Oil Spill Insights from a Retired Manager of an Offshore Underwater Service Company

Posted by Gail the Actuary on May 8, 2010 - 10:40am

This is a guest post from Oil Drum commenter shelburn, who is a retired manager for an offshore underwater service company.

I have been reading the various reports from the media for the last few days and am distressed by the amount of misinformation that is being provided to the public. In response, I have put together some rough calculations and have tried to develop analogies that are understandable to laymen regarding what has happened and what is/can be done.

I have some relevant background, as I was in the offshore industry, primarily in the underwater service side for many years, so I am familiar with diving and ROV operations. I have also been involved in designing and building an oil capture and recovery dome (actually a pyramid) in much shallower water. I also was involved in the Exxon Valdez cleanup and environmental surveys, several years after that incident, among other things.

I’m not a downhole expert, so I’ll leave that side to Rockman and others with the necessary training and experience.

The Leaks:

There is every indication that the Blowout Preventer (BOP) was activated and at least partially worked. There is a good probability that the “leak” is inside the BOP. As the oil leaks through the BOP, it then finds its way through the damaged riser and drill pipe, where it will exit from any open end or damaged area.

Therefore trying to repair the leaks in the riser does not decrease the flow, but it can reduce the number of places where oil must be captured--which is why they capped the end of the leaking drill pipe. If a company tried to stop all the leaks coming from the riser, it would probably be like trying to repair a rotten garden hose. Every time the company stopped one leak, another one would appear. The task is to try to reduce the leaks to one, or to a couple in the same area, so the containment dome can be put over them and the oil recovered while waiting for the relief wells to "kill" the well.

Every deepwater work class Remotely Operated Vehicle (ROV) carries sector scan sonar. Sonar can pick up oil leaks that the naked eye cannot see. The picture of oil bubbles painted on a sonar screen looks like fireworks going off.

There was an ROV survey of the BOP and riser within hours after the rig sank. At that time, there was no indication of any oil leakage from the BOP, and everyone breathed an extremely large, and extremely premature, sigh of relief.

Estimates made about leakage are primarily done from aerial surveys and satellite photos These are notoriously inaccurate, as is clearly stated in the USCG manual on reporting oil spills. The gravity and thickness of the oil, temperature, weather, currents, time, weathering of the oil and other factors all have a major impact on the size of a slick from a given amount of oil.

For example, if you are on a lake in very still water and pour a gallon--not a barrel, a gallon--of gasoline over the side, in a matter of minutes you can have a slick covering a square mile. If you want to try this, pick a cool day as on a warm day the gasoline will evaporate before the slick finishes forming. Also, the Coast Guard would be most unhappy if it knew you were attempting this experiment.

If you do the same with heavy crude similar to what was involved in the Exxon Valdez spill, it will probably take a few hundred barrels to cover that same square mile. Over a long enough time period, though, the type of oil involved in the Exxon Valdez spill will end up covering an area many times larger, and will take months to dissipate in the absence of heavy weather. The sweet crude involved in this spill is somewhere in between.

It was sometime during the night after the sinking that oil leaks started appearing from buckles and holes in the riser. This was stated to be about 1,000 barrels per day. I would read that to mean the leak was between 250 and 3,000 barrels per day (bpd). And a 5,000 bpd leak is probably between 2,000 and 10,000 bpd. Until there is some way to measure the flow--like running it through a pipeline or into a tank--it is impossible to have any accurate measurement of the leakage.

Factoid: If you assume that there is over 5,000 psi of downhole pressure at the BOP--and everything I have heard indicates it is probably substantially higher than that--then a 1/4 inch diameter hole is large enough to “leak” 5,000 barrels a day. That “leak” would probably cut off your arm if you passed it in front of it.

There is almost certainly sand in the oil. As that sand passes the leaking portion of the BOP, it acts as an extremely high pressure sand blaster, eroding the area around the leak and enlarging the hole. So there is a perfectly rational explanation why the leak would escalate from 1,000 bpd to 5,000 bpd to whatever it is now.

Nobody was lying about the volume or covering up. The leak was, and is, getting worse.

How much is 1,000 bpd? It works out to 30 gallons per minute, about the output from 3 garden hoses running wide open, or about enough to fill a smallish backyard swimming pool in 24 hours.

Weather

I’m not an oil spill expert, so I won’t address the clean up much except to mention the effect weather has on it.

For actually recovering the oil, calm weather is the best. It only takes about 3 or 4 foot waves to greatly impede skimming operations and render inflatable booms ineffective.

Unfortunately, the first week of the spill had enough bad weather that recovery operations were slowed and actually stopped for a few days. This week things have been much better, and a lot of oil, but certainly not all, has been recovered before it reached land.

