The BP Deepwater Oil Spill - Why Top Kill May Have Failed and Monday Open Thread

Posted by Heading Out on May 31, 2010 - 9:30am

Please transfer discussion to http://www.theoildrum.com/node/6558.

Note: this is the same prose from last night's post of 6p or so, just with a new comment thread this morning. Enjoy.

The Top Kill attempts have failed, and the Government has given its response.

He (President Obama) said US Energy Secretary Steven Chu was leading a team of "the world's top scientists, engineers and experts" in devising a contingency plan should the "top kill" attempt fail.

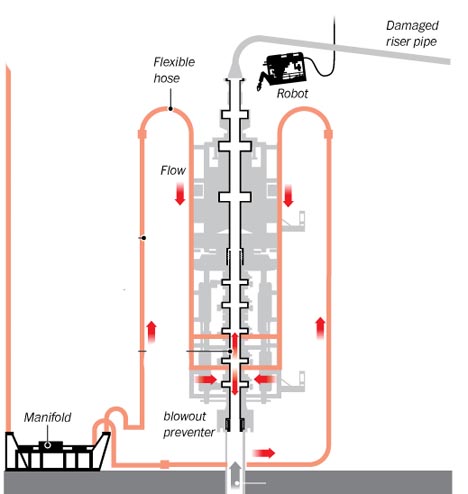

But while waiting for that, and for the Lower Marine Riser Package (LMRP), I thought I would spend a few paragraphs discussing why Top Kill may have failed as a substitute for my tech talk tonight; you can find that under the fold by clicking "there's more."

(The last post has a very technical discussion of LMRP, check that out there and in the comments.)

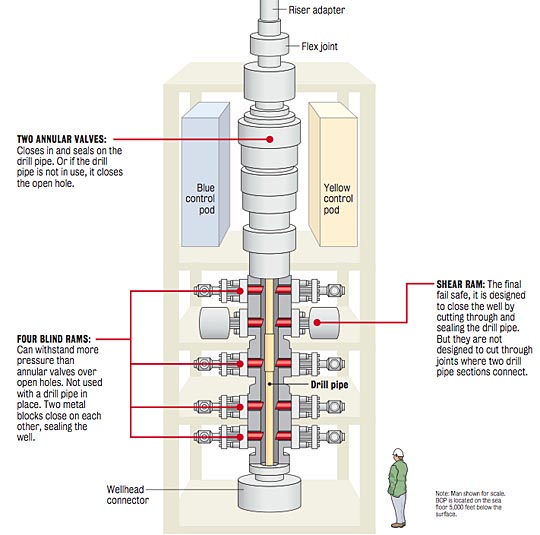

In a couple of earlier posts I wrote about how it was necessary to fill the gaps that ran through the Blow-Out Preventer (BOP) either with spheres and triangles or with wire (string would act similarly). To refresh your memory, in the initial simpler analysis, I had put up a simple sketch of the BOP and well, to show how the blocking particles were injected.

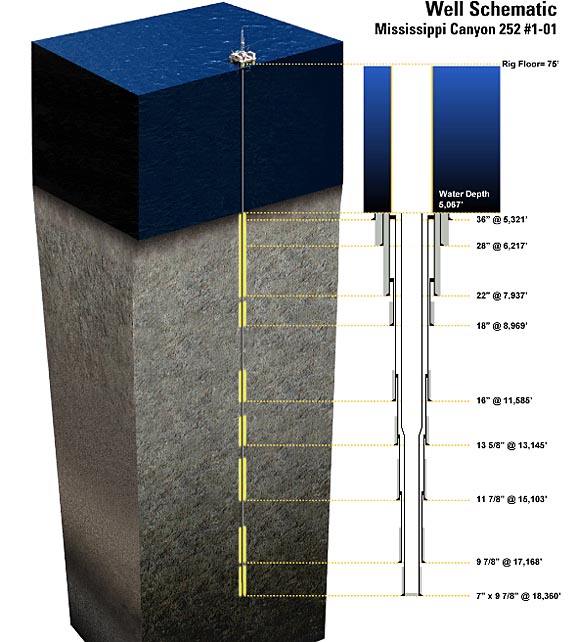

Now, unfortunately that diagram left a significant part out, and that is that there are three sets of pipes leading down into the well. These are the well outer casing, which, surrounded by a layer of cement, holds the BOP in place. Then there is the production casing, which had just been set to the full depth of the well. And then there is the drill pipe that, at the time of the incident, extended down 8,367 ft from the platform, or roughly 3,367 ft below the BOP. That drill pipe (DP) had previously been used to locate the production casing at the bottom of the well, and itself now rode inside that production casing. In most normal operations it is closed at the bottom by a drill bit, but (and I’ll come back to this later), it had just finished the cementing of the production casing into position, and once it detached from that and was being pulled from the well, it was an open pipe all the way up to the rig floor. And in that condition, it could be used for other things. By pulling mud out of the DP and transferring it to the mud pits (or standoff vessel), the level in the riser would fall and be replaced by seawater flowing in at the top. Unfortunately this also lowered the weight of mud in the well, and that is what caused the oil and gas to flow into the well.

Outside of the DP is the casing and cement segments that make up the outer lining of the well. The diagram presented in Congressional testimony, shows these various pipes, except for the central drill pipe.

BP do not know, but believe that the oil is getting into the well through the cement wall at the bottom of the well, and probably rising up the well through the empty space (annulus) between the production casing and the outer lining of the well. However the oil and gas may have broken through the bottom of the cement plug and be rising up within the production casing, in which it is also rising through the DP once the oil reaches its lower end. It could also reach the bottom of the DP by flowing up the annulus then go down the production casing to the bottom of the DP and then back up into the BOP.

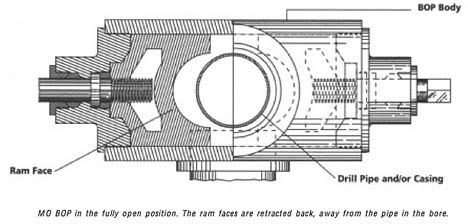

Most normal blowouts occur when the well is being drilled, and mud is flowing down, through the drill bit, and then back up the space (the annulus) between the DP and the rock wall. Thus, when there is a blowout, the oil and gas that flow into the well normally flow up this outer passage to the rig, and give the spectacular fountain of oil. The BOP was invented (by Harry Cameron and Jim Abercrombie) to stop that flow and to protect the crew at the surface. Because the flow is normally up the outside of the drill pipe, the initial BOP designs were rams that pushed seals across the flow path through the BOP, and sealed against the side of the DP.

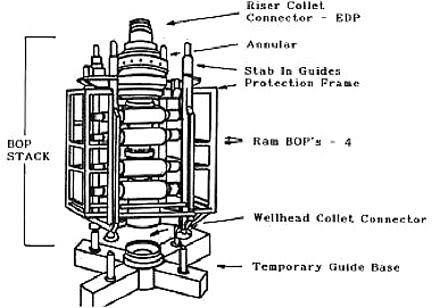

A BOP could have two of these mounted so that one sealed to the production casing in the well, and one to the drill pipe, but if underwater then the production casing is tied back to the Wellhead Collet Connector, and then the only tube running through the BOP will be the DP, to which they will seal.

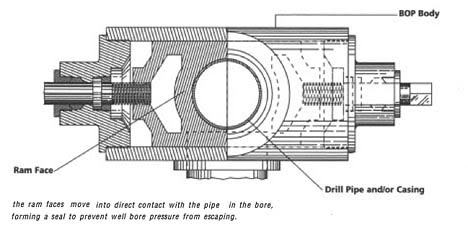

The problem that this leaves, in the current situation, is that the pipe that runs through these two seals is open at the bottom to the oil flow. So how can the flow through this be stopped?

The answer is to mount a top ram set that has a set of shear cutting blades on it, that will cut through the pipe and seal the full face of the well.

The DP should shear, but would be held in place by the grip of the annular sealing rams below.

