The Gulf Deepwater Oil Spill, sheen, other oil layers, and RIT flows

Posted by Heading Out on May 20, 2010 - 10:36am

There have been a number of steps forward in dealing with the massive oil spill and continued oil leak from the BP well in the Gulf. BP has now posted a status illustration of the two relief wells that are being drilled to intersect and finally kill the initial well.

The picture shows both of the relief wells and the original well, as of today. It gives some idea of the overall layout of the three wells, and the points where the original well will be intersected.

UPDATE: CNN has been carrying live feed of the flow out of the riser, as the RIT is now removing around 5,000 bpd from the riser.

While there has been steady progress on a number of fronts; the riser insertion tube (RIT) is now pumping 3,000 bd; a check on the fluid being collected shows that the gas content is higher with a gas:oil ratio of 5,000 rather than the 3,000 initially estimated; and the top kill injection is now scheduled for Sunday. There were four successful surface burns yesterday. There is not a lot otherwise that is new in terms of killing the well, though the oil is now arriving on shore and starting to have an impact. There was also the possibility of a Kevin Costner idea being adopted; a problem for a CBS crew; and a clarification of the role of Schlumberger.

There was a Press Conference today, and a BP official on PBS News Hour, and it is from these sources and a quick reference that I am writing the post tonight.

One of the issues that has been continuously referred to has been the progress of the oil spill both on the surface, and underwater. Unfortunately the underwater, and heavier oil, is now beginning to appear in the marshes of Louisiana and the surface traces of the plume are beginning to get drawn into the Loop Current. The surface indication is the presence of a sheen on the surface. The thickness of that layer can be assessed by looking at the refraction, but it is not that easy.

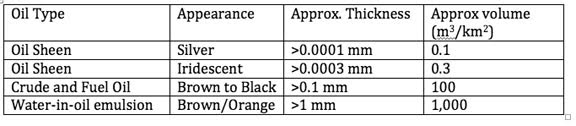

An estimate of the quantity of oil observed at sea is crucial. Observers are generally able to distinguish between sheen and thicker patches of oil. However gauging the oil thickness and coverage is rarely easy and is made more difficult if the sea is rough. All such estimates should be viewed with considerable caution. The table below gives some guidance. Most difficult to assess are water-in-oil emulsions and viscous oils like heavy crude and fuel oil, which can vary in thickness from millimeters to several centimeters

The transcript of the News Hour interview with Bob Dudley of BP this confirmed the 3,000 bd recovery figure through the RIT, and that they are continuing to open the choke that controls the flow up to the surface ship that is collecting the oil, and flaring the gas. He noted the high gas content, at the greater oil flow. The pipe is now collecting more than 13 million cubic feet of gas a day. With that high a gas content, at least half the plume that has been coming from the pipes is made up of gas. Because of that gas content, it is hard to measure the exact volumes of fluid that are leaving the pipe. But he also noted that the larger numbers that have been quoted in the press, of 70,000 to 100,000 bd are purely sensational and not based on science. Unfortunately they also serve to increase alarm and suggest threats to the tourist industries of Alabama, Mississippi and Florida that do not realistically exist.

He further commented that the failure of the blowout preventer (BOP) in this circumstance is unprecedented, and that the dispersant being used is the one that the Coast Guard has been using for over 20 years, after extensive EPA testing. And, in regard to liability:

We have said we're not going to hide behind a $75 million cap on the liabilities. To date, we have spent more than half-a-billion dollars on the spill response. We're not going to ask for reimbursements for the American people for that effort.

And we're going to keep at this. And shutting the well off, containing it at sea, and keeping it off the beaches as long as it takes, Jeff.

The transcript of the press conference was not posted as I write this, but there are comments available from it, which largely bore out what the BP official said (unfortunately I have lost the site that I was getting the info from). There was, however, a comment that the “hot tap” had made it back into consideration, and that an idea by Kevin Costner was also possibly going to be tried.

Costner came forward last week with an oil spill cleanup technology he started devising after the 1989 Exxon Valdez spill in Alaska. Surrounded by local and state politicians, he demonstrated a $24 million centrifuge device that he said could be placed on barges and used to suck in oily water, separate the oil and spit out mostly pure water.

Incidentally there has been a response to the story of a CBS crew being stopped. The Unified Command issued a statement that said, in part:

Tonight CBS Evening News reported they were denied access to oiled shoreline by a civilian vessel that had clean-up workers contracted by BP, as well as Coast Guard personnel on board. CBS News video taped the exchange during which time one of the contractors told them (on tape) that " ... this is BP's rules not ours."

Neither BP nor the U.S. Coast Guard, who are responding to the spill, have any rules in place that would prohibit media access to impacted areas and we were disappointed to hear of this incident. In fact, media has been actively embedded and allowed to cover response efforts since this response began, with more than 400 embeds aboard boats and aircraft to date. Just today 16 members of the press observed clean-up operations on a vessel out of Venice, La.

The only time anyone would be asked to move from an area would be if there were safety concerns, or they were interfering with response operations. This did occur off South Pass Monday which may have caused the confusion reported by CBS today.

The entities involved in the Deepwater Horizon/BP Response have already reiterated these media access guidelines to personnel involved in the response and hope it prevents any future confusion.

And in regard to the Schlumberger crew that apparently were on the rig to run a Cement Bond Log (CBL), Schlumberger has made a statement .

The company, which had not previously revealed its work on the Horizon, said in an emailed statement that it performed wireline services for BP Plc on the rig in March and April, completing the last services on April 15 and leaving a crew on standby in case any more were needed. "On the morning of April 20, 2010, BP notified the Schlumberger crew that it could return to its home base in Louisiana," Schlumberger said in a statement, which a spokesman for the company confirmed by phone. The crew departed the rig at about 11:00 a.m. on April 20 on one of BP's regularly scheduled helicopter flights, Schlumberger said.

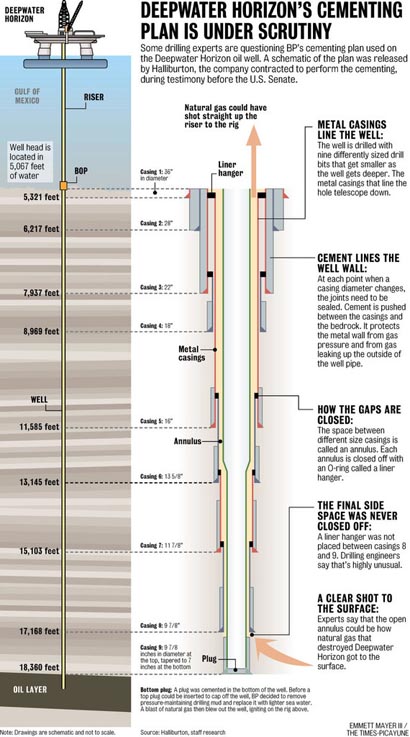

It has been suggested that they could have performed a CBL (cement bond log) to assess the quality of the cement lining at the bottom of the casing, but were not asked to do so before they left.

Probert (of Halliburton) told a Senate committee last week that the cement bond log is "the only test that can really determine the actual effectiveness of the bond between the cement sheets, the formation and the casing itself."

Gregory McCormack, director of the Petroleum Extension Service at the University of Texas, called the cement bond log the "gold standard" of cement tests. It records detailed, 360-degree representations of the well and can show where the cement isn't adhering fully to the casing and where there may be paths for gas or oil to get into the hole.

Schlumberger's Harris said the contractor was ready to do any such wireline tests, but was never directed to do so. The team had finished doing tests on the subsea layers of earth being drilled five days earlier and hadn't done any work since, Harris said.

The Times Picayune has a graphic showing that the last cement injection did not seal to the one above it, leaving a gap through which gas could enter the well. It is not clear whether the gas entered the well there, or from some other point in the well, nor whether the initial gas flow then progressed up the outside of the casing (the annulus), or up inside the production casing itself.

Nice summary of all the news, thanks!

So yeah, that scuttlebutt about SLB leaving 6 hours before the explosion for fear of their safety. Complete bullshit. Good detective work Alan...

