it's the same thing in trying to "care" for the earth. Some will care. Many will care. Those of us who care will tighten our belts, so to speak. Will use less to no oil, etc. But then what? Then some greedy and powerful people will either grab those same resources or go to war for them.

Seems to me that unless we ultimately decide we are one planet and we are all citizens of this one earth, this one universe, and unless we determine that resources MUST be preserved and shared for the good of all - and that may mean deciding to put them into some sort of "whole earth" receivership - and unless we decide to give up wars, how can we truly conserve these resources? For wars seem to be about "controlling resources" - and wars, above all, are "resource-hungry" machines that destroy what they seek!

One final thought: We all must die. As such, we know we must give up everything. On the way to facing that fact, we might as well learn that "giving up things" is part of being human, it's nothing more than what we face at death anyway. And in the process of living life - in spite of the death we all know is coming - the best we can do is care about our fellow humans and do all we can to foster a better society and a better planet for those who come after us.

Sorry for this long comment. But I've been thinking about this for several days. And it seemed appropriate here.

Oh I think it's a lot worse than that!

Not only do we "wait for laws to mandate", but in fact we spend large amounts of lobbying dollars to keep the mandates from being passed and/or enforced.

That's another type of "war" - isn't it? The lobbying war - to enable the greedy and the wealthy to control (and waste) what we seek to save.

Thank you for that important point! :-)

Wait till you see the Water Wars coming soon to the West. Where I live, we're gonna have Peak Oil waltzing around with Water Wars. Gonna need a whole lot of TheraP.

I am well aware we are talking "resources" of all types. Yes, water is huge! More important than oil - since we cannot live without it. Food sources and what we eat, that's important too - vegetarians we will have to become! We should have no more than one home each - of a size that's sufficient, but not wasteful. We have to give up oil-wasting "toys" etc. Give up oil-and-water-wasting lawns! Lots to think about here. But also - end wars.

Thanks for pointing out that crucial "resource"! :-)

Secretary Salazar used the term "The Resource War" (like the Cold War I guess but probably destined to get much hotter - briefly anyway) during a congressional hearing. Seemingly to describe the current era. I think it just slipped out.

Since the beginning of the Vietnam war (around 1963 or so) firts the US then other (copycat) nations fell into the habit of applying easy expedients rather than cultivating measured approaches that might not yield immediate results but would be consistent with good management practices and yield good long- term results. Around this application grew up a 'cowboy culture' of macho indifference to the long- term problems recognizeable in the beginning with the expedients. Drill baby drill equals, the Gulf “is a very big ocean” and “the environmental impact of this disaster is likely to have been very, very modest.”. Some of the 'instant solution approach' was learned during previous wars - for instance, the 'Mulberry Harbors' that created a faux anchorage for Allied shipping on Normandy Beach post- the June 6, 1944 invasion. These were cheap and easy ... and blown to bits in a gale a couple of weeks after the landing (doing much more damage to Allied efforts than did the German resistance up to that point).

After 1963 came a whole series of 'quick fixes' such as forceably removing the government of our Vietnam client, using B52 heavy bombers as tactical gound support, using Agent Orange, using cluster bombs, having the government print more money ('Guns and Butter') ... of course more and more highways plus crappy subdivisions to provide links between the roads.

In 1970 US oil production peaked then started the decline. Among the easy solutions was to import via US energy companies with concessions overseas (which resulted in nationalization of US oil interests and OPEC), closing the gold window and floating currencies worldwide (and the resulting oil embargo), proposing a Europe- wide currency, capitulating to the advance of mercantilism in Japan and Germany (rendered somewhat mercantilist by US policy post- WWII) and defending foreign exchange (FX) advantages versus the dollar so as to create hedges against high energy prices in dollars).

The ongoing and accelerating inflation from commercial expansion (including wars plus new government programs) was subdued the old- fashioned way, by the bond market (with support by Paul Volcker) going on a lenders' strike, but the temporary reduction of high inflation to more manageable levels sparked a new round of expedients. In place of energy conservation came credit product expansion along with that of finance to manage that expansion, the blowing of asset price bubbles (beginning in Japan), industry deregulation and the introduction of the euro (as a hedge as well as a dollar- alternative for the buying of fuel). The fortunate end of the USSR (only one major WWII combatant is left intact, the US) allowed for the open- ended looting of Eastern Europe then Russia itself, then the looting of S. America and then Southeast Asia in a series of well- executed currency/FX runs on reserve capital, alongside more auto infrastructure expansion - the idea being to spread cash flow 'benefits' to all areas in the process co- opting any agency that would question the growth imperative.

What J.M. Greer calls the thirty- year absence from reality; the all- out assault on the resource base with more and more 'high tech' that is, more efficiently removing resources without having any better tech to use with the found resources ...

The opening of China, then India and their creation as mercantile entities, then manufacturing powerhouses, the export of high- wage US workers (and the customers for US goods at the same time), the import of millions of unskilled Latins, the preference given to US industry over resource concerns, regulatory lapses (and conquest of regulators by the industries to be regulated), the expansion of automation driving out more high- wage jobs (and more customers) the vast increase in credit (as a substitute for wage/labor purchasing power).

All of the preceding expedients had the goal of kicking the political, economic and resource cans down the highway. We live the culture of expedience. The 'top hat' is an expedient. So is the BOP, the top kill, the junk shot, the magic wand. They are quick and dirty. Drill, baby drill. Another expedient.

The simplest ezpedient of all, of course, is less.

Nobody dare use the word less, it is politically unpalatable.

Don't provoke the energy lobbies, the car lobbies, the defense lobbies, the banking and insurance lobbies, the doctors' lobbies. Don't feed the bears.

Now, the lobbies have gotten what they wanted for a long time. The expedients have run out of gas and don't work any more. There is less bang for the expedient buck. Just like $12 in debt produces only a couple billion in GDP growth (and that is a fraud), the application of expedients - and the macho culture that has grown up around the application of these same expedients - is counterproductive.

What is the outcome? Whatever we as a nation gained by the application of expedients, we have to pay back. This will then leave us at the place - economically and from the resource standpoint - where we started, in the 1960's. There is one glaring exception; we don't have the energy reserve we had in 1963.

Sow the wind, reap the whirlwind.

Whole civilizations have died out due to what you term the "culture of expedience". But this time it would seem the whole planet could be involved. I love your term! And it distresses me no end that people are rushing headlong toward an abyss. Unless we pull back. All together!

Steve, I agree with most of what you say but only the American mulberry harbour was damaged. The British one

landed over 2.5 million men, 500,000 vehicles, and 4 million tonnes of supplies. It lasted 8 months although only designed for 3.

It is not just that fresh water will become scarce but also that it will be harder to get in many areas. Pumping deeper into depleting aquifers takes - you got it energy. Cleaning water that has been polluted takes - yep energy again. And as we keep burning FF well we melt the glaciers that feed so many streams and rivers. No water in summer.