In this case it seems to be recognized that for some reason this shear event did not totally succeed. Thus the pipe was not totally severed and the two shear plates did not fully move over one another to complete the seal.

Now this is where the problem arises, because, in part, that pipe is still open at its lower end. If the leak is around the outside of the pipe, through a gap that has generated between the pipe and the annular seals, then the use of the junk shot to fill the cracks and gaps could conventionally have worked. But the configuration of the rams on the Deepwater Horizon had changed from the initial simpler configuration to add seals for occasions where the drill pipe was not in place.

And the "junk" is being injected at the bottom of this stack.

If the leak is coming up through the remnants of the drill pipe then life is complicated. It can’t all be coming up through an undamaged pipe alone, since it was the far open end of that which was successfully closed at the beginning of the remedial steps, but if it is coming through the pipe and leaking out at the shear rams into the annulus that feeds into the riser, and out to the sea, then putting sealing particles into the bottom of the BOP to seal the cracks could have sealed some of the leakage around the DP trapped in the shears, but not that flowing through the shears in the remaining pipe section.

The reason that it can’t is that the access to that flow is occurring 3,367 ft below the riser, and there is no easy way to get the sealing particles down that far. If they are mixed with mud and pushed down the well to that level and then released they have a different problem. The hope when they were released into the well was that the flow of the current would be enough to carry them up to the cracks that they could seal. But if they have to be carried down to the zone where the oil remains, then their density may be sufficiently high that they get into the flow without enough speed to lift them up into the BOP, instead it will cause them to sink to the bottom of the well.

The materials that BP tried included materials that might float on the surface, and might not be dense enough.

Those materials, including fibrous pieces of rope and chunks of rubber, were supposed to force more of the mud down the wellbore, but ultimately it did not work.

Rubber has a specific gravity of 0.91 and rope varies from 0.9 to 1.4. But remember that at that depth any buoyancy from air entrainment would be lost.

In other circumstances it might have worked, If they could have dropped the DP out of the shears perhaps, but they couldn’t and it didn’t. So on to the LMRP.

UPDATE: Thinking about this a little more, I had two more thoughts. The first is that once the LMRP preparation cuts off the riser and the bent drill pipe, then the full weight of the pipe below the shears may come onto the section in the shear jaws at the moment, pulling them further out of alignment and increasing the flows. It could also cause the pipe to drop out of the jaws, pulled out by the underlying weight, and hopefully not distorting them too much so that in the best of worlds they could then be cranked shut.

One could also, once the bent riser and pipe had been cut, go in down the pipe bit that extends up, go down past the annular seals with an abrasive jet lance (most of the flow is around the DP as we have established above) and cut it off, right above the shears. Then partially open the shears, drop the pipe out, and close them again. If they move all the way closed, without the obstruction, then the well may be sealed.

A *very* sincere thank you to all who have donated thus far. It will help with the increased costs we face (see point 3 below).

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of threads yesterday and today before you start on this thread. They were really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 400 comments, as it's really unmanageable. Lots of good stuff in there though.

For those new to TOD who would like a little variety in their reading instead of just following the Gulf spill posts, there is a wonderful section called Tech Talk. There you will find an enormous amount of info on energy topics written by experts. Rather than say more about them, I'll just point you in their direction and let you explore.

At the top of the Home page, in the five by three grid in the center of the page, the link for Tech Talk is the one on the lower right.

I've learned a lot there, hope you do too.

Several questions, Goose:

How damaged/distorted is the DP where the shears made contact. Is there enough clearance to allow it to drop free?

If the DP drops free into the well, how much velocity will it have achieved when it reaches the bottom? What damage could it do to the cement plug I undestand is in place? Assuming the seal at the bottom is intact and that the current flow is around the casing, could this punch through and open up a more direct path between the formation and the wellhead.

Also, how would having the DP sitting in the bottom of the well affect the relief well attempt. It seems to me that the relief wells need to be below the DP for best chance at success.

Many questions...........

Ah, the ol' drill pipe and the shear rams. How tempting they are, like naked gurls on the other side of the bullet proof glass.

This topic has been a pet for your's truly going back a couple of days. One idea floated during the conversation was that res pressure would blow the drill string out of the well. I personally don't think so but what are the odds?

If the drill pipe won't drop, why not pull it up by 'fishing' for it?

My idea was to affix new drill pipe to what is in the casing already (about 3,000') and push it to the bottom and kill the well this way with a 'kill pill'. The 3,000 feet of drill pipe and cutter head partway down the casing are the superhighway (Thx ROCKMAN) to the center of the problem. Why not use it?

Why not attach a mud line to the drill pipe with a Dresser coupling and start pushing mud into the hole while the LMRP or backup BOP is readied for installation? Mud can also be pushed throught old kill and choke lines as was attemped during the top kill. The drill pipe would put mud into the well @ 3,000 feet as well along with mud entering at the top.

The first top kill was sending mud down the casing and having it return to the surface via the drill string. Obviously a waste of time.

Gushie's still having his wonderful show!

Even better, his friends along the seafloor are coming to party too! Seabed's collapsed and volcanic vents of oil are spewing joyous plumes miles from the well.

There's no stopping them now, the fantastic four shall pour forever more!

I've been thinking a lot out this leak. When the leak first began, I dismissed claims of how game-changing an event it might be.

However, up to now, the pessimists have been proven right.

And now with the prospect that the thing will keep leaking at least into August, I see it differently. I keep thinking about the satellite pictures I've been looking at, which show the spill stretching out over a substantial area of sea. It pains me to imagine what that slick is going to look like from space three months from now. Will the whole damn Gulf be a sheen of oil?

Who's gonna want off-shore drilling in their "back yard" going forward? Nobody.

So much for new drilling in Alaska; so much for drilling in the Gulf. Not saying it won't happen, but it will be a ferocious battle.

So, this event is a game-changer not unlike Three Mile Island was, which cast nuclear power in the public's eye as, well, dangerous. TMI effectively killed new nuclear energy production in this country, if I remember my history right, when the public developed a negative attitude toward nuclear energy as a result.

On the other side of the coin, there will still be a terrific demand for oil--that doesn't go away overnight--with concomitant pressures to extract more. But with our enhanced NIMBY mentality, where will it come from? Other parts of the world? Will we become more imperialistic, our relationships with oil-producing countries more, well, hegemonic and exploitive in order to garner cheap-ish oil?

Well, I could go on hypothesizing in this manner, but. Something's gotta give and I'm not sure what.

My not-very-expert guess is that there will be new initiatives to build new nuclear energy plants. TMI is more than a generation past, and people forget. Well, that's not so much a prediction as it is a musing.

If they can get the LMRP to work couldn't they depending on the condition of the BOP and drill pipe left in the hole rig a snubbing unit and run tubing to bottom and kill the well from there?

An earlier diagram I saw on Rigzone depicted the 9 5/8 / 7 inch as a liner from 15,000 to 18,000 but the diagram in this thead show it as production casing covering top to bottom, so if the leak is in fact coming up that annulus you would have to perforate or cut a window in the 7 inch near the bottom for my idea to work.

The current video shows the plume from the end of the broken riser...they must be staging equipment...what was the reason for deploying the mud mats yesterday? What are they going to set on the mats?

Could they be there to catch things that the robots drop?

No, mud mats are a glorified road fabric that support weight on muddy surfaces.

That would include dropped things too... No one wants to see another saw disappear into the mud. But yes, of course, it could include things they "intend" to set there as well. ;)

Rio - That would be the standard aproach to killing the well. BTW for those that haven't heard of snubbing units they are like a BOP in that you can run drill pipe thru it while keeping the well from flowing by using an annular packer wrapped around the drill string. But the first problem would be the drill pipe stuck in the BOP. I haven't seen any report indicating it wasn't still there. But if they could attach a snubbing unit or BOP and IF the seal between the old BOP and the new unit is sufficient they can inject ("bullheading") mud thru the new choke line at a pressure greater than the well's flowing pressure. Bull heading isn't the best approach (it could break down csg or other cmt shoes and pump mud somewhere else other than to the bottom of the hole) but it seems like the only option at this point. But as I understand the current plan they will not try to pump in but instead pipe the oil/NG to the surface. I'll guess this is an acknowledgement that they don't think the seal could handle the high pump pressures required to kill the well.