Greg, not to take sides here, but it doesn't rule anything out - it does confirm that Schlumberger people were on the rig the day of the accident and also states that they left on a "regularly scheduled flight". It is the kind of plain vanilla statement that doesn't confirm or deny much of anything. If there is some pending legal action this is the kind of statement for the press that might be expected. That said, it doesn't specifically support the "scuttlebutt" claims either.

I personally wouldn't expect much clarity on legal issues arising from the accident for quite some time.

The details are in stark contrast to what has been presented before with no hint that any of the details match up other than the fact that Schlumberger was on the rig the morning of the accident (which hardly supports anything as I would have expected them to be involved in some aspect of the drilling).

1. The "story" said they arrived on the platform specifically to do a CBL. Schlumberger says they were there earlier for "wireline" services and they were on standby and did no more work after cementing

2. The "story" said they were told they were not going to be able to leave because there were no more helicopters for the week. Schlumberger said their people left on the regularly scheduled BP helicopter.

3. The "story" said they left around 4 in the afternoon. Schlumberger said they were off around 11am.

Unless you claim that Schlumberger is withholding information, it sounds like their involvement was minimal around the accident which is why they haven't spoken up earlier.

But don't let me stand in the way of the grand conspiracy against the American people that so many here want to believe.

It is not a "grand conspiracy", just normal greed and poor judgment that has resulted in multiple tragedies to date along with significant economic costs and other ramifications as yet unknown. If you want to quickly jump in there to defend the kind of behavior on display here that is of course your choice.

The email did not address whether there was any dispute between the subs and BP - if there was it is a legal matter that will be sorted out in due time. The specific story may well be false in some or all of its details. I am just pointing out that the central claim that there was a dispute about proper procedure was not addressed in the response.

Lets all hope that the efforts directed at containing the damage and killing the well effective, the sooner the better.

I figure everyone else is jumping to conclusions, why the hell not me.

You say greed and poor judgement and not even that has been proved out. There have been a great deal of assertions made here based on hearsay that has not been confirmed by any source, so if you want to take the cautious approach, how about not affirming the consequent.

Poor judgment is a given at this point. BP did blow up a drilling platform and got an ocean floor oil dump, both of which were supposed to be impossible, according to them. So their credibility is nil right now.

Nothing is impossible. Highly improbable yes. You can't plan for every contingency. I don't doubt that given hindsight, there should have been readily dispensable equipment to take up the flow and for the future, I'm sure this will be in consideration, but BP followed all industry and government standards for accident planning. Unfortunately, setting up this chain of events apparently did not occur or was thought to be too remote a possibility. Industry will learn and this particular event will be planned against in the future.

They (BP and TransOcean) may have followed industry and government standards for accident planning, but based on all available information to date, they didn't follow much in the way of industry or government standards for drilling, casing, or completion; not to mention industry or government standards for maintenance and care of critical equipment.

I would only point out that all available information to date is highly speculative and likely misleading.

My biggest concern is around the BOP, but I'm not going to make a call on the suitability of it or the decisions to use it or not at this point in time. I'll wait for the investigation to sort out what happened first.

Fair enough, and I am certainly waiting for that same data. I am, admittedly, biased toward suspicion: when a rig and its various and sundry attached contractors and equipment is costing ~1 million a day, and it is already weeks behind schedule... well, let's just say that I've been there when the corners were determined to be worth cutting by people who really didn't have a full grasp on the mechanics of the corners that they were proposing to cut.... and when the people making those corner-cutting decisions had more authority than the people who knew just how dangerous such a course of action would be.

Industry (not just BP) has not exactly held themselves above repproach in the past, which makes things worthy of suspicion, but accusation based on personal anecdotes unrelated to those involved does not make the situation any better. Consider the mental shortcut you're taking in painting a guilty until proven innocent sign on a company however. Granted, you're not in a position yourself to cause damage based on your shortcut, but society as a whole (through their representatives) is. Taking the easy and fast way in judgement can be just as damaging as taking the easy and fast way on technical decisions.

Did you see the 60 Minutes episode with Mike Williams? Granted, that is the personal testimony of one person, he's not under oath... but let's assume he's telling something close to the truth as he saw and heard and experienced it... It paints an ugly picture; one that meshes with my own (and I am sure your own experience) near the end of a long, frustrating and expensive job.

Thanks for mentioning the 60 mins episode - it is available at http://www.cbsnews.com/video/watch/?id=6503436n&tag=contentMain;cbsCarousel

But the interview was not just Mike Williams. They also interviewed offshore drilling safety authority Professor Robert Bea. ( http://www.ce.berkeley.edu/~bea/about.html )

I have over 30 years oilfield operating experience on 4 different continents. I recall the comments of a good friend when faced with difficult challenges, "you can always solve your problems in the oil industry by lowering your standards". Most of the time it all works out well, but sometimes there are consequences.

BP and its contractors are not evil people and it is wrong to try and portray them as such. The are just a bunch of professionals trying to get the job done in very difficult circumstances.

Texas City Refinery Explosion, North Slope Pipeline Leak, GOM Blowout.

Three strikes and you are out. IMO, there is something deeply wrong in the BP corporate culture.

Yeah yeah yeah and the Nazi's weren't evil people either, just nationalists trying to get a break for their country.

To put corporate financial concerns over and above the health of the planet that sustains us all is EVIL.

Our society defines evil with laws about felonies.

BP is a twice admitted felon.

Alan

Alan, there you have it. They rank with other felons who are considered evil enough to be locked away in prison. "Three strikes laws are statutes enacted by state governments in the United States which require the state courts to hand down a mandatory and extended period of incarceration to persons who have been convicted of a serious criminal offense on three or more separate occasions."

http://www.youtube.com/watch?v=gP5gIDrNlrY

I didn't want to offer some inside information until SLB made a statement. My source confirmed that the dispatcher had transported a total of 23 (or 26) hands back in from the rig that afternoon including the Schlumberger loggers. Normal procedure at this point of the operation: as I said earlier at this point it's a big rush to pack up and get on the boat (or chopper). Hands fly and equipment goes by boat.

OTHO did the SLB express concerns to the company man about hole conditions? Do know. (Corrected below to 'Don't know'.) Was the lead SLB engineer concerned about the safety of his crew? Don't know. But eventually all the hands on board will be questioned under oath and state exactly what their thoughts were on all subject matters the day of the blow out. For obvious legal reasons I wouldn't expect such statements to come out from any source until folks are sworn in.

Mass transport of hands and equipment 1 day from completion and capping of the well? Sure, it's absolutely standard operating procedure. The HSE folks I worked with, and all the statistics I've seen have also shown that it's the time when the worst decisions are made and the most accidents occur (danger time: shift change, meal/coffee break, and job finish).

Regarding what Schlumberger loggers/managers (or Halliburton cement team, for that matter) may or may not have expressed to rig manager or company man... you're absolutely right - we'll just have to wait and see what they say when testifying.

Rock...is your first OTOH comment 'do know' as in 'know that SLB was concerned about the well'? Or was that a typo and really a 'dont' know'?

Also - I seem to remember reading something a few days before the whole SLB rumor got posted about a CBL being canceled at the last minute. People on this board were speculating as to why (difficult to run, difficult to find tools, etc).

Am I remembering that incorrectly, or were people speculating that the CBL was canceled at the last minute as well?

Hmmm...This Huffington article seems to indicate (without specifically stating, mind you) that SLB HAD been contracted to run the CBL.....

http://www.huffingtonpost.com/2010/05/20/bp-smoking-gun-oil-giant_n_5835...

toll -- the Huff report isn't much of a smoking gun. On offshore wells you bring almost all your equipment even if you think there's only a small chance to run it. Waiting 24 hrs and $800,000 for a 200# piece of equipment you didn't think you were going to need does not get you a gold star.

Sorry toll...meant to say I didn't know. Just one of the problems we two-finger typers have...can't watch what we type. Given the seriousness of such a charge I wouldn't repeat such a claim unless I heard it directly from the SLB engineer. It may be months down the road but eventually that engineer will testify publicly and be able to tell exactly what he thought or didn't think about the situation at the time.

When dealing with a convicted felon, my level of suspicion is raised and I am less willing to give them the benefit of the doubt if something goes wrong or missing. Quite normal behavior IMO.

BP is a convicted felon, twice in the last few years#.

Alan

# One was a guilty plea, the other was a plea bargain that held up prosecution with BP paying $100 million in criminal penalties. In yet another case BP plea bargained down to a misdemeanor.

We should really apply this kind of rational logic to all criminal matters, and not restrict it to only corporate persons. Think how much better this world would be if you could just pay a fixed fine for bank robbery. Something rational, like say $5000. As long as you make sure to steal more than what the fine costs, society will admire you for being a savvy capitalist who knows how to maximize profits.

(But only if you're wearing a nice suit when you rob the bank; otherwise, your scummy ass still goes to jail)

Since we are dealing with a convicted felon, the best suggestion I have heard yet (I've been a trial lawyer for 32 years) is for President Obama to appoint a special prosecutor.

I am gravely concerned that evidence is being lost, or not collected, and/or prevented from being collected or discovered.

The sooner a special prosecutor is appointed, the sooner someone can go to a judge and get some orders that prevents the loss of important evidence and allows and requires the collection of important evidence that is not being collected now or possibly even destroyed.

I have seen the game of lost or destroyed evidence played many times in 32 years of trial work. It is not pretty and I fear it is happening here.

Start demanding that a special prosecutor be appointed.

President Obama will not kick his big corporate contributors in the butt until he absolutely has to - he needs lots and lots more oil-soaked dead birds before he is forced to do that. This is Amerika.

Exactly

Good interview on Democracy Now

Interview and transcript at http://www.democracynow.org/2010/5/20/fmr_epa_investigator_scott_west_us

This man was pulled of the investigation of the Alaskan Spill well before he felt it was complete. He felt a felony would be proved but at the time he was told to stop he only had enough information for a misdemeanor.

Given what we know already, believing ANY statement from BP is an act of faith.

"No senator! Nicotine is NOT addictive."

"Senator, we didn't know that we were betting that these loans would default."

"I'm sorry Senator, I don't recall."

" This spill is (only) releasing 5000 barrels a day."

"We're sorry, Senator. That information was lost when the rig exploded and sank."

"DUH!"

Perhaps not proved beyond a shadow of a doubt just yet but it is starting to look like there might be the beginning of a sea change with regards how the US government is now no longer accepting what BP says at face value. My only question is what the heck took them so long?!

http://www.cnn.com/2010/US/05/20/gulf.oil.spill/index.html?hpt=T2

So Greg, are you going to continue trying to defend these felons?

I agree, but why has it taken the Obama administration a month to take action? A whole month of trusting BP when if even the most basic common sense is applied here would have assumed trust but verify.

Did no one at the EPA or NOAA hear BP president Hayward describe the discharge as relatively tiny when the scope of surface oil surpassed tiny weeks ago?

Excuse me? Why are you shocked or surprised? When in all of history has an Administration ever gone after its corporate buddies (and campaign contributors) before its feet were firmly held in the fire? Nothing will be done to damage BP - nothing.

BP as a corporation is a tool. If it is no longer useful to those whom it serves, then it will be discarded. The wealthy elite is not some homogeneous entity (more like cats in a sack), and some may lose money along the way, maybe a great deal. It looks like there is a lot of maneuvering for position among players who are becoming fearful that they may get something sticky on them. But the system will not change, and all of these entities serve that system, regardless of if they are corporations or government entities. The people have the ability to make a more permanent change to that if they were not so ignorant, distracted and easily manipulated, but there is no real threat there. There will soon be something to distract them and they will get bored of this story.

Greg--I'm with you. There's no grand conspiracy afoot, some very loud voices in the room, and it's easy to forget that "easy does it." Most TODers would prefer a return to BAU. True, some may not. Don't be deflected from weighing in on point and on target. Balance, calm, brain power, and steady as she goes is what's needed, below and above the waves of the GOM.

Good comments...let's also don't forget this is a blog and not a formal news outlet. Some comments are emotional, some factual, some boring and some humerous. It is up to the readers to decide what to take away from it.

Now, that said, in this particular case, the oil leakage in the GOM, I think TOD has probably been more effective in revealing the science and facts of the actual events than major news outlets. I also highly value Alan and others' comments on the "front lines" of this event as I did during Katrina.

Is someone pulling someone's leg, then?

You are both absolutely right! Plus there really can't be that much to worry about...even though a 15% of the Gulf is closed to deep water fishing.

http://www.cnn.com/2010/TRAVEL/05/19/gulf.coast.tourism/index.html?hpt=T1

I wonder what she knows about deep sea food webs and zooplankton, but I guess knowing about that isn't all that important anyway, so why would we want to risk people like her getting worried about the long term of effects of things like that as long the tourists are drinking their margueritas on the clean sand.

What BAU do you refer to?

I hope BAU does not return, though I might be of the ones you claim are different in you next phrase

But we only have the words of the posters, and how many of them are there compared to readers on this site?

But the majority of posters that I read from, don't want BAU, as that just leads us down the road of collapse.

So again I ask, what do you mean by your comment?

Charles,

BioWebScape designs for a better fed and housed future.

I have partly opted out BAU as I am sure many on this site have. But what TODers want or don't want is irrelevant. Continuing to burn oil is leading to destruction. Adding to that oil spills just leads us down that path earlier. And for what - BAU forever, for another 100 years, for 50 years. Deepwater oil will not as far as I know give us even 50 more years of BAU. We have to give up BAU, that is a given. We might as well do it while saving what we can of the environment that feeds us. If some TODers want no end of BAU in their lifetime, then they are trading that for a livable world for future generation. That is beyond selfish. Frankly it is time that someone or something made us powerdown as quick as possible. Calm is not what we need. It is time to panic, not about beaches but about climate, water, phosphate, air quality, life in the sea, biodiversity. Calm hasn't stopped much of anything. Lets try a little panic based not on whose estimate is right about the spill but about burning oil and coal in the first place.

+10

More panic please!

Panic? Just because we thought our big fat trust fund was limitless and we spent like there was no end, and now we find out we've blown a billion years of deposits in just a few centuries? What panic?! Can't we sweet talk the bank manager or something? Son of a bitch!!

Xlouisiana wrote;

Who are you to speak for the majority of us? Your perception building attempt is rather amateurish.

Rockman like BAU. Rockman sell oil. Rockman go back cave now.

Cave have LOTS of rocks to lick !

Alan

Rockman have long term vision. Rockman see many scenarios based on choices. Rockman ponder and pick right path to take...

Rockman need solar generator for electricity in cave? Me can get him good deal!

NO!! Electricity make rock taste BAD!!

Careful, don't point that thing in my direction ...

BAU Humbug!

Clever! :-)

It was previously known that the last cement job was completed 20 hours before the blowout.

We now know that no CBL (cement bond log) was run AT ALL !

On a $200 million well with a variety of problems and issues.

Don't bother, we decided we did not need to check the concrete job out after all. Sorry to keep you here sitting on your hands for 5 days now.

THAT part of the story is confirmed.

Likely enough for a guilty verdict for negligence on that issue alone (BOP maintenance and alterations are another "risk exposure" as BP managers say).

The question is civil or criminal negligence ?

Alan

The Huffington Post has a link to Thom Hartmann's website, which has the version of the SLB story that you posted:

http://www.huffingtonpost.com/2010/05/20/bp-smoking-gun-oil-giant_n_5835...

As discussed up the thread, it will be interesting to see what the actual testimony is--with a key question being whether the SLB guy demanded to be evacuated, or BP sent them home because they weren't needed. In any case until today, insofar as I know, we couldn't even confirm that SLB personnel were on board.

I still find it interesting that BP apparently thought that if they didn't disclose the crash in production from the main structure at Thunder Horse, the MSM and trade journals would not report it. And they would have been right, if it had not been for Glenn Morton's article on TOD. I think that this one incident tells you a lot about their corporate culture.

Hi All:

You can see if the oil has reached the most southerly point of the Keys i.e The Dry Tortugas here:

http://www.teens4oceans.org/cam-dry-tortugas.htm

I think these are the best two links I have ever found on the internet!!! I saw a Goliath Grouper and a lemon shark yesterday and there is a barracuda sat there right now!!!!

Also just a bit further up the Keys is Bahia Honda:

http://www.teens4oceans.org/cam-bahia-honda.htm

Please support Teens4Oceans if you can Oildrummers!

I worked with a process engineer who designed the Kostner centrifuge and he claimed it was the greasted thing since apple pie. But you know how that goes.

"Unfortunately the underwater, and heavier oil, is now beginning to appear in the marshes of Louisiana"

What could this mean for the expanses of seafood nurseries in the Wetland State, where the word coastline includes miles of marshy estuarian shoreline? What will it do to the first few feet along every water's edge of every grassy point, inlet, and bay on the bottom of Louisiana? This is precisely where young sea life grows and feeding fish eat. Here is a link to Bob Marshall, one of the best journalists in New Orleans getting to the bottom of it:

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/tiniest_victim...

HO,

Can't say "thanks" adequately for your superb coverage of this situation. Your clear and organized information is very much appreciated, as are your level-headed assessments.

Has there been any discussion about deploying the top-hat for the BOP leak? Given the success off the RITT, it would seem that as long as the weight of the top-hat is sufficient to prevent gas buoyancy issues that it would work as well as the RITT if properly throttled from the surface.

Can the drill-ship handle multiple inputs? Are there other similar vessels available?

I second the thanks HO.

My education is continuing.

Thanks for the kind words, they are appreciated.

In regard to the difference between the RIT and the top hat - the former is pushed into the riser, and makes it less easy for the seawater to mix in with the oil/gas and form hydrates. There is more risk of seawater getting into the top hat and blocking it in the same way as happened with the first attempt. While there are ways of getting around this, the RIT seems to be working and gradually ramping up oil removal, though to guard against having blockages I anticipate they will always allow some leakage.

18,360' x 0.052 x 13.7 ppg = 13,000 psi reservoir pressure.

5,067' x 0.052 x 8.5 ppg = 2,240 psi hydrostatic pressure of seawater at wellhead

Differential of 10,760 psi

Collapse pressure of 9-7/8" 62.8 ppf Q-125 casing is around 11,640 psi, depending steel quality.

Normal practise is to lower this value by 10% [design factor] for any defects arisen during manufacturing/transport. (for safety there is a 20% factor on top of this ---> 11,640 x 0.7 = only 8,148 psi which would be considered the maximum differential pressure to be put on the casing from the outside)

Let's stick to the 10% reduction: 11,640 psi theoretical collapse pressure x 0.9 = 10,475 psi is below pressure differential occuring at wellhead when the well was displaced to seawater and assuming leaking cement with gas migrating up the annulus.

The other casing at wellhead is 16", I do not know the weight & grade of this casing but the 13,000 psi reservoir pressure would be working on the inside of this string. The strongest 16" I find is 16" 147 ppf P-110 with a burst pressure of 10,900 psi, if we take-off 10 % design factor ---> 0.9 x 10,900 = 9,810 psi.

To me this means that if the cement was leaking gas this was able to build-up below the pack-off to a pressure well above what is normally tolerated in casing design.

My guess is the 9-7/8" casing collapsed or the pack-off started leaking.

Remark: on the daily report is written that the positive test (2,500 psi) on the casing was started at 10h30 AM which is only 10 hours after the cement job, not too good for the bonding it seems to me.

dolf

this would mean that the casing design was not appropriate

When they drilled the reservoir the last casing in wellhead was 16". I'm very interested to know the weight & grade of this casing

Dol -- actually the csg string run over the pay zone is 7" changing to a 9 5/8" csg at around 13,000'. I don't recall seeing any grades posted.

look in the drilling report, 9-7/8" 62.8 ppf ??? 125 with 7/8" wall

now we need the same for the 16"

dol -- ppf is #'s per foot...the csg weight. There are other parameters for grading uncluding burst pressure and collapse pressure.

Rockman, I know what ppf is, I made the calculations using the burst and collapse pressures for the casing and unfortunately I seem to be the only one in the whole world to understand what it means if I look at all the comments.

The question marks I put since there are 3 letters before the '125' which I cannot read on the drilling report.

Waiting for comments ......

dolfijn

I agree,

When rockman mentioned collasped casing the penny dropped, so I headed for my trusty Green data manual and found the same as you. I was actually surprised to see 9 7/8 casing as I had never heard of it before and I had just suspected the press had got the detail wrong again.

Q125 in the highest grade in the book, my 8th edition is published 2006. It is possible they have a higher grade by now.

When it comes to the 16" casing, what ever the specs are, I doubt if it would have a high enough burst strength for these pressures, which raises the question about all this top kill talk. As if they did stop the flow and trap the pressure, they will just end up with a sub sea blow out and a total mess. In hind sight, if the BOP had of worked 100% we may have been in a worse position than we are in now.

"In hind sight, if the BOP had of worked 100% we may have been in a worse position than we are in now."

Oops, that is not exactly a ringing endorsement of the safety of the techniques being employed here. All is well when all is well, but when TSHTF ya better be wearing your lead underwear...

[Edit] In hind sight we know it did work - at least once the initial surge incinerated the platform... as it held well pressure for some hours until the leaking began in earnest (no fault of the BOP in general - just ram specs and repair issues). But perhaps it is that initial surge you refer to here.

Some interesting reading here:

http://books.google.ca/books?id=NigwG_BYRsYC&pg=PA566&lpg=PA566&dq=casin...

Whats the odds of counterfeit casing? Since ID and OD are the same on different grades - how would you field verify the alloy? I just don't like where a lot of the casing comes from now.

FE that page isn't working for me (over limit message). I wonder if casing being sourced out of a large Asian country known to produce lethal baby formula, toothpaste and dog food?

The link is to Google Books and to a specific page in the book "Rock Mechanics:Petroleum Applications" by Philippe A. Charlez. Page 566. 11.5.4 "Recommendations for dealing with casing collapse in a compacting environment"

Quote:" At the present time, there is no solution which can prevent casing collapse in a highly compacting environment. However there are a number of precautions which can considerably delay (sometimes by several years) the phenomenon"

The book goes on to state to use Q-125 casing and double cemented liners. There is a lot of good info on casing collapse situations, cement bond logs, cement testing and the geologic forces impinging the cased wellbore.

In regard to the grade of the casing that was used- the casing is usually stenciled on the side. I personally haven' t been around Q-125 however the tables that I have indicate that the ID and OD are identical to other grades. I think that the grade of the casing could be confirmed by finding other casing on the bank from the same batch.

What draws my suspicion is that a few years back there were "shackles" or depending on where you are "clevis fasteners" that were counterfeit. They were stamped wrong and I think some guys got hurt when they snapped.

I'm not saying this is what happened. It is something that will need to be checked. Since like Tool push I didn't have anything in my books other than Q-125 it could be that there was a special grade for this application. The tour sheet is damned hard to read.

Another good book with limited viewing is "Advanced Blowout and Well Control Handbook" by Robert Grace. I see now that the viewing on this one has been restricted within the last couple of days.

Look up the Rock Mechanics book while it's still online.

"how would you field verify the alloy"

PMI gun. It's a portable X-ray fluorescence widget that looks like a the bigger phasor from the old Star Trek.

Counterfeit metals are a problem all over now. I work at a PSM regulated plant, and we have to verify pretty much everything coming into stores. And we don't accept anything from China or Africa. And we still have trouble staying in the specs. There is some latitude for bolted fittings, but when you are welding, you have to be right or bad things can happen, starting with cracks and porosity, and finishing with sirens and ambulances.

That may be something they would use in the world of deepwater, but ID and OD and strap is what is normally done around the locations that I have been on. PMI= Pulse Magnetic Induction?

Positive Materials Identification

They use X-Ray Fluorescence to tell the elements (from magnesium on up) and approx. percentage of them.

http://www.niton.com/Default.aspx?sflang=en

see them used screening imported toys for lead, etc.:

http://www.niton.com/Toys-Consumer-Goods-Screening-with-Handheld-XRF/app...

Wouldn't help with temper, (small) inclusions, grain size, etc. with pipe, but at least you'd know it wasn't plain steel if you're expecting an alloy.

Amazing miniaturization - I couldn't believe it when I saw an early one at a trade show years ago - an XRF analyzer with source in a little gun?

I'm sorry, I didn't read your original message more carefully.. The subject of counterfiet steel, bolts, etc is an ongoing huge problem as you have experienced.

Most of the casing collapse stories I have personally heard were in a salt environment. I would say the Deep Water Horizon was probably in as extreme a "compaction environment" as I can conceive relative to their location near the mouth of the Mississippi River.

I'll keep in mind for future reference the PMI process that you use.

Thanks for the information.

Sorry dolf...misunderstood. I'll keep an eye out for the grades.

dolfijn

The strongest and heaviest 16" casing I have listed is 128lb/ft Q125 burst = 73.6MPa =10674psi

As I said before maybe we are lucky the BOP did not hold pressure as full formation presure on this casing would lead to a sub surface blow out ie outside the casing. I sure BP knows this and though they are working to control the leak I do not believe they want to stop it until the well head pressures can kept under control, and that involves getting a heavier fluid between the well head and the producing formation.

Toolpush,

In my calculations I assume that the reservoir pressure is 13,000 psi, however, do you have any source (besides the drilling report which is stating a mud weight of 14 ppg when displacing cement)stating the actual drilling mud weight?

Shouldn't a good cement job boost the effective rating considerably by not allowing deformation failure of the casing?

Toolpush,

We should look at it more in detail: (everything below assumes a 13.7 ppg equivalent reservoir pressure)

The differential pressure is what counts, meaning, if the cement was leaking:

There could have been 13,000 psi reservoir pressure in the 16" x [9-7/8" x 7"] annulus with 2,240 psi inside the [9-7/8" x 7"] casing, filled with seawater, giving a differential of 10,760 psi which is too high in design terms and for sure in real life, if the 9-7/8" 62.8 HCQ-125 casing collapse pressure is 13,840 psi theoretically, but (13,840 - 30%) = 9,690 psi including design & safety factor.

Now for the 16" if we assume the strongest casing, the theoretical burst pressure is 10,900 psi.

For design we subtract again 30% leaving 7,630 psi.

In the annulus 16" x 22" is filled fresh water of 8.345 ppg for a minimum.

This gives at 5,067' wellhead depth x 0.052 x 8.345 = 2,200 psi.

Differential over the 16" casing is 13,000 - 2,200 psi = 10,800 psi which is far too much.

So if the 16" would burst the 13,000 psi pressure could get to the wellhead seals of the 22" & 28" causing them to burst, since they have a much lower rating normally, ending-up in a blow-out at wellhead.

Another senario could have been a blow-out via the 18" liner top to the 22" shoe and then up to surface.

Even if the expected reservoir pressure was much lower or even zero, still the whole design of the casing programme is wrong.

- first of all it seems they never heard of 'buckling' since they leave a heavy casing string 9-7/8" 62.8 ppf x 7" 41 ppf hanging free over 12,100 ft on the casing hanger???

- What do they think will happen when they run completion and start flowing the well and is warming-up?

- if you have so many strings/liners,each with minimum cement behind it, for sure you will do a CBL at the end to verify you have isolated everything

- why is only the upper prt cemented back into the previous casings and the rest not, weak zones which cannot support cement column? never heard of external casing packers or stage cementing, specially for the production casing?

- the reservoir is probably drilled in 8-1/2", if they would have had a 13,000 psi kick, even with the BOP functioning properly and ultra heavy casing everywhere, how where they going to control this? Certainly not with the 7,500 psi max. WP mud pumps, remaining the Halliburton HP unit (probably 15K rated) but at which flow rate??? Pissing against the wind!

This design is so wrong I almost cannot believe that the data provided by Halliburton are correct.

Now next is why to have a 9-7/8" casing on the top? Of course you will answer: to allow to run a 7" completion string! Why they would like to run a 7" completion? Because there is plenty oil. 5,000 barrel/day can be easily produced through a 3-1/2" completion string. Now if there is plenty oil they could have invested a little bit more money in the well isn't it?

A lot of good insights here by the Dolphmeister.

Still don't think with your fine analysis you have to assume the collapse happened at the surface, could have happened deep.

FF

'not appropriate' is not even close ... they can change their name in Blow-out Planners

I got an email request from a fellow PE wanting this info this morning. Thanks.

Is it necessary for it to be a closed system (able to give up fluid but not take it) in order for your scenario to develop. How likely is that given that the oil wasn't far behind.

FF

FF, I do not fully understand the question, for pressure to build-up the system has to be closed.

The space between the final 9-7/8" casing and previous 16" casing was closed at the top (wellhead) by

a 'pack-off' a kind of cork.

Imagine a bottle of soda water, there is pressure sitting under the cork above the soda water, this pressure comes from the CO2 gas which is dissolved in the soda water. If this pressure becomes too high (like in summer when the water heats-up) the cork might pop-off and next most of the CO2 dissolved in the water will suddenly come-out (blow-out), even with the water. Now imagine there is a continuous pressurized feed to the bottle at the bottom of new water with dissolved CO2 in it and you have the average oil well, so the answer is yes, the oil is right behind the gas.

When the 13,000 psi gas migrates upward due to gravity it can either retain its internal pressure or expand. You assume it retains its internal pressure.

Now take the case when it is halfway up the hole let's say... it hasn't expanded and is setting at 13,000 psi with 13. lb/gal mud underneath it. Now oil is flowing in but you cannot re-inject?? So the pressure on the exposed formation is 18,000 psi or so but it does not frac or stop the flow of oil. At the top of the hole, the pressure on the formation face is 26,000 psi but it does not frac?

Not be critical just talkin at the whiteboard.

FF

As long the gas migrates in a closed system the pressure and volume of the bubbles will remain the same, when arriving just below the wellhead it start building a gas cap which is getting bigger by time. The gas cap pushes back the oil /mud into the formation, at a given moment there will be a balanced situation with the well almost full of gas at reservoir pressure.

This would suggest that the fraction of oil in the leak should be decreasing? Or the dynamics of the leak will alter this tendency?

Described is what probably caused the leak [in my opinion] and has little to do with the current flow rate of the well

So would the 13,000 psi gas pressure in your scenario have to reach the mudline or just unbonded pipe above the top of cement??

FF

Deepwater Horizon

The DEEPWATER HORIZON is a Reading & Bates Falcon RBS8D design semi-submersible drilling unit capable of operating in harsh environments and water depths up to 8,000 ft (upgradeable to 10,000 ft) using 18¾in 15,000 psi BOP and 21in OD marine riser.

Top Drive Varco TDS-8S, 750 st, 1150 hp with PH-100 pipe handler

Mud Pumps 4 x Continental Emsco FC-2200, 7500 psi

BOP 2 x Cameron Type TL 18¾in 15K double preventers; 1 x Cameron Type TL 18¾in 15K single preventer; 1 x Cameron DWHC 18¾in 15K wellhead connector

LMRP 2 x Cameron DL 18¾in 10K annular; 1 x Cameron HC 18¾in 10K connector

Diverter Hydril 60 with 21¼in max bore size, 500 psi WP and 18in flowline and two outlets

Control System Cameron Multiplex Control System

Riser Vetco HMF-Classs H 21in OD riser; 90 ft long joints with C&K and booster and hydraulic supply lines

Riser

Choke & Kill Stewart & Stevenson 3-1/16in, 15K, with 2 x adjustable chokes and 2 x hydraulic power chokes

Cementing Halliburton (third party equipment)

NOW THESE ARE THE SPECS SO STOP THE NONSENSE about a 10,000 psi BOP with 5 sets of shear rams etc.,

FF

Regarding your question you can calculate yourself the answer since you know very well what I'm talking about, stop waisting my time!

Dolfijn and Fractional Flow,

Thanks for letting me see the conversation on the pressure differentials vs working strength of the steel and where the failures could be. I am not associated with the oil industry in anyway and I clearly understand the ramifications if your calculations are correct.

Now I understand why there is so much emphasis on the relief wells. They are the only way to stop the flow from the blown well if you are right.

Settle down comrade, and keep your shirt on ... it's not compulsory to spend time here. And BTW ... anyone can copy specs from a company website - no big deal.

According to roger_rethinker, the fluid in the reservoir is a supercritical solution. In a a previous post, he estimates its density to 0.6. A column of 13000 ft would then have a hydrostatic pressure drop of ~3400 psi. The pressure on the liner would be ~5650 psi below reservoir pressure.