For America, no pools, poor babies. For India no irrigation for crops, dead babies.

It doesn't have to be this way, as has already been reported on this website the Saudis have contracted the Chinese to build solar farms in the desert to power their desalination plants to get fresh water from the sea.

Their oil is too valuable a resource to waste on electricity for that purpose. They use the money for a better purpose, that will also have a more long lasting impact, once their oil has been depleted. At least they do seem to have an eye to the future.

Tell the 2.5+ million people who live in Las Vegas about easing off on fuel and water consumption? Air conditioning, water, transportation for tourists, all in the middle of the Mojave Desert.... And so it goes.

Eloquently said... Your conclusion that we must learn our in living lives that we face in death anyway is a platform that we should all learn to stand on... Thanks for the great insight!

What TOTALLY scares me is that it is predicted that the "Party of NO (regulations)" will be a majority in Congress, come the November midterm elections.

I am terrified at that prospect because nothing will be done to regulate "the wealthy, the greedy, the powerful" companies - and the lobbyists who exert control over members of Congress.

As a further extension of my own comment, I'd like to link to a post by Chris Durang, which contains a long commentary from Rachel Madow. It is so eloquent and I highly recommend that everyone take time to read it. Scroll down to the quote box at the end of the post:

http://www.huffingtonpost.com/chris-durang/i-want-my-earth-back_b_600859...

I'm glad someone with enough media savvy and air time is thinking like this! And I thank her for it!

Nice list BUT they forgot the main one ....

Develop a CONTAINMENT strategy that's ready to

deploy the moment there is a BOP failure resulting

in a sub-sea blowout !!!

First priority following a sub-sea blowout will be

CONTAINMENT rather than wasting time on sure to

fail "kill" procedures ..

Triff ..

Given all the problems in attaching the riser pipe to the BOP perhaps a standard connector on the top is needed that can "easily" be unbolted and provides a good surface to attach whatever is required, e.g. another BOP, mud/top-kill, riser pipe...

Fingers crossed the latest containment cap works as expected/hoped for and the spill is significantly reduced. Should also be better in 2-3 weeks when the "top-kill" valves can also be used.

I'm also guessing that this will lead to more research/solutions to improve the clean-up.

Best hopes for making good use of this catastrophe and not just "going shopping".

Well Design and Construction?

Where is the requirement to drill a relief well at the same time as the new one?

Two observations:

1) They should not even be thinking about new BOP regulations until they examine the failed BOP. I can see them coming up with a whole bunch of new design requirements - then discovering that none of them address what went wrong with this BOP.

2) Notice that there is no comment whatsoever on establishing research programs for mitigation of deepwater oil leaks?

3) I would establish an FAA-style reporting and formal investigation process for 'near-accidents.' I suspect that there have been several occasions where accidents like things like this accident 'almost happened' - but the lessons learned remained inside the heads of the people involved.

Yea - I know. Do not attempt math before coffee. ;-)

Did you read the article posted today?

http://www.theoildrum.com/node/6543

On this well if the BOP had worked properly all the flow could have been bubbling up around the outside of the BOP, or a few hundred meters away. The big problem now is the well can't be shut in due to lack of casing integrity.

This BP animation demonstrates what a successful containment cap installation process would look like.

http://bp.concerts.com/gom/lmrp6_060310.htm

I wish we could get some top-side information on what if anything is coming to surface. If you look at the subsurface ROV video feeds (here is a good site; http://bp.isevil.org/ ) the escaping flow looks really dramatic and seems to indicate that very little is going up the pipe.

You scan the news and you see nothing. Tight-holing information is making this a painful process for TODers but conversely this site is thee most informative and usually 12-24 hours ahead in knowing what is going on.

Not to worry, most of it is being dispersed in deep sea hydrocarbon plumes that will only slowly kill off marine plankton at the bottom of the food chain. The large pelagic fish, dolphins and turtles will die off slowly over the next few years and will hardly be noticed. Very little of it will wash up on those nice snow white beaches where the plump little tourists drink their margaritas and the local sea food restaurants will import oysters and shrimp from New Zealand...

Oh, never mind, Tony Hayward said on TV that there were no plumes so it must be true!

Don't worry be happy!

BTW He deserves every penny of his compensation:

Salary £1,045,000.00

Bonus £2,090,000.00

Restricted stock awards £0.00

All other compensation £23,000.00

Option awards $ £0.00

Non-equity incentive plan compensation £0.00

Change in pension value and nonqualified deferred compensation earnings £0.00

Total Compensation £3,158,000.00

Underwater plumes would seem reasonable, given that there are thermoplanes in the water (the things submarines hide under), with accompanying step-changes in density - after loss of enough light ends the remaining oil might have high enough density to 'float' on these density change surfaces. How do the dispersants work - do they strip off the light ends?

Oh, and maybe "crude oil plumes" do not exist - maybe they are "hydrocarbon product plumes", resulting from the interaction of the oil and the dispersant. I guess it depends on "what the meaning of the word 'is' is."

The plumes will surface once they reach the Atlantic; Sorry if this has already been posted but it's a must watch.

"Ocean currents likely to carry oil to Atlantic"

http://www.youtube.com/watch?v=pE-1G_476nA&feature=player_embedded

I've been wondering about his compensation - do you have a URL for this?

Yep, that's his 2009 compensation as listed on Forbes.

http://people.forbes.com/profile/a-b-tony-hayward/13022

Excellent comment by Yves Smith today on the Naked Capitalism blog:

http://www.nakedcapitalism.com/2010/06/wtf-alert-bp-ceo-is-a-mere-pr-pro...

The remarks about the quality of "reporting" by the NY Times is totally on the mark.

I think the point this article misses is that Heyward was hired in large part to clean up BP after the Texas refinery and Alaska spill incidents.

Just on that basis it seems that he has failed and the people in charge of sacking CEOs should get busy.

Video seems to have gone a bit dark. Are they trying to save energy by turning out the lights when nothing's happening. Or is it a cover up?

The top hat is jiggling around wildly. I trust this is a deliberate attempt to get it to sit down over the flange. I does not seem to be doing much good. Another design of top hat has been lowered to the sea bed

The ROV's sway in the current. It is much more likely you're watching a camera on the ROV that is undulating in the current and you're thinking it's the BOP infrastructure swaying because of the relative perspective. (I've seen this comment many, many times on the IRC channel).

Feed from Enterprise 2 looks as though the cap is clearly moving relative to the rest of the riser which is stationary. Has been going on for a while.