Rockman

I have been having a closer look at the BOP. They did not have much.

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf Warning 18 mb

Lower Rams = Test rams work from top not bottom. Non well control

Middle Rams- OK tested 7100psi

Upper pipe rams - OK tested 7100psi

Casing rams, yes they were there, but going by the Transocean BOP test they had an exemtion not to function test= not operating. This would have been written by Transoceans, but BP would have known.

Shear blind- OK but not tested during normal BOP test. Though it was used during the casing test to 2500psi

Lower Annular- stripping element installed max 5000psi, tested 3950psi

Upper annular- Tested 5200psi Max 10000psi

BOP test pressures as I understood it, are suppose to be a min of expected BHP. Maybe the pressures got higher than expected but I would have expected they would have bumped up the test pressures. In effect they only have two pipe rams tested to 7100psi, 1 annular tested to 5200psi and one tested to 4000psi.

In the last minutes before the explosion one annular was closed and the SPP had reached 6000psi before the records stop. If the annular that was closed was the lower one, with the stripping element, this could explain its failure.

Toolpush...

Go read this article - you will probably understand it better than I do...

http://www.nytimes.com/2010/05/30/us/30rig.html?pagewanted=2

It mentions previous BOP issues w/ hydraulic leaks, and testing at a lower pressure after the well control incident in March. (e.g. 6500 instead of 10000)

tollertwins

Thanks for the link. So they started testing correctly and then dropped back just as they entering the higher pressure zones. Makes you wonder if they were having trouble getting a 10000psi test, and nobody wanted to that the hit of a weeks down time.

Makes you wonder what they were nursing

pusher -- great summary...hang in there...much appreciated. I know enough about the details of BOP functioning to be dangerous.

Rockman

Just remember when the sh** hits the fan, press the enable button, then the rams.

So true pusher. The two company men I knew who died in blow outs hung in there and did just that. Good hands to say the least. Unfortunately the families didn't even have a body to bury. Just a memorial at water's edge. Coincidently a good day to dredge up such memories.

Chris Pleasant, subsea engineer, stated that when he came to the BOP panel at the bridge it showed the lower annular closed and all other ram elements open. He activated EDS and the panel acknowledged but there was no hydraulic pressure to complete the operation. He concluded that the well could not be shut in and they needed to abandon the rig.

There has been a persistent rumor since the sinking that the shear ram did partially operate, but the testimony suggests otherwise - the explosions severed the hydraulic lines to the BOP stack and the accumulators on the stack had bled off or were non functional.

The drill pipe, by testimony, was not the source of the seawater and mud during the blowout, but the annular space.

I have the impression that the BOP stack had multiple problems, but was functional enough for normal drilling operations and they hoped to nurse it along until they could pull it at the end of the job and effect repairs.

In the testimony one gets the impression that the OIM was not aware of the details of the operation - just the general work-flow, but depended on the various crews to do their jobs effectively. He apparently made a statement the day before to the effect that if there was any trouble with the well, "well, that's what the BOP is for" (to shear the pipe and close in the well). The people actually doing the work give pretty clear testimony with straightforward answers to questions.

I am leaning toward a conclusion that the well design was insufficient for the task - it was a minimal solution that could be expected to work if all the components performed exactly as expected, but had very little safety factor. It also seems that the tests that were done the last day were equivocal and did not provide clear information on the status of the well - they were a little off, not red flashing lights, but not completely satisfying. Perhaps the production casing masked some potential problems and the tests were inadequate to identify the problem. The VIPs were on board, they were behind schedule, but were over the hump and just needed to complete the last cement plug - so the indicators of potential trouble were easier to pass off as just normal variation - not perfect, but not damning either.

My background is in oil refining, not oil exploration/production. As I read descriptions of the BOP, it's not clear to me if any of the various BOP components are "fail closed" by design. In oil refining, safety critical valves are often designed to fail closed or fail open, depending on which fail state is required for a safe shutdown of the process. We premise emergency scenarios where the valve's external energy source (electrical, hydraulic, or pneumatic) is lost, in which case the valve's mechanical design causes it to go to its fail position (open or closed). What is the fail position of the BOP's components?

There is a 'deadman' condition (loss of all communication, power, and hydraulics) from the rig that is supposed to trigger the shear ram and annulars to close the well. Two problems - there is a battery backup system that provides power to the BOP stack and its controls and this was functioning because the rig control panel at the bridge had control lights and status indicators after the rig power went down. However, the loss of power and/or the explosions led to complete loss of hydraulics. The accumulators on the stack that were supposed to provide hydraulic pressure in case of loss of pressure from the pumps on the rig failed - perhaps because that system had long-standing leak issues. The deadman condition was not met but the rig could no longer supply pressure to the rams, so attempts to close the rams from the rig controls failed also.

The crew on the rig floor communicated that they were attempting to close the well, but the gas explosion killed them before they could successfully complete this operation.

There was an attempt to start backup generators on the rig to provide power but they would not start. Speculation: the gas alarm system prevented the manual start of the backup power - even though it had live batteries. The workers that tried to start it said it would not turn over even though the batteries were charged and ready.

Lines of questioning during MMS investigation suggest to me that the air intakes for the power generators were inboard - and therefore subject to gas ingestion from the rig floor area. I got the sense that if they had been to the outboard side this liability might have been minimized.

BP is going to try and claim that their well design was not at fault and that the Transocean crew was negligent and ignored warnings. Likewise Haliburton will claim that their crew just provided what was specified by the well plan and that it was up to Transocean and BP to check that the cement was doing its job.

The OIM said that use of nitrogen cement that low in the well was unusual - he might have had to do this "a couple of times"...

I don't believe Transocean will just roll over and take the hit - though the problems with the BOP and the testing of the well condition will surely be cited as contributing factors.

There was a lot of questioning about the mud returns - reports that the returns were going directly to the boat and not being monitored were flatly denied by the OIM - he said it was impossible to do this, that the mud had to be first stored on the rig and off-loaded in a separate operation. A couple of other witnesses said the same thing.

Thanks. Unless I am not understanding, the deadman system is not describing a fail closed design. A fail closed valve requires that the energy source that normally activates the valve (hydraulic, electrical, or pneumatic) must be present in order for the valve to stay open. If the energy is lost, the valve's mechanical design causes it to close. For example, a valve may be spring-loaded to close, energy is required to keep it open. If the BOP annulars were designed that way, when the hydraulics to the BOP were cut the annulars would have automatically closed.

I'm surprised to learn that the last line of defense to prevent a well blowout was premised to require fast human intervention to shut down the well. Human factors science, as well as experience from industry near misses and accidents, tells us that humans cannot achieve sufficient reliability in that kind of scenario. In oil refining we have augmented operators with fail safe valve designs as well as more complex automated shutdown systems that are independent of the main control system.

"Unless I am not understanding, the deadman system is not describing a fail closed design"

Yes, my understanding is that it is not "fail closed". I am not sure if it is possible to generate the force necessary to operate the shear without hydraulic pressure.

The design seems to incorporate some redundancy and a "fail safe" mode, but also to guard against accidental activation. I don't think solution here achieved the right balance - tragically.

It may not be practical for the shear rams to fail closed with a simple mechanical design, given the force required to cut through the high pressure piping. I don't know. But could the other devices on the BOP that shut well flow be fail closed by design? Does anybody design BOPs that way?

If the system had been in good repair - the accumulators charged and no hydraulic leaks - the subsea engineer should have been able to shear the pipe and unlatch the rig - despite what had just occurred (gas explosion, well coming in, power loss, etc). Even if he had not the deadman system should have operated when the rig sank. I think BP had ROVs down there ASAP and they were unable to operate it either.

