Pipe Insertion into the Riser of the Deepwater Horizon Oil Spill

Posted by Heading Out on May 15, 2010 - 10:39am

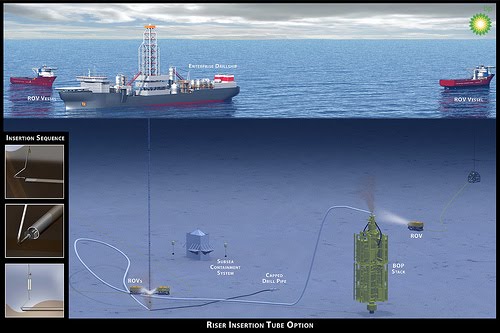

There is a little confusion about the current status of events that will take place to try and shut off the oil flow into the Gulf. At the present time it appears that the first line of attack is going to be a tube that will be inserted into the riser, capturing all the hydrocarbons, and feeding them to the surface. The intent in trying this route first is that it captures the fluids before they mix with seawater, and thus will prevent the formation of the methane hydrates that were a problem with the first containment box. Should the pipe insertion not work, the “top hat” is sitting on the ocean bed near the site, ready to be deployed.

The pipe is being inserted at the leak that is creating about 85% of the flow into the Gulf and could start siphoning oil as early as this evening (Friday, May 14).

At the present, the next alternative to this is planned to be the “junk shot.” After taking a gamma ray scan of the Blowout Preventer (BOP), there is a path to get the bulk particles (golf balls, bits of tire etc) into the well below the BOP where they will fill most of the voids in the flow path, and hopefully slow the fluid flow to the point that a counter-flowing feed can be introduced that will weight up the hole, and then stop the flow. It is expected that this will be tried, regardless of the pipe insertion success, some time next week, since it will effectively kill the well.

Because the pipe that is being inserted into the riser won’t be a perfect fit for the pipe it is going into, there has to be some form of seal to make sure that the oil and gas flows into it. This planned seal is based on the use of rubber flaps.

The 6-inch insertion tube is intended to rest inside the 21-inch riser pipe, surrounded by rubber flaps meant to prevent more oil from pouring out. The tube would carry the oil to a tanker on the surface.

Proegler described the procedure as a stopgap measure.

I have mentioned that specifically because there has been a lot of conjecture on how much fluid is flowing out of the riser, and what pressure that it is at.

The condition of the BOP seems to suggest that the flow through it is still acting as an orifice that resists most of the driving pressure from the reservoir that is moving the oil and gas into the well. By relying on rubber flaps, BP seem to accept that there is little additional pressure in the fluid beyond that point (which is somewhat evident by the behavior of the fluid leaking from the well as shown in the video). It is the size of the flowing orifice, and the velocity of the flow that has given rise to some of the recent higher predictions of oil leakage which have reached up to 70,000 barrels per day.

While the velocity of the flow can, to a degree, be point estimated using particle image velocimetry, the ability to average that over the whole flow, and the actual size of the orifice (it is leaking through a crack in the riser) makes the orifice estimation more of a guess, as is that of the total flow volume. I suspect that once the flow is captured, then the actual flow will be reported, and will come in closer to the BP estimate, which remains about 5,000 barrels per day, and remains much lower than the more recent estimated values.

Looks like a vasectomy reversal, but probably much more difficult.

Can somebody PLEASE tell me how/why I'm wrong. I HATE the answers I'm coming up with!

The insertion pipe is a dream and so is the "tophat", but hydrates AREN'T the problem! If the gas escaping from the end of the riser is conducted to the surface inside a pipe, the expansion of the gas will make the velocity near the top unmanageable. If you try to close a valve on it to control the flow velocity, the backpressure will blow the insertion pipe out of the end of the riser.

I've said it in a few different threads now, but I'll repeat it here. Unless they figure out some way to separate the oil from the gas AT DEPTH (where the gas is under pressure), any attempt to recover the hydrocarbons is a waste of time.

If the GOR is anywhere close to the 3000 cu ft/bbl that I picked up in another TOD thread, then they're talking about something on the order of 15 million cuft of gas/day, even if the oil flow rate is only 5000 bbl/day. If that's coming up a 6" pipe, we're lookin' at somewhere near 600 miles/hr when it expands to STP.

I SINCERELY HOPE that I'm just a bungling calculator jockey and that I've missed by a couple of orders of magnitude somewhere, but so far, nobody's said anything convincing about where I've screwed up.

That's scary, and makes sense to me. I heard one of the workers from the rig say that gas had come up the pipe really fast and then was ignited by the drill engines. In short, a blowout, right?- where all pressure control over the huge volume of evolved gas was totally lost.

The tube in the pipe idea is meant to just transfer the force of the gas/oil gusher to the surface, without pressure control, and they'll be back to having a blowout on the surface, which can't be pressure-capped without blowing the small pipe out at the bottom, unless it is made as a high-pressure connection, which these mud flap thingies probably won't provide. That's what it seems like to me, (basically the same as the way you already explained).

So if they get this "straw" to take all this fizzy foamy flammable fluid out of the bottle, so to speak, to the surface, what then? The ultimate Mentos foamarama, only highly combustible?

I'm not trained in anyting oil, but just an interested amateur, and find this TOD site the BEST, by far, that I've seen for scientific/technical discussion of the problem.

This is my first comment. I registered just to participate in the discussions here. It was very refreeshing to read the comments here compared to most other forums I've seen, which are too general, to say the least (and to be kind about it!)- and populated mostly by people who can't even calculate the area of a circle, or who just want to gripe about lefty-righty politics; or top each other in creatively blaming various "they"s and "them"s; or hate on the "drill baby drill" cheerleaders.

But if one's house in on fire, the only important thing is to put it out, not assign liablity and blame. The only important thing is to get the well plugged, and then roll heads later, if heads are gonna roll.

I've always been fascinated by marine salvage, having grown up on the coast around ships and mostly submarines (near the SUBASE in Ct.) Which reminds me, we sure could use the abilities of the late great marine salvage dude Edward Ellsberg on this job. I bet HE could have had the thing plugged by now. He was really really good at impossible-looking marine salvage jobs.

But since he is gone, I wish the president would order the Navy to take control of the whole operation, to get on it with everything they have got- that is, if they have any necessary capabilities BP doesn't have.

fisherseye

The Explorer is one of the few ships capable of handling the mixture, up to 15,000 b/day.

Since most of the pipe area (and flow) has to just blow by the flaps (not sure why they are there), this could significantly reduce the back pressure that would force/eject the smaller pipe out.

Just positioning the pipe 1 yard/meter outside the blowout pipe would likely capture a certain % of the flow (2% - 5% SWAG) and that would be good.

Alan

Newdood,

The BP spokesperson said that the GOR (Gas to Oil ratio) is 3000 quoted in Upstream. 3,000 cu ft of gas per barrel of oil is close the limit of 10,000 where it is considered a gas well. What will happen if they let the gas escape at 600 mph?

Maybe Matt Simmons was right. I thought he made a pretty bold prediction at the start that they would not be able to fix it.

(to clarify) matt simmons said:

http://news.nationalgeographic.com/news/2010/05/100513-science-environme...

new question - if the cement job is bad, will sealing off the bop be effective?

perhaps someone at BP should read this paper from Journal of Hydraulic Research Vol. 41, No. 4 (2002), pp. 339–351

titled

A model for simulating deepwater oil and gas blowouts – Part I: Theory and model formulation

ABSTRACT

A model developed to simulate the behavior of oil and gas accidentally released from deep water is presented. This model presents major modifications to a three-dimensional model developed earlier (Yapa and Zheng, 1997) that simulate the behaviour of oil from under water accidents (shallow water). In deepwater, the ultra-high pressure and cold temperature causes phase changes in gases. These combined with relatively strong currents in some deepwater regions presents extraordinary challenges to modeling jets/plumes from deepwater oil and gas blowouts. The present model incorporates the phase changes of gas, associated changes in thermodynamics and its impact on the hydrodynamics of the jet/plume. Hydrate formation, hydrate decomposition, gas dissolution, non-ideal behavior of the gas, and possible gas separation from the main plume due to strong cross currents are integrated with the jet/plume hydrodynamics and thermodynamics.