That's right, I saw Enterprise 2 lock itself to some mesh shelves on the BOP before it starting taking the shot. I can't make out any other ROV doing the jiggling from any other view. If the movement is deliberate, they must be doing it from above which must be difficult to say the least and if it is not deliberate it means the top hat has been pushed of the small grip it had on the flange and is being buffeted by the oil and gas flow. Constantly bouncing the grommet up and down on the rough flange cant be doing it any good and reduces the chances of low leakage even if they do get it to sit down.

What keeps that mile-long pipe to the surface from acting like an incredibly tall vertical separator and basically just letting gas out the top, with the oil accumulating in the bottom and being expelled around the base?

Glenmore -

Both the oil and gas are less dense than sea water and thus will tend to rise due to their natural buoyancy. The problem though is that there is a pressure differential between the fluid inside the device and the surrounding water. So if the seal is insufficiently tight, oil will still escape, and that appears to be what we are currently seeing.

If the seal were totally secure, then there should be a rather high velocity of oil/gas going up that riser, so much so that it probably have to be throttled back to prevent a violent eruption out the top.

Even without a seal the gas is going to accelerate up that riser, and do so faster than the oil (with the water finishing third.) As the gas rises and expands, it should occupy more and more of the available riser volume, to the exclusion of the liquids. As you said, you have to choke the flow back at the surface (+/or elsewhere) to prevent a vicious 'whipping fire hose' effect at the surface, not to mention overwhelming flare capacity and exploding, but how would that choking affect the oil flow, what with the bad base seal? (And I gather they don't want a good seal even if they could get it, due to resulting back pressure and well integrity concerns.) I guess the oil recovery would be limited by the ability to produce and handle the gas?

If this is a near-saturated oil, of ~35 gravity, and ? reservoir pressure (13,000 psi?), what GOR might be expected? 3000? Then if the well is blowing 25,000 BOPD they'd have to be able to handle something like 75 MMCFG/D?

People advocating a pressurized seal don't seem to realize how fricken DANGEROUS that would be. Any surge from the well or mistake in controlling the flow will result in a big pressure surge in the highly compromised BOP, potentially breaking the whole thing wide open.

Then we are talking a much much bigger problem.

So if I understand what you're saying, unless there's a good seal, the gas will rise - because it's got more "power" and the oil (with less power than the gas) will be pushed out into the gulf. In that case, they need to do everything to find a way to seal this as well as possible. Or it becomes mere "window dressing" - giving the appearance of a solution, gas flowing up and oil continuing to pollute.

Suttles is saying they should capture 90% of the oil if this works and he says 'it should work'

http://www.reuters.com/article/idUSN0410525120100604

Thats pretty optimistic based on what I have seen so far. Sounds more like damage control for the stock than well control.

just for the record for those who have faith in the top hat, a weight of about 650 tons is needed just to get the top hat to hover on the escaping oil if the seal is good and oil is not flowing up the pipe. The top hat might weigh a couple of tons. The other weight comes from a flexible pipe one mile long moving around in a current suspended from a ship. Meanwhile you have a turbulent large flow of gaseous oil that becomes more gaseous and wants to expand all the way to the surface that has to travel up a narrow pipe one mile to the ships low pressure pumps to have a hope that the weight required on the top hat can be reduced. Has anything like this been done before?

I heard a BP person say they were going to put a stack of heavy drill collars on it to help hold it down.

Judderbar -

The purpose of the top hat is not to seal the leak, but to provide a secure pathway for the oil/gas to get to the surface where it can be collected in a controlled manner. The interior of the top hat is open to the water column in the pipe to which it is attached. Thus, the top hat does not 'see' the full pressure at the top of the BOP as long as the pipe to the surface is kept open. Should that be closed or block, then it would see a much higher pressure.

I will jump in here and make a fool of myself probably but I think the general non engineering/non technical audience is totally confused in respect to the various pressures involved, so I will thrown in my nickels worth.

There are two basic ways to measure pressure as a practical matter, which are psia (pressure absolute) and psig , usually just referred to as psi.( pressure gauge).

Air pressure at seal level is around 14.7 psi.A tire GAUGE shows zero if you check a totally "flat" tire,but the air pressure inside the tire is still 14.7 absolute-at sealevel of course.

I'm not an engineer, or even a professional plumber , but the pressure numbers being thrown around in respect to the well head or bop mean next to nothing so long as the flow is unrestricted into the surrounding water, except that the high absolute pressure due to the wieght of the mile high water column keeps the gas in solution at the sea bottom.

If I hook up a two hundred foot long half inch hose to a faucet with pleny of pressure and available volume, and leave the end open , and attach pressure gauges to it at intervals, the the first one close to the faucet wuill read about the same as the water system pressure;each one farther away will read less and less as the distance increases, until the last one will read approximately zero if it is a foot or two from the UNRESTRICTED open end of the hose.

When my domestic well pressure gauge is showing sixty psi, I can fill a five gallon bucket about thirty seconds thru a six foot stub of old half inch hose.

At the end of two hundred feet of half inch hose,filling the bucket takes several minutes everything else the same.

If you pinch the hose shut at the end, the pressure on EVERY gauge will read the system pressure, unless your hose is running downhill, in which case the ones farthest down the hill will read higher;or if the hose is going uphill , the farther up the hill the hose goes, the lower the pressure will read.

As a matter of fact many domestic water well pumps are not capable of producing enough pressure to raise water more than a couple of hundred feet against the counter pressure created by the wieght of the water in the pipe. A deeper well requires a more expensive pump.

Now something is limiting the VOLUME of the oil emerging at the end of the pipe where it exits into the water-probably a restriction somewhere in the well or the BOP, or maybe (less likely) the nature of the formation, maybe even the size of the pipe from the bottom of the well to the BOP is contributing significantly to slowing down the oil.

If I could stick a gauge in the side of the riser pipe a few inches below where it is cut off, the GAUGE pressure would read very close to zero,as the flow would be unrestricted to any serious extent by the last few inches of pipe.

All the pressure considerations begin to come into play WHEN the new top hat or whatever is being put into place;as soon as it is close enough to start restricting the flow, the pressure will start building up.Apparently the well can genetate pressures closte to ten thousand pounds per square inch at the sea floor if the flow is restricted.This could turn into a wrestling match worthy of superman himself if there were not tricks to make it easier.

Getting the cap into place and fastened down against this constantly increasing pressure is analogous to trying to screw another piece of garden hose onto one connected to and flowing unrestricted from a water system with good pressure.If the second hose is open at the far end it is much easier but still hard for someone without very strong hands and good coordination.If the second or extension hose is closed at the other end, even a very strong and well coordinated man has a tough time screwing the hoses together.

The new cap has apparently vents to hopefully keep the pressure from getting so high that the connection can't be made.The vents are opened so as to to bleed off the oil while the connection process is in progress.