It was designed to function even under the circumstances that were encountered - but it didn't.

There is the unanswered question of whether the shear ram installed was powerful enough to cut the pipe/casing in the well at the time, but whatever the answer to that specific question there are rams available that can.

Pneumatic brakes on trains for instance, fail closed (or used to) - the air pressure holds the brake shoes AWAY from the wheel, and in the case of a broken line, the brake is activated. You could imagine BOP designs with a similar approach.

I think that a bigger problem with BOPs (and similar safety measures) is likely to be the psychological barrier to activating them...no one wants to be known as the idiot who triggered the bloody thing by mistake and caused everyone another two weeks' of work (or whatever).

I don't know for sure, but I believe I read that the drill pipe was open ended and the top of it should be a clean cut. They should be able to run tubing of a smaller diameter thu the drillpipe depending on what damage the rams have done. Of course the seal might be a problem. I just aways think in terms of how can we get to the bottom of the hole where you can more effectively kill the well. And there will be so many more options once they have access from a rig though the top of the BOP.

I have personally been involved in killing wells in the deep Anadarko Basin with higher pressures than this one, but being 5000 ft below sea level introduces a whole new set of problems.

bsmyth292:

My particular focus for quite some time has been on global net oil exports, and "Net Export Math." Most people don't realize it, but the US became a net oil importer in 1948, 22 years before our domestic production peaked, and our net imports increased at a double digit rate per year from 1948 to 1977:

http://www.eia.doe.gov/emeu/aer/pdf/pages/sec5_4.pdf

In any case, given a production decline in an oil exporting country, a simple model (the "Export Land Model" or ELM)--and numerous case histories--show that the resulting net export decline tends to exceed the production decline rate and that the net export decline rate tends to accelerate with time.

Here is a link to a paper that Sam Foucher an I worked on, which attempts to model a range of future net oil exports from Saudi Arabia, Russia, Norway, Iran and the UAE:

http://www.energybulletin.net/node/38948

A quantitative assessment of future net oil exports by the top five net oil exporters

One interesting aspect of the net export situation that surprised me is the extent to which developing countries (especially China & India, "Chindia") have been increasing their oil consumption, as oil prices rose at 20%/year from 1998 to 2008, while developed countries were basically forced to reduce their consumption, especially after 2005.

I suspect that we will continue to see developing regions like Chindia outbidding developed countries for access to declining global net oil exports, and I therefore anticipate that the US is well on its way to becoming largely free of our reliance on foreign sources of oil--but not in the way that most people anticipated.

I agree with you that it's likely to be a game changer. And personally I think a lot of things may "give". There are chances that people will wake up and consider conservation of energy. Or they may seek to switch energy sources. Plus, many people may realize that this terrible catastrophe in the Gulf is set to SPREAD - and that we need to wake up and consider how what happens on our shores affects the whole world - and that those effects can endanger the whole world. And that we need to wake up to our sense of responsibility and examine how our behavior led to this crisis. That's a painful pill for many people to swallow, but they just might "get" that we all need to work together for the good of the world, not just in terms of this oil gushing but also in terms of our wider behavior, which can affect the whole planet for good or for ill.

So I'd like to see the game change in a whole lotta ways. And I think this current crisis - which has people on the edge of their seats watching oil gush under the gulf as robots work - can become a huge teaching moment. And much of that teaching may happen right in people's living rooms or around the dinner table.

I, of course, feel terrible for all those directly affected by the leaking oil - people, fish, birds, microorganisms, the beaches, the marshes, the reeds and seaweed, the water itself, the air - but I am sincerely hoping that this crisis can also become a springboard for rethinking and for change, individually, nationally, and in terms of our common humanity and common inheritance on this fragile planet.

Welcome to the Drum :>)

Uranium Depletion and Nuclear Power: Are We at Peak Uranium?

Posted by Prof. Goose on March 21, 2007

http://www.theoildrum.com/node/2379

The whole NIMBY boogieman is nonsense. All around the world people live next to industrial environmental disasters right in their back yard. They blow the tops off of mountains that people lived on and loved just to keep the air conditioners running. If you look at the places where things like that happen it just means that the people who object are powerless. As times become more and more difficult due to peak oil, climate change, and economic and political crisis, wealth and power will continue to concentrate in the hands of a smaller and smaller group - which means that unless the masses are organized in some way (unlikely), most people simply have no say. And the media can convince them anyway. Beyond which, as our access to oil becomes more limited and we're stuck with the oil-based society and infrastructure we have, people will become much more focused on immediate needs.

It was not public outcry that killed nuclear power, but rather the incredible costs that made it a poor investment.

In the end what will give is protecting the environment in favor of keeping BAU going a little longer.

where will it [oil] come from?

It (oil) is not going to come.

At least not in the quantities that we need to survive and function at anything close to BAU.

That is the raison d'être for The Oil Drum.

Alan

---------

Our "culture" here is based on a diverse group of intelligent people grappling with the myriad implications and mitigations of this simple fact.

Many have noted how we seem to stand alone in a fact and logic based search for facts regarding the BP Deepwater spill, with some quite experienced oil industry types on board.

This is a simple re-purposing or change in focus of what we do, week after week, struggling with a much larger intractable problem.

There are solutions#, but they are not easy ones and getting the body politic and the public at large to seek those solutions is an intractable problem (see Nate's latest post).

Best Hopes for Our Future,

Alan

# After long and bloody debates, most (not all) commentators on TOD will agree that there are, in theory, solutions, but many doubt the likelihood of their implementation.

TOD debates rarely focus on the primary subject for long. Peak Oil has far reaching effects on all of the systems that modern civilization depends upon, as these systems also affect oil availability (think credit, climate change, environment, politics). One article posted here:

http://beforeitsnews.com/news/48/397/Apocalypse:_Six_Trends_Converging_o...

Was discussed recently on this Drumbeat: http://www.theoildrum.com/node/6502

The author descibes this "convergence" as "a perfect storm", possibly leading to decline/collapse. Many of us believe that it is this convergence of factors that will limit our ability to respond in any effective way.

Hold on to your butts folks. It's gonna be a wild ride!

Alan, I do agree there are many things we could do, thought I would not call them solutions - more like mitigation strategies. And we could even fund it: cut the military budget by 10x, bring home all troops and close all foreign bases and start building out electric light rail, insulating homes, building renewables where that makes sense, etc. But I don't believe we will do that.

Excellent analysis, I just want to point out that the world of electricity is almost completely separated from the world of oil. You can't decrease dependence on oil by increasing production of electricity; transportation in this country (and most of the world) is 99% dependent on oil. The only way to decrease dependence on oil is to construct electric trains and an urban structure that can take advantage of those trains.

An exception is Switzerland.

The railroad, SBB (which does not include the city tram systems) uses 3% of the transportation energy (all renewable electricity) to move 1/3rd of the freight tonne-km and 1/6th of the passenger-km. And they could increase these % if need be (and they are investing 31 billion Swiss francs# over twenty years to move freight to electrified rail and improve passenger service).

# Adjust for population and currency and 31 billion CHf is >$1trillion for the USA.

Best Hopes for Those that prepare,

Alan

Alan, I'm a big fan of your freight studies, and I quoted you in my forthcoming book. Also, Gar Lipow, a fellow (somewhat ex) blogger at Grist has been referring to your freight studies as well (maybe you could try sending something to Grist?).

At any rate, I also wanted to point out that Switzerland may have the highest concentration of geothermal heat pumps, that is, heat pumps that are drilled into the ground and provide much of the heating and cooling needs of a building (with an electrical assist). For countries/regions that use oil for heating, cooling, or generating electricity, this is another good way to move from oil, and if the electricity is renewable, from fossil fuels as well.

You don't have any data on Swiss geothermal heat pump use, do you? The latest study I can google is from 2004.

Thanks for your work,

Jon Rynn

Geothermal should be a crash program everywhere, and it's not. I wonder myself what sideways drilling could do for geothermal. I suspect a lot.

I wish I had data on Swiss geothermal/ground loop heat pumps, but I do not.

The Swiss are aware that their primary source of domestic energy is hydroelectric (plus nukes) and there is a limited amount of it (and they are reluctant to build more nukes).

So they are trying to use the limited renewable resource they have (plus nukes) as efficiently as they can. Make their homes efficient and then use a source that turns each kWh of electricity into as many kWh of heat as possible.

Minimize imports (except French nuke electricity late at night when it is dirt cheap) and maximize efficiency.

The Swiss are also moving towards CHP (central heat and power plants, some fueled with garbage).

CHPs burn something, generate electricity first with it, then use the rest (waste heat elsewhere) for heat and hot water. VERY efficient. They are behind the Danes in that area.

Best Hopes for the Prepared,

Alan

OK, I admit that I got here because of the BP spill, but as a Dane living in Switzerland (at least for now) and very interested in environment/climate change/energy issues I thought I would comment on this one:

Here are some Swiss stats for 2008 (unfortunately in German):

http://www.bfe.admin.ch/themen/00526/00541/00542/00631/index.html?lang=d...

That still seems to show 45% dependence on oil. 24% nuclear and 11.5% hydro (page 7).

So even here there is a long way to go and I personally keep wondering what happens when all those nice alpine glaciers have melted later this century.

Also, I thought that CHP actually led to loss of efficiency in power generation and that we are better of with our heat pumps.

As to geothermal, the Swiss are still mulling that one over after having triggered small earthquakes under Basel during a test drill a couple of years ago.

Finally, many many thanks for all the thoughts on the BP spill. I was pretty sure the press and general public had no clue what conditions they are operating under down there, but your comments really bring that one home. Will just ignore the news from now on! ;-) Sadly, it seems to mean no respite for the Gulf.

Swiss solutions for Switzerland, maybe, but I don't think it can be very generally applied.

Let's compare Switzerland with the smallest country in South America,

41,284 km2 - 15,940 sq mi - Switzerland - 7,8 million people, very rich

176,215 km2 - 68,037 sq mi - Uruguay - 3,5 million people, poor

Switzerland is a very small, densely populated, very rich country with a high technological level, surrounded by the most advanced societies in the world, its trading partners.

I don't think that solutions for a country like this (where does it fit in size, if it were in the USA?) are appropriate even for the USA.

I don't know the specifics of Uruguay, but the Swiss are still pretty densely populated, I believe. In other words, an electric train network works in Switzerland, and much of Europe, because the towns/cities were not underfunded, as in the U.S., and sprawl was not encouraged, either by cheap oil (since the taxes in Europe are so high) or by government policy (the U.S. government created the mortgage industry, etc.).

I have a feeling that much of the structure of Uruguay, and much of Latin America, is pre-1920, that is, before the full effects of cheap oil could be felt. I could be wrong about that - witness the sprawl of Mexico City. But it might not be too hard for even a poor country like Uruguay to concentrate on its older, denser cities and towns. You don't need high-speed rail; "regular" rail will do as well, and by using electricity even a poor country has many more options than being dependent on oil.

As for ground source heat pumps, they seem to be expensive, because you have to drill. I don't know whether there are some economies of scale there; a dense city with big buildings would probably be cheaper to provide with ground source heat pumps than a mass of single family homes.

I think you may be confusing geothermal energy (hot rocks, thousands of feet down) with ground effect heat pumps, which are very shallow systems. A new house was built using this technology in western UK village where I live - the hole was dug with a standard JCB, uh, "backhoe". See for e.g. http://www.energysavingtrust.org.uk/Generate-your-own-energy/Ground-sour... -- there's tons more on your friendly local search engine.

imipak, thanks for the info, but actually I know that there is a huge difference between ground source heat pumps (gshp) -- with 200,000 units in the US already alone -- and geothermal power plants, which for some inexplicable reason (well, probably a bunch of reasons) have not been extensively researched and built. The problem with gshp, from a research point of view (at least someone who basically has to rely on the internet) is that it's hard to come up with a lot of figures on cost. I've found quotes of $20,000 for a 2500 sq ft dwelling, which sounds like a good ballpark sort of figure, and which is still fairly expensive, and I figure it must be mostly the cost of digging; I don't think the heating/cooling equipment is that expensive, and the pipes aren't either...at least, I don't think so.

Re: ground source heat pumps, costs, savings

Check out the new New Hampshire Institute of Art building in Manchester, 7 stories tall, includes student dorms. Source for heat pumps is 2 wells, deeper is 1800 ft deep. Of course

they have a boiler too. The building opened last fall, and the boiler was NOT fired for the entire winter.

quotes:

some green energy goals for the building were a high-performance envelope (including blue jean insulation) including maximizing daylighting and managing solar heat gain; minimizing fossil fuel use with two geothermal wells with heat pumps for heating and cooling, plus photovoltaic panels on the sunshades; and conserving water and reducing runoff by using roof rainwater collection for toilet flushing.

http://www.hippopress.com/091217/News3.html

The Right Design

It started with desire. “The Institute was committed to doing the right thing, They wanted to reduce their carbon footprint, and as a non-profit, reduce their operating costs over time.” . . .

“From the get-go, energy efficiency was central to the design,” . . the estimated energy savings for the project are 56,255 kWh annually, with an associated annual savings of $8,440.

State of the Art

As most homeowners now know, energy efficiency starts with an energy envelope. Constructing the new building’s envelope was “a pretty intensive process,” according to NHIA President Roger Williams, but one can now literally feel the difference. “Normally when it's cold out, and you feel the interior wall, it’s cold,” said Williams. “That's because the dew point is at the interior wall. The way these walls are constructed, the dew point is on the outside. It's using less energy, because it's able to hold the set temperature longer.”

Lighting was also an important consideration for the Institute, which sought energy-efficient options that would not compromise the lighting quality needed for artistic creation and exhibition. “The improvements in lighting fixtures are incredible,” said Williams, noting that, as an art college, NHIA uses a lot of track lighting and chose special LED bulbs to showcase students’ artwork. “Their color correction is pretty close to daylight,” he said.

Power from Above, and Below

While the building’s roof was designed to reflect sunlight (mitigating the “heat island effect” that plagues urban buildings), each row of its window awnings incorporates solar panels that collectively are capable of generating up to 14.2 kilowatts of renewable power. Williams estimates the payback for the renewable generation to be about seven years. “The energy created by our solar photovoltaic system runs the other energy efficiency features in the building.”

In addition to solar power, the building has two 1,500 foot geothermal wells. The system takes advantage of the relatively stable ground or water temperatures near the earth’s surface (roughly 50 – 55 degrees F year-round) to heat or cool buildings above-ground. Instead of creating heat, geothermal pumps “move” heat in the desired direction. “From what I understand, ours is the first urban application of geothermal technology in New Hampshire,” said Williams. “We were pretty lucky in that the lot is just large enough to accommodate the two geothermal wells.”

Finally, using a vegetative roof and 4,500-gallon water tank, the building employs a sophisticated rainwater collection system to flush toilets. In addition to conserving water, the system conserves the energy that would be needed to pump and deliver the water to the building.

http://psnhenergybrief.com/index.php?option=com_content&view=article&id=...

The geothermal ground source system was built by Skillings & Sons

http://www.skillingsgeothermal.com/about.php

Construction video here (fun to watch):

http://www.nhia.edu/88-lowell-construction-video/

Awesome! Notice that these things usually pay back within 10 years -- yet it's very difficult to finance them. Before the government stepped in in a big way during the Depression, most mortgages were for about 5 years. I think we're going to need a really big commitment from the federal government to show the "market" that there is a market, by providing (or better yet, simply guaranteeing) low-cost financing for things like heat pumps, good building design, and solar panels.

HereInHaliax is noteworthy for his promotion of ductless air-air heatpumps on TOD. SEER 25 & 26 for the best ones. Much lower capital cost for almost the same performance.

Not that ground source HPs are not good, they are ! but there is an "almost as good" much cheaper alternative that can fit a broader range of applications.

Best Hopes for Efficiency,

Alan

Switzerland is roughly 1/3 the size of Ohio, with about as many people. The Swiss living experience is nearly completely that of living in "small" cities and villages - Zuerich is the largest city in the country, and it has 380,000 people in it. You are right that the Swiss infrastructure is perfectly suited to mass transit (although many people now own cars); however, my take on that would be, so what?

If we (the US) are interested in retaining a functioning society after liquid transportation fuels are no longer cheaply available, we are going to have to rebuild pretty much everything that has been built here since 1950 or so...

The caveat is, that the US in 1900 had a MUCH lower population density, and a perfectly functional network of interurban trains and trolley-based mass transit, all of which were private for-profit companies (and therefore presumably profitable). The difference was, the more 'convenient' option of a personal car wasn't available (as it soon won't be once again), and therefore people HAD to take the trains and trolleys.

The only question that remains is how soon we as a society wake up to the inevitability of this, and start doing the build-out (hint: the sooner we get going, the less disruptive to whole thing will be).

I know of a developing nation, population about 100 million (about half rural), with just 3% to 4% of USA GDP, and limited access to advanced technology that, in just twenty years, built subways in all of it's largest cities, trams (or streetcars) in 500 cities, towns and villages and built electric interurban networks through it's richest farmlands.

Just 20 years !

I will give you details later, when I finish with a little energy conservation chore.

Alan

PS: NO FAIR for any regulars answering this !

...hmmm....if it's a trick question, these United States? Otherwise I'm stumped, who is it? who is it?

At the ASPO conference I first outlined current French efforts and then my "developing nation".

I put up a slide with a 44 star US flag with 1897 - 1916 underneath it, with the statement "We did it before, with coal, mules and sweat, we CAN do it again !

Best Hopes,

Alan

Not to mention building the Interstate Highway System, which according to Wikipedia cost $425 billion over 35 years, close to the US High-Speed Rail Association's estimate of $600 billion for 17,000 miles of high-speed rail. It may be the biggest infrastructure project in history. Eisenhower championed it, and was inspired partly by Germany's Autobahn's. So how about if Obama was to champion a high-speed passenger and freight rail system, partially modeled after Europe's? (and how about that other developing country, China, spending 300 billion dollars equivalent over less than 10 years for high-speed rail?)

Without naming names, it's one thing to do that when (1) filthy, slowly creeping horse-and-buggy is your prime current "technology", and the new mode is actually quicker and visibly cleaner; (2) you're learning about the mechanisms by which transmissible disease is cutting life expectancy by decades, and you'll be even gladder than before to mitigate the inches-deep manure deposits and vast thrumming swarms of disease-bearing flies infesting all the larger towns; (3) you have yet to develop a vast impenetrable thicket of rules and regulations that (whether justifiably or not) makes it utterly impossible to build subways and trams cheaply.

In other words, it's easier when it looks and feels like a substantial improvement in health and utility, and it doesn't seem to cost the earth.

It's quite another thing when (1) your current technology often, or essentially always, depending on where you live, gets you where you need to go, at any hour you need to go, without waiting forever on the implicit permission of whatever schedule some lackadaisical quango or government agency feels like failing to adhere to, and without being confined solely to those places it feels like taking you to; (2) there's nothing comparable to the disease problem in the decades around the end of the 19th century to mitigate, as evidenced by today's vastly longer lifespans; and (3) you're so self-saddled with rules, regs and specs that it takes the entire product of several lifetimes to pay for just one subway car, and hundreds of lifetimes to pay for just one mile of line.

In other words, it's hard when it looks and feels like a gigantic step backwards in terms of utility, and it costs the earth - plus the sun, the moon, and the stars.

I am not from Switzerland either, but from southern Germany.

Unfortunately, the quake activity after geothermal test drills in Basel was not the only setback. Another project in the German city of Staufen has taken a quite unfortunate turn lately, too. The boreholes for the project were drilled through an anhydrous gypsum (a keuper marl) stratum directly under the city. The bore hit ground water, which is now seeping into the marl, hydrating it, thereby increasing the volume massively. The ground under the city has been rising by several centimeters per year lately, doing severe structural damage to many buildings.

Worst case scenarios expect a rise of up to 3 meters with subsequent cave-ins which could lead to a complete loss of the city.

While this is mostly a result of bad exploration and no intrinsical problem of geothermal, the reputation of the technique has been severely damaged by that.

Since you are writing a book, perhaps you should note that the use of the term "geothermal" and "heat pump" together is a misnomer. There's very little energy available near the surface of the Earth from geothermal heating. These systems take advantage of he large thermal mass of the ground, heating the dirt during Summer, then cooling it during the Winter. Thus, the more precise engineering term to use is "ground source heat pump". These systems work well in climates where the heating and cooling demand are somewhat equal. In very cold climates, where the heating demand dominates, or in warm climates, with no cooling demand, the resulting energy savings are not so great.

E. Swanson

Black_dog, point well taken, thanks. And thanks for the Swiss info. I didn't touch geothermal drilling because I keep hearing about earthquakes, but hopefully some good research can be done on this very important topic.

GlobalMakeover, the topic has been studied, and geothermal production is definitively the cause of induced seismicity. You can pretty much start a stopwatch after starting deepwater injections until the time M3 earthquakes will start, as has been done many times over the past couple of decades. There are a few article references here (and a good primer on what's known, too): http://en.wikipedia.org/wiki/Induced_seismicity

Maybe someone can answer the question: if you can drill for oil all over the planet and not cause earthquakes, why does geothermal drilling keep doing it? Or if they don't drill for oil in some places because of the earthquake risk, why can't they use the same techniques to avoid geothermal drilling earthquakes? Of course, I don't want to break theoildrum etiquette if this question should be in a different post.

Yeah, we're getting off-topic, but the short answer is that it's not the drilling itself, but the injection of liquid into a dry, hot formation that causes fracturing and seismic events.

The Swiss still use quite a bit of oil. A good chunk would be for moving people and goods the last few km or sometimes tens of km. The electrified intercity rail hardly reaches everywhere, it's way too capital intensive for that. After all, nowhere are you allowed any more to build track by just dumping some gravel, running a grader over it, eyeballing it, and casually throwing some crossties and two rails on top. It's nothing like as easy and cheap as letting lightly used access roads towards the edge of town or out in the country revert to gravel, should it come to that. So it will always serve densely populated cities, plus places that just so happen to lie along routes between such cities, plus possibly a smattering of places where the expense can't possibly be justified but political corruption causes them to be served anyhow. (Pretty much like European motorways or US Interstates in those respects, really.) So the question is how far can they really scale it before any further increment collapses of its own weight. Some for sure - but enough to make a real difference, or only just enough to justify a supercilious academic paper or three?

Another issue that's easy to overlook glibly is distance. With ca. 10-20km between towns in the USA, instead of ca. 1km, you simply have to spend far more on intercity rail in the US, to provide track and train cars connecting up the same number of people making the same number of trips. So we need to adjust for distance, which might put as at, say, >$5 trillion (if it's sub-linear) or >$10 trillion, or even more.

And instead of the issue with the last few km, we'll often have an issue with the last few dozen km, or even hundreds of km. If we can solve that - gas/diesel cars have been the solution for a long time - we don't need nearly as many trains: no use waiting four hours for the next train - and then shelling out an astronomical cab fare for those last km - if you can drive the trip in two - or even in five. But if we can't solve it, or if we can't afford the astronomical cab fare, then we won't need quite so many trains either. IOW most of the time, and as with so many other things, 90% of a trip will be 100% useless, one needs a (very nearly) 100% solution.

No use kidding around by lowballing it. In the end the costs and impracticalities can't possibly be concealed. With people already skeptical - and observing the hopelessly corrupt and incompetent leadership and massively featherbedded, overpaid, woefully underdisciplined operating staffs at so many existing systems - it will die a very fast political death indeed when it comes to be seen seeing it as a hairball of huge cost overruns offering little practical utility.

PaulS,

first, the US High-speed Rail Association has estimated that a 17,000 mile system would cost about $600 billion -- at 50 million per mile, even duplicating the Interstate Highway System would "only" cost 2 trillion, which over twenty years is "only" 100 billion per year. So even in the U.S., a good system shouldn't be prohibitive. And Alan Drake here has done similar, reasonably priced estimates, IMHO.

Second, the argument of Kunstler, etc., is simply that places that are off the main line too far won't survive. That's not because of the problems with a particular mode of transportation -- that's because of the problems with particular mode of urban structure. Which leads to

third, urban structure leads to transportation system leads to energy system; or the other way around. With oil, you can have cars and trucks, and with cars and trucks you can have sprawl. With dense cities and towns holding most of the population, you can have trains, and with trains you can have electricity. and..

finally, I think there is a role for electric cars and trucks exactly for those final kilometers you wrote about, only if people stop waiting-for-electric-car-Godot of long-distance, fast, big electric cars. Actually-existing electric cars (and trucks, too, I believe) have ranges of 50 miles, which should be more than enough for those last kilometers.

And there was no WWW back in the 70s. There were no forums like this to share info with the public and connect concerned people quickly. And from what I've read there was actually - and it took decades for this story to congeal - more radiation released and damage done than was reported at the time.

Maybe because of the 'net public response can be greater.

bsmyth,

Governor McDonnell from Virginia has been a persistent, vocal advocate for offshore drilling in his state's waters.

Seems as of yesterday, at least, he has softened his rhetoric a little, but not his position.

http://www.msnbc.msn.com/id/37420234/ns/local_news-norfolk_va

There are several politicians in Alaska who want full steam ahead on offshore drilling as well.

As you opine, people forget...most people don't have much of a memory of the Exxon Valdez...this spill is already portrayed by some as a very rare (once in a generation) accident which was caused by pressure from environmentalists...

...and the allure of mythical 'energy independence' and being able to stand up to the 'enviro-nazis, tree-huggers', etc. will make for great political theater for some politicians.

The key difference is, the containment field (analogous to the BOP) worked like it was supposed to at TMI - because the company that built it didn't cut corners. I have never set foot on an oil rig, but I have built a house. I know this maxim to be true from first-hand experience: Your choices are fast, cheap and right. You get to pick two, at the express exclusion of the third.

"Pick Two" is a direct consequence of the three laws of Thermodynamics and should be taught as such in all engineering schools.

One of my favorite professors, who singlehandedly pounded 25 hours of chemistry into my brain and gave me my first lab job, summed up the three laws as "You can't win, you can't break even and you can't choose not to play."

He gave me a graduation card and enclosed a couple of bumper stickers...one said "Everyone has Avogadro's Number" and the other one said "Honk if you passed P Chem." No one ever honked. Until I drove to Houston for a conference instead of flying. At least one person beeped and gave a thumbs up every single day I was there.

25 years later, I still have nightmares about P Chem.

IMO, the "pick two" concept is also a really good shortcut to deciding if a boss is going to be a success...the ones who come in and start talking about revolutionary new developments in -whatever- that will let them do all three, are the ones that should cause you to go screaming out into the night.

It seems to me that the oil industry has largely wasted its opportunity to demonstrate that it can drill safely and responsibly. The cowboy culture of exploratory and development drilling has always put that at risk.

That was driven home to me when I read some of the technical reports and presentations on the MMS website. The risks of kicks and BOPs were well understood - and very little was done about it.

I summarized my takeaway yesterday in a diary on dKos.

I would be interested in getting a reaction to it from TOD experts. In my day job, I understand engineering and safety and quality management, but I am absolutely not an expert in oil drilling.

Grapes – I wish I could offer a strong argument against your point. But you are correct to a degree. But I wouldn’t characterize it so much as a “cowboy culture” as just accepting the difficult nature of getting the job done. When you get up on the drill floor you know the risks your taking: risk to your safety, risk to the other hands, the rig, the environment. No different than the occupations where other professionals accept such high risk. The “industry” didn’t waste an opportunity to make such a demonstration. In fact, if we have the details correct, just the opposite was shown: if the hands onboard had followed standard protocols (like monitoring mud returns) it’s very unlikely the blow out would have occurred. The process didn’t fail; the individuals responsible for conducting safe ops failed and 11 hands died and the GOM suffered a wound that could take decades to heal. Those hands died because they stayed with it instead of running. They did their jobs. Someone else didn’t. Those parties know they are responsible for the death and destruction. They’ll have to live with that.

I do agree that many near misses happen more often than the public realizes. And there will never be a zero risk. But if standard procedures are followed such events will be rare. I’ve been in the same position that the BP personnel were in many times. I know how to keep the hands, the rig and the environment safe. I don’t let money concerns override safety protocols. If my policies are rejected by management I walk. But some won’t. An easy fix IMHO: third party observers that have authority to shut down ops if they don’t think it’s safe. MMS inspectors have always had such power but they have to be there at critical junctions to exercise such control. The BP blow out wasn’t a Black Swan. It was a set of conditions seen thousands of times on other wells. Again, the BIG IF: if the reports are correct the rig personnel didn’t do their basic jobs. The same safe protocols that hundreds of hands are following as you read this message.

Rockman, I have been lurking and I immensely appreciate your contributions, so I take your comments very seriously. So let me try to rephrase my question.

The cowboy culture makes perfect sense given the business risks associated with offshore drilling. Where it starts to go wrong is when the industry begins to push the envelope into much deeper water.

In the early days of flight, pilots flew by the seat of their pants. Then it was stick and rudder. By the time NASA started trying to go to the moon, they looked for the Right Stuff. When NASA tried to commercialize space (Shuttle), they had to change their approach. It became test, model, test, model, test, fly. Every time NASA slipped in its discipline (Challenger), bad stuff happened.

My sense is that the oil industry could have seen the Apollo/Shuttle transition coming and didn't adjust its style or its culture. The deepwater environment is at least as alien as space. Oil industry rhetoric talks about 'space-age technology', but I see no indication that it realizes it needs to adopt the appropriate safety first/last/always culture.

Does that make more sense?

Just my $0.002

Does make sense grapes. DW drilling does have a host of challenges never before seen by the oil patch. But you really won't like to hear what I'm about to repeat from a few days ago. The same circumstances that BP ran into with the APPARENT cmt failure were seen by a barge rig drilling an 18,000' hole in S La in 1958. But as the cmt shoe failed on that well they were monitoring the mud returns and saw the kick coming. They shut the well in (didn’t even need to go to the BOP) and pumped a kill pill down and got it back under control. Another rig just down the bayou had a similar incident. Except they weren’t monitoring the mud returns. The well blew out, 11 hands were killed, the barge burned to the water line and the swamp was fouled for many months.

Yes…I made those details up. But if you searched the scout tickets from the 1950’s you would find such reports…I promise you. The BP well didn’t blow out because they ran into some one-of-a-kind situation never been seen before. Stopping the blow out at 5,000' water depth is a whole new game, of course. As I mentioned earlier: the situation BP had to deal with had been successfully managed thousands of times before. Very simply: how many times have you gone to your brakes when you see the stoplight turn red? Not too difficult, eh. BP’s stoplight turned red but they weren’t looking. Sometimes you run a red light and no harm. Sometimes you hit a bus and kill 11 people. Just the luck of the draw. They weren’t being “cowboys”. They were just being very dangerously unobservant.

"The BP well didn’t blow out because they ran into some one-of-a-kind situation never been seen before."

Absolutely true. I totally agree.

But one-of-a-kind situations seldom cause major catastrophes. More often it is exactly they type of "system accident" that you are describing as having occurred on the Deepwater Horizon. Those are much harder to defend. 499 rigs can be on their toes, yet it only takes one rig to be a little dozy and boom!

The oil industry seems to have passed a watershed where it is much harder to fix a system accident if it occurs. Aviation had to rethink when they discovered that parachutes didn't work in space. The only thing that works is a pervasive 'culture' that viscerally understands and bears the costs of those new risks.

The other factor is that, as the risks are increasing, many of the consequences will be visited on society, rather than on the industry actors. On the hypothetical rig that killed 11 men, the victims were there willingly. Presumably their pay motivated them to accept the risks. With Deepwater Horizon, most of the costs will be borne by people other than BP. BP can never pay the full bill. They can't, for example, fully compensate Exxon or Chevron for the spillover loss of public confidence. They can't restore the quality of life that Louisiana fishermen enjoy.

Deepwater is new territory.

New rules.

The thing about these deep water wells is that people are operating at the limits of the available technology. If something goes wrong, dealing with it is like rescuing climbers from the top of Mount Everest. You really can't rescue climbers from the top of Mount Everest, you just hope they can get themselves down to an altitude where someone can effect a rescue.

I tend to think in those terms because I know a number of people who have climbed Mount Everest, and a number of people who do mountain rescues, and a number of people who have been killed in mountain accidents.

The thing about Deepwater is that there is no scope for accidents. If you have a blowout, it is going to be all over the ocean. By contrast, even a big on-shore blowout is controllable. You get in a lot of bulldozers, you build a dike, a huge lake of oil forms, and you truck it off to the nearest refinery. In the mean time you drill a relief well, get the blowout well under control, and cap it. At the end of it all, you have contaminated maybe a square mile of countryside. Throw some oil eating bacteria into the soil, turn it over with a cultivator, truck in topsoil, fertilize it and plant alfalfa. Then hand each of the affected farmers a thick wad of $100 bills for their inconvenience and everybody is happy - except maybe the environmental activists who the farmers don't like anyway.

Rockman: "BP’s stoplight turned red but they weren’t looking." Why? is the question. Perhaps, they had run the red light many times before and nothing had happened. So why look; I'm bulletproof.

EL -- Not defending them but at the phase they were in it was assumed safe. The folks responsible for monitoring mud returns were likely very busy shuting down. They also assumed (wrongly, of course) that the drilling supervisiors wouldn't be displacing the mud if they were completely satisfied with the cmt job.

To carry on with red light example: when you get a green light do you immediately hit the gas? I don't. I usually look for someone running their red light. Why? Because about 20 years ago a neighbor didn't look and his wife and child were killed by a red light runner. Later he unsuccesfully tried to commit suicide over guilt.

It's very hard to forget such an event. You might call me overly careful but it costs me nothing to look. I don't really think about it...it's become an almost automatic reaction. It would have cost BP nothing to make sure mud returns were being monitored properly. Nothing. It's not difficult to imagine how much closer ever drill crew out there is watching mud returns these days.

Ummm...oh, man, yeah, the red light thing. Years ago, I was giving some acquaintances a ride. The light turned green and I sat there. A split second later some yokel creeping in from the right floored it and came within inches of hitting somebody else. We were all real shook up. "How'd you know he was gonna do that?". Honest, damned if I know, but somehow I was kind of expecting it - it was not long after student days, and riding a bicycle probably had something to do with it. Now, tomorrow morning, who knows what could happen... as I keep insisting, life's not zero-risk...

Rockman: More "red lights." [I think I'm gonna make you regret you used that metaphor.] If you need to get from A to B as quickly as possible, you might run a few red lights. Does BP's blow out relate to fast, cheap, and right? Somewhere on theoildrum I saw that operations were behind schedule. Was the crew under time pressure? Furthermore, it might be informative to look at the experience of the members of the crew at the time of the blow out. Was the crew inexperienced? Had any key member of the crew ever been around a near disaster? As the cliche goes, experience is a great teacher. Maybe survivors of the blow out should teach safety procedures. But I'm old and I stray off topic. Thanks for all your time and effort devoted to educating us all. You are truly an expert.

I suggest you listen to the testimony of the people involved:

http://www.c-spanvideo.org/browse?date=2010-05-29

http://www.c-spanvideo.org/browse?date=2010-05-28

These two days provide a pretty good overview.

The Transocean crew was very experienced, but they were at the end of a difficult job and thought they were home-free - might have let down their guard. I think they were implementing a marginal well design under difficult circumstances and when the crisis came whatever warning signs there were had been down-played and they were caught unprepared for a situation that went down in just a few minutes. On top of that critical systems failed immediately and left the survivors defenseless.

In Iraq we regarded the most dangerous part of a mission was driving the final couple of miles back to the FOB. Everybody is tired and starting to think about that shower, clean uniforms and an air-conditioned hooch - instead of whether or not that trash by the side of the road is an IED.

Even in industry - most accidents occur right before quitting time when people are rushing to 'beat the clock.'

The bissgest problem with safety is that the people supervising things are constantly having to fight human nature.

You're right - and as I get older (I'm now 46 for God's sake), I find that I keep adding subroutines like that. But the one certainty that we all need to accept is, if we continue to drill in deep water, we will eventually have another blowout like this. No matter WHAT set of safety procedures we decide to institute, and no matter how careful or professional the people implementing them are (and they clearly are by-and-large VERY good at what they do), it WILL happen. And when it does, two new things need to have happened - first, we ALL need to understand that drilling on the OCS is demand driven (which is to say that ALL OF US cause it because we use oil); and second, we need to have gotten much better at dealing with this sort of oil release than we are now.

Rockman: as usual, thanks for your incredibly insightful and leveheaded posts.

your Traffic light analogy really impressed something on me that i think we are quick to gloss over: Societies perception (and tolerance) of risk. This goes beyond the Oil&Gas Industry but i believe the DWH is a direct result of its impact. these days, people assume right of way, are generally 10-20mph over the posted speed limit, roll through stop signs, change lanes with no signal etc etc. Traffic is just one obvious example but you see these examples EVERYWHERE. People have minimized risk so much that they are willing to disregard precautions that were put in place to protect them so that they may get to their destination a minute or two earlier, or get something done faster. Perhaps the man responsible for the cmt was on the edge of failing the operation and not singing off on it, but didnt want the headache of the additional paperwork , or was in a hurry to get home to the wife and kids... or whatever. but regardless, along the way, people disregarded red flags in many areas because people do not have an accurate demonstartion of the risks they face.

i know you've said before about having spill disaster courses you're required to maintain, i had similar working in an ER and as an EMT. Personally i'm coming to be of the mindset that these sort of preparedness drills need to be far more intense and actually have an associated risk. as you alluded to above, when people see the accident they nearly miss, it changes their actions in the future. When firefighters train to be firefighters, shit is on fire. any hazardous job needs to have training that really demonstrates the risks. IMO thats the only way to effectively mitigate them.

Risk aspects of system engineering are fascinating. Check out the Risks Digest: http://catless.ncl.ac.uk/Risks .

I think we need someone of the stature of a Richard Feynman to tell us the obvious to our faces. Just substitute Deepwater Horizon, Bp Engineers and BP management in the following excerpt from the Challenger Shuttle disaster. All the lessons we need to learn have been taught over and over again. We just keep flunking out...

Fmagyar, we'll always flunk out in the long run, as this is result of cognitive biases, "the human tendency to draw incorrect conclusions in certain circumstances based on cognitive factors rather than evidence". Our human brains are naturally wired to make irrational and incorrect conclusions in situations. and attempting to reprogram ourselves is unnatural (and carries the risk of being called a geek or nerd :) ).

Specifically, I think this is reflective of optimism bias (http://en.wikipedia.org/wiki/Optimism_bias) and overconfidence bias (http://en.wikipedia.org/wiki/Overconfidence_effect)

How to mitigate the effects of cognitive biases? In a word, awareness. I think everyone that deals with high-risk, low-probability events should get training in common cognitive biases. If nothing else, meetings will be more fun as participants laugh when stereotypical biases are presented.