OTOH, reservoir pressure may be higher than 13000 psi. IIRC they used a mud weight of 14.5 ppg, which results in an upper limit of 13600 psi. 8000 psi on the liner/casing. A lot, but not above specs.

Makes your theory less likely.

Rainer

So the siphon into the broken riser pipe is collecting 3000 barrels per day?

Is that barrels of oil, or oil equivalent?

And if the siphon is collecting 3000 barrels, what does that say about the actual magnitude of the leak?

Given the videos of the various leaks now available, I'd say that there is significantly more than 5000 barrels a day coming out of that well.

And with a GOR of 5000 to one, it certainly seems like the flow rates aren't going to slow down any time soon.

BP is going to actually release some evidence if they want anybody neutral to believe 5000 bpd. Their credibility went to zero when the platform exploded. You can't beat something with nothing.

The RIT certainly provides reference size for the riser leak.

Have not heard of any video being released of the RIT concurrent with the new recovery rate.

It seems we must be prepared for the possibility that pressure reduction may be a result of total flow rate increase from the two leaks.

wait, what? Explain why pressure reduction may be a result of flow rate increase.

What would the observed pressure reading below the BOP be if the well was totally sealed at the BOP? Now what would that observed reading be if the BOP was a total wide open leak?

That's highly dependent on an unknown reservoir pressure which may have been dropping for the past month and the pressure loss upstream of where we are taking the measurement. If the formation is collapsing, then there would be more pressure loss to the wellbore, or if the driving force is moving farther away from the wellbore, then the reservoir pressure is essentially dropping. Both of those events could result in less pressure below the BOP and both would be associated with a rate decrease, not increase.

That's just it. The reservoir pressure is an unknown.

There have been as I understand it x-ray pressure readings that have been taken at the BOP and apparently there is more opportunity to get the leak rates than has been done. I don't think we automatically should be led to believe that the reservoir pressure is dropping or collapsing at a greater rate than the output is increasing while TPTB have better means at their disposal to get confirmation on the rather more easily observed flow rate/pressure relationship at the BOP.

Heading Out, my apologies if this has been asked and answered already: why are the relief wells being drilled to that depth? Wouldn't intersecting the original well at less depth mean stopping the flow sooner?

Hey aangel, I heard BP officials publicly state during one of the broadcast hearings that they had determined that the relief wells would only work if they were drilled to that depth, they didn't seem to want to elaborate on why that might be so. Just a guess but perhaps they aren't willing to trust the integrity of any of the casing...

This was posted by Interested_Public in yesterday's thread. It is a must read:

"The bad press is starting to flow like oil from a high pressure pipe:

Worsening Gulf oil spill overwhelming Coast Guard:

http://www.mcclatchydc.com/2010/05/18/94418/coast-guard-despite-bp-effor...

"The Coast Guard commandant, Adm. Thad Allen, said that despite the siphoning, the spilled oil is spreading and now stretches from western Louisiana to Florida's Key West. The extent of the spill was straining even the substantial resources deployed for one of the worst ecological disasters in recent history, he said.

Allen said the approximately 20,000 people now working to prevent the spill from reaching land were struggling to deal with an environmental threat that he called "omni-directional and almost indeterminate" in size. He said federal disaster plans had been formulated to deal with far more localized spills.

"We're dealing with something that's more complicated than any spill I've ever dealt with," Allen told the Senate Committee on Commerce, Science and Transportation. "The national system did not contemplate that we would have to do all of this at once."

The National Oceanographic and Atmospheric Administration widened its no-fishing zone to cover 19 percent of the Gulf, or 45,728 square miles, and its head, Jane Lubchenco, told a news conference that "a light tendril of oil" is spreading eastward and approaching the loop current, a powerful warm-water current that could drag the oil around Florida and into the Gulf Stream that flows up the Atlantic coast.

Lubchenco said the current would dilute much of the oil into thin strips, and some scientists have warned that these strips could cause major damage to the extensive coral reefs that hug Florida's southern coastline."

BP withholds oil spill facts — and government lets it:

http://www.mcclatchydc.com/2010/05/18/94415/bps-secrecy-keep-facts-on-gu...

" WASHINGTON — BP, the company in charge of the rig that exploded last month in the Gulf of Mexico, hasn't publicly divulged the results of tests on the extent of workers' exposure to evaporating oil or from the burning of crude over the gulf, even though researchers say that data is crucial in determining whether the conditions are safe.

Moreover, the company isn't monitoring the extent of the spill and only reluctantly released videos of the spill site that could give scientists a clue to the amount of the oil in gulf.

BP's role as the primary source of information has raised questions about whether the government should intervene to gather such data and to publicize it and whether an adequate cleanup can be accomplished without the details of crude oil spreading across the gulf.

Under pressure from senators, BP released four videos Tuesday, but it hasn't agreed to better monitoring.

The company also hasn't publicly released air sampling for oil spill workers although Occupational Safety and Health Administration, the agency in charge of monitoring compliance with worker safety..."

BP told feds it could handle oil spill 60 times larger than Deepwater Horizon

By Ben Raines

May 19, 2010, 5:00AM

http://blog.al.com/live/2010/05/bp_told_feds_it_could_handle_o.html

"In its 2009 exploration plan for the Deepwater Horizon well, BP PLC states that the company could handle a spill involving as much as 12.6 million gallons of oil per day, a number 60 times higher than its current estimate of the ongoing Gulf disaster.

In associated documents filed with the U.S. Minerals Management Service, the company says that it would be able to skim 17.6 million gallons of oil a day from the Gulf in the event of a spill.

As of Tuesday, BP reported recovering 6 million gallons of oily water since the ongoing spill began four weeks ago. BP spokesman Tom Mueller said that only about 10 percent of the skimmed liquid was oil, which would amount to about 600,000 gallons of oil collected thus far.

Mueller also said via e-mail Tuesday that "the spill has stayed about the same size or even shrunk on the water as a result of our response efforts."

Skytruth.org, a website that monitors environmental problems using satellite imagery, reported Monday that the spill had grown to 10,170 square miles, based on NASA images. John Amos, head of Skytruth, told the Press-Register then that the spill had approximately doubled in size since Friday.

BP did not respond to questions about the NASA images.

BP's Deepwater Horizon Initial Exploration Plan suggests that the well's unchecked flow would be 6.8 million gallons a day. ..."

Gulf oil spill leak now pegged at 95,000 barrels a day:

http://www.mcclatchydc.com/2010/05/19/94467/engineer-oil-spill-videos-sh...

" WASHINGTON — The latest video footage of the leaking Deepwater Horizon oil spill in the Gulf of Mexico show that oil is escaping at the rate of 95,000 barrels — 4 million gallons — a day, nearly 20 times greater than the 5,000 barrel a day estimate BP and government scientists have been citing for nearly three weeks, an engineering professor told a congressional hearing Wednesday.

The figure of 5,000 barrels a day or 210,000 gallons that BP and the federal government have been using for weeks is based on satellite observations of the surface. But NASA’s best satellite-based instruments can’t see deep into the waters of the Gulf, where much of the oil from the gusher 5,000 feet below the surface seems to be floating.

Federal officials testified in hearings on Tuesday that they were putting together a crack team to get to the bottom of big the spill really is. That effort comes a month after the April 20 explosion that triggered the unprecedented oil spill in deep waters of the United States. Experts say knowing that amount is crucial for efforts to cap the broken wellhead and to monitor and clean up the oil.

Steve Wereley, an associate professor of mechanical engineering at Purdue University, earlier this month made simple calculations from a video BP released on May 12 and came up with a flow of 70,000 barrels a day, NPR reported last week. Werely on Wednesday told a House Commerce and Energy Committee subcommittee that his calculations of two leaks that show up on videos BP released on Tuesday showed 70,000 barrels from one leak and 25,000 from the other.

He said the calculation could be off by 20 percent — meaning the spill could range from between 76,000 to 104,000 barrels a day. But Wereley said he would need to see videos that were not compressed and showed the flow over a longer period so that it would be possible to get a better calculation of the mix of oil and gas from the wellhead."

and an interesting one from back on May 1st:

Video shows federal officials knew quickly of potential for massive oil flow in Gulf spill.

http://blog.al.com/live/2010/05/video_shows_federal_officials.html

"... In it, officials are discussing the search for survivors of the Deepwater Horizon explosion. There is a hand-drawn map of the spill dated April 22. At one point, the video freezes on a sign next to a door that reads, "War Room."

In one scene, officials say that the estimate for the leak in a worst-case scenario is between 65,000 and 100,000 barrels per day. A dry erase board on the wall reads "Estim: 64,000 to 110,000 bbls/day. CNN reported 300,000 gal/day."

The high end of the estimate, 110,000 barrels, is about 4.6 million gallons. At that spill rate, 32 million gallons of oil would enter the Gulf every week. By comparison, the entire Exxon Valdez spill was about 11 million gallons.

Officials estimate current flow from the damaged well at 210,000 gallons a day.

It is unclear from the video what events would have to transpire to raise the flow rate higher.

A confidential NOAA report, dated April 28 and circulated among federal agencies, makes similar projections regarding spill size in a worst-case situation.

It describes newly discovered leaks in the tangle of riser pipe, attributing them to ongoing erosion of the pipe. The riser pipe, in this case about 5,000 feet long, connects the wellhead on the sea floor to the drilling rig on the surface.

"If the riser pipe deteriorates further, the flow could become unchecked," reads the report.

On Thursday, the day after the NOAA report was circulated, BP officials said they were worried about "erosion" of the piping.

Sand is an integral part of the formations that hold oil under the Gulf. The raw crude rising from the bottom of a well carries sand and other abrasive materials. In effect, the oil is sandblasting the piping as it rushes through with tremendous force, according to petroleum engineers.

"I think we need to be prepared for it to be the spill of the decade," Debbie Payton of NOAA, the meeting's coordinator, says during the NOAA video. ..."

Shows how the attempt to manage and control information has turned out badly - openness from the beginning would have been best in my opinion."

Interested_Public

You have to intersect the original well as deep as possible, and as close as possible to the productive interval, otherwise you cannot get enough pressure in the relief well to kill the flow. You need a very tall column of kill mud, and the only way to get that tall column is to have a deep well.

In addition, if the casing of the original well is compromised (either because of bad original work, or because of erosion and destruction due to the blowout and subsequent "sandblasting"), you want to avoid as much of that as possible, and get below it.

Thanks everyone for the answers.

Rockman gave the authoritative answer back on May 8th:

http://www.theoildrum.com/node/6444#comment-620428

The following presentation was given in 2008 and addresses regulatory issues in the Ultra-Deep areas of the Gulf.

http://www.rpsea.org/attachments/contentmanagers/1931/Vicic.pdf

more can be found here

http://www.rpsea.org/rpsea-2008-forums/

Isn't the leak thru a 9" drill pipe?

Purdue research exposes error in BP video

"...Once Wereley used particle image velocimetry to create freeze-frame shots of the video, he used a computer code he developed to estimate how many pixels the diameter of the pipe was. BP said that the diameter was 21 inches, which Wereley estimated is equivalent to 400 garden hoses.

Wereley created a conversion from pixels to inches to compute how fast the oil was coming out of the pipe. He used the area of the pipe and the speed of the oil, which he concluded was 2 feet per second, to compute the volume of oil being released. It was through these calculations that Wereley deduced 70,000 barrels of oil had been leaked..."

http://www.purdueexponent.org/index.php/module/Section/section_id/11?mod...

The jet in the video was issuing from a 21" pipe, so that's what was used. The velocity in that pipe was about 2 ft/sec.

Anyone forming an oil flow prediction pool among you cohorts?

I've already made my call

My pick would be a maximum flow rate of 40,000 to 50,000 b/day which has since declined (due to normal depletion for wild wells) to the 20,000 b/day range now with further declines in the future.

Alan

Based on limited and flawed information, lack of denials, assertions made and legal implications, my guess is that it started at about 52,000 BPD, and has decreased to about 20,000 at present. By the time the relief wells are finished, it will be flowing about 5,000 or less, making the job quite a bit easier by then.

It looks like they deferred the top hat b/c the flow was dropping and there would be a better chance of success to wait a few more days, for a slower flow.

Of course, we could all be wrong, eh?

Craig

I'd WAG about 30,000 bpd. But with BP sitting on most of the video it could be a lot worse.

Is there any particular reason why the leaking pipe can't be slowly crushed, then crimped using a "jaws of life" type device? Just a thought as I was stopping up an old copper water pipe this afternoon, that didn't leak when mains pressure was turned back on.

Regards, Matt B

Every day the news seems to get worse; my best hopes for all those in the area.

If the riser is blocked completely, then in short order it will need to support the static pressure coming up from the reservoir. My understanding is that even if it is rated for that kind of pressure the uncontrolled distortion of the riser pipe while the rig sank will have weakened it considerably.

A nice, gaping split failure in the riser pipe where it has bent just above the BOP would complicate things more, I think.

WharfRat -

Aha, this is the sort of determination I previously tried to make simply by eyeballing the BP video!

First to answer your question: yes, the actual leak(s) is(are) in the 9-inch drill pipe, which is inside of the 21-inch riser. The oil/gas leaks out of the drill pipe and enters the annular space between the two pipes. However, what you are seeing in the video is the oil/gas exiting the end of the 21-inch riser pipe. Therefore, the cross-sectional area of the 21-inch riser pipe pertains.

A 21-inch riser pipe has a cross-sectional area of 2.4 sq. ft. So, an exit velocity of 2 ft/sec (as estimated by this professor) would give a fluid flow rate of 4.8 cubic feet per second, which is equivalent to 2,150 gal/min, which is equivalent to about 74,000 bbl/day. But that is the flow rate of total fluid, which consists of a mixture of oil and gas.

So, if we reasonable assume that half of the volumetric flow rate of that fluid (at the deep-sea pressure at the end of the riser is oil, then the estimate of the rate of oil release becomes something like 37,000 bbl/day. This is over 7 times greater than the original estimate of 5,000 bbl/day, but less than half of some of the more high-end estimates.

This looks reasonable to me (particularly since I myself had eyeballed the velocity of the plume leaving the riser at about 3 ft/sec.). Not bad for someone without sophisticated imagining technology, don't you think?

How do you reconcile your statement that only 50% is gas when the measurement on the drill ship is around 5000:1 gas to oil ratio? I don't know if that ratio is at STP or at the pressue in the siphon line, or if the pressure doesn't matter. IIRC, anything over 3000:1 is really considered a gas well not an oil well.

The number I keep hearing is 3500:1, but that would be at sea level. At the floor, the gas is compressed. More like 3:1 as it leaves the pipe.

(Disclaimer: I'm way over my head here. I'm just repeating an explanation I heard on NPR.)

CuriousGeorge -

The gas numbers are given at STP.

5,000 cu ft gas per bbl oil is equivalent to 890 cu ft gas per cu ft oil at STP.

If the leak is approx 5,200 ft below the surface, it is at a pressure of about 2,300 psi or 157 atmospheres. Thus, at depth the 890 cu ft of gas will occupy a volume of roughly 5.6 cu ft (assuming ideal gas behavior).

Note: This assumes that the natural gas is all in the gas phase and that none of it is actually dissolved in the oil. In other words, two-phase flow. (Anybody out there know what the saturation point of gas in oil is at that pressure?)

But for the sake of argument, for the plume we are looking at, if we assume that for every 1 cu ft of oil we have 5.6 cu ft of natural gas, then the ratio of oil to total fluid in the plume is 1 /6.6 or 0.15. This would be much less than my guess of a 50/50 split.

Then if that were the case, the amount of oil in that 74,000 bbl/day total flow would be more like 11,000 bbl/day, which is still over double the original estimate.

Again, this assumes zero solubility of gas in oil, which were know is not the case, so my pure hunch is that we might be more in the range of 15,000 bbl/day, but the real number depends on what the solubility of gas in oil is under those conditions.

Maybe someone with better knowledge of what an oil/gas mixture looks like under high pressure would be able to make a better adjustment.

I think the ratio of 5000:1 natural gas to crude oil mixture is in units of (cubic feet of natural gas at 1 ATM) / (barrels of crude oil at 1 ATM). The pressure at the ocean floor is much higher than 1 ATM making the volume ratio much lower.

I provide a more robust analysis of the ratio of natural gas to crude oil below based on the BP data.

Retsel

9" DP does not even exist - how do you calculate the cross- section of a 21 inch riser?

People on a couple political websites I read are now throwing around a leak estimate of 95,000 barrels a day, thanks to this estimate:

http://www.mcclatchydc.com/2010/05/19/94489/gulf-oil-spill-may-be-19-tim...

In an earlier thread here, there was a discussion of this and I interpreted some of you to think it was probably in the 20,000 barrel range.

Any more thoughts on the estimated flow?

Best flowing well in GOM so far has been around 50,000 bbls/d peak.

Nothing about this formation suggests that it was predicted to do better than that.

Is that number for a cased, perforated, pressure-controlled production well, or for a completely unconstrained hole in the ground?

You know what I'm referring to and don't pretend you know the dynamics of an uncontrolled well vs. a controlled well. It is my belief, though I can't prove it, that the controlled flow wells would be better production rates overall than an uncontrolled well.

Do you think a 25,000 bpd rate is totally out of the question or do you think it is reasonable based on what you have seen from the videos?

Or are you sticking with the 5,000 pbd rate and if so why?

My bet (for my unclaimable salary) was that the oil flow rate was no more than 20,000 bbl/d. I base that on the fact that the highest flow rates achieved in the other GOM wells peaked around 50,000 bbls/d and this was not considered the best well by any means, added on to the fact that this was not a completed well and flow is occuring through a great deal of pressure drop. The 5,000 bbl/d number was a back of the napkin guess made in the first week and has simply not been revised, I believe, because of the dynamic nature of the well. 25,000 bpd of oil may have occurred, or even perhaps a short period of even high flow rate, but once all is said and done, I expect the flow rate average to be well below the estimates provided the "scientists" and well well below the chicken little consiracy reports (500,000 bpd, please, be serious).

I'm wondering where are the "live video feeds"?

Can't find them on Markey's site.

If anyone can find the live feeds, please provide link. Thx

( I'm wondering if BP will wait till the junk shot to produce the live feeds? )

I appreciate everyone's help here.

Perhaps they will provide the congressman with a feed from an ROV with lights turned off to show him they are conserving electricity.

Show us the live feeds now!!

http://www.reuters.com/article/idUSN2014884920100520

I read they were supposed to start streaming the flow feed last night @ the Congressional website.

What happened?

live feeds now up:

billnelson.senate.gov/

globalwarming.house.gov/spillcam

The link, GlobalWarming.House.Gov: Oil Spill in the Gulf LiveCam, is presently timing out when I try to load it.

And the CNN version is showing odd shots of video screens.

http://www.cnn.com/video/flashLive/live.html?stream=stream2&hpt=T2

eta.. now a bank of video screens, all quite dark. Oops, now one screen is showing the leak.

The truth is we don't know... My recollection of the expert consensus is that it was in the ~20k range given what could be observed. 100k was deemed to high and would put the reservoir at the top end of those ever discovered in the region - yet BP apparently discussed numbers in this range with NOAA in the early days after the accident on the rig.

A reliable estimate from evidence at the site would be welcome.

Tell me about it. I personally would love to have the numbers and calculations. The numbers on the internet have gotten rediculous. Of course, as soon as BP released a number, there would be those yelling that they waited until the flow came down so they could make it look better than it was. Its a no win situation for them to appease the internet.

Greg, there is plenty of video of the leaks over time - may even be nearly continuous. If an accurate measurement can be made at any point it will be possible to back calculate the leak rate at any other point within a reasonable error envelope. There is really no reason this should be a matter of debate and speculation - some of it damaging.

Oh, but the assumptions that go into back calculating are treacherous. If there is channeling of flow inside the diameter of pipe (say if the main leak is through the drill pipe), then actual flow cannot necessarily be calculated using the pipe diameter visible. Or if the flow is mostly gas with oil suspension, then you have to know that ratio throughout time, which may have been more or less in earlier pictures.

Whatever their shortcomings, such estimates would be FAR BETTER than what is currently occurring. I would be willing to bet more than a round or two at the bar that the drill pipe is busted at the riser kink and all downstream flow is in the riser. The more video is available the better the estimate of the gas fraction. BP now has additional data from their capture process - data over time. Don't make this seem more difficult than it is.

The sensible thing to do would have been to set up to make reasonable estimates from the beginning - having failed to do this means that the level of suspicion has increased - especially among those inclined to be skeptical. BP may, in fact, already have pretty good flow estimates as it would be a reasonable assumption that this information was important to their efforts to control the leak - including estimates of the gas fraction.

Personally I am tired of the apparent foot-dragging and stream of excuses that seem to substitute for straight-forward information.

Me too. But as a lawyer, I know the drill. Either don't get the evidence to begin with so you can't be accused of destroying evidence, or do everything you can to keep it to yourself.

That is why I am advocating a special prosecutor, to see that the evidence gets collected.

David G. Mills -

I wholeheartedly agree that all relevant evidence should be preserved, and the order to do so issued ASAP.

Another piece of critical evidence is the broken drill pipe itself. Though it would entail some difficulty and expense in bringing it back up to the surface after the leak has been sealed, it could provide a highly definitive means of determining the size of the release.

Once one has taken accurate measurements of the size and shape of the openings, then one could use that in conjunction with the already known pressure at the downstream side of the blow-out preventer to make a reasonable accurate calculation of the amount of fluid that was released. As we already have a pretty good handle on the gas/oil ratio, we can then easily determine how much of that fluid consisted of oil.

Since they can measure the pressure below the BOP why don't they shut it in and due a pressure buildup test?

Then they could back calculate the flowrate from Darcy's law.

FF

Because the BOP is not able to be completely closed to do that test, if it had worked as designed this whole issue of how big is the leak would never had occured. The number would have been zero. They have pressure readings at the choke and kills lines under the BOP, and that should be pretty close to the well pressure as the BOP is mostly closed. I'm not an expert but it makes sense that if you shut in the well 100% it should eventually stablize at the formation pressure which is a known value from the logs of the well. If they can overcome that pressure with the top kill mud injection they stop the flow.

pass

Why indeed? Why don't they stick a pitot tube in the leak plume and get velocity measurements? Possibly because they know they won't like the answer.

Hey, I think think I know of a European airplane manufacturer who might be able to get them a really great deal on a batch they no longer need. They might actually even like the results these particular pitot tubes would give. They aren't considered very accurate for measuring air speed...

Current measurement equipment is standard ROV instrumentation. Should be easy to modify for a point measurement using the manipulator. Risk would seem to be to the ROV if it got bounced around but now the RITT is installed any attempt could risk pulling the RITT out of the riser.

I would not risk anything around the BOP that wasn't absolutely necessary.

GregTX -

I think the only way there could be any significant channeling of the flow out of the 21-inch riser pipe is if the main leak is not far from the open end of the pipe (say within less than 100 ft).

However, give the fact that the riser pipe is about 5,000 ft long and is seriously bent not all that far from its upstream end, it is probably a pretty good bet that the main leak is nowhere near the open downstream end. And if indeed that is the case, then the high velocity jet has more than enough opportunity to transfer its momentum to the surrounding fluid to create a more or less uniform flow stream.

Picture filling up 55-gallon drum with a small garden hose placed at the bottom and pointing up. While the water coming out of the nozzle may have a very high velocity, by the time the water level reaches the top of the drum and starts to overflow, the flow pattern has smoothed out considerably, even over that sort distance. I do happen to have some experience with jet eductors, and it has always struck me how rapidly the kinetic energy of the jet is dissipated into the surrounding fluid.

I thought the leak was near the end of the riser? I can't imagine sticking in the "plug" 150 feet or more down the riser and into the end of leaking drill pipe with an ROV. Maybe the ROVs and the operators are really, really good.

There is good reason to believe the primary leak(s) exit(s) is(are) in the neighborhood of the kinked riser and the top of the BOP. Or is that what you meant?

This is right above the BOP.

http://www.youtube.com/watch?v=V7Vkgr-FEgg

Any questions?