If the connection can be made really secure, the entire flow of oil could be captured and carried to the surface by the new riser-IF IT is strong enough to withstand the pressure.Apparently nobody knows just how high the pressure will be, because the flow of oil has not been measured but only roughly estimated.But the friction of the oil traveling up through the riser to the surface will restrict the flow considerably, and the pressure in the riser will get pretty high, especially near the sea floor.

I presume instrumentation is included enabling the operators to watch the pressures as the vents are slowly closed, forcing more and more of the oil up the riser;if necessary, some oil can continue to be vented into the water to protect the riser from failing due to excessive pressure.

One thing seems certain to me; that is that once the cap is in place and secured, the pressures developed inside will be more than ample to cause oil and gas to flow OUT thru any cracks or crevices , rather than water flowing IN.The absolute pressure WITHIN the pipes carrying the oil and gas will be HIGHER than the absolute pressure of the SURROUNDING sea water, even though it is a mile deep.

The energy need to deliver the oil and gas up the pipe will be supplied by the well itself, and there need not be any so called suction involved as a result of water being allowed into the system, or deliberately introduced into the system , as was the case with the first dome or cap, which froze up.

If this one works the antifreeze lines will apparently only be needed to clear any hydrate ices formed during the installation process.

It occurs to me that if the riser is unable to carry the entire flow that an additional riser might be employed and the oil fed into it thru one of the existing fittings or pipes atteched to the BOP which were originally used for other purposes.

Or maybe if the engineers were on the ball the aforementioned vents are so constructed that a hose can be easily attached to them and run a short distance across the sea bottom (to get working room ) and another riser added to carry the excess flow, or at least a large part of it.

Of course I'm only a farmer who necessarily does his own plumbing and mechanicing.But there's a lot of it and some of it is fairly high pressure, up to about 2000 psi.

If somebody who knows better sets me straight in some respects , my feelings won't be hurt.

I just hope this comment will help those without ANY technical background understand the situation a little more clearly.

oldfarmac,

"unless your hose is running downhill, in which case the ones farthest down the hill will read higher"

For practical purposes, wouldn't your hose be running 'downhill' TO the surface, due to the continuing exsolution and acceleration of the gas as it moves through the riser?

nice explanation but you missed a bit about how the oil rises up the pipe.

once the pipe is in place and the oil starts flowing up it,

the gas in the oil comes out of solution - and it expands a lot too as it gets to a higher position (=lower position)

This makes it less dense, so it rises, so it is at less pressure, so it expands, so it rises etc

So the oil is the pipe rushes up at an ever accelerating rate , powered by the gas expansion.

This could mean that there is even _suction_ at the base of the LMRP.

Ben

You and Glenmore are right about the gas coming out of solution as the gas and oil mixture rises toward the surface.In effect the pressure will fall even though the pipe is rising more or less vertically,as the flow approaches the nd of the pipe and therefore the end of the friction slowing it down. The only way to keep the pressure from falling off too much as the flow nears the surface (so far as I can see) is to choke off the flow with a valve.Otherwise the gas will probably shoot out at very high speed and carry the oil with it and blow the oil all over the place, including all over the work boats/barges/ ships and right back into the water.

This partially colosed valve would of course have the undesirable effect of raising the pressure farther down the pipe all the way back to the BOP and down into the well itself, possibly leading to a pipe failure anywhere along the way-we don't know what sort of shape the pipes are in and there might be places thqat are cracked , kinked, or eroded by sand in the oil.

I don't really have any idea just how the people on the work boats at the surface will go about seperating the oil from the expanded gas, but my personal wag is that the oil will be carried along by the gas like water is carried by a hurricance force wind.In principle it is easy to direct the oil into a barge or tanker,ONCE it is seperated, and to direct the gas into another pipe which is long enough to get the gas safely away from the boats and people and simply burn it off.

I know how small water and air seperators work;some use filters that selectively trap water, and some simply run water saturated air into one side of a large tank or pipe at the top, and out the other side again ,again at the top. If there is actual liquid water carried along by the air, it will fall out like rain because the air speed thru the tank is not high enough to carry it along like wind driven spray.

Water vapor on the other hand must be removed by lowering the temperature of the air so that the water cannot remain in vapor form;if the tank is chilled, the water will collect on the interior surfaces and run to the bottom;this can be quite effective, capturing nearly all the water vapor, as for instance when you need dry air for spray painting a car.

(It is also possible to seperate water from air by compressing it until the water returns to a liquid form, and this water can be drained off from the COMPRESSED air but his does not seem relevant to the current problem, as the oil is already in liquid form).

My seldom used homemade rig uses a coiled copper line in an old beer keg full of ice to chill the air, with compressed air coming in at the top, and exiting at he bottom, where there is a water trap.This works like a charm and cost almost nothing to build or operate and lots of painters use something along these lines, even including some professional shops.

A lawman once expressed considerable interest in this little piece of equipment but gave up when he could not immediately visully locate "the rest" of my supposed still.He never did come back with a warrant so I guess he must have found it necessary to accept my explaination as to the use of this appartus. ;)

(If I did happen to own a still I would certainly not store it in plain sight in a shop where anybody in the community is welcome to walk in anytime I'm home.)

I hope somebody who knows something about the way the work crews handle seperating the oil and gas will post a comment telling us how it is done in some detail..

Another question : there is supposed to be or may be an erosion problem due to sand in the oil.

Surely this question could have been answered at least in rough form almost immediately by taking samples of the oil with a rov and measuring the amount of abravise material in it. Why haven't we heard anything about such testing for abrasives?

Darn fine comment from a "non-engineer". Seems like you've got a bit of good old common sense. The old rule: "engage brain before putting mouth in gear" would seem to apply to many of the comments I've seen over the last week or so.

You could me my engineering assistant anytime. Better yet, my technical supervisor.

One can only hope

Judderbar,

How did you make this calculation? Do we know the pressure at the top of the BOP? Also, there are valves at the top of the LMRP that will be open when the cap is positioned allowing gas/oil to escape from the top of the cap. If and when (hopefully) the flow in the pipe starts, additional pressure relief will come.

Then again, I am looking at the Enterprise ROV1 feed and it seems that the cap is "dancing" around. I put a piece of tape on my screen to monitor the position of a cap tab relatively to a flange connection at the top of the BOP.

Looks like the Reynold's number should come in at about 1000, which is still laminar in the pipe.

You only need 650 tons if you're capping the riser -- but obviously all the pressure is squirting out the bottom right now. As the pipe flow increases the differential will drop, eventually to about zero, and weights would just provide a wider sweet spot around zero differential without too much leakage in or out.

No pump will be needed at the surface, and you can only pull a vacuum at most anyway, an 15psi is nothing compared to the pressures down below you have already.

The 6" pipe is narrow, relatively, but run the math and only a dozen or two psi will be lost in transit, depending on the actual viscosity, pipe characteristics, etc.

The exact same process was used with the RITT, only with a poorer (and horizontal) seal. It mostly worked then, and it'll work better now. Or at least I hope so!

This is my first and last post, but this idea is driving me crazy and would appreciate any critical comments on it:

--if, for instance, the casing rising from the sea floor (that is supporting the BOP) is 22" outside dia., why not just cut off the BOP and slip over a riser with a 22" inside dia. and gently pound it down the few hundred feed to the bedrock. Problem solved--no? I mean, I can't believe much, if any oil, would escape.

Again, thanks for any critical comments.

On Friday morning, the success of the effort remained unclear, but BP chief operating officer Doug Suttles said he was optimistic.

The oil that is still surging into the gulf from around the new cap is coming from vents that will be successively closed during the course of the day Friday, Suttles said on ABC's "Good Morning America."

"I'm actually pretty confident this is going to work. It probably won't capture all the flow, but it should capture the vast majority," Suttles said.

This from a WAshington Post story this morning - Hope springs eternal

Isn't the operative question 90% of what. If some of the recent estimates of 12,000-19,000 bd are right that would mean that there is still 1,200-1,900 bd - greater than the initial estimate of the leak.

The PR misworded it (deliberately IMO).

The lower bound of three independent estimates (using 3 different types of observations) ranged from 12,000 to 19,000 b/day. All 3 groups refused to put an upper bound on the rate of BP pollution.

Alan

Alan,

I thought only 1 group refused (Plume modeling team) to estimate because they couldn't get enough data. Was there another press release or more info released? Where did you get the info "All 3 groups refused to put an upper bound ..."

Here is the info from the first press release:

"Given the amount of oil observed and the adjusted calculations for the amount of oil that has been burned, skimmed, dispersed, or evaporated the initial estimate from the Mass Balance Team is in the range of 12,000 to 19,000 barrels of oil per day.

This methodology carried several challenges, including the fact that the AVIRIS plane can only fly over a portion of the spill in a day, meaning that an assumption must be made that the area imaged is representative of the entire spill region.

Plume Modeling Team

The second approach led by the Plume Modeling Team used video observations of the oil/gas mixture escaping from the kinks in the riser and at the end of the riser pipe alongside advanced image analysis to estimate fluid velocity and flow volume. Based on advanced image analysis and video observations the Plume Modeling Team has provided an initial lower bound estimate of 12,000 to 25,000 barrels of oil per day. They continue to work to provide an upper bound.

This team faced several methodological challenges, including having a limited window of data in time to choose from, getting good lighting and unobstructed views of the end of the riser, and estimating how much of that flow is oil, gas, hydrates, and water."

Did they ever put up the promised website with their data and approach calculations?

...the Plume Modeling Team has provided an initial lower bound estimate of 12,000 to 25,000 barrels of oil per day. They continue to work to provide an upper bound.

the RITTI Team calculated that the lower bound estimate of the total oil flow is at least 11,000 barrels of oil per day...

http://www.deepwaterhorizonresponse.com/go/doc/2931/569235/

Alan

Alan,

same release I read. Only one team - not three - did not provide an upper bound - it was the "Plume Modeling team".

If they ever put up the website we could look at the calculations and understand better what they were doing with their approaches.

The Riser Insertion Team also put only a lower bound on their estimate for the total oil polluting the Gulf of Mexico. Read carefully.

Since the "Mass Balance" team did only an "oil on the surface" analysis with no estimate of how much oil was entrained in the water column (we know a LOT), it also implicitly has no upper bound.

So no reliable upper bound on the BP oil polluting the Gulf of Mexico.

Alan

I have an estimate for the upper bound....A big stinking sh*tload...how's that?

I've read this, many times, as carefully as I can. I think Alan's interpretation is correct: No upper bound estimate has emerged from that work.

Weren't all of these estimates made before the riser was cut off?

12,000 - 25,000 barrels per day on the lower end? seems like the plume team is giving themselves a very wide margin of error. 100+%, to be exact. Why bother with an upper end number if You can't 'guess' any closer.

Unfortunately, it's ingrained in petroleum management.

see http://www.cwsx.org/21darts.pdf

(I apologize for saying nice things about BP in that document. They hosed all of us with Monte Carlo blue sky flow characteristics at Thunder Horse.)

While watching the Kill line installation Video, I was impressed by the ease of installation of the HSF connectors (http://www.oceaneering.com/oceandocuments/brochures/subseaproducts/PRS%20-%20Hydraulic%20Smart%20Flange%20(HSF)%20Connector.pdf) . No bolts, no fuss. I'm sure the guys at Oceaneering could have Prototyped one of these to fit the BOP flex joint flange! (in 40days)

A number of posts have suggested removal of the existing LMRP flange and attachment of a new package by the same method. The response to these posts often takes issue with the amount of pressure caused by the rapid expansion of the oil stream at this point. Perhaps an adapter plate could be bolted on to accomodate a larger LMRP diameter.

Surely removing those flange bolts (cut or wrench) and letting the flange fly away would reveal a much more attractive surface for BP to mate their top hat adapter to?

This may not be much different than the suggestion for upsidedown installation of an annular preventer.

Just some thoughts from a mechanically inclined outsider.

You don't need to go to the bother of removing those bolts. All they need to is create a hinged collar that fits around the lower riser mount, using the flange to lock on to.

The collar could be shaped to fit around the stub of the riser pipe, and engineered to provide a properly locking mount for the containment cap.

Would probably take a day do construct, and would do wonders for the process. I have a bet going that we'll be seeing one soon.

You don't need to go to the bother of removing those bolts. All they need to is create a hinged collar that fits around the lower riser mount, using the flange to lock on to.

The collar could be shaped to fit around the stub of the riser pipe, and engineered to provide a properly locking mount for the containment cap.

Would probably take a day do construct, and would do wonders for the process. I have a bet going that we'll be seeing one soon.

I thought about this too watching the videos. Bolting something to the top of the existing LMRP flange (of whatever we are looking at below the cut) seems like a better option than hovering something on top of it. Alternatively, it seems possible to create a device that closes around/below the bolt connectors or wide spot just below the cut. Then again, it doesn't seem like capturing the flow is the main problem ... hydrates are. I'm not sure what this adds to the equation?

BP is claiming they do have flow arriving in the drillship. Not saying how much though. This morning they were talking about closing the cap valves. Could be that the increased flow from under the cap indicates that the closure resulted in more oil being diverted down and unseating the cap. Seems like the lower seal is the weak link here (unsurprisingly).

you would expect some flow. The question though is how much flow can you reasonablý expect over a distance of one mile if the pipe is not able to transport oil by its own mechanism? if the cap forms a reasonable seal there is no transport mechanism to take the lighter oil to the surface since the water and oil are now independant. So you need a pressure of one miles worth of oil at the seal plus a large posative pumping pressure to move that large flow rate along a narrow one mile long pipe. The seal has to be more or less perfect. Can a rubber seal even survive that 3500 pressure before the seal is made good?

You can expect a LOT of flow with 2250psi of pressure, which is what you have at equilibrium at the bottom! If you have a tight seal, the well will pressurize the column. With a weak seal, the water will flow in or out on either side of the equilibrium pressure, but you still have the 2250psi.

With an oil column, that 2250 psi equates to about 450psi of differential pressure. Only a small fraction of that will be lost due to a mile of friction in the pipe, and some more will be offset by the drill platform height above water, but there will still be plenty of pressure.

The real issue is limiting water intrusion and clathrate issues. They'll close the cap at the top of the LMRP when it starts sucking in water, IMHO.

Some quick calculations. If the mile long column of oil/gas weighs 1800 Lbs/in sq.

And the diameter of the flange is about 32 inches, or 800 sq inches. That means there is 1,447,200 pounds of upward thrust to the LMRP assuming no restrictions in the riser and oil is reaching the surface.

Sealing to the 21 inch riser (110 square inches) would have only produced 200,000 pounds lift.

Edit: There has been mention of the oil/gas sucking itself up once it gets going. I don't see how that can happen. The water pressure will have no effect on the contents of the pipe to the surface. The only place where the water pressure comes into play is restricting the leaks somewhat.

Paul

1,447,200 pounds of upward thrust to the LMRP

You're neglecting the water pressure outside, which is pushing the opposite way. The actual hydrostatic pressure force on the BOP is the *difference* between the weight of the column of oil/gas and the weight of the water it displaces... since oil is less dense than water, it'll pull the LMRP *downward* against the BOP flange.

Edit: There has been mention of the oil/gas sucking itself up once it gets going. I don't see how that can happen.

I've been arguing the "suction" thing for a few days now, and that's not quite what I said. I was talking about the pressure difference between inside and outside the LMRP cap, as above.

(PS: it's clear that the oil is still being pushed *outward*, so where's my suction effect? At the moment, BP is holding valves at the surface closed to keep the pressure in the LMRP deliberately high to avoid water intrusion.)

Two omissions in this calculation:

1. Gas to oil ratio is estimated at 350:1 from this well at sea level. As the gas expands from well head pressure to 2250 (unrestriced flow at seabed) it takes more volume in the riser. As oil /gasflow reaches the surface to zero pressure the gas takes up 99.7% of the pipe's volume, so your density calculation/weight calculation is way off, thus making force calculation way off. This bouyant effect will be offset by the weight of the new LMRP or about 600,000 lbs IMO.

2. The well head is at about 7000 to 8000 psi static estimate (with no flow). Since cutting riser and DP the only restriction is inside the BOP, so the pressure is much less, but still creating a "jet" of large volume coming out of sheared end. But this jet is now restricted by the first cap or tophat or whatever you want to call it, and attachment of LRMP will add more restriction (due to smaller pipe) creating more (edit-was "less") pressure drop across the seal. Unless the seal has very good fit a lot of oil will exit the seal even it it only sees 100 psi or a few 100 psi pressure drop. And sealing 500 psi around 21 inches is still 175,000 lbs.

Bottom line is that a huge amount of oil/gas is likely to exit the seal. I think less than half of the unrestricted oil/gas flow will be captured with this arrangement. If the seal integrity could be assured most of the flow could be captured, but then the control of flow at sea level in the tank ship is the issue.

Increase sea-level pressure by 10x (say, 150 psi) and the gas volume cuts by 10. At 80/20 gas/oil you'd have 2000psi available, and you'd need 90x the pressure, or about 1300psi. The remainder would still drive plenty of flow for that blend.

Where is the edge? With a total pressure of 2250 you'd have a multiplier of 150 times ambient sea-level. If you had 95% gas at that pressure that adds another ratio of 20. So a ratio of 3000 is about worst case that would self-drive in a fixed-diameter pipe, or so it seems. Much beyond that you'd need a bigger pipe and a low-floor surface rig, or maybe just a giant flare-ring.

You could imagine a top-hat separator that could bleed of some gas at the bottom, too, which could help even in such a case.

RITT experience should have calibrated the GOR pretty well, I would think. The engineers should know about what they're dealing with by now.

"flow" - but flow of what? If it's mostly flow of gas, with the oil being pushed out around the poor seal, then what does that accomplish?

Am I just misinterpreting what I'm seeing or is oil now coming out of the open valves on the top hat / cap whatever you call it and not out of the bottom?

(Looking at pics from Skandi ROVs.)

That's what I thought at first, but the view actually shows the leak enveloping the whole cap as it flows out the bottom. You can see the "fins" of the cap protruding from the billowing oil. You can see the level on the top of the BOP in Skandi ROV 1. In Enterprise ROV 2 you can see a view that is level with the bottom of the cap. It's hard for me to believe that any significant capture is occurring from these shots.

Yes, thanks, I see that now. I was confused by the yellow level thing. I had thought that was situated on the cap. Maybe they moved it.

Scandi is looking from above. The feed from Enterprise ROV1 shows gas/oil leaks from below the cap.

Why the tiny 6 inch riser?

With expanding gas, sounds like a sure loser.

With a 6" pipe, a flow of .5m/s would carry 200,000gpd. The more gas you have, the greater the differential pressure drive, and the higher the flow.

For each 1% of the column volume that is displace by expanding gas, the resulting differential pressure will increase about 5%. For each 10ft of water you have about 5psi (actually about 2250psi at 5000ft, IIRC).

Replace that water with oil at density of .8 of water and you get about 4psi per 10ft, for a differential of about 500psi at 500ft.

Replace 50ft of water (1%) with gas (really low fraction of water weight) and you pick up about 40psi of differential.

With no choke on the top you get a screaming gas flume (like on the rig). Add a choke and dial down the flow until you reach a gas/oil flow equilibrium roughly equal to the leak, and you're set. Unchoke a bit and you get too much flow and suck in water from the bottom. Choke too much and you leak oil out the bottom.

Since the base 500psi is plenty of drive to get the requisite .5m/s of flow, there should be a wide "sweet spot" of gas/oil ratios that will capture the full leak flow in a 6" pipe.

It's not intuitive, but math doesn't lie.......

Good series of posts explaining the math on the pressure differentials and the possible flow rates.

Thanks

You will never get that turbulent, multiphase flow to GO into that 6" pipe over the tiny manifold of the mini cap. Especially without a real seal. With a good seal, you will get a terrific pressure spike inside the BOP and a large choke effect.

If BP has only done what you are doing, that's really bad.

This is a very complex CFD problem. One that doesn't have a nice static pressure solution.

The ONLY way to deliver that mess of a flow to the surface is through a tightly sealed 21" riser pipe.

2000psi can make a lot of anything go through a 6" pipe. Look for the video of a 6" crab fitting nicely through a 1/8" pipe slit.

I will readily admit that a real-world mix of oil and gas isn't fully modeled by simple flow calcs, but there is a large margin for error. A few hundred pounds of pressure will keep a lot of the gas in suspension, and drastically decrease the volume of the rest. I'm sure they are doing detailed simulations, enhanced by experience with the RITT. At least when the basic engineering calcs say it should work, there is some chance it will. If the rough hand-work was questionable, I'd be very skeptical, but since the rough numbers seem robust I assume the finer calcs have a decent chance of working out.

Barring clathrates, I would think that by tomorrow the volume of emitted oil should be very visibly reduced, maybe to 1/4 of what we see now. We'll know in a day or two if this is working. If not, I'll humbly eat my hat, as I had to after the first dome failed. At least the rough numbers on that indicated it would float when full of gas, so there were obvious risks, but the clathrates are what killed that. The RITT didn't suffer much from clathrates, and I assume they'll have solved the issue for the top-hats as well.

We'll just have to be patient and see.

Full size crab sucked into 3mm cut http://www.youtube.com/watch?v=I30pcTBzbkI

I am neither a mathematician nor an engineer but your comment rings completely true to me! Thanks for not cluttering it up with all sorts of formulas.

It's important to get such elementary ideas out to the general public - for they can easily be bamboozled by overly complicated sounding concepts and formulas, which obscure the important points.

It's not intuitive, but math doesn't lie.......

How does the back pressure provided by the seal at the bottom figure out in the equation?

Intuitively, if the oil and gas is screaming out of the BOP at x psi, and the seal provide y psi back pressure and the pressure of the oil/gas/water in the pipe provide Z psi, I would imagine that at long as Y > Z (i.e. the back pressure provide by the seal is bigger than the weight of oil/gas/water in the pipe), oil/gas will come up to the surface. I think that is where we are now. But should the leakage around the seal determined by x-z (i.e. the different between the pressure of oil/gas coming out of the bop - back pressure provide by the seal)? How would BP reduce the leak from the seal?

The key point is that Y starts at 2250psi relative to the surface. Depending on where your column pressure Z (weight plus any topside restriction) falls relative to Y, your pressure at the seal could be positive or negative. Positive, and you spill oil. Negative, and you suck in water.

I don't think it's reasonable to design a clamp-on 2250psi seal, let alone a 5000psi seal, of that size. So, we're left with a balancing act for Z, with the only control being a valve at the top.

The key point is that Y starts at 2250psi relative to the surface. Depending on where your column pressure Z (weight plus any topside restriction) falls relative to Y, your pressure at the seal could be positive or negative. Positive, and you spill oil. Negative, and you suck in water

So if I understand what you said correctly. The size of the leak really is determine by the difference between (pressure from the BOP + natural pressure at sea - friction in the pipe - surface pressure) and (pressure of oil/gas from BOP - seal back pressure).. So if the leak is too much, I can acutally rav up the pump in the drillship and help to suck up more oil/gas faster to increas the flow upward (and hence reduce the pressure between the seal and the water outside).. So they do have control in the flow rate as they continue to experiement with the set up..

With RITT, I assume the same math work..but they did not control the leak very well.. Is it becuase the back pressure provide by RITT seal is too weak that even if they pump it at max, the pressure at the seal is still too much so oil/gas just leak?

I a not an expert but the cap currently being used (tried) does not appear to be the same one described in the post above (described as LMRP #7 - Yellow). On the BP site #7 looks like:

It matches the the illustration at the bottom of the post above. Note that it is white, not yellow (seems ready to deploy in image above, doesn't seem like more painting planned).

But the cap they actually used -- yesterday referred to on TOD as #2 but painted with a big 4 -- looks different. I can't find a good image of it now, but the current one seems to lack the open section in the graphic below, where you can see the yellow riser through it. #7 also seems to have 2 tall dark pipes, one of them shown here on the left side:

It seems to me like they didn't deploy #7. As mentioned, I an not an expert, so I could very well be missing something. Thoughts?

According to Thad Allen, they have about 5 possible caps they can use in storage on the sea floor. We may yet see the one used in your graphic.

I agree with you. The top hat BP installed yesterday was yellow on the sides, white on the top, had fins that projected outward and had "4" written on it. Thus, I named it Top Hat 4. Here are some images within a few minutes of it being put in place:

Local News about the Oil Spill

We are blessed with one of the better local papers

http://www.nola.com/news/gulf-oil-spill/

Animated Graphic

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/gulf_of_mexico...

The best tracking of the spill (it was about to show first limited entrainment into the Loop Current) was stopped (too much effort, their revenues are down 40% (they sell data to fishermen))

Their last map

http://www.roffs.com/deepwaterhorizon_contact.html

Best Hopes for Good Information,

Alan

Geez that June 4 projection looks like the spill is anthropomorphically recognizing state boundaries and has it in for Alabama.

Okay looking at the dispersant cam feeds now and this isn't working as planned it's obvious that the tophat cannot make an effective seal and most of the oil is billowing out from underneath. BP may be capturing 20-30% of the oil but I doubt it.

Amateur question again:

If this cap can't get a sufficient seal to allow oil capture, can more work be done to the sheared pipe? In other words, can the saw(s) get back in there to finish the edges better before attempting another cap off?

Was the flat, circular plate visible in earlier camera angles supposed to be a mating surface?

note: no oil experience but participated in many repairs and procedures in my industry, although none come remotely close in magnitude to what's going on here.

And since cutting what they did enabled perhaps 20% more oil to flow... then they may not be much better off than they were before!

Just eyeballing what I say a week ago flowing out vs. what's flowing today...I would say they increased it over 100% what it was.

This is the first opportunity to see all the oil leaking at one spot. Before it was split between the end of the riser and the kink. This makes the change in volume hard to judge.

Even so, it does not negate my point!

The kink was leaking progressively more oil every day due to erosion that was accelerated when they pumped the mud. It was only a matter of time before most of the oil was leaking there relatively unrestricted - and that leak point with the riser attached was a very hard place to design a capture system. There are no 'good' options in this mess, unfortunately.

For years I thought the bird on the Road Runner cartoon was saying "Beep Beep", now I realize it was "B P"....

OLD NEWS

Shelburne et al -- On a previous thread there was mention of a CNN "theory" that the rig sank due to being flooded by the fire boats shooting water on to the rig. I checked the rig specs to make sure there wasn't something unique about the design of this rig. From the pics I've seen it was constructed just as other semi's I've been on. The entire upper structure of the rig, including all the drilling equipment and crew quarters, sits upon two giant pontoons. These pontoons are empty for the most part when the rig is in transport. On location they are partially flooded to add stability.

As best as I can tell if one were to cut the drilling rig section free from the pontoons and set it in the water it would sink like a lead weight. There are water tight doors on the structure but these are for crew survival in case the rig were to sink. But the volume of the water tight area could not keep the rig from sinking if the pontoons were completely flooded. The analogy I used back in the beginning was to imagine two submarines (the pontoons) with a very big building (the drill rig) sitting on top of the two subs. The building can't float without the support of the two subs. Thus the CNN "theory" (couldn't find the story) is that these two subs were sunk as a result of the fire boats spraying water on them. Maybe if you left the windows open on the subs.

Another flaw in this "theory" comes when viewing the early pics of the incident when it was reported that the rig was listing at 70 degrees. I'm not a mariner but I don't think any vessel can list at 70 degrees. It would appear that one of the pontoons was breached and flooded. The rig wasn't listing...it was floating on its side supported by the remaining pontoon. I can't find the time line but the rig was half submerged for some time. If laying on its side didn't sink it immediately then spraying it with water doesn't seem like it would cause it to sink. It appears the rig finally sunk when the second pontoon flooded.

As I'm not a marine engineer I'll readily consider any explanation other than mine as to how spraying water on the rig made it sink. But I would like to see the details of such a "theory".

Going forward, it would be worth considering a new req to have some "survival" buoyancy as part of the basic design. Two big air bladders with plumbing is not very robust, compared to maybe 20 sealed tanks. Of course you still need bladders for controllable buoyancy, but surely there is a middle ground where the rig would at least float low in the water but maintain the feed?

It also seems like multiple break-aways in the riser string with hydraulic collets should be added. You'd think it would be possible to re-stab a collet to collect oil in such an emergency.

Is most of the oil leaking from the drill string? Or around it? If the drill pipe maintained integrity (questionable in the BOP, I'm sure), could that be "reacquired" to cap or to pump mud back down?

ROCKMAN - we'd have to look at the vessel drawings to know for sure, but it's quite likely that pathways existed from the deck box down into the columns. Unless all of the watertight doors and hatches are closed water on the decks of the rig COULD run down through the columns and into the pontoons. If you remember, on the BP Thunder Horse inclining test a few years ago there was communication from the deck box down into the low pontoon. I think something similar could have happened to the DWH. It's quite as likely though that some piece of gear falling off the drill floor hit the pontoon on the way down and put a crack in it which over a day and a half admitted enough water to sink the rig. But I guess my point is, that I doubt very much that after the explosions, abandonment and fire that there was watertigth integrity between the deck box and the columns and that would have allowed a path for water to run down into the pontoons. Not sure how much "water" would have survuved being sprayed into that fire. Seems like most of it would have turned into steam before it ahd a chance to collect and run downhill.

Something else I was going to ask about.... what's the well design review process like at MMS? Do they have enough skilled people there who can actually look at a well plan on the permit application and say whether it's a sound design or not? How would industry set up some sort of peer review process to make sure well designs going forward are based on best practices before a permit gets issued? Because unless you have the right people looking at things like that you end up with a bureaucracy that slows down legitimate work and doesn't add any safety or integrity to the process, a la OSHA or MSHA.

grump -- Certainly merit to you thoughts. I recall that when the RANGER sunk off Canada decades ago there was speculation that a open hatch allowed sea water to get to a control panel. This inflow didn't sink the rig but the loss of control over the system allowed the stucture to be flooded. It would be great to see if there were pathways for the water to reach the columns/pontoons. You would think standards ops would be to have those hatches secured at all times. But back to that human error factor again.

But the big clue for me is that the rig floated on it's side with just one pontoon. At that point the sprayed water couldn't fill that pontoon as the pathways were then horizontal.

The pontoons should have been designed like a ship, with bilge pumps to remove unwanted water, IMO. Ships do get small leaks in the hull from corrosion of welds, bad seals around prop shafts, doors/hatches above waterline not sealing during high waves. I know this from a friend that used to work at shipyard for river going and sea going barges.

Since bilge pumps did not work after power failure, then water may have been entering one of the pontoons and caused it to loose bouyancy. Maybe open hatch or door caused more water to enter pontoon as water was put on rig fire.

Kind of like the sinking of the Edmond Fitzgerald in Lake Superior (1972?) - its hard to find cause when its at the bottom.

While the additonal volume of water played a role in the sinking of the vessel it was the change in the metacenter (center of gravity) and resulting change in the metacentric height which ultimately led to the the rig turning turtle and sinking. Semi's have a comparitively high CG while under tow but once ballasted down to drilling drift they are by far the most stable of floating vessels. As I recall a typical semi (catamaran hull) will turn turtle at a list of approximately 23 degrees whereupon the leading deck edge is at or near the water line. That places the opposite pontoon near surface.

All that melted iron and equipment didn't simply vaporize, it changed levels and moved.

I am not a marine engineer by degree or profession but I d@mn sure went to stability school when I started working floaters.

I've never been a sailor or marine engineer, but isn't it pretty common to have some amount of leaking on a large ship? I can imagine the pontoons may never have been totally watertight, but would ontain pumps to eliminate the water from any smallish sized leaks. Once the rig fire destroys the ability to run the pumps, then they are gone, and it ought to start filling up.

I can imagine water being sprayed onto heated parts of the rigs causing all sorts of thermal stresses, as some parts of the structure heat and cool rapidly depending upon how much spray they were getting versus how exposed they were to the fire.

I've been thinking about that too; last night I watched the Nat Geo special on the disaster and it had some pretty good footage of the rig fire. At the time of the sinking I kind of thought the fire fighting efforts might have flooded the DWH--after seeing the footage I don't think that would be the case.

The fire was intense enough to soften the steel the semi was made of and there was clearly some distortion of the ship's structure; also there are many reports (and you could hear some in the video footage) of internal explosions prior to sinking. I think the deformation of the structure changed the water line, and probably pulled open some conduits for flooding down into the pontoons, and who knows what trauma those internal explosions might have inflicted on the vessel's integrity.

Of course, all the fire and smoke made clear observations very difficult.

A report from the CBC and oil industry fire fighter Mike Miller takes this perspective:

http://www.cbc.ca/money/story/2010/06/02/f-gulf-spill-canadian-oil-indus...

The rig looks pretty burned up at the time of sinking and the water beneath the rig is completely covered in fire. I believe it was just a matter of time before fire consumed the rig. It's also possible the volume of hydrocarbons spilling on the rig floor and spreading throughout the ship exceeded the volume of water reaching the rig from coast guard boats. And the stuff is flammable. Still, it's worth looking at.

A question for Mr. Miller: what would have been the eventual consequence of having the rig, with is positioning capability gone, tethered to the wellhead by the riser? How long before the wellhead failed and unconstrained flow from an open well occurred? Or if the riser parted above the well the situation is identical to what we now have.

Rockman

Everything you say is factual.