This paper presents the complete model development and testing of various computational modules with available data. A companion paper presents the comparison of model results with three large-scale field experiments conducted in the Norwegian Sea.

realist:

Your link is wrong. It actually points back to HO's initiating post on TOD. At least that's the way it shows up on my computer.

Woops. Here is the correct link:

http://people.clarkson.edu/~pdy/publication_files/jp17.pdf

I found the paper mentioned here

http://www.iahr.org/publications/assets/jhr41-4/2397-i.pdf

newdood, I'm not an engineer nor have I ever worked in the oil business. But I do have a degree in physics. And the first time I read about this option (Rube #2 I call it), my thoughts were exactly the same as yours.

If this brew does get to the surface I wouldn't want to be anywhere close to it. No way would I even think about getting on that containment ship.

If they're using rubber "flaps" the intention is not to achieve a complete or "airtight" seal. If the conduit to the surface is initially filled with oil, let's say, with a valve at the surface and (2) pressure gauges, one before and one after (before receiving vessel), you can crack open the valve as you start to "thread" the six-inch tube into the larger riser. I think as the pressure builds up inside ahead of the insertion tube, the idea is to have much of the gas "blow by" the flaps to keep the sea water from entering. They don't need gas to enter the tube, and it's better if most of it doesn't, both from a hydrate point of view and excess velocity as it nears the pressure level at the surface.

By observing the behavior remotely, one can determine if the "right" amount of gas is blowing by and also by monitoring the flow and pressure at the top, although there will be a significant delay, decide how far and fast to open the valve. That's about all I have--hope it helps somebody.

HvyOilGuy

That is an interesting observation. Has anyone else thought about these issues?

Yes Gail. The rubber flaps are only to control the amount of water going into the old riser. Net flow must still be out of the riser to guarantee that no water is flowing in to cause hydrate problems. A throttling valve at the bottom end of the new oil pipe would be adjusted to allow all of the oil and as much gas as wanted to pass up to the tanker above. This valve should be at the bottom end as the dynamics of a mile long pipeline filled with a mix of liquid and gas would be very difficult to control at the top end.

All the equipment from the bottom going up is standard equipment used for drilling and producing oil and gas from these water depths.

The Discoverer Enterprise is purpose built to drill and test wells in water depth up to 10,000 feet. At the cost of almost a billion dollars it is specifically designed to handle high pressure, high velocity, mixed phase flows.

It has equipment on board to separate the gas from the oil - the gas will be flared and the oil put in storage tanks.

The processing equipment is rated at 15,000 bpd but, depending on the composition of the flow they may be able to handle more.

I did a back of an envelope calc about how much oil could flow to the surface through a 6 inch drill string based on the buoyancy of the oil and came up with a minimum of 20,000 bpd, probably about 30,000 bpd or more. As soon as you add some gas that will act as an air or gas lift that number increases.

In other words they use the same physics that concern you to actually produce the oil and gas.

When the oil/gas stream reaches the surface it is still under pressure, the 6" drill stream does not go to STP, the stream goes in to separation pressure vessels so the velocity is reduced to near zero during the rest of the processing.

BUT there is a very real problem. The flow rate will be controlled at the surface by throttling the stream as it exits the drill string into the processing system. Control of that flow is critical to stabilizing the flow where the pipe is inserted into the broken riser.

Open the valve too much and the pipe will develop a suction that will try to draw salt water into the system which will cause hydrate formation.

Close off the flow and it will cause a build up of pressure behind the seals or flaps and try to blow the pipe out of the riser.

If it was my project I would try to install a clamp on the riser that would attach to the drill string with a chain or cable - similar to a thrust block.

It may be that the sheer volume of the riser - 21" dia by several thousand feet long, and the compressible gas inside will be slow enough to react to pressure changes that they will be able to adjust the throttle on the drill ship.

I don't know if anyone heard this before but "its never been done at this depth". And actually as far as I know this particular procedure has never been done before at any depth.

if the cement job is bad, then any plan to plug the bop will fail, is that not correct? it certainly won't stop the leak, right?

If they can slow the flow enough to pump in drilling mud then they can kill the well, at that point bad cement, nonoperational BOP, blown casing, etc, will no longer matter.

After it is killed they can reenter and do a complete P&A (plug and abandon) as is standard industry procedure for any non-producing well, even dry holes.

I have to leave for a couple days, will be interested in seeing the threads when I return.

You are contradicting yourself. If the flow is due to buoyancy you need water in the pipe. They you say you can't have water in the pipe because of hydrate formation.

Buoyancy is obviously provided by entrained gases in the oil flow, the gas bubbles tending to rise in the column of oil in which they are mixed, and dragging the oil along.

I don't think that is what he had in mind and I think that would be stretching the meaning of the word buoyancy. You can drive flow that way, e.g. shaken soda water shooting out of the bottle (also not buoyancy), but the immediate consequence is that the the force of the gas expansion in the tube are going to push the 6" tube out of the riser (Newton's 3rd law)

I think what shelburn meant is he was taking the buoyancy of the oil into account in his calc. Obviously the main driver of flow is the reservoir pressure, but acting in the opposite direction is the weight of the oil column - and also, although less significant, frictional loss from the fluid flow.

I haven't done any calcs but the figure of 70,000 bpd being bandied around seems implausible. If you were designing this as a production well (ie coming up tubing perhaps 4 - 5 inch NB) even 40 - 50,000 bpd would be considered high rate. And here we have some obvious impediments to flow in the kinked riser sections. So I think 20 - 30,000 bpd with the kinks removed seems a reasonable guess. And I'm sure BP is very grateful for those kinks and in no hurry to dislodge them until a reliable gathering mechanism is in place - or the well is killed.

I don't see why he is using buoyancy at all if there is not a lot of water in the tube. I agree that BP seems to be setting this up to be driven by reservoir pressure, but driving a lot of oil for a mile in a 6" tube seems to be wishful thinking since the pressure is limited by the seal of the rubber "skirt" on the 6" pipe.

Spot on - the oil would flow quite nicely a mile up a 6-inch pipe, AS LONG AS it was anchored firmly to the riser end. The differential force between the two pipes will be large, particularly if the flow goes from horizontal to vertical in the "new" pipe (due to change in fluid momentum). Way more than could be resisted by any form of rubber seals, unless a mechanical anchor or big deadweight was also included. And if you just had a big deadweight on the "new" pipe then the free end of the riser would fly away like an out of control garden hose.

Unless the idea is only to capture a portion of the flow and have a (significant) portion bypass the seals. And that would seem a bit pointless.

I would like to see a diagram of this proposed scheme - anyone come across one? I might be talking nonsense if I have got the wrong end of the stick.

The keyword you‘re all missing, except shelburn, though he‘s not using it, is hydrostatic pressure.

They will try to keep the pressure inside the broken riser equal to the water pressure outside (~160 bar). Shelburn has explained why. Now if you imagine the pipe to the surface filled with oil of density 0.85 and closed on top. The weight of the oil column will cause a pressure difference of 136 bar from bottom to top. So the oil will be under a pressure of 24 bar at the top. When you open the pipe, these 24 bar become available to push the oil through the pipe. Enough for 20-30000 bpd.

With gas in the oil, density and pressure difference decrease, even more pressure to drive the flow. A rather high backpressure will be necessary to maintain 160 bar at the bottom. Newdood, that‘s why the 600 mph speed is wrong. Outflow at the surface is not at STP, if it‘s at 30 bar (I‘d expect more), speed would be more like 20 mph.

HTH

Rainer

I understand the hydrostatic pressure point. When no oil is flowing up the tube you will have equal pressure at the bottom, but once you have flow, the pressure of the oil at the bottom has to drop. The more flow you allow, the more the pressure will drop, the more water enters the tube.

Yes. The pressure at the bottom of the pipe is going to be close to the hydrostatic pressure of seawater at that depth, since it is effectively open to the sea. The driving pressure within the pipe will be caused by the difference in density between the pipes contents and the surrounding seawater. The more gas content,then I would presume that the tendency is for the density to drop and pressure differential to increase. Since the flow is going into the pipe and up, the pipe bottom pressure will be less than seawater pressure, i.e. it is a suction force. It shouldn't blow away from the BOP, more like it would stick because of suction. Unless the drill ship applies enough pressure at the top to overcome the hydrostatic head (caused by the density difference).

Of course if the flow rate from the riser is greater than can be stably handled, then they can only siphon off some -not all of it.

Buoyancy driving the flow would be reduced by water in the pipe. The driving pressure due to buoyancy scales with the difference of average density in the pipe compared to the surrounding sea water. The end of the siphon tube will be sucking with a an increasing pressure differential as the pipe to the surface fills with oil (presuming it is originally full of sea water). If the pipe is full of crude oil at .8 g/cc, and the oil rises 5000 feet there will be a pressure at the top of the pipe (at zero flow rate) of ~500 psi. Interesting about the gas...it's expansion would decrease the average density in the pipe, tending to increase the differential pressure at the surface. Therefore, I wonder if it might be OK to suck in enough water to allow the methane to be converted to methane hydrate...which will not expand on the trip up the pipe...problem with that, how to shed the heat of crystallization without sucking in a great deal of sea water?

"you need water in the pipe"

Certainly not! You need a column of water that is connected to both the top and bottom of the pipe. Bouyancy is a shorthand way of talking about balancing hydrostatic forces the situations where the geometry is simple to visualize. If bouyancy talk causes argument, you map out the pressure gradients cause by the gravitational field to get a correct answer. I often get into arguments with myself when I try to stick with bouyancy. So I often jump directly to presure gradient maps to get an answer I believe. Then I sometimes spend some time trying to construct a bouyancy argument that gives the same answer.

I realize this all boils down to minimizing potential energy in a gravitational field.

Nevertheless you will not have flow without water in the tube after t=0. If, somehow, you start out with oil filling the tube and the tube is open to water at top and bottom, the oil will travel up, displacing the water at the top. Water will displace oil at the bottom of the tube. Now you have water in the tube and any new oil to be transported will need to move through this column of water at the bottom of the tube. Now you have water in the tube. The tube will continue to fill with water until a steady state is reached. The steady state oil:water fraction in the tube presumably depends on the diameter of the tube, friction, and density differences between oil and water, viscosities, etc.

More realistically, the tube will start out filled with water. Oil will float up through the column, displacing some water, eventually reaching the same steady state as above.

I think you have missed some of the boundary conditions. If you have a closed system what you say would be correct. But in this case the tube is open to oil at the bottom and as the oil moves up it is continuously replaced with more oil.

Think about it long enough and you might believe you have discovered perpetual motion. At that point - think again.

I understand what you are saying, but in the actual case we are dealing with, the tube will have difficulty sucking in only oil at the bottom. Even with the rubber skirts, presumably some water will get in, particularly if high flow rates are attempted. Once water starts entering the tube it will tend to accumulate since it will want to stay at the bottom of the oil column. The other issue is the starting condition. Presumably the tube will start out filled with water and it will be hard to prevent the accumulation of methane hydrate.

I don't know anything more about the difficulties of handling the expanding gas in the oil /gas mix than I have learned here, and I have no real idea if the idea is to have a controlled leakage between the larger pipe and the smaller pipe that is to be inserted into the larger one.

But I am very sure if a tight seal between the two pipes that will not blow out is the goal , it can be easily achieved.

If long rubber ribbons are attached to the smaller pipe so that it looks like a wig with lots of long straight hair hanging down, and 1 the pipe is forced several feet into the larger pipe,2 a TEMPORARY barrier of some sort is inserted behind the ribbons , and the force being applied to keep the pipes together is relieved, the pipes will start to shoot apart, obviously.

If the ribboms or streamers are sized correctly they will jam or bridge , locking themselves into place,and the more pressure from the well, the tighter the locking effect.The ribbons can be made of something similar in construction to the sidewalls of truck tires-VERY TOUGH, VERY STRONG, VERY FLEXIBLE.It would probably be necessary to embed some sort of abrasive in thier surfaces, so that there would be ample friction between the ribbons and the inner surface of the larger pipe.The temporary barrier behind the ribbons must hold long the outer ends of the ribbons in place for a few seconds, just long enough for the ribbons to bridge.

I lack the proper words to describe the effect, but many of us here will remember seeing a toy called a Chinese finger cuff;this is a tube woven out of scrap paper or cloth.

If you stick a finger in each end of it and pull, the harder you pull the tighter it grips.Although the construction differs, the effect will be the same.

Isn't that a good reason to leave the methane in the form of methane hydrate for the trip to the surface? Surely there should be a way pump a slurry of methane hydrate slush to the surface without destabilizing it by increasing the temperature or adding methanol?

So...Containment dome #1 is rumored to be seafloor junk,due to some sort of structural failure? Wasn't there several of these being built a few weeks back? I remember seeing a second "big box" being built back when they were going for 3 caps for 3 leaks.I'm thinking they may have abandoned this angle a bit too soon.

The problem being Methly Hydrate formation, wouldn't it be possible to deny precipitate environment by simply filling containment vessel with a slightly overpressured medium such as glycol or other(I'll leave that fluid choice to the chemistry dept.)? No H2O- No Hydrates. What happens up tube is beyond my pay grade. Certainly drill ship has the capacity to run the hydralics. Not worth a second try?

Containment #1 is absolutely seafloor junk.

From reading previous posts here, I believe that there was a plan to drop the "building" on top of the blowout, and then hook a riser to the "chimney" on top of it. Even before the plan failed, one of the knowledgeable TOD contributors mentioned that they -do- have plumbing in the riser to supply warm water and methanol, an antifreeze, to the device so hydrates wouldn't clog it up.

The plan failed because the hydrates formed more quickly than anticipated. There was never a chance to hook up the riser. The container was choked with hydrates and gunk from the blowout within minutes of hovering over the leak. It had to be simply moved off to the side and abandoned.

This tube-insertion plan is an attempt to do just what you are saying, and siphon off some of the oil/gas mixture without the H2O in it.

Here's hoping that this, the junk-shot, and the top-kill all work.

I seriously doubt this will work.

Reason?

So you think this is really going to work? For the sake of the dolphins and turtles, I hope you are right.

Can't they side flare this tremendous gassy flow as it emerges and burn the rest in a fireproof boom surface corral? Or is that just too much of a hot volcano?

Isn't there a processing ship for this kind of thing?

Think back to what the rig looked like while it was on fire - that's what the flare would look like. This setup leaves no way to control the flow, which is the same process that melted the rig and sent it to the seafloor. They know this won't work. I just hope these PR stunts don't create even more carnage.

I have an idea that's more likely to work: build a dam from Florida to Yucatan, then pump out all the water. Easy! xD

A lot of what was burning on the rig was oil from the well

and fuel/flammables on the rig - if you look at one of the burning rig pictures, you

can see a rectangle burned in the helideck - probably stored fuel nearby.

Also, they were using oil-based drilling fluid.

So, flaring off the natural gas should be less of an issue.

They can throttle the flow at the surface ship with the oil/gas/water separation facility. Hope there really is < 15,000 (or 20,000?) bpd, cause that's all the Discoverer Enterprise (nice video there) can handle.

This new graphic

http://www.deepwaterhorizonresponse.com/go/doc/2931/551107/

claims a methanol line to the insertion tube too.

Also claims they will use nitrogen to pump the petroleum up.

Maybe the whole idea is to let (most of) the gas leak out at the seafloor,

and only snarf up the oil.

I'm looking at:

This new graphic

http://www.deepwaterhorizonresponse.com/go/doc/2931/551107/

claims a methanol line to the insertion tube too.

Can anyone tell be what LMRP means and what the box labeled LMRP is supposed to do?

I'm very worried by this graphic. It seems to me that they think they have to blow nitrogen into the pipe to get flow of oil up to the surface. This indicates a very different view of what will happen than the one Rockman has given. I think Rockman's view is much more realistic. They don't realize they is danger of another blowout --- why else would they not indicate any provision for controlling it? This is like indicating how one intends to get flow of oil started in a graphic of a plain old oil well.

A little detail indicates serious ignorance.

Lower Marine Riser Package

Basically a quick release connection from the riser and all the misc. pipes (control/kill, control lines, etc.) so the riser can be disconnected from the BOP if the drillship needs to leave due to hurricane, etc.

I would think the nitrogen only has to get blown in at the top, maybe 50' or 100' down, just to get some circulation going - like an air-lift that sub-sea archeologists use.

They may have calculated the viscosity of cold oil affecting the flow,

or want some suction to bust loose clathrates - dunno.

I think the problem is that the gas doesn't emerge from the surface at one specific, albeit "wandering" location. The "physics" seems to require that the gas break-up randomly into "bubble trains" which interact chaotically with the much denser and more viscous water phase.

Thus you could be burning gas in one location, and the flow would suddenly disappear and pop-up somewhere else. In fact, the gas could be emerging from several locations hundreds of feet apart from one another at virtually the same time, or at least, within seconds of one another.

Somebody who's actually seen what happens, please correct me if I'm wrong about this.

As I've suggested before, it may be possible to "rotate" the water column around the rising gas and oil, creating a "virtual chimney" to make sure it all comes out in one location. It may require quite a bit of energy to maintain this rotation in a 5000 foot water column, but how much is being expended in the clean-up?

Of course, you would have to vacuum the oil phase up as fast as it reached the surface, or you would hardly be any better off than if you did nothing.

Something just occurred to me--could a fleet of medium/large ships in motion be employed to maintain the rotating water column or "whirlpool" on/from the surface--or would the forward motion of the ship cancel out the "backwash" from the propeller jets? Hmmm...not sure.

Personally, I think these efforts are all doomed to failure and exist only to buy time for the relief well drilling. BP could not just do NOTHING, or the public would have their heads. This slow deployment of Rube Goldberg devices is simply to appease the public. Like booms in 4 foot seas, useless. Note: I have no deep water PE experience ( other than classroom).

Disclaimer: I may come by my skepticism genetically, my Mississippi rough-neck cousins say you cannot reliably directionally drill by dropping through 5,000 feet of water and directionally drill another 18,000 feet and meet a 24 inch target (like the leaking well bore). They say you can take pressure off the formation by drilling close into it, best case. Or you can try to kill the well with a huge injection of seawater into the formation near the well. Maybe.

Is that true?

I cannot think of a case where (eventually) they did not get a relief well working, though it sometimes takes several tries.

Read this paper:

http://www.jwco.com/technical-litterature/p11.htm

for how they sense the target borehole with electromanetics..

acronym alert:

BHA - bottom hole assembly, the mud powered drill motor + steering unit + (probably) Measurement While Drilling and/or Logging While Drilling.

Also:

http://www.vectormagnetics.com/Relief%20Well%20Services.htm

http://www.vectormagnetics.com/Case_HistoryO&G.html

http://en.wikipedia.org/wiki/Mud_motor

http://en.wikipedia.org/wiki/Measurement_while_drilling

Thank you for that information!

I´m a novice, but why no´t use a FPSO wessel as a vacuum cleaner over the leaking pipe.

http://en.wikipedia.org/wiki/Floating_Production_Storage_and_Offloading

http://www.fpso.net/

This beyond my understanding of the physics down below the water depths, but could the out flowing mixture be ignited as it leaves the riser?

Even if large amounts of air or pure oxygen were injected down @ 5,000', it might mingle with the natural gas (to a very limited extent) but not the oil. Ignition would quickly go out.

Such NG & air/oxygen mixtures are explosive so they would likely explode as much as burn.

Alan

Not any oxidizer to speak of down there.

That could be a suggestion - pump compressed air at 5000 feet * .445 psi/foot-of-seawater = 2225 psi. Possible, dive tanks are filled to that (more likely about 3000 psi).

But what's the stoichiometric quantity required? (a rough calc, done late at night - caveat emptor)

assume 5000 barrel/day of API 35 crude oil.

Specific Gravity = 141.5 / (35 + 131.5) = 0.85

5000 barrels * 42 US gals/bbl ---> liters is 795,000.

795,000 liters ("same" as kg of water) * specific gravity of 0.85 = 676,000 kg crude/day.

Call the crude oil dodecane (C12H26), molar mass 170.34 grams/mole.

C12H26 + ___O2 = 12 CO2 + 13 H2O

12 + 13/2 O2 = 18.5 O2 to burn the dodecane molecule.

(i.e. each mole of dodecane requires 18.5 moles of oxygen to burn it)

676,000,000 gram dodecane / 170.34 grams/mole = 3,970,000 moles dodecane.

3,970,000 moles dodecane/day * 18.5 moles O2/mole dodecane = 73,000,000 moles O2 per day needed.

Air is 21% oxygen. One mole of gas at Standard Temperature and Pressure is 22.4 liters.

To get one mole of oxygen at STP requires 22.4 / .21 = 107 liters of air.

73 million moles of O2 * 107 liters air/mole of O2 = 7.8 billion liters of air, or

7.8 million cubic meters, or a cube 198 meters on a side.

Hmmm, "largest air compressor" gives a hit on a 4000 cfm, 600 psig compressor from Ingersoll-Rand.

7.8 million cubic meters = 275 million cubic feet.

4000 cfm * 60 min/hr * 24 hr/day = 5.76 million cubic feet/day.

275/5.76 = 47.7.

Well, you'd only need 48 of the worlds largest air compressors to get to 600 psi, then you need to boost the pressure further.

Uhhhh - I don't think so.....

A big scuba compressor can fill an 80 cubic foot tank in 7.5 minutes.

275 million cubic feet / 80 cubic feet/7.5 minutes = 26 million minutes to compress enough air to burn one day's oil leakage at that depth.

That's 18,000 days - can you round up 18,000 largish SCUBA air compressors?

That's all assuming that 5,000 bpd is really the leak number...

I'm going to bed - and praying that the insertion tube works.

Good night all...

That would be so cool. The high partial pressure of oxygen in the riser would light off that 2' carbon steel pipe too, assuming you got ignition of the gas at the end. You'd get a one-mile long underwater sparkler. I'd for sure want video of that.

LOL - would be a sight - just keep feeding pipe down from some huge airlock on the surface. ;-)

I get 21 cfs at 2225 psi, that's some flow rate.

Obviously impractical, but one can dream big.

One would need a complex burner manifold to get good mixing, maybe made out of alumina to disappoint the fireworks fans.

But the biggest stock tube I see from Coors Ceramics is only 8" diameter.

Evening All:

Looking for some TOD'ers more informed than I;

IIRC, there is a leak from the sea floor some distance from the riser. I assume it is leakage from the shoe/cement/borehole interface and migrating up through rock/mud. Is this correct?

Assuming the junk shot works:

Would a mud injection be sufficient to seal all leaks, or would a large cement injection be required? It would seem to me that we could just have a mud leak instead of an oil/gas leak. Preferable, but not ideal.

Assuming the relief well is successful:

A nearby relief well will reduce leak flow (pressure) but it seems to me that an intercept of the existing well is essential to completely stopping the leaks, by cementing or mud injection.

IOW, total success (if you can call it that) can only be achieved if the existing well is killed.

Lastly, are there any implications of BP not wanting to kill the well for financial reasons? Considering the present liabilities, I doubt it, but just asking. Always looking to learn.

I work in the patch, but about as far away from the mud and bits as possible (remote sensing) so I would appreciate anyone setting me straight on my assumptions.

Cheers

The other leak is from the bent over part of the riser atop the BOP.

Sealing the BOP would stop this leak (too).

The main leak is at the end of the riser, some distance from the BOP.

There is no leak around the casing that I'm aware of.

Heavy enough mud would stop the flow down inside the well.

The junk shot is to cut/stop the flow rate through the BOP so that kill mud (extra heavy) can settle down in the well.

Then they might put in cement through the BOP to seal that.

I think to officially seal the well, they have to go in through the BOP and fully cement the thing, but don't quote me there.

Relief wells (in the oil patch) are misnamed - they are kill wells.

Did you see this reply in this thread?

http://www.theoildrum.com/node/6467#comment-623745

Rockman has implied that "by regs" they must plug and abandon a blown-out well. He'll have the definitive word, but given the high flow rates and who knows what else is going on down there damaging the formation/casing/cement/..., it would be safest to plug it full of (dense) cement and start all over.

BP is on the hook for cleaning every inch of oiled beach, every oiled bird, every disappointed hotelier, every out of work fisherperson, etc., so unless they want to loose a lot of money, they have a lot of incentive to stop the flow ASAP.

latest relief well graphic (pdf):

http://www.deepwaterhorizonresponse.com/go/doc/2931/551163/

May 9 - BOP maintenance and testing

May 14 - running the BOP

guess they're about to start drilling again.

I wish this were the case, but I believe you are wrong. BP is on the hook for the total cleanup, with the assistance of $1 Billion from the Oil Spill Liability Trust Fund. They are NOT liable beyond $75 Million for any other costs. That means all the fishermen, all the hoteliers, all the people who lose their jobs over this are not their problem. They will push back on every single claim, and the litigation will go on for decades. That is probably the ONLY aspect of this disaster that is absolutely immutable at this point.

Now, congress is trying to change the law to raise the $75 Million limit to $10 Billion, but even that probably wouldn't cover the losses, and the oil companies (predictably) are pushing back. Besides, they can't pass an ex-post facto law, and that is exactly what they are trying to do by going retroactive.

Oil companies obviously have absolutely no fear of repercussions from gerrymandering our society. They do very positively OWN us.

http://thehill.com/blogs/on-the-money/corporate-governance/97903-oil-ind...

Normally I'd agree, but when BP's American Division CEO testified before both Senate and Congressional committees last week and categorically stated the 75 million dollar cap will not apply, that's going to be pretty hard to back away from.

What did you *expect* him to say?

Talk is cheap, and when it comes down to the Tens of Billions of Dollars likely to be claimed, the talk will be forgotten and exchanged for ruthless legal defenses.

A year from now, if BP hasn't put up a massive wall of legal defenses against any claims they can't be absolutely forced to pay, I'll line up for public flogging. They might cover a few obvious claims like the fishermen who are currently being banned from pursuing their livelihood, but a small hotel owner on the Alabama coast who loses half their business due to the uncertainty over the path of the oil from the spill? They are screwed.

It appears that the US Government was not convinced by BP's proclamations last week any more than I was:

"The US government has demanded immediate clarification from BP over its commitment to pay for costs caused by the oil spill in the Gulf of Mexico."

http://news.bbc.co.uk/2/hi/americas/8684912.stm

moabite,

Keep in mind he was under oath when testifying. There is no legal way to get out of it. BP's only option is to argue the individual amount of each claim. That option will not sit well with Congress, the Administration, or the Courts. BP will focus their efforts on making sure the scammers don't get paid.

What the Government is doing by asking BP for clarification is simply further tightening the noose and assuring the public they have BP by the throat.

This is not the same type of case as the Exxon Valdez where punitive damages where the issue.

When he said the $75 million cap would not apply, he did not say that every claim, no matter what would be paid. He could have thought that $200 million was enough. And that cap is over and above the actual costs of the clean-up, and the $75 million applies to categories like lost future income, mental problems and categories like that.

Actual clean-up, they are the hook for that no matter what, up to liquidation of their company.

I wonder how much I could get for wasting my time reading all this BS due to this damn event rather than working.

FF

Exactly my point. BP have total legal control over how much they pay above the $75 Million. Another point being glossed over is that the Oil Spill Liability Fund will pretty much certainly be tapped to its maximum limit here (it already has paid out to the Coast Guard to the tune of $100 Million), meaning $1 Billion of the cleanup costs will come out of that fund, not out of BP pockets. It wouldn't surprise me if in backroom meetings BP has already decided that they will pay One Billion plus Seventy-Five Million in damages, and call it good. Everything over that? Boo Hoo for you. Therefore, their actual cost above the cost of cleanup? Seventy-five million.

What do you think the odds are that my previous example, a small coastal Alabama hotel that loses half its business simply due to the uncertainty over the spill, will see full reparations? I put the odds at somewhere between slim and none.

You do know that very early on in this catastrophe that BP had sent people to Alabama to try to get them to sign away their rights to sue for a measly $5000, don't you? What does that tell you about what kind of company we are dealing with? What possible defense can you come up with for that behavior, other than pure, unmitigated greed?

http://www.telegraph.co.uk/finance/newsbysector/energy/oilandgas/7687843...

http://www.cbsnews.com/8301-503544_162-20003978-503544.html

I'm part of a team working on a solution to deal with deep horizon oil leaking. We'd need 2 more informations to go further on our plans.

1) What's the temperature of the oil at the time it exits the broken pipe?

2) How long is the oil able to stay in contact with sea-water before degrading?

Could someone help me with these questions?

Thank you!

Maybe this is old news but last night was the first time I saw a BP Exec in Houston categorically reject the 70,000 BOPD number. Until then, they had said they did not know but would go with the Unified Command number. He said they know what the pressure drop is and that the high number made by the Purdue prof, who is getting his 15 minutes of fame on all the networks, is wrong. So they must have a lot better idea of what is going on inside the BOP and of what this well can do.

I actually think if they can show by way of data the range of flow and that some of the arm chair quarter backs, who assume the team working on this are not a bunch of "know nothings" it might help their PR. Of course one of these other ideas would need to work to really help.

As others have said, the capture and insert methods have a lot of drawback but are being tried while they engineer for the junk shot /top kill and after that perhaps cut the riser to put a valve or new BOP on the well. They are experiments that they can do quickly , learn from, and at least show visibly that they are trying something while designing things that have a better chance of working.

Organizationally I like the way they are approaching problem solving, checking ideas, and the way the coordination is working with the agencies. That part beats what I have seen in past disasters.

The kill wells, of course, are the proven way. They are each being engineered to make multiple attempts. Fortunately, well bore mapping is much more accurate, as are directional drilling tools and procedures than when I was in the "patch". I am sure the best folks are involved in the drill planning and work.

it is puzzling to me why anyone would trust any bp management statement.

but, okay, they're sure it isn't 70,000. WHAT IS THE FLOW THEN?

the 70,000 figure is from 2 different teams, you can go on about how the purdue prof is milking this.

we only get to use science when it supports your position, is that what you're saying?

if bp knows the flow, it's time for them to release a number. easy, simple. why isn't that happening?

I would ask you why I should not? I gave the context of the BP information.

i repeat, if bp knows what the flow is, why don't they just say so?

the trust issue has to do with their decision to give one guy the power to kill the entire gulf of mexico, and to have that moron decide that he's man enough to wager $500k against the homes, families, businesses of the gulf coast. if you're not yet ready to accept that story, fine. then, here, they lost my trust when they sent down the containment dome. you guys have been hopelessly optimistic about 'solutions' that matt simmons calls 'a joke'. these seem like desperate moves to me, doesn't seem like they have a clue. top hat. junk shot. please get serious, join reality, stop pretending that bp has any option other than the kill wells.

if bp knows the flow rate, tell them to share the info. as they refuse to do so, we have to rely on the satellite and surface monitoring and gathering, all of those confirm at least 25k bbl/day.

another number i'd like from bp - how much oil have they skimmed off the surface? should that also be impossible to gauge? please stick your head in the sand if you like, but don't expect everyone else to do the same.

who would pick these people (bp) to run the recovery operation? the guys who helo'd off the rig 6 hours before it blew, put those guys in charge. they sound like they understand how this stuff works.

I think you can pretty safely assume that, by the time it has wandered through the riser for almost a mile at a FAIRLY leisurely pace, the temperature will be pretty close to that of the water in the area. I think I remember seeing somewhere that this is about 40 deg F

As to the dynamics of hydrate formation, you'll have to find somebody a few pay grades above mine.

Oil temp from a well that I know about up on the north slope is about 450 degrees F.

oil and water do not mix, certainly some of the compounds in the oil degrade or are affected by water but your guess would be good as mine.

I am a refrigeration engineer, who did some work years ago up in deadhorse.

if you part of this team, i know its bad, i always for some reason gravitated towards where the shit hit the fan.

good luck!

Pit: I believe that the oil will rapidly approach the ambient temp of +/- 4C after it leaves the riser. The degradation of the oil takes place at surface due to evaporation of light ends and release of dissolved gas. The UV from the sunlight and bacteria also start working to degrade the oil on surface. There may be dilution of the oil underwater but I don't expect that there will be any degradation.

Thad Allen quote,"He said an X-ray type analysis of the failed blow out preventer indicated that it had worked partially and was limiting flow from the well to some degree. He said officials had been able to measure the pressure, learning that oil was flowing into the device at 8,000 to 9,000 pounds per square inch and flowing out into the Gulf at around 2,650 pounds per square inch."

From http://blog.al.com/live/2010/05/national_incident_commander_oi_1.html

How much oil is that?

Knowing the pressure differential is a good start, but we can't calculate flow unless/until we also know the effective orifice size. Given the spectacularly convoluted flow path through the partially closed BOP and the riser kink, there isn't going to be any way to even guess at this

You mean to tell me that X-ray analysis can measure pressure, yet you cannot use an X-ray image to measure linear size? If you know the image scale and can see how big the flow is at the smallest point, could not a reasonable estimate be measured? After all, is that not at the point where greatest pressure differential exists.

You can see the flow's smallest dimension from one side at a time in each location in the flowpath. If you've got unlimited use of the gamma-ray imaging equipment, you can even get shots of the flow path from multiple directions that'll give you a sort of three-dimensional picture of the flowpath.

Unfortunately, without some SERIOUS computer modeling (super computer, months of programming, etc) there's still no way to figure out how all these weird-shaped orifices - in close proximity to each other - interact.

The realistic way to estimate it is to measure (estimate) the flow through it and calculate back to the orifice size.

And for what it's worth, X-rays can do some pretty cool stuff, but they DIDN'T measure the inlet pressure with them. As I understand things, they've picked up a signal from a down-hole pressure transmitter

But, I'd bet if you just took the two or three smallest orifices and assumed you can add up the flow impedences you'd get into the ballpark. So you wouldn't know the details, but you might have a halfway decent estimate of flow rates and pressures.

I bet they have a good effective orifice size range and know enough to model it to get a flow magnitude range. They can then compare it with surface observations to come up with some reasonable guesstimate. As they have always said "do not hold us to 5000 BOPD, that is from Unified Command " but if it is 20000 that is a far cry form 70000. At least they have not been like a prof who says it has to 70,000 BOPD per day plus or minus 20%. I am not sure I would go on TV and be so emphatic given what he had to work from. He then went on to say he did not know what information BP had or how they made their calculations. I'd prefer the BP approach using Coast Guard, NOAA and their own knowledge to say they are not sure but use 5000 as a number.

The issue with the high BOPD number is it give people the ammunition to say "See this means there is all sorts of damaging oil that is stuck beneath the surface which is why it has not covered the sea shore!(and of course to compare it to Valdez for scale while ignoring Ixtoc which is a better analogy). The uncertainties in all this are apparent and all sorts of folks with all sorts of agendas trying to justify their need for more funding or who would benefit from saying this will destroy the planet for hundreds of years, pop up all over the gazillions of available media outlets. 99% of everything that comes through these outlets is there to fill time and like Wikipedia is poorly sourced or for entertainment rather than for accurate information delivery.

If I know the pressure differential and the density of the outflow, could I not calculate the orifice size?

It's complicated because it is mixed phase (gas/liquid) flow. That said, volumetric flow rate is proportional to the pressure difference times the area of the orifice. Even if the orifice size isn't known, one could calculate an upper boundary assuming an open BOP, IMHO. I think it was said somewhere that the well was projected to produce 60,000 barrels per day.

tealeaf -

This is more or less what I have been saying in several ways in several previous posts.

One doesn't need to estimate the flow with extreme accuracy to determine what is the likely range of flow rates.

One thing that I hope should be readily apparent is that a large volume of liquid can move through even a relatively small effective orifice area provided there is sufficient pressure differential.

For example, if we had an effective orifice area (i.e., the total area of the openings in the damaged pipe) of only 1 square inch, then a velocity through that orifice of 20 ft/sec would give you a liquid flow rate of roughly 2,100 bbl/day. And it doesn't take an exceptionally high pressure differential to achieve a velocity of 20 ft/sec through an orifice.

Of course, once the fluid leaves the orifice, its velocity starts to drop off quite rapidly as the flow stream fans out to a much larger cross-sectional area. That is why the oil doesn't appear to be moving all that fast in the videos of the leak; it has already fanned out to a much larger area after leaving the orifice.

My point? You don't need a major rupture to release a very large amount of oil/gas. Even a relatively small break in the pipe can easily result in several thousand bbls/day of released oil/gas. That is why I tend to be skeptical of the lower release estimates.

Actually, for an incompressable fluid, flow rate is proportional to thw square root of pressure.

it is reported that skimmer vessels on site are picking up 20,000+ barrels a day. where is that coming from? shouldn't the whole leak be mostly cleaned up by now if we're only seeing 5,000b/d?

The skimmer vessels pick up a mix of oil and water. In calm water under ideal conditions it may be 5 parts water, 1 part oil, in rougher weather it could be 10:1. So when they say 20,000 bbls that is probably closer to 2,000 to 3,000 actual barrels of oil.

Apparently burning the oil in fire booms is much more effective than skimming:

Skimming oil spill mostly ineffective; controlled burning destroys more

as i said in the previous thread, this is the total oil skimmed after being decanted. no water, just oil. 20,000+ barrels collected every day.

Given that through the 15th they have only skimmed a total of 6,000,000 gallons of oil/water which equals 142,000 barrels, your number of 20000 barrels of oil per day seems more than far fetched. Every skimming report I have ever seen says 10-20% max oil in the oil/water mix which is more inn the 22000 barrels skimmed range.

Your number means they have created oil. Things are bad enough we do not need more to oil drop out of thin air.

If the pressure at the output side of the BOP is known a good estimate of the total gas/ oil flow rate can be made by modeling the geometry of the twisted mile of pipe. No super computer required but CFD software is (which unfortunetly I don't have access to) plus a good map of the geometry of the pipe and images of any kinks.

A simple calculation can be done however to put an upper limit on the flow just by assuming the pipe is straight and unkinked. THis could be done with a paper and pencil. The unknown is the ratio of oil to gas I've seen a few estimates but they mostly amount to guesses.

Big storms in the Gulf this morning, south of LA.

Probably not a good thing. Moving north x northeast.

I don’t think the rubber flaps will work. But the seal doesn’t have to be perfect.

There was some discussion about the smaller pipe being blown out from the 21 inch. This will definitely happen because of the change in flow direction-a momentum change causing a huge force. This is much like the change in direction in a steam turbine blade causing a reaction force. What can be done is drop a huge concrete block next to the ell so that the thrust can be absorbed by the block. Everyone says the floor is pudding so I don’t know how they will support the block. The block will need to be massive.

This is done all the time around underground piping such as fire mains and pipelines.

Even relatively low pressure lines will "walk" from pressure pulses without hefty anchors.

The only way I can see the internal tube mechanism working is to positively anchor the sippy straw to the riser or drill pipe. Assuming the ROVs can weld, perhaps they'll simply scab on anchors, attach a structural member, and then stab the straw? Or perhaps there is an insertable expanding seal that could be put in place as an anchor? Or an external crimper that could crush the pipe around a lip on the straw? For any of this one would think the straw must have a release valve to allow oil to flow through unimpeded while they stab it.

As for the expanding gas, the obvious solution would be use a big enough pipe to keep the flow velocity down to something you can handle at the pressure you have to work with. There certainly can be a good bit of pressure maintained, given the density difference between sea water and a very gassy oil-water mix.

With a high gas fraction, the pressure available for lift is a couple of thousand pounds, IIRC from last week's math work. Part of this can be used to maintain gas pressure, and reduce volume, without preventing flow. In fact, there might be a solution point where the rubber flaps keep water out, instead of oil in, due to a partial vacuum at the bottom of the straw.

EDIT: I think I have a logical inconsistency in my rough analysis -- if the gas/oil/water mix rises with constraint (back pressure), the straw will actually suck itself into the leaky pipe. Only if it is sufficiently restricted at the top will pressure build against the rubber flaps and the straw itself.

It's the same physics at work as for the top hat and dome, only with an "innie" instead of an "outie".

The thing I am not getting is that some of these approaches don't preclude any of the others. Why not go ahead with the "crap-shot" - worst case is that nothing happens. Best case the flow is reduced somewhat. It seems like they are waiting to see if some of the other things work before they try that one.

My understanding is they are working in parallel on the "crap-shot" but that technique is more complicated than it sounds (I read there are 100 people working on it). I've read three reasons for this. One, they want to choose their materials carefully, and shoot them in pre-defined waves, one after another, at certain time intervals. Two, they need to figure out how to monitor its success/failure (in particular, they want to make sure it's not accidentally making things worse). And three, the BOP has weird curves in it, and they want to make sure they don't plug a valve (rather than the BOP).

In summary, they are working as fast as possible, it's just more complicated than shoving some junk in some valve.

I talked to someone who has been over at the BP offices. He estimated BP had about 250 to 500 people working on at least a dozen different approaches in the BP offices and that most of those people (the majority are specialist subcontractors) was probably backed up by 5 to 10 people in their own offices.

Just for example I know of one company that has a department that specializes in the design and manufacture of underwater equipment for the drilling industry. Within a couple days after the initial incident virtually everyone in that department (over 100 people) was pulled off every project they were working on, split into two 12 hour shift and have been working on this 24/7 ever since. That is only one company working on one aspect of the problem.

Good!

(and I would add we need the same sort of effort on some other large scale problems, that are as bad but just don't seem as urgent)

Exactly, right on. Thank you Nate for injecting some sanity into this insane situation. I vote for a manhattan project on solar-thermal electricity generation and electric vehicles. If Florida was entirely using solar thermal powered electric autos would BP still have a market for the oil from DWH? Or the next one at 3,000 m sea depth?

len

as you know, the only reason this amount of expertise and resources have been marshaled is because there is a clear and present danger. ALL of our environmental success stories (DDT, chlorofluorocarbons, unleaded gasoline, etc) had smoking guns. Sovereign debt crisis (and oil leak) are the current smoking guns. A system based on unlimited growth on a finite sphere doesn't have a 'natural smoking gun' with enough lead time to be mitigatable. So adaptation will be our likely course, though perhaps we will learn from, on wider boundaries, from this situation in the GOM.

The broader problems we face are not technical but political.....

I just finished reading Jared Diamond's "Collapse" and he said much the same thing.

His conclusion in a nutshell is that societies that are pre-disposed to long term thinking, either through accident of geography or through enlightened leadership, are more likely to effectively manage both their population and resources and therefore avoid most of the worst mistakes, such as the tragedy of the commons that we currently see playing out so vividly in the GOM.

Societies that are pre-disposed to short term thinking and immediate social/political gain, on the other hand, are more likely to either degrade their environment to the point where it can no longer sustain them, or fail to adapt to gradual changes in climate that play out over decades (if not centuries), but in either case ultimately leading to collapse.

He ended the book on a highly optimistic note by citing examples of societies that were able to recognize that their accustomed behaviors were un-sustainable and then quickly adapt those behaviors and customs to that new reality, albeit with sometimes authoritarian methods such as China's one child policy.

This, however, is in striking contrast to the bulk of the rest of the book which provides one example after another of complex societies that utterly failed to adapt to the ecological reality of their situation. This includes examples where there was simply a flat out refusal to adapt, such as the Greenland Norse who slowly died out with nary a fish bone in their middens despite the presence of Inuit (whom the Norse considered sub-human) thriving all around them on a diet of plentiful seafood and marine mammals.

Cheers,

Jerry

Shelburn, this is a good point, ditto your earlier post about the need to process the stuff properly at the surface and work backwards down the system as part of designing how to intervene at the leak point. I'm afraid I don't know anything about drilling, but I have been involved in design of deepwater production systems and FPSOs for many years. These are the issues we have to deal with all the time, and I am sure BP have a whole bunch of such people working the problem who have this knowledge as a starting point. (But I would rather not be doing it on the hoof with only a few hours' sleep a night...)

In one sense this is reassuring - contrary to some sections of public opinion, the industry is not sitting there scratching its head saying "gee, we never expected these kinds of phenomena to occur...". But the other side of the coin is - given we already know how tricky these fluids are to bring to the surface and process safely, how come we, as an industry, haven't engineered a few workable options for intervention and "emergency processing" in the event of a deepwater blowout? The public might well ask - if we have oil booms and skimming vessels accessible for such an incident, why not have a few caissons capable of fitting over a BOP in storage somewhere? And if a caisson won't work because of flow assurance issues like hydrate formation (again, something we grapple with in design of most production systems) could we not perhaps have worked that out in advance rather than wasted days building and deploying one only to find out the hard way - with the public looking on?

Yes BOPs and well cement jobs are pretty reliable - for the most part - so are aeroplanes. But when your plane crashes during takeoff or landing, you expect the airport will have fire engines ready to race down the runway, rather than the airport manager saying "you know, what we could do with is some kinda vehicle which could head over there and spray large quantities of foam - or maybe it should be water - what do you think?".

The idea that there should be standby containment dome(s) has been floated around a lot. And if any blowout could be expected to be configured as this one is then that would make sense.

But, I have never known of another blowout that had the oil flow going into a large, riser where it escaped at near ambient pressure a long way away from the BOP.

The "standard" blow out, if there even is such a thing, is blowing a high velocity jet of oil and/or gas and and you would not be able to get a containment dome near it. By the time the flow velocity and turbulence has decreased to where you could have a dome hanging over it, it has also dispersed out into a much wider area than any of the domes contemplated.

If you try to build the dome large to contain the flow area you run into the same problem that doomed BP's first large dome to failure. The dome must be heavy enough that it will not float up when filled with gas.

Basically this is a one off situation in that it is probably the only underwater blow out where a containment dome could help.

There was an attempt on the Ixtoc blowout to build a massive containment dome. It was after I left, but some of the other divers that were there said it was an almost total failure, irregardless of the PR from the oil company and the construction company that built it.

OTOH - A containment dome could be usable in the case of a pipeline leak. Gulf of Mexico pipelines (there are thousands) are relatively safe and have break away sections and flow restrictors to stop the flow in case of a leak. I think over 50 pipelines were damaged or destroyed during the 2008 hurricane season without, in the words of the MMS, any "significant oil spills". But this incident reminds us that when a system is 99.9% safe it really means it will fail 0.1% of the time.

Would it be possible to use a large diameter fabric-based dome. e.g. based on neutral buoyant rubberized fabric, say 300-feet wide at the base, to form a "chimney" for the rising oil? such a fabric structure could be very large without being too expensive.

Shelburn: Thanks I used to live a few blocks form that office and many friends from other companies are still there. I do not think people understand the Oil Patch network and the ability of a company like BP who has to deal with hurricanes, to mount a response campaign. I laugh when pol and others think they would not have university and government folks in from the beginning. I would love to be on one of those round the clock teams. Have done that before and it is amazing the work and drive and commitment. Despite the competition at times like this people come together. Aerospace is similar.Some of thee execs were just young bucks when I was working and have moved up. Hate to be in their shoes now. I had heard 165 organizations working the problem.

Which brings to mind a different question - if they can pump stuff in there, can they pump in a viscous fluid of some sort - (perhaps even increasing the viscosity as time goes on)? No risk of jamming the valves. They would need to continually keep pumping it in to keep it all from being blown out, of course.

I don't know what sort of viscous material would be best suited for this sort of job. Something that wouldn't readily mix with either the cruide oil or the seawater, I suppose.

After the junk shot slows down the leak at the BOP, they would inject heavy drilling "mud" (specialized heavy fluids - 16ppg or more) into the well via the kill lines that are underneath the rams. BP would inject the mud under pressure until the hydrostatic weight of the mud balanced the pressure of the oil/gas coming from the formation. Then they close off the BOP lines the well is "killed" and the leak is stopped. After the relief well is done, at some point they will have to re-enter the well via the BOP (maybe with a 2nd BOP on top) and put in a cement plug starting at a predetermined depth and about fill up about 300 feet of the well with cement, wait for it to dry, then cement another plug just below the seabed, then the well is plugged forever. This all has to happen to be in compliance with Federal Law.

Even if the leak were stopped today it's going to be a few more weeks and many more millions before everything is wrapped up on-site. Of course about then the courtroom will heat up to determine what happened, was there negligence from BP/Transocean/Haliburton, and who is heed liable to pay for what damages. Of course then comes the lawsuits from the dead workers, shrimp fishermen, Federal Government, etc. Fixing the leak is only the beginning of the next chapter,not the end of the story.

Maybe not. Worst case is they blow the seals on the wellhead and there is a wide-open flow path for 8000 psi oil to the sea bed. Low probability, but possible.

To me it looks like the riser is making gas and the drill pipe is making oil. It is difficult to see, obviously. Could be wrong. But if gas is in the annulus and forcing oil down to bottom of hole inside casing, as seems possible, that's exactly what it would be doing. If pipe is stabbed, might be most of the oil in it; allow casing to keep blowing.

As I understand things, the drill pipe has been shut off - valve installed last week. The remaining leaks are at the end of the riser and at the kink just above the BOP.

I have not seen a clear explanation of the dynamics of the leak and its path through the BOP - BP likely has some reasonable idea, but I haven't seen information posted by anyone who knows. Some of the pipe rams operated and I believe the annular preventer is closed. Its hard to evaluate the situation without more information (in order to discuss what reasonable solutions might be).

The NYTimes released this graphic of the BOP re the 'junk shot:

http://www.nytimes.com/imagepages/2010/05/15/us/15junk_graphic.html?ref=us

So you can see that they have re-plumbed the choke and kill lines that were damaged when the riser collapsed. It seems there is not an easy place to connect new plumbing at the top end - perhaps because that connection has been damaged, but I believe some people are working on how to do that.

Full article link:

http://www.nytimes.com/2010/05/15/us/15junk.html?pagewanted=1&hp

Why are they doing this from the hole in the bent riser pipe?

Why not sever the riser pipe above the BOP, so that they can get a direct shot into the top of the BOP without having to maneuver around a bunch of bent and twisted steel with holes - and weak spots that will be holes if they plug the existing holes?

This has been bothering me for a while now.

Maybe they think the kinked riser is backpressuring the BOP to some extent?

Tey're not sure how much of the down-hole pressure is being held back by that kink in the riser.

If they just slice it off, they MAY make the effective orifice bigger and wind up releasing MORE oil if they can't get the thing shut off or plugged up.

I was reading this morning that the government approved the use of underwater dispersants to help combat the spill.

http://www.cnn.com/2010/US/05/15/gulf.oil.spill/index.html?hpt=T2

One of the lines in the article states: "Dispersants are generally less harmful than the oil itself, which is highly toxic, and they biodegrade more quickly, the Coast Guard said."

Is this true? I am just wondering why it needs Fed approval if it is less harmful and biodegrades quickly... is BP more concerned with public perception of the oil spill than with the actual environmental effects?

I remember someone using Dawn as an example of a dispersant but what will they really be using down there at 5000 feet?

from the msds for corexit 9527a:

this is not dishwashing liquid.

If they come out of the top, that would eliminate the momentum and all they need to do is stop the pressure thrust. The weight of the pipe would probably be enough conteract the pressure thrust.

A reader sent in this proposed solution.

http://www.youtube.com/watch?v=JbUAAHuJUHs

This solution uses "storage barges" to store oil near where it comes out.

This appears much like the initial containment box, only several magnitudes larger...almost like sinking a bottom-less oil freighter on top of the leak site like an enormous inverted bathtub. Why not pre-fit the "barge" with couplings to allow a reconnect to the risers that go to shore?

I'm not sure the capacity of one barge is several days of oil, more like 1 day? Barges are not that cheap. One problem I see is that it prevents work around the leak area.

It is not dissimilar to the containment dome idea. If the problem of hydrates could be addressed, and oil separated sufficiently from gas, a riser could be attached to a filled barge and oil removed. So while one barge fills, the others are drained. It would seem such a system (or two) could be built and tested and kept on standby, before the next deepwater leak happens.

At this point in the game, I don't think anyone's worried about the costs of the barges. I'd personally be more worried about MOVING one of 'em after it had been filled with oil/gas.

On the other hand, it has some possibilities. There would still be a problem with the hydrates, but this'd provide enough volume to act as a realistic gas/oil separator. You could tap in a riser to take the oil to the surface and just let the gas go - as far as I'm aware, the gas isn't TOO environmentally dangerous.

To deal with the hydrates in the long run, you could cut off the end of the drill pipe and install an ell over the end of the riser to direct the flow up a few feet. This'd get the flow up to the gas pocket or at least into the oil layer.

To deal with the hydrates in the medium run (while the gas/oil layers are being established) lower the barge with the receiving compartment filled with light oil.

To deal with hydrates in the short run (while the barge is being lowered) EITHER:

1. Lower the barge far enough off to the side so that the floating hydrates don't collect under it, then slide it into position at depth.

2. Install a deflector (wouldn't have to be much more substantial than sheet metal) over the opening in the "deck" (now the underside) where the ell from the riser will enter. Move the deflector aside at the last minute.

3. If I got my numbers correct, the hydrates are SLIGHTLY lighter than the seawater at depth, but heavier than the oil. It's POSSIBLE that the bottom of the "installation oil" pool will serve sufficiently as a deflector

@BobCousins Since everyone is uncertain about the flow rate of the leak, you may be correct. The video was created considering a barge with an internal volume of around 2M gallons. The lift system shown is capable of handling a barge with a volume of around 6M gallons. Let us suppose that the leak is triple what BP is saying: 15,000 barrels per day (630,000 gallons per day). A barge with an internal volume of 6M gallons would be able to capture oil pollution for roughly 9.5 days. With regard to cost, we're probably still talking in the 10s of millions of dollars for even the largest of barges. Smaller ones cost less than that. With the relief drilling, ROV, and support vessel spread that BP has deployed to address this disaster (easily in excess of $2M/day), and not to mention the increased lawsuit and punitive damage potential, I doubt they would blink at spending the money on the barges themselves. And as you astutely pointed out, the barges could then be drydocked and then redeployed in the event of another disaster.

I don't see preventing work around the leak area as a big problem assuming we can contain the oil reliably. We propose that the oil is stored until the relief wells are in place or they devise a way to repair or replace the existing BOP stack. The big "dissimilarity" with their prior attempts is that it decouples the capture and extraction efforts. BP seems hell bent of doing both at the same time, which makes the entire operation significantly more complex. We feel that taking each task on separately is the way to go and increases our chances of success tremendously.

Ok, the barge volume is higher than I estimated! I guess you allowing that the oil/gas/hydrate volume which needs to be collected is higher than the nominal "oil" volume? Either way, I agree that KISS is a good approach, and BP are perhaps over-engineering.

It seems like this system is simple, could be deployed very quickly (in future if not for this). It also doesn't require custom solution for the pipe topology which BP are attempting. How quickly could a barge be converted for use?

We should not be worrying about BPs profits, but if a solution has potential for economic recovery of oil spilled then it could be used to offset the cost and provide an incentive for developing the system and having it on standby. If I was the MMS, I would mandate that offshore operators must have access to such a recovery system as a condition of the lease.