Congressional Testimony and the Deepwater Horizon Oil Spill

Posted by Heading Out on May 13, 2010 - 10:55am

Leading officers of BP, Transocean, Halliburton and Cameron appeared before the Subcommittee on Oversight and Investigations, a Sub-committee of the Committee on Energy and Commerce today. There are a number of documents available at the Committee Site, including the opening statements of Chairman of the Committee Waxman, and Congressman Stupak, Subcommittee chair. I am largely going to review the documented information on the Sub-committee web site, since it included virtually all of the information that was also gone over in the subsequent questioning of the witnesses. I am also going to use more extensive quotes than usual, since there was significant information given at the hearing that is useful to know.

In his opening remarks Congressman Waxman focused on four issues. The first was that while the cementing operation of the well may have passed the first positive pressure test, it may not have passed the following negative pressure test. The second related to the pressure monitors and what they told the people on the rig. He then noted that the blowout preventer that sat on the top of the well at the sea bed had, according to Cameron who made it, a leak in a crucial hydraulic system and a defectively configured ram. And the fourth area being examined is the response of the companies to the spill of oil.

To illustrate his concerns he used a submission from BP called “What we Know.”

The first bullet says: “Before, during or after the cement job, an undetected influx of hydrocarbons entered the wellbore.” What this means is that there was a breach somewhere in well integrity that allowed methane gas and possibly other hydrocarbons to enter the well.

The second bullet says: “The 9 7/8” casing was tested; the 9 7/8 “casing hanger packoff was set and tested; and the entire system was tested.” BP explained to us that this refers to a positive pressure test in the well. What this means is that fluids were injected in the well to increase pressure and to monitor whether the well would retain its integrity. The well passed this test.

Rigs like the Deepwater Horizon keep a daily drilling report. Transocean has given us the report for April 20, the day of the explosion. It is an incomplete log because it ends at 3:00 p.m., about seven hours before the explosion. But it confirms that three positive pressure tests were conducted in the morning to early afternoon.

The next bullet says: “After 16.5 hours waiting on cement, a test was performed on the wellbore below the Blowout Preventer.” BP explained to us what this means. Halliburton completed cementing the well at 12:35 a.m. on April 20 and after giving the cement time to set, a negative pressure test was conducted around 5:00 p.m. This is an important test. During a negative pressure test, the fluid pressure inside the well is reduced and the well is observed to see whether any gas leaks into the well through the cement or casing.

According to James Dupree, the BP Senior Vice President for the Gulf of Mexico, the well did not pass this test. Mr. Dupree told Committee staff on Monday that the test result was “not satisfactory” and “inconclusive.” Significant pressure discrepancies were recorded.

As a result, another negative pressure test was conducted. This is described in the fourth bullet: “During this test, 1,400 psi was observed on the drill pipe while 0 psi was observed on the kill and the choke lines.”

According to Mr. Dupree, this is also an unsatisfactory test result. The kill and choke lines run from the drill rig 5,000 feet to the blowout preventer at the sea floor. The drill pipe runs from the drill rig through the blowout preventer deep into the well. In the test, the pressures measured at any point from the drill rig to the blowout preventer should be the same in all three lines. But what the test showed was that pressures in the drill pipe were significantly higher. Mr. Dupree explained that the results could signal that an influx of gas was causing pressure to mount inside the wellbore.

Another document provided by BP to the Committee is labeled “What Could Have Happened.” It was prepared by BP on April 26, ten days before the first document. According to BP, their understanding of the cause of the spill has evolved considerably since April 26, so this document should not be considered definitive. But it also describes the two negative pressure tests and the pressure discrepancies that were recorded.

What happened next is murky. Mr. Dupree told the Committee staff that he believed the well blew moments after the second pressure test. But lawyers for BP contacted the Committee yesterday and provided a different account. According to BP’s counsel, further investigation has revealed that additional pressure tests were taken, and at 8:00 p.m., company officials determined that the additional results justified ending the test and proceeding with well operations.

Congressman Stupak began with a list of recent incidents that BP had been involved in, including problems on the North Slope and in Texas City. He focused on problems with the BOP, specifically

Our investigation is at its early stages, but already we have uncovered at least four significant problems with the blowout preventer used on the Deepwater Horizon drill rig.

First, the blowout preventer apparently had a significant leak in a key hydraulic system. This leak was found in the hydraulic system that provides emergency power to the shear rams, which are the devices that are supposed to cut the drill pipe and seal the well.

I would like to put on the screen a document that the Committee received from BP. This document states: “leaks have been discovered in the BOP hydraulics system.”

The blowout preventer was manufactured by Cameron. We asked a senior official at Cameron what he knew about these leaks. He told us when the remote operating vehicles (ROVs) tried to operate the shear rams, they noticed a loss of pressure. They investigated this by injecting dye into the hydraulic fluid, which showed a large leak coming from a loose fitting, which was backed off several turns.

The Cameron official told us that he did not believe the leak was caused by the blowout because every other fitting in the system was tight.

We also asked about the significance of the leak. The Cameron official said it was one of several possible failure modes. If the leak deprived the shear rams of sufficient power, they might not succeed in cutting through the drill pipe and sealing the well.

Second, we learned that the blowout preventer had been modified in unexpected ways. One of these modifications was potentially significant. The blowout preventer has an underwater control panel. BP spent a day trying to use this control panel to activate a variable bore ram on the blowout preventer that is designed to seal tight around any pipe in the well. When they investigated why their attempts failed to activate the bore ram, they learned that the device had been modified. A useless test ram – not the variable bore ram – had been connected to the socket that was supposed to activate the variable bore ram. An entire day’s worth of precious time had been spent engaging rams that closed the wrong way.

BP told us the modifications on the BOP were extensive. After the accident, they asked Transocean for drawings of the blowout preventer. Because of the modifications, the drawings they received didn’t match the structure on the ocean floor. BP said they wasted many hours figuring this out.

Third, we learned that the blowout preventer is not powerful enough to cut through joints in the drill pipe. We found a Transocean document that I would like to put on the screen. It says: most blind shear rams are “designed to shear effectively only on the body of the drillpipe. Procedures for the use of BSR’s must therefore ensure that there is no tool joint opposite the ram prior to shearing.”

This seemed astounding to us because the threaded joints between the sections of drillpipe make up about 10% of the length of the pipe. If the shear rams cannot cut through the joints, that would mean that this so-called failsafe device would succeed in cutting the drillpipe only 90% of the time.

We asked the Cameron official about the cutting capacity of the blowout preventer on the Deepwater Horizon. He confirmed that it is not powerful enough to cut through the joints in the drillpipe. And he told us this was another possible explanation for the failure of the blowout preventer to seal the well.

And fourth, we learned that the emergency controls on the blowout preventer may have failed. The blowout preventer has two emergency controls. One is called the emergency disconnect system or EDS. BP officials told us that that the EDS was activated on the drill rig before the rig was evacuated. But the Cameron official said they doubted the signals ever reached the blowout preventer on the seabed. Cameron officials believed the explosion on the rig destroyed the communications link to the blowout preventer before the emergency sequence could be completed.

In other words, the emergency controls may have failed because the explosion that caused the emergency also disabled communications to the blowout preventer.

Still, the blowout preventer also has a “deadman switch” which is supposed to activate the blowout preventer when all else fails. But according to Cameron, there were multiple scenarios that could have caused the deadman switch not to activate. One is human oversight: the deadman switch may not have been enabled on the control panel prior to the BOP being installed on the ocean floor. One is lack of maintenance: the deadman switch won’t work if the batteries are dead. The deadman switch is connected to two separate control pods on the blowout preventer. Both rely on battery power to operate. When one of the control pods was removed and inspected after the spill began, the battery was found to be dead. The battery in the other pod has not been inspected yet.

And one appears to be a design problem. The deadman switch activates only when three separate lines that connect the rig to the blowout preventer are all severed: the communication, power, and hydraulic lines. Cameron believes the power and communication lines were severed in the explosion, but it is possible the hydraulic lines remained intact, which would have stopped the deadman switch from activating.

These are not the only failure scenarios that could impair the function of the blowout preventer. The Cameron official we met with described many other potential problems that could have prevented the blowout preventer from functioning properly. Steel casing or casing hanger could have been ejected from the well and blocked the operation of the rams. The drill pipe could have been severed successfully, but then dropped from the rig, breaking the seal. Or operators on the rig could have tried to activate the shear rams by pushing the shear ram control button. This would have initiated an attempt to close the rams, but it would not have been successful. The shear rams do not have enough power to cut drill pipe unless they are activated through the emergency switch or the deadman switch.

The BP document on what we know notes that BP are focusing on

Cementing – design and execution

Casing - design and installation

Casing Hanger – design and installation

BOP-- configuration, maintenance and operation;

Well Control Practices

Halliburton provided the well log for the last two hours of the rig operation

The Daily Drilling Report ends before the fire.

There is a procedure given for the running of the negative pressure test RIH means Run In Hole, POOH means Pull Out Of Hole,

DP is Drill Pipe, DS is Drill String (I believe).

1. Test casing per APD to 250 / 2500 psi

2. RIH to 8367'

3. Displace to seawater from there to above the wellhead

4. With seawater in the kill close annular and do a negative test -2350 psi differential

5. Open annular and continue displacement

6. Set a 300' balanced cement plug w / 5 bbls in DP

7. POOH -100-200' above top of cement and drop neft ball / circulate DS volume

8. Spot corrosion inhibitor in the open hole

9. POOH to just below the wellhead or above with the 3-1/2" stinger (if desired wash with the 3-1/2" / do not rotate / a separate run will not be made to wash as the displacement will clean up the wellhead)

10. POOH and make LIT / LDS runs

11.Test casing to 1000 psi with seawater (non MMS test / BP DWOP) - surface plug

a. Confirm bbls to pressure up on original casing test vs bbls to test surface plug (should be less due to volume differences and fluid compressibility -seawater vs sobm)

b. Plot on chart / send to Houston for confirmation

The Testimony of the President of BP America (Lamar McKay) included spill remediation activities but specifically talked about their ongoing program to seal the well, including continued efforts to activate the BOP; using a containment and riser system to collect the oil still leaking; drilling two relief wells; and looking at a “top kill” where the well will be re-entered at the top and sealed around the area of the BOP. Their analysis of the failure of the well is focused on the failure of the BOP.

Steve Newman, CEO of Transocean testified as to the different subcontractors that had responsibility for the different phases of the operation, from mud monitoring through casing insertion and cementing. He dealt with the actual failure thus:

the one thing we know with certainty is that on the evening of April 20, there was a sudden, catastrophic failure of the cement, the casing, or both. Therein lies the root cause of this occurrence; without a disastrous failure of one of those elements, the explosion could not have occurred. It is also clear that the drill crew had very little (if any) time to react. The explosions were almost instantaneous.

What caused that catastrophic, sudden and violent failure? Was the well properly designed? Was the well properly cemented? Were there problems with the well casing? Were all appropriate tests run on the cement and casings? These are some of the critical questions that need to be answered in the coming weeks and months.

Over the past several days, some have suggested that the blowout preventers (or BOPs) used on this project were the cause of the accident. That simply makes no sense. A BOP is a large piece of equipment positioned on top of a wellhead to provide pressure control. As explained in more detail in the attachment to my testimony, BOPs are designed to quickly shut off the flow of oil or natural gas by squeezing, crushing or shearing the pipe in the event of a “kick” or “blowout” – a sudden, unexpected release of pressure from within the well that can occur during drilling.

The attention now being given to the BOPs in this case is somewhat ironic because at the time of the explosion, the drilling process was complete. The well had been sealed with casing and cement, and within a few days, the BOPs would have been removed. At this point, the well barriers – the cementing and the casing – were responsible for controlling any pressure from the reservoir.

However he did note that while the BOP failure was not the root cause of the incident, the inability of the BOP to properly function needs investigation.

With the failures of both cementing and the BOP being thus headlined, it was appropriate that testimony also came from the companies involved. Thus Tim Probert, President of Global Business Lines for Halliburton, testified about the cementing. Halliburton’s jobs included:

With respect to the Mississippi Canyon 252 well, Halliburton was contracted by the well owner to perform a variety of services on the rig. These included cementing, mud logging, directional drilling, and measurement‐while‐drilling services. In addition, Halliburton provided selected real‐time drilling and rig data acquisition and transmission services to key personnel both on board the Deepwater Horizon and at various onshore locations.

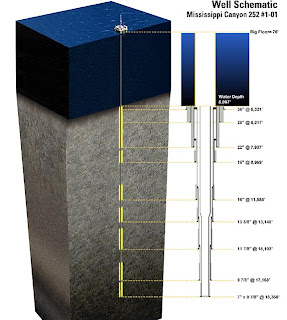

He showed a schematic of the well showing the intervals that were cemented, and the stages of casing down the well.

It was interesting to note that he stressed that the well was not fully cemented over its full length, but

It should be noted that cement is used at specific designated spots and is not designed to be a complete barrier through the entire wellbore.

He noted some of the factors that can influence the cement job:

There are many external factors that impact the design and execution of a cement job. These include the variability in the hole geometry, relative location of hydrocarbon zones, hydrocarbon content and the prior condition of the wellbore and associated fluids as determined by the drilling fluid provider. Casing strings are typically run with devices to centralize the casing concentrically in the wellbore and prevent incomplete displacement of drilling fluid, or “channeling”. . . . . . . . Confirming cement integrity after placement would require the well owner to direct the wireline provider to obtain cement evaluation logs.

(It should be noted that later response to questions elicited the response that running these integrity logs was not always carried out, and was not done on the Mississippi Canyon well).

Following the placement of 51 barrels of cement slurry, the casing seal assembly was set in the casing hanger. In accordance with accepted industry practice, as required by MMS and as directed by the well owner, a positive pressure test was then conducted to demonstrate the integrity of the production casing string. The results of the positive test were reviewed by the well owner and the decision was made to proceed with the well program.

The next step included the performance of a “negative” pressure test, which tests the integrity of the casing seal assembly and is conducted by the drilling contractor at the direction of the well owner and in accordance with MMS requirements. We understand that Halliburton was instructed to record drill pipe pressure during this test until Halliburton’s cementing personnel were advised by the drilling contractor that the negative pressure test had been completed, and were placed on standby.

The final witness before the panel was Jack Moore the President and CEO of Cameron, who made the BOP. He basically said that he did not know enough facts about what went wrong at this time.

There were many questions from the Committee, but the main points that they went after were those which I reviewed as part of Congressmen Waxman and Stupak. I believe that the testimony can be viewed using access from the bottom of the Web Page.

There will be more hearings, and more information will come to light, but this can, perhaps, act as a basis on which to build an understanding as the additional information comes to light.

this is the best summary i have seen so far.

and looking at the wbd(wellbore diagram), can we put the idea of methane hydrates in the wellbore to rest ?

i have to admit, i dont understand the wbd. it appears that a 7+" liner was set at td with enough cement to tie back to the 9 7/8" liner shoe.

the 7+" liner appears to extend to above the 9 7/8" liner hanger and then the 7+" liner is swedged out to ? " with ? " casing to the surface ???

maybe rockman knows or can make something up.

I have worked as a wireline engineer and for the rest of my career as a Reservoir Engineer, reading the above makes me believe that stinking BP was looking for ways to save money any way it could.

On this well they were drilling in environment that was at the limits of our technology. The First priority should have been SAFETY. Over design and pay the cost because you do not have a lot of experience in such environments and should be ready for anything.

To me it sounds like the Bean Counters (I hope I am not wrong on this and find out later that it was the engineers who made these decisions) had other ideas of how to operate beyond ones comfort envelope. Guess the Power Point presentations made everything seem so "Under Control".

At several times the witnesses were asked if anything had been done (or not done) with this well which was not common industry practice for deepwater GoM. Nobody (BP, Transocean, Halliburton, Cameron) seemed to think anything was unusual up to the point of the negative pressure test. Then they all got a bit fuzzy on what happened next...

Running bond logs has become unfashionable in recent years.

The normal operating procedure is now only to run CBL logs when something goes wrong with the cement job, i.e. mud loses, plug did not bump, etc. or when the perforation zone is close to a water leg which requires a good cement bond.

I am not saying this operating procedure is correct, just normal.

P

elwood -- Yes...I had read earlier they ran a tapered string back to the BOP. It starts as 7" and increases to 9 7/8" above the 11 7/8" liner. I'm not sure about getting cmt all the way to the 9 5/8" shoe though. I don't recall the number but I saw one cmt volume that didn't seem to be enough to get cmt that high. But no idea if that number was correct.

Halliburton testimony was 51 bbls of cement

Multiply 51*5.615

If you know hole size outside 7" then figure (HS^2-49)*3.14/4/144 to get ft3 per foot of pipe.

Then divide ft3 of cement by ft3 per ft to come up with feet of coverage.

FF

Since the string above the 7" taper is 9-7/8" I assumed a 9" hole and get around 1650 feet of coverage.

FF

Well Schematic Miss.Cyn.252#1-01,above, seems mis-leading or wrong. Any diagram presented to Congress that contains errors immediately is suspect overall.

E.g. The 36" casing that extends to 5321' is shown cemented as yellow color in left diagram, yet not cemented [grayed] in right diagram [yellow on left and gray on right seem to indicate cemented.]

Also, at bottom of wellbore at 18,360', cement [plug?] is shown within the 7" DrillPipe in right diagram, but no corresponding [yellow] cement in left diagram.

Further, there is vital omitted data on depth of the cement [plug] at bottom of 7" DP.

Also omitted at top of diagrams is any data on size of pipe [DP?] entering and exiting the BOP and how riser is configured, particularly the dimensions [and whether DP extend upward thru riser?, and was the DrillString still within the riser at any point?].

The game is to sow confusion and doubt to destroy transparency, therby controlling the outcome...in typical Public Relations damage-control fashion.

Hi Reddot,

You are over analysing the diagram.

It is simply a schematic to show the sizes of the casing and liner and the esitimated top of cement (TOC).

The more detailed diagram is on the right.

The one on the left also shows the rig happily floating on the surface, are you going to point out that error too?

P

I take a middle position. BP management is not deliberately trying to sow confusion and doubt. They do it instinctively. It is in their DNA.

FF - and that's why we need the caliper measurements to know the empty hole volume below the 9 7/8" casing shoe. Then you can subtract the 7" casing volume to get the annular volume. From there you can calculate how high cmt would have gone. If there was a lot of washout the cmt would not have gone very high. The Halliburton cmt recomendation should have followed this procedure.

How bad can you be off? I just ran cmt on a badly washed out well that would have required 60 bbls of cmt to reach the height needed. But due to the large annular volume from the washout it took 300 bbls of cmt to reach the same height.

Agreed,

Common practise now is to acquire all FE (Formation evaluation) data via LWD (Logging while drilling) tools.

Normally wireline is only now used for Sonic, Image and Pressure (MDT,RCI,RDT) data. Caliper data is often not acquired. LWD does record sometimes record a basic caliper, I am not sure if this was the case here. If the hole was washed out (large diameter) in places then the volume of cement pumped would be too small, hence the cement would only have covered the lower part of the casing, the upper part would be completely unsealed.

P

So why is caliper not acquired? I sorta thot it was needed....

toll -- My basic guess would be costs. Might take half a day or more to run a caliper. But if they are running open loging tools it's typically a part of the package. I haven't determined if the ran "wire line logs" (electronic equipment run into the hole at the end of a cable)in the bottom part of the hole or if they only had LWD data (log while drilling -- electronic equipment right behind the drill bit.) If they only did LWD then no caliper. But you can still get a good cmt job by pumping what you might consider an excessive amount of cmt. The additional cmt volume actually costs almost nothing. Your paying for the equipment and personnel. So if they didn't want to spend $400,000 to run a caliper they might have just ordered an extra $1,000 of cmt.

All these unkowns will come out in time. I'm acutally surprised how much detail we've gotten so far this early in the event.

Offshore is apparently a different world. Never been in that arena and never will, but still...

No caliper measurements? Somewhere between sorta understand and "OK." Open hole wireline. Old technology. Newer better faster. Which brings us to ---

No bond logs??? Unless I am missing something, [and I make this observation in the context of having paid my fractional share of several squeeze jobs] without a bond log you only know what you were trying to do, not the result.

As you wrote, a few extra sacks of cement would amount to nothing in terms of costs and I guess with a marginal bond over a more than sufficient interval the result might require a squeeze job sometime in the future but would not result in a catastrophe.

Which begs the question: Wouldn't another 12 hours of rig time just be part of the price of poker?

Thanks for sharing your knowledge. As noted above, never been there, never done that, but curious just the same.

amoco did a study in about 1980 that found that rigorously following accepted cementing proceedures, i.e. rotation, reciprocation and centralizing during a cement job was a more effective way to insure a good cement job than running cbl's.

a cbl is not infallible.

Point taken: It is better to build quality in rather than to try to "inspect" in quality at some later time.

OTOH, from an oil company's perspective, does anyone think they are knowingly paying a contractor to perform a bad job in cementing a well? Excrement occurs.

elwoodelmore

Land and surface stack rigs have the ability to rotated and move pipe while cementing. On a floater once you land the hanger in the well head, there is no way anyone want to move the casing in case it gets stuck with the hanger in the BOP.

Surface stack with casing slips, move it as much as oyu like as long as the connection is not at the cut. Get stuck 5t to 10 ft off bottom, no problem. Differant with a casing hanger.

thanks for the info. i am only familiar with onshore operations and i was operating on the assumption that they were cementing a liner. apparently, what they were cementing was a full length 9 5/8" to 7 " tapered casing string(this according to rockman).

i have experienced a stuck casing string 10 ft. off bottom on the cement job. no real problem, the real problem occured later when the 7" casing was packed full of resin coated sand, the result of a screen out on the frac' job.

Thanks, HO.

It looks like there are a lot of new posters here. If you wish to keep bringing articles like this to the attention of the world, there's a little orange "donate" button at the top left. Your support would be greatly appreciated.

Rat

I think this was from day 1....

http://www.npr.org/templates/story/story.php?storyId=126759962

Amazing. As usual, it's never just one thing.

HO, I agree and disagree. No, the BOP didn't cause the well failure. But the failure of the BOP lead directly to the spill. And the loss of life.

It seems that there are major design flaws in the current BOPs that will have to be fixed before deep underwater drilling can be contemplated again.

-Shear rams that can't penetrate DP joints are unacceptable. Being unable to shear 10% of the time is an unacceptable risk.

-If the explosion did damage the control link, then the acoustic backup comm link will be a necessity

-Undocumented modifications and poor maintenance (half charged batteries) basically indicate criminal negligence.

-And what is the point of a shear ram button that "..would have initiated an attempt to close the rams, but it would not have been successful. The shear rams do not have enough power to cut drill pipe unless they are activated through the emergency switch or the deadman switch."

"-Shear rams that can't penetrate DP joints are unacceptable. Being unable to shear 10% of the time is an unacceptable risk."

I don't see the problem--I would assume the drillers could see where the joints are and thus make sure to position the shear rams at a place where there are no joints.

And if the pipe happens to be moving at the time?

That's true past. But as I understand BOP design that's why there are multiple shears at different intervals. That way there will always be just DP and not collars across on the the SR's. The other problem is humna erro: the driller has to know excatly where the collar is at every moment.Not easy to do especially if you think you in a safe phase and it doesn't matter.

pasttense -

The problem is that that the BOP is fixed in one place; it doesn't move. So you can't re-position the shear rams vertically once the BOP is in place. What does move, though, is the drill pipe, both going and coming. As such, each joint in the portion of the drill pipe in the well has to at some point move past the shear rams. If one is unlucky enough to have a blow-up during the 10% of the time a joint is passing the shear rams, then the BOP will not be totally effective is stopping the blow-out.

I agree with the previous poster that this is highly unacceptable. Would you drive a car if you knew that 10% of the time the brakes would fail when you attempt to make an emergency stop?

Again like was stated ealier their are multiple shear rams on the BOP for just this purpose, the rams are positioned so that at least one (or more, I belive that this particular BOP has 5 different ones) would not be on a joint at the time it fired. The question does still remain could these rams effectively do thier job 1)With the extra strength of the pipe necessary for the depth and 2) With the drill pipe possibly coming back up the bore at a very high rate of speed.

Though unproven yet it is possible this BOP should not have been used on this particular well as the design may have been inadequate for these particular conditions. This does not mean any flaw whatsoever exists with the BOP, but we are back to human error in picking the correct equipment.

Back to your car analogy, my car is suitable for every day driving and has a very high reliability in the conditions I drive in, will probably run for years. Take that same car and push it to it's limits on a race track and something is going to fail (probably the brakes due to overheating) in very a short (15-30 minutes) period of time. Was this the car makers fault?

From the illustrations provided by BP it can be seen that the BOP had two banks of shear rams - a lower set of 2 and an upper set of 3. I believe it also had a set of two annular preventers in the upper section. Given the overall size of the device I would guess that the ram sets were separated by several feet. In looking at various industry literature it seems that shear rams with different working pressures and different strengths are available and that some are made just to shear pipe and others are designed to shear and seal. Does anyone know if the banks are typically made up of different types? Also, when activated do they all fire off at once, or sequentially, or in sets? It would seem a large task for the hydraulic system to make them all go off at once - providing sufficient volume and pressure to activate them all simultaneously. There was also information circulating that one ram set had been modified so that it could be used for tests - perhaps by replacing the shears with something that wouldn't damage the drill pipe?

I wonder if it was believed that the overall functionality - the typical use of the valve to control fluid pressures in the well - was sufficient for deepwater operation, but that safety aspects were deficient - especially at depth, but this was considered acceptable in the industry.

I don't see how it is acceptable to have such a fail-safe device that is not robust enough (by design, let alone due to poor maintenance) to perform all its intended functions, and most especially under emergency conditions - this seems just crazy!

Except that apparently at least one of the shears on the BOP was replaced with a useless test ram. Murphy's Law guarantees that this ram will be the one in the right position.

That is a silly example, BP are supposed to be operating in normal, everyday conditions. Unless you are implying that we should expect the risk of deepwater drilling to be comparable with the race track? In the macho world of the oil industry, it might be considered an acceptable risk, but not to the man on the street.

If you look at the problems Toyota had, even a very small risk of failure is considered unacceptable.

The Brazil (Show Me) Rule

According to "Toolpush" (and toolpushers are third in line in command, after God and President of the United States), Brazil appears to have a "Show Me" Rule regarding BOP's, to-wit, before a drilling contractor can spud a deepwater well, they have to demonstrate that the shear rams can cut through a length of drill pipe, at depth.

I don't see why the MMS could not implement a similar rule tomorrow morning.

http://online.wsj.com/article/SB1000142405274870396920457522063063839762...

Safety Device Questioned in '04

WT: Maybe MMS is owned or operated by the oil companies? This is just another instance of deregulation working ever so well!

Craig

zap -- The MMS/oil industry has never been de-regulated. The MMS is free to put out any regs they chose. Perhaps we'll see some fast movement now that there's more public eyes on them..

ROCK:

I had heard that under the first Bush, industry compliance with MMS regulations was change from mandatory to voluntary. If true,

this change should have been revoked by Obama administration, but who knows? Was there a change during Bush I? Is it still the Bush I way? Are people in MMS confused? Do people in MMS hope to get consulting contracts in industry on leaving Government?

I do know that I heard this on radio talk show. Times are so crazy that a person can be sane and yet believe this story, IMHO.

geek -- there may well have been some changes as you describe..too far from my little world. The offshore oil industry is heavily regulated and monitored. What every might be done by the industry voluntarily I suspect it is a rather small percentage. There are MMS inspectors out in the GOM doing surprise inspections and writing fines every day.

But I do expect the investigation into the BP blow out will show some of those regs were truly substandard for the conditions/risks associated with Deep Water drilling. I also expect the MMS monitoring efforts will be shown to be substandard also. I expect to see much tighter standards and procedures. I would hope the biggest change (which would be the easiest/quickest/cheapest IMHO) way to improve safety significantly would be an independent third party monitoring of DW ops, at the least, or the entire OCS. We still need to wait for the final investigation but let's assume we have most of the story. Had an independent third party been onboard and had their concurrence to displace the riser at that point in time been mandatory we might not be seeing oil on the GOM right now. If the company man gave up the fight with the engineer he did so to save his job in all likelihood. An independent third party wouldn't have that pressure on them. It would really simple: comply with the third party observer or lose your license to operate in the OCS. That would end any arguments on the spot IMHO.

Rock,

This

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/kenner_hearing...

which I just started reading because it is linked to from a posting on this TOD discussion, has this sentence:

"Saucier said most of the action MMS has taken to control blowout preventers has been through "notices to lessees," letters that go to drill operators but are not enforceable."

in the fourth paragraph below the picture of Mr. Saucier. It seems there is some truth to what I heard on the radio. Which things are enforceable and which are advisories needs to be studied, not shoved under the rug. Mr. Saucier is portrayed as a credible witness by reporter, David Hammer. Its nice to know that MMS has the power to enforce some rules, but rules for BOP seem not to be included in the enforceable set. Are there rules for the color of pencil to be used in check off the steps in a printed checkoff list? Maybe those are strictly enforceable...

"What is enforceable" is determined by management. A questioning of the MMS inspectors might reveal how many of their cited violations are quashed by MMS management.

I'm afraid that what you heard was just a bunch of anti Bush, anti Cheny propaganda. Don't bite on stuff put out by people with Bush Derangement Syndrome.

Most MMS people I've dealt with had industry experience prior to going to work for the MMS. From what I've seen they are hard working, practical people.

And more to the point: the MMS has absolute authority to shut any operator down for any reason they choose. No trial...no court order....no appeal. Operating in the OCS is considered a priveledge...not a right. For an obvious example: right after the blow out the MMS issued immediate orders to not approve any additional drilling permits. No drill permit = no drill for every and all offshore operators.

Pretty obvious authority.

OTOH, could the MMS has tougher standards? Certainly. Could they have more manpower for inspections and enforcement? Certainly.

When all the facts come out - we will see that rather than the regulation, enforcement was a big problem. When the party in power believes regulation is evil as a matter of ideology, enforcement always suffers.

The Democrats have been in power well over a year now-plenty of time for theem to have installed some new guys and girls at the top.

I certainly do agree with Rockman and the other folks with more knowledge of the industry that enforcement should be tightened up and so forth.

But I also have a distant RELATIVE IN JAIL WHO HAS BEEN ACCUSED OF JUST ABOUT EVERY UNSOLVED CRIME committed within twenty five miles over the last twenty years or so.

He would have to have been big enough to drive at six years of age, and there would have to be three or four of him to have done all the things he has been accused of.

For the record:I think The Bushes one and two were miserable presidents.

But nearly all the remarks directed at them , and the rupblicans in this forum, have a distinct flavor of mud about them.Getting your partisan licks in while the getting is good is the way the game is played of course.

HINDSIGHT IS ALWAYS TWENTY TWENTY.

But there are a lot of people here who are able to think a bit.

Who can make a seriuos case for the current crash not happening in the early nineties if Saddam had held Kuwait, and continued on his merry way?

Who is niave enough to believe that the democrats would have actually initiated REALLY serious energy and conservation initiatives had they been in power at any given time during the past three decades or so?

Remember the mantra that got Clinton into office folks?

Of course not, SELF RIGHTEOUS liberals have SELECTIVE memory problems.

"It's the economy, Stupid".

Ring any bells?

More than a few perceptive commenters have remarked here that in this country we have two right wing partys.

When it comes to the economy, and keeping it glowing like a forge with the blower fan on, I couldn't agree more.

The only real difference is that the people who get the subsidies are not necessarily the same people, but there is a huge overlap in every case.

The personal hypocrisy level is simply breathtaking in many cases;a regular reader such as yours truly can generally remember remarks indicating the speaker has been globe trotting , or living in places where the cheapest houses run to half a million or so..

It is not likely that they would have earned enough money to indulge in such lifestyles except for the fact of the economy being in overdrive for the last few decades.

Most people can't think, and the ones who can generally avoid doing so except in the lAST EXTREMITY.

I see the Obama administration spending huge money bailing out the big boys,SUCH AS GOVT MOTORS and the big DEMOCRATIC SIAMESED unions(I have been in unions myself, and have family members who were life long union men-My old Daddy was in the Teamsters for fifty years, his job in town was his PARTIME FORTY HOURS).

I SEE HIS ADMINISTRATION DOING NEXT TO NOTHING TO CHANGE THE BUSINESS CLIMATE THAT makes it impossible for companies to continue to do business in the US.

WE JUST LOST ANOTHER SMALL FURNITURE PLANT NEAR HERE,only about five hundred jobs, but five hundred that will be sorely missed.

And yes , I know that the repugs are more than a little bit=mostly- responsible for the legislation that created this job flight.But they didn't pass it without a lot of help, and the dems are doing nothing to rewrite it now that they have the opportunity.

Let us please try not to be so simple minded as to think scapegoating will solve our problems.

If my comments are aimed at any PARTICULAR individuals, I will name them in the first lines.

MMS and the Oil industry are far too cozy. MMS is second only to the IRS in the amount of money it brings in. There is OH SO MUCH MONEY. The result is that MMS is a very rich agency. They want for very little and they spread the wealth liberally in the form of bonuses and awards for upper management.

Wow!

So much complexity to monitor, so many systems, so many failure modes, so much redundancy in the system.

This was an awesome summary.

Thanks.

A person wonders what the workers were thinking. I suspect they thought that there was so much redundancy in the system that if anything went wrong, another system would catch it. And maybe they were "pretty sure" everything was going fine--strange readings could be discounted as a problem with the systems giving the unusual readings. Perhaps since it had been 40 years since the last major blowout in US waters, a blowout didn't seem like something that could happen with all of the high tech equipment and systems.

Gail -- from many first hand experiences I can promise you no one feels safe with regards to the redundancies. We're always suspicious of every reading for a variety of reason: bad equipement, bad procedures, incompetant hands. Almost every op has two or more folks checking. My job as a well site pore pressure analyst was to look for signs of potential trouble that other parts of the system should catch. And my work was always subject to additional scrutiny. But if they thought they were in a very safe mode then human nature kicks in: If you think there's little or no chance of a problem then you stop looking for signs of one. Again, as painful as it may be to hear, if the story is correct and no one was monitoring mud returns once the pumps were shut off the it might have been as low tech as someone seeing mud flowing fast out the end of a pipe when it should not have been. It's easy to imagine the mud engineering doing a variety of house cleaning chores as they were quickly shutting down ops and not watching for well flow.

"Almost every op has two or more folks checking."

What a ... funny ... coincidental ... comment ...

I've just done a clean-up job of a problem in Calgary, I'm not giving you any details except that I do not expect to get paid because the principal cannot raise any money, any more. He's exhausted the investors' patience.

And one of the potential investors commented that Mr X and Mr Y are so senior engineers that nobody checks their work. Mr X hadn't even checked the Cumulative Production from the field he was investing in. I'm a P.Geol. with a suspicious mind. Of course I checked. Mr X was claiming ... let's alter the numbers, 125 Bcf Cum, and I Discovered the Cum was 110 Bcf. 15 Bcf additional reserves from the geologist. Was he red faced? No. "I told you it was a good prospect".

Sad but true Harry. I tend to follow Dr. House's philosophy; Everyone lies. Not really true but I "allow" everyone to prove they are providing valid info.

Where would he get the cumulutive production numbers? What is the chance of error between two production numbers?

I got the monthly prods and the cum prods from the provincial government going back to the 1980's.

Which I then matched accurately to the partners' numbers.

Mr X had purchased the large interest through a broker, and not opened the CD since he bought it.

An error?

"No chancee, Mr Whelan, no chancee!" (Tor Kanata talking to Ed Whelan on Stampede Wrestling).

When I was at "a major Canadian midstreamer" in the late 1990's, I bought two gas plants off a well-known company, now defunct, the Canadians will know who it was, that was reporting raw gas as sales in their public filings. We all thought it very peculiar, but the acquisitor was and still is a major midstreamer who really is interested in raw and sales gas volumes WRT facilities. So we just shrugged it off and purchased the plants based on our own due diligence for our valuation. I wish I'd reported it straight to the security commission. Today, I have all the telephone numbers and wouldn't think twice.

Just like anything else, the greater the complexity the greater the liklihood of something going wrong.

I need to reread Tainter's Collapse of Complex Societies.

Craig

This is the update I received by e-mail today on the oil spill response from the Joint response initiative:

Some time back, there were comments about the sand being carried in the stream of materials, and the possibiility of that basically eroding away pipe and enlarging the leak. Has there been any reduction in this, or is it still a lurking problem?

I heard on CNN yesterday the tophad was going to be placed tomorrow (Friday)... not that today is any too soon. At least they should be preparing it for placement today.

Is there any sort of clamp to hold it in place over the leak?

Also, this is still being done over the 'smaller' of the two leaks, right? And, once in place they have to go after the other, larger, leak? Have they said anything more about how they plan to do that? A while back, before the first dome failed, they were planning a second dome. Is there a second top hat in the offing?

Craig

zap -- As long as there is flow from the well sand erosion is always a possibility: either stopping or increasing greatly.

Seems to me they should be fabricating a second Top Hat with a more specific opening. They can see what that broken riser is shaped like and how it is behaving. I don't see why they can't make a grabber that attaches the Top Hat to the broken riser while it is still away and then pulls it down onto the flow in a way that channels it into the Top Hat until it is pulled completely snug-in onto the riser. Seems they could seal it off and catch all of the flow if they could pull it off. And I don't think this violates the "as long as you don't make it worse" edict. The Top Hat would have a fluted opening that got screwed down snug onto the broken riser making a sealed connection.

What would be tragic would be if a simple bypass pipe and valve built into the Blowout Preventer could have allowed them to hook-up a pipe and redirect the flow. Pages of technical calculations and readings vs a simple metal bypass pipe.

The 'tophat' is to be placed over the larger leak at the end of the broken riser with the drill pipe sticking out. They also are preparing an 'insertion tube' as an alternate method of capturing the flow at this spot. This is the same place the large modified cofferdam was tried. BP has released a couple of large pretty graphics that show how they might deploy these methods and depict the overall situation. There are links posted to these in the last two days threads.

Regarding the leak itself - I had been assuming that some oil was coming through the BOP via the drill pipe (now capped), and the rest (most of it) through the BOP around the outside of the pipe. It was suggested over here:

http://www.flickr.com/photos/uscgd8/4551846015/page6/

that the drill pipe may have snapped at the kink in the riser and that all the oil leaking through the BOP is coming through the drill pipe. This seems possible because the annular preventer within the BOP stack was closed and it should restrict flow around the outside of the DP... but, if this is really the case then how would a 'junk shot' affect the flow of oil as the DP still extends down into the well quite a ways(I assume)? The fact that they expect the junk shot to help says to me that oil must be leaking through the BOP outside the pipe. It would be interesting to know exactly what the gamma ray scanner revealed about the guts of the BOP. I would think that sand erosion would be more problematic outside the DP than within.

You can see an image of a gamma ray scan of a semi trailer down on this page:

http://www.tagalder.com/template.php?showpage=tagi-gamma.htm

I think we are talking how much hydrate accumulates as they are snugging the Top Hat onto the flow. Even a kid could see we are talking how much seawater mixes in in the final formula.

Ok, I'll play...

Did you look at the pics BP posted of the device and the graphic showing how they expect to deploy it with the plumbing (methanol and warm water) hooked up and active? Did you see that there is a semicircular port for the riser pipe that looks as if it will be a fairly close fit and a smaller one for the drill pipe?

As for how they expect to anchor it down against the pressure of the flow the graphics don't offer much information.

It seems to me that with the enclosure being so small this time and the turbulent nature of the leak as it exits the riser there won't be any space for separation of oil, gas, and seawater as there was in the previous design. Not sure how this will affect things - depending on buoyancy for lift up the pipe to the surface I would guess that the delivery rate might be well below the leak rate.

"A gamma sensor provided by the Department of Energy has scanned the blowout preventer (BOP) to see what the actual damage is. "

I am very surprised to hear that DOE has a gamma ray imaging system that can work in 5000 ft of seawater. I really wonder for what purpose was it developed? Does DOE have any ocean bottom ops. of its own?

For those who might not know, gamma rays are hard, penetrating x-rays that are produced by radio-active sources. They're not called X-rays because of naming rights of discoverers. (A very over simplified version of the history)

I think they had help from Sandia Labs with this operation - Sandia may have provided the equipment.

I had always viewed Sandia as a wholly owned sub. of DOE. Do they have undersea ops. funded from other source? Interesting. I wonder who.

Sandia could provide some expertise with robotics and remote sensing and demolition.

You might cnsider that it is just in case a B-52 or B-2 falls out of the sky and happens to be carrying nukes when it does.

Just a guess geek but I suspect some overlap with the DOD: submarine warfare etc.

I live in Gulf Shores Alabama and we had 35 small tar balls. Granted, we might end up like Sea Island 1991, but for now they are setting up for a music festival. Ben Harper is playing. Maybe we should sign Midnight Oil to come play, 'Beds are burning'.

Maybe the law is upside down. Would it make more sense to ban DEEP sea drilling and allow drilling closer to beach in diver accessible waters? Because I'd bet with divers available, this would have been take care already?

I mean this is like a couple of Mars rovers deep down there pushing buttons and putting a "finger" to the manhole. "Well, that did not work either but look at that cool video feed!" :)

tim -- In the GOM we can drill right up to, and in many cases, right on the beach. The politicians/public has to make a choice: either drill or don't. Even if they improve the regs significantly in the Deep Water the risk will always be there. IMHO there will be much talk about banning/improving safety of DW drilling. And then when gasoline goes over $6/gallon again most of that talk will evaporate.

But it would be easier with divers available, closer to beach?

Easier...maybe but that's not where the oil is right now...and you wouldn't have as much time before wash up (maybe a single tide change).

The best that can happen (assuming we don't quit drilling for oil entirely) is to learn from what happened and ensure that this scenario can't happen again. Industry gets a good lesson and quietly changes equipment and procedures and wipes their brow thanking their dear and fluffy lord it they weren't the ones to learn the lesson.

Yes tim but it's like the old joke about a guy looking for his lost car keys under a street lamp when he actually lost them down a dark alley. He's just looking there because he has better light. You can't drill the new big DW oil play from the shallow waters.

The Ixtoc One blowout was in shallow water, and it took them nine months to control the well--with relief wells:

http://www.npr.org/blogs/thetwo-way/2010/05/one_gulf_oil_spill_went_for_...

Found a link to this off ZeroHedge.com. Video doesnt work for me (stupid fire wall at work) but article seems legit.

http://news.yahoo.com/s/ynews/ynews_sc2031

Cooter

First of all BP didn't "cave to pressure". I watched the first briefing where it was requested. They said they would try to get video from the boats offshore as soon as practical. In yesterday's briefing coast guard verified that they and other agencies were getting it real time. There was no indication that they were intentionally holding it back. It was posted on Coast Guard site yesterday

BTW the best briefing I have see in the last few days is posted on BP web site. It is about an hour and part includes the a BOP model to talk in more detail about the plans.

I think it also gives a better flavor for the strategy including other methods to stop the flow. Even though a few days old it my be informative to many.

Oh, I didn't mean to stake a position. I was just sharing video (that I cant see from work).

Cooter

All this focus on the BOP's is wrong. The BOP should not be part of any well control plan. Never will it be explicitly or implicitly said "... and if something goes wrong we can close the BOP."

The BOP is like the seat belts in a car. If your retainer locks up then you know you made a mistake ... driving too fast, following too close, not looking far enough ahead, whatever. You, the driver, made a mistake.

If they got to the position of needing the BOP's (and they obviously did) then there were mistakes made. Serious mistakes. Of course the BOP should work and of course we should investigate and regulate as required.

But the bigger issue is why did they need to close the BOP? What did those negative tests look like? Why were they misinterpreted? Or ignored, or whatever ... ?

Hmm, so if I am the best trained driver and careful I would not need a seat belt or airbag to function because I know every situation that could happen including another driver hitting me head on, something on the road etc?

Of course decision making that led up to the explosion is the key point. Despite that, BOP's should work. Also the BOP is the focus now because it is where the riser, therefore leak is and is critical in some of the plans to stop the leak to know exactly the inside condition. This is not an either or situation.

Even if we understand the how why and improve procedures we would not do away with mitigation plans nor look at ways to improve mitigation response including skimming, boom, and dispersant technology and use.

I know a lot of people think the idea of briefing all passengers on a water landing on every airplane flight was a waste of time because no plane had ever actually been able to land on water. Then came the Hudson river.

"Hmm, so if I am the best trained driver and careful I would not need a seat belt or airbag to function because I know every situation that could happen including another driver hitting me head on, something on the road etc?"

Correct ... if you need your seatbelt you made a mistake. Of course it should work and be tested and etc. But you made a mistake.

Future deepwater drilling will depend on us proving that we won't make mistakes ... not that we have a bail-out option to cover us every time.

It is human nature to be imperfect, to make mistakes - your assertion is ridiculous if you would consider it more carefully. So no industrial safety measures should be required because workers should never make mistakes? No ejection seats in jet aircraft? People should be expected to have complete knowledge of subsurface conditions in advance of any drilling operation? Mechanical failure should never happen and unexpected conditions should never arise? The world is just not that way - sorry to break the news to you.

Sorry ... I think we're missing my point.

I did not say the BOP was not required. I specifically said "Of course the BOP should work and of course we should investigate and regulate as required."

My point was to comment on our "investigation" on this thread. In a worst case scenario they could stop all deepwater drilling. Proving that we can drill safely will not be based on a bigger, fancier BOP. It'll be based on proving that our procedures and processes are sound enough in their own right without needing the BOP

And then, of course, we'll have a functional, tested, approved, certified and redundant BOP. Just in case.

I think its difficult to know at this point what the nature of the failure in the well was. Hopefully that will be made clear and an evaluation of the drilling and lining techniques that were used will be possible. Since blowouts of this type are uncommon, and some things are known about the procedures that were followed a reasonable speculation can be made that a at least portion of the blame will be assigned to poor decision-making (e.g. failure to let the cement set long enough or other things of this nature) rather than inherent risk in trying to develop a field that is beyond the capability of current technology to handle.

It also seems clear to me the the BOP that was used was neither state of the art nor properly maintained. This is correctable.

It is also probable, in my opinion, that it is possible to develop better contingency plans and deploy better technology for deep water drilling (such as modifications to equipment and submersibles that will allow easier and more effective repairs).

I foresee that oil that is within the reach of current technology will be developed unless the world economy crashes in some spectacular fashion - our current economic and social systems are wedded to oil, and a divorce is not possible without accepting radical changes that societies will not voluntarily accept absent the imperative of absolute and unavoidable necessity.

Papa:

I think I understand your attitude, but in the real world of natural and man-made disasters, I think it is a bad idea to put restrictions on what responsible people are allowed to say. And never say never.

All I can say is that I've been in many, many meetings where people said exactly that. Not only did they say it, it became part of the written plan.

It appears to me that they cemented after displacing the drill mud with seawater.

After cementing, they conducted the negative pressure test, and it failed...

So, my questions:

1) In a well that had demonstrated extremely "bad behavior" why in the hell would you displace drilling mud to cement. Yes, the cement job will take a bit longer and be more complicated, but for god's sakes....

2) After failing (miserably, it appears) the negative pressure test, they elected to continue with the capping operation??? WTF??

3) In a reservoir known to have high pressures and gas, why elect to use the foamy nitrogen cement at all? First, when gas expands it cools rapidly (hence refrigerators), and cement needs heat to cure. Second, gas itself can chemically and physically disrupt the cement curing and stabilization process (bubbles are bad!)

By way of intro to me: Geologist, worked on a riser drilling rig doing scientific drilling, LWD, casing and so forth. Not directly involved as technician or op, but responsible for communicating science needs to drillers and cementers and loggers, and communicating drill/ops requirements and etc to scientists.

Are you working on the A&M program?

I was working with one of the sister organizations, in Japan. Not any more, though.

Welcome to the discussion. I have a few questions regarding your questions.

1) Explain whereby you came to this conclusion. I have not see any evidence they displaced the mud to cement?

2) We are missing key data between the last failing negative pressure test and the accident to know whether that is true or not...unless you possess up to the accident info you would care to share.

3) We don't know, but I have yet to see a drilling engineer come on this board and name that as a reckless event, so I can only assume this is a fairly standard, if tricky practice with lots of very good reasons of why this is done. It may turn out in the future that this does not work, but I'll let actual experts explain.

As to displacing mud before cementing:

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/safety_fluid_w...

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/gas_surge_shut...

And the operations log cited in this post...

The key data is that it failed a neg. pressure test, by a lot, after cementing and letting cement cure for 16.5 hours (which is not long enough, btw). They may have run another pressure test, but the DCIS logs leading up to the event should be gone over with a fine toothed comb to see if there are any further indications of pressure problems... failing one (critical) test like that on a good well, much less a bear like this one is a BAD sign that should not have been ignored.

As far as I know the nitrogen foam cement is still quite new, untested in extreme conditions, and should be used with care. I may be behind the times, however.

Could the negative pressure result have been an artifact of a failed pressure sensor? Or is there usually sufficient redundancy or other measures to exclude this? Or insufficient info at present?

Also this:

3. Displace to seawater from there to above the wellhead

4. With seawater in the kill close annular and do a negative test -2350 psi differential

5. Open annular and continue displacement

6. Set a 300' balanced cement plug w/5 bbls in DP

7. POOH -100-200' above top of cement and drop neft ball / circulate DS volume

This, to me, indicates displace the mud with seawater until there is nothing but seawater in the well ("displace to seawater ... to above the wellhead")... then test, then cement.

Fair enough... we still don't have the full operation logs... even so, to displace the mud at all is a big decision, esp. in a well with such (apparently) dodgy behavior. If you've already had several big kicks and one near blowout, you'd better be DAMNED sure you're good to go before displacing the drill mud.

Halliburton, BP And Transocean all said that the time interval was long enough. Now they may be wrong but they all agreed.

I believe Halliburton said they had used this mix "hundreds of times before" in similar situations.

Like I said, I may be behind the times - I do know that the nitrogen cement mix will have a lower compressive strength than standard cement, and that cement with bubbles of any kind is prone to "channelizing" esp. if hydrostatic head in the well is less than or near the pressure in the formation. Given that tendency, and given the prior behavior of the well, and given the negative pressure test, I simply cannot imagine ok-ing the order to displace the drilling mud.

"cannot imagine"

RedDan: I think you are not alone. Lives have been lost. Careers may be ruined. I continue to watch as we move toward a conclusion.

Now all of this I totally agree with...and I think it quite likely that some people are gonna have careers ruined....at the least.

Careers are ruined everyday in this industry for alot less. The only difference will be how much the decisions made by this individual haunt them the rest of their lives.

In all the blaming and badmouthing that goes on, people forget that the individuals that made these decisions are not monsters. They were probably just trying to do the best they could and made lapses in judgement like we all do, especially under the stress of working in such a high profile job. Others doing the exact same thing may have gotten away with those same decisions. That never excuses their failures, but a failure to appreciate the force of nature is not akin to murder or vandelism and I hope that those people lucky enough never to encounter these situations remember this.

The oil companies themselves are prepared to deal with fixing the errors of their employees, as well they should, but we really shouldn't spit venom at those just trying to do their job and failing. Its something within each and every one of us.

While I have zero experience with oil development and production I do have first hand experience with the forces of nature and decision making under difficult and changing conditions. I have seen good people who made reasonable, responsible decisions under difficult conditions get crucified and hung out to dry for their efforts when they deserved support, both from their organization and the public.

That said I must disagree with your broad brush approach (assuming that's what you intend here) to pass off a management operation that is so focused on production bonuses and wall street numbers that they sacrificed safety and good practice and gambled that they would be laughing all the way to the bank as victims of forces beyond their control - good people who just had a run of bad luck. You can bet that the families of those incinerated on the rig aren't laughing. And neither are those who make their living from the biological (rather than geological - though they will suffer too) wealth of the Gulf.

http://www.oilvoice.com/n/BP_CostCutting_Set_to_Increase_Annual_profits/...

"BP's first quarter 2010 profits were $6.08 billion"

That said I must disagree with your broad brush approach (assuming that's what you intend here) to pass off a management operation that is so focused on production bonuses and wall street numbers that they sacrificed safety and good practice and gambled that they would be laughing all the way to the bank as victims of forces beyond their control - good people who just had a run of bad luck. You can bet that the families of those incinerated on the rig aren't laughing. And neither are those who make their living from the biological (rather than geological - though they will suffer too) wealth of the Gulf.

Of course its mere speculation to say that management operation was focused on production bonuses and wall street numbers. Most of my first hand experience has been that the focus was on safety and procedure, personal preferences to finish and move on aside.

Evidence from this incident suggests otherwise.

I have failed to see that evidence yet.

And what happened after the first negative pressure test seems to be crucial. No real light was shone upon that in the testimony.

one reason to foam the cement slurry is to lighten the weight of the cement to prevent breaking down (fracturing) the rock. fracturing the rock will lead to loss of cement, a faulty cement job and possibly a blowout.

this cement operation was at 18,000 feet , the reservoir temperature was undoubtedly in excess of 100 deg f and provided plenty of heat for hydration of the cement. hydration generates heat and cement will continue to hydrate down to 40 deg f, so i think your concerns about light weight cement and lack of heat are unfounded.

gas entrained in the cement slurry, however, may have facilitated ng flowing from the rock to channel through the cement slurry.

Reasonable stuff... decreasing load and lowering probability of hydrofrac during cementing is pretty important, and I hadn't fully thought through the reasons for the nitrogen mix... and yes the temperatures down there are pretty high, so again, that shouldn't be an issue (i guess that really depends on just how much expansion and adiabatic heat loss there is)...

but the channelizing and bubble potential in a lighter/foamy cement seems to be a significant potential issue.

Interesting change in BP strategy, with artist's graphic.

BP hopes pipe insertion will capture spewing crude By the CNN Wire Staff May 13, 2010 4:37 p.m. EDT

Is the problem a bad cement job?

The failure of the BOP seems to be beside the point.

Cementing in methane hydrate mud is a known problem.

http://www.netl.doe.gov/kmd/cds/disk10/labelle.pdf

" beside the point "

It depends on what you think the point of this discussion is. (sort a "meaning of is is" question)

For me, the point of this discussion is to become better informed about how drilling engineers know what to do next while they are drilling a well, and how confident they can be of their knowledge. I hope to use this knowledge in the coming political turmoil over the future of deep off shore drilling. I hope to help avoid stupid political decisions.

Also, there must be a lot of real experts who have some intellectual curiosity. For them the point is, I suppose, just figure out what happened. Followed by don't let the guilty get away with blaming the innocent.

By the way, I think there is absolutely no reason to believe that there was, or is, any methane hydrate at or near the level where the cementing was being done. See the phase diagram in HeadingOut introductory discussion. They were cementing at the bottom of the well.

If they had methane hydrate coming into that well, it was because the casing or cementing near the surface had failed. 18000 feet is far, far below the hydrate stability field.

As far as I can tell, the gas in the well was from the producing formation, and nowhere else.

You're correct maj: two different problems though related perhaps. Right now it looks like they had a bad cmt job. But cmt jobs often don't work well at first. That's why you run the CBL and do the tests. If you think it's a bad cmt job you do a "squeeze job": either pump more cmt down the bottom of the casing or actually perf the casing and pump cmt through those new holes. And then test again. Important take away: bad cmt jobs, especially in this setting, are not uncommon. By taking the head (the back pressure) off of the bottom hole by displacing the riser with sea water would allow high pressure oil/NG to flow back thru the bad cmt job. I don't want to sound judgemental until we confirm all the pertinent facts but taking the weight of the mud colume off the botom hole without being 100% sure you have a good cmt job is beyond stupid IMHO. And even if you were 100% sure your cmt was holding you would still monitor your mud returns closely just in case you 100% was actually closer to 90%.

BOP failure: a whole nuther set of factors. If thet had not brought the well in it would not have mattered if the BOP would operate properly or not because it would not have been activated in the first place.

This is for anyone who has some experience in the business. The press is starting to make some noise to the fact that accroding to the hearings "They did not have a backup plan/system in place if the BOP failed." My qustion is simple isn't the BOP in fact THE backup system?

ROCKMAN,"but taking the weight of the mud column off the bottom hole without being 100% sure you have a good cmt job is beyond stupid IMHO" . I agree, but what I do not get is that BP is not an operator who has little experience in deep water, in the Gulf, or with these kind of wells. People can say what they want about the downstream accident but as an operator on wells they are experienced and I think have a pretty good record. I keep thinking there is something we are missing as far as data or communications. People can say it is "all about cutting costs". Of course all decisions require efficiency consideration but they have been drilling a lot of very expensive wells in a lot of places for a long time. Perhaps as you have conjectured the mud guys were packing up and things were missed and they had a confluence of things that got out of control. Add the issues with the BOP and the riser not disconnecting and you get a mess.

As you or someone else has already pointed out, all the BP folks made it off the well,they have the guys in the office who were in on the decisions and the real time data. Hate to be the guy who dropped the ball if he did.

Of course it may not turn out to have been so black and white when it was going on as it might be in hindsight.

Dan -- I’ve seen more than one hand who I considered being one of the very best make very poor judgment calls. Didn’t kill anyone but might have. For all the technology and instrumentation it’s not that easy. And you often can’t take the safest route because it often seems unnecessary. Almost every bad accident I know of resulted not so much from someone not understanding the process but making an incorrect assumption.

I would go further and say it would be clinically insane. So either one person (or group) actually was suicidally insane or they were somehow convinced 100% they had a good cement job. How did they reach that conclusion?

You know the next question of course. Was it Criminaly Negligant?

Pipe is not perfectly round. It is oval and rough on the inside. This is not a machined surface. If they think they are going to shove a smaller OD pipe into a 22 inch with a O-ring? and expect the O-ring or any seal to hold, they are on serious wacky backy.

"O-ring?"

I think I have seen something that looks like a baffle or skirt surround on the smaller OD insert. The flow in videos is vigorous, but is not full bore in the 22" riser pipe. It could behandled by a notably smaller pipe without extreme back pressure build up. I think they might have guys on the team who can run the numbers on this. And I don't think the real baffle/skirt/packing will look end up looking at all like what the artist drew. I really can't credit BP with top to bottom, wall to wall, total incompetence. Can you? We shall see.

A post from May 6 notes that the buoyancy of the oil will create a substantial pressure differential to the sea water at depth. Kind of like smoke going up a chimney creating a draft, when oil gets going up the pipe it should suck seawater in. A good seal may not be that critical.

I've done a little seal design myself. Can someone tell me what baffle skirt seal is?

idontno:

Those are my words for describing what I see in the picture. They are not technical words, so far as I know. If they are technical words, I didn't use them in their technical sense.

I made a comment because I thought someone else was saying, or hinting, that what BP is doing was stupid or crazy. I think the picture depicts something that could work, NOT stupid or crazy. I think it can work, and BP has the resources to make it work, IMHO.

Here is the picture.

http://www.flickr.com/photos/deepwaterhorizonresponse/4601914103/sizes/o...

warning: large file

We shouldn't forget the whole issue of the flow rate from the leak possibly increasing substantially:

http://www.businessweek.com/news/2010-05-04/gulf-oil-leak-could-be-12-ti...

[quote]May 4 (Bloomberg) -- Oil leaking from a BP Plc well in the Gulf of Mexico could increase as much as 12 times to 60,000 barrels a day if the company fails to stem the flow, Representative Edward Markey said after a briefing by industry executives. “The amount of oil per day could actually rise from 5,000 to 60,000 barrels,” Markey, a Massachusetts Democrat, told reporters in Washington today. “Although in a worst-case scenario the most likely number was in a 40,000-barrel range.”[/quote]

It's looking more likely. High velocity sand cut may be accelerating the flow rate. Barrett808 caught this breaking NPR story that the flow may now be more than 10 times previously reported by the Coast Guard.

Along with the released video they report

Various scientists are saying that with access to ROV's and BP video they could provide better estimates of the current rate. How can BP not have a pretty fair idea how much oil is currently flowing. Is there that much gas entrained? Is the flow that variable?

I don't think this issue has been raised yet.

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/kenner_hearing...

The last sentence says a lot. Anyone know what the difference in standards is?