The most effective spill cleanup is a violent storm. Mother Nature is much more successful than man at taking care of herself. In Alaska, we found areas prone to heavy storms were essentially clean after one winter, while protected bays and inlets still have oil deposits more than 20 years later.

A number of years ago, a small tanker with a full load of fuel broke up on the Scottish coast during a North Sea winter storm. Heroic efforts by the British Coast Guard and the salvage tug crew saved most of the crew members, but the tanker was completely destroyed, and all the cargo spilled. There was a great fear of massive environmental consequences. But after the storm abated, there was almost no sign of the oil. The power of the storm had effectively dispersed all the oil and cleaned the rock beaches and cliffs.

Obviously the answer is to recover the oil before it reaches land, but a large storm that pushed the oil out to sea and broke it up would be beneficial. That is unlikely to happen at this time of year. It is much more likely any storm would push the oil onshore and would not be violent enough to disperse it.

Remotely Operated Vehicles (ROVs)

The ROV videos available on YouTube and other sites have been edited or cropped to remove some of the company information and data that is normally visible on the screen. Also, the picture quality is severely degraded from what the operators (BP and all the others) are seeing. But they do give a bit of insight as to what the pilots are seeing and the quality of visibility. So far the ones I’ve seen do not show much detail about the leaks, except for the end of a piece of drill pipe which has been capped.

Incidentally, BP will almost certainly be watching all the ROV video in real time and high definition in their war room in Houston, surrounded by people from the MMS and the USCG.

Twenty years ago a typical ROV spent about as much time on deck being repaired as it did in the water. Today anything less than about 98% to 99% “uptime” is considered substandard. I would be surprised if the ROVs come to the surface except to change tool packages, or if the vessel has to leave location. At that depth, it takes about 3 hours to make a round trip from the work site to the deck and back down.

All the ROVs onsite are considered large work class ROVs. They are at least 150 and often over 200 horsepower. They have multiple thrusters that give them accurate positional control in three dimensions plus pitch and yaw. They carry two strong manipulator arms, color sector scan sonar, several high definition color video cameras, and an incredible multiplexed data system. They have jet pumps that can move vast quantities of mud, wire rope cutters, grinders and cutting systems. Besides the ROVs, BP has access to numerous tool packages that can repair pipelines, clean platform members, etc.

All the deepwater BOP stacks and other equipment are specially designed to interface with ROVs as they operate WAY past the depth any diver can go.

There are some reasonably good short videos of ROVs at www.oceaneering.com. Go the section on ROVs.

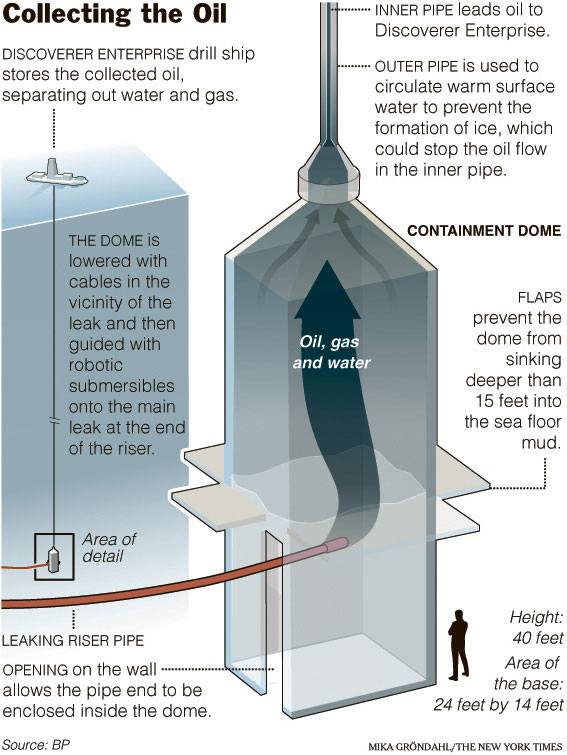

The “Dome”

Let's talk about the dome a little. It would appear from the photos that the dome is designed to be large enough to encase the BOP. It has mud mats 16 feet off the bottom, so obviously the idea is to let it sink into the mud which will stabilize the dome and keep it in place.

The dome should act as a primary oil/water separator and minimize the amount of water going up the drill string. But even better, if I understand the plan correctly, the leak will probably be above the oil/water interface (water will not entirely fill the dome), which means if the dome system is working smoothly, the oil leaking from the riser will never come in contact with the water before it heads up the drill string.

The dome has to be open to the sea water near the bottom, so the pressure will equalize. If the dome were to seal tightly to the seabed, any negative pressure created by the oil rising in the drill string would suck the surrounding mud sea bed right up into the drill string (this is the principal behind suction anchors for drill rigs), and possibly collapse the containment vessel.

I assume the way they will control the system will to be to monitor the level of the oil/water interface inside the dome and throttle the flow at top of the drill string to keep the oil/water interface at a set level.

It is to be connected to the Discoverer Enterprise with a 6-7/8” drill string. Based on some rough estimates I made, if a person assumes the specific gravity of the oil is 0.89, the specific gravity of sea water is 1.026, the depth is 5,000 feet (actually this is of little importance in calculating the maximum flow), and a freeboard of 33 feet to reach the drill ship deck piping, it should be possible to get about 24,000 bpd on the ship using the natural buoyancy of the oil alone. Most of my numbers, especially the specific gravity of the oil, are conservative, so the maximum throughput could be greater, maybe much greater.

If the drill string is filled with oil, the static pressure is entirely dependent on the specific gravity of the oil and the actual water depth. Roughly, if the specific gravity is 0.80, then the pressure at the water surface would be about 500 psi; if the specific gravity of the oil is 0.90, the pressure would be just under 300 psi.

In real life any entrained gas will make a major difference. If the drill string was entirely filled with gas, the static pressure at the surface would be over 2,200 psi. And as soon as you start mixed flow, you get into undefined territory unless you know the exact percentage of gas mixed in the oil.

Entrained gas in the leaking oil will greatly change the flow dynamics, as the gas will expand approximately 150 times going up the drill string and act as a giant airlift. The problem then won’t be getting the oil up the drill string; it will be throttling back the flow onboard the drillship. Luckily, a deepwater drillship will have the proper equipment to handle this.

The expanding gas also has a substantial cooling effect, enough to freeze the water entrained in the stream. So the design of the drill string has been modified to include a warm water jacket and a methanol (antifreeze) injection system.

They have a potentially dangerous situation separating the oil, gas and water, but since the Discoverer Enterprise has processing equipment on board they should be able to handle that safely. The Enterprise also has dual draw works and drill floor, so they are equipped to handle a second drill string to another dome if needed.

The Politics

This is obviously a disaster. It is quite possible that a human error or series of errors, coupled with possible equipment failure, are to blame.

Does BP have culpability because of trying to move too fast? At over $500 a minute, they certainly have the incentive to move fast. We don’t know - yet.

Is Transocean to blame for some sort of negligence in not properly monitoring the mud return or some other aspect of cementing process? We don’t know - yet.

Was Halliburton’s cement job faulty? We don’t know - yet.

Did Cameron International’s BOP fail due to manufacturing or design fault? We don’t know - yet.

Is a combination of one or more of the above? Quite possibly, but we don’t know - yet.

There are unsubstantiated reports that the kick registered over 30,000 psi. If the BOP stack saw that kind of pressure, it could be a important factor, both in determining what happened and how to prevent it from happening again.

For those who are appalled that BP had no contingency plans in case of a spill, perhaps you think the skimmer vessels, the miles and miles of inflatable boom, and the couple hundred trained oil spill control personnel that you see on TV just materialized out of thin air. In fact, they have been on standby for a couple decades. They train, work on small spills, and prepare for disaster. As Rockman says: think of them as a fire department, paid for by the oil companies, under requirements of the US government.

For those who are appalled by the lack of government response, consider that the US Coast Guard was underway in minutes after the blow out, and their spill response personnel (as well as the teams and equipment from the oil industry) were already onsite, standing by, before the rig sank.

For a week after the initial incident, from the blowout April 20 until April 28, things weren't going well. The BOP was still leaking, and the weather was slowing recovery operations, but it is fair to say that the incident was reasonably "under control". There was no need for Obama to get directly involved, mobilize the Dept of Defense, etc.

On April 29, everything started falling apart--a true worst case scenario. That morning, it was obvious the leakage from the BOP had increased dramatically. Even worse, the weather changed and strong offshore winds start moving the oil directly toward some of the most sensitive barrier islands in Louisiana. Not only did the wind change direction, but by evening, it also increased to the point it effectively shut down all skimming and recovery operations and most boom deployments.

The media, which had had only superficial coverage up to this point, got heavily involved and disseminated a great deal of technical information that was just plain incorrect.

There is a certainly an expectation that someone may be to blame for the uncontrolled blow out with its loss of life, and potential for extreme environmental and economic damage. But, it is my opinion, with some understanding of the complexities and technical and operational challenges involved, that both the oil industry and the government operational people have responded to the incident quickly and professionally. I wish I could say the same for the media, the politicians and the bloggers.

The only operation after the blow out that I might question was the decision to keep pumping water into the rig. I wonder whether it might have been better to let it float, assuming it didn’t sink due to a hole in a pontoon, and let the oil burn. But with the rig's engines and thrusters dead, the only thing holding it in position was the riser, so the potential for it to further damage the BOP probably played into that decision. It is always easy to "Monday morning quarterback," especially if a person doesn’t understand the technical or operational problems. Fortunately, some of the best and most experienced people in the world are working this problem.

BP has stated they will pay for the cleanup and environmental damage (as required by law), and will pay any legitimate claims for economic damage. This is a reasonable requirement. During the Exxon Valdez disaster, we saw numerous outlandish claims from “fishermen” who couldn’t tell you the difference between the bow and the stern and “landowners” and “tourist industry people” who had never been to Alaska until after the spill.

There is a lot of press about a $75 million cap on BP’s liability. This has been taken out of context, as it does not apply to the cleanup or environmental damage--there BP’s liability is unlimited. The $75 million is in reference to economic damage, and BP has stated they will not hide behind that limit. Time will tell, but for now I am taking them at their word.

I’m sure this will require some effort on the part of people filing claims. For instance, if you are a charter boat owner or fisherman, I expect BP will require you to submit business records proving you are really in that business, and substantiate the amount of business you had before and after the event. It is fair and reasonable for BP to protect themselves from scams, just as it is fair and reasonable that those who have been economically damaged by this event be given realistic compensation.

I have a much greater problem understanding why the 200+ lawyers currently meeting to decide how to split up the pie should be entitled to the hundreds of millions of dollars in fees they will eventually receive.

We are lucky that this happened to one of the very few companies in the world that has the financial resources to pay the billions of dollars this will cost. This spill is in some ways similar to the Exxon Valdez spill, where Exxon, despite their overwhelming arrogance, did pay all the costs of the cleanup, even while they fought paying many of the economic damage claims I considered valid and tried to avoid all of the punitive damages.

If either spill had happened to a foreign tanker firm or an independent oil company, the taxpayers would have ended up paying for the entire cleanup bill. The people economically affected would have been out of luck, and the companies involved would have already declared bankruptcy.

Hopefully, this accident will now provide the requirement of relief wells as part of the cost of doing business, and perhaps real jail time for politicians and industry people who manipulate environmental safety requirements.

I am sure that other considerations will have to be implemented in the future.

As a long time construction worker, go go go means accidents are inevitable, and all safety laws are written in blood. If it is too expensive to do things right with a few 'needless requirements' thrown in, then the best bet is to leave the oil in the ground until the price reflects development costs.

20 20 hindsight is just that. If there was something nefarious going on, then hang em high. If it was an accident, then let us learn from it.

When the inevitable inquiry happens, leave the lawyers out, ensure the process is transparent and credible, and make the penalties for lying and obfuscation severe, indeed.

Respectfully,

Paul

The relief wells (2 in this case) ARE a part of the cost of doing business.

Good luck with locking the lawyers out of the room.

At the risk of being politically (or legally?) incorrect - What are a 100 lawyers laying on the seabed?

A good start.

Or, did you hear about the bus load of lawyers that plunged over the cliff killing everyone? Ya, the tragedy was there were two empty seats.

Personally, I don't have a dislike for lawyers. Matter of fact I have a high regard for their informational skills in synthesis, reasoning and logic. It's when they start running things that it get precarious - just like accountants. Oops, did I say that?

http://www.commondreams.org/headline/2010/05/01

At the risk of being trounced, do tell how many of those lobbyists are laying on the seabed. The lawyers will get fees but they will also get money for the families and hopefully enough penalties to get BP to find it financially better to do business safer rather than to pay to get exemptions. Sometimes a trial lawyer is the ONLY way to get companies to pay attention to safety.

IMHO the lobbyists should be under the lawyers as to me they represent pretty much everything that is wrong with America today.

There are many good lawyers, but few, if any good lobbyists.

My ire is for lawyers who chase the class action suites and very often take advantage of people who are not legally sophisticated about their rights. Just last week I reviewed a class action suite that settled for the plaintiffs at $1,137,000 - the legal fees and expenses were $1,125,000.

For those people with a legitimate claim who are stiffed by an oil company when they try to get a reasonable compensation, by all means they should get a lawyer and stick it to them.

I have no doubt that top BP execs would hire a lawyer to get damages for them if say someone did shoddy work and caused an accident that paralyzed their child.

I don't like lawyers who take advantage of people who are not legally sophisticated about their rights either.

But perhaps any lawyer is better than none when you read stuff like this

"May 02, 2010, 8:49PM

Attorney General Troy King Attorney General Troy King has asked BP to cease circulating settlement agreements among south Alabamians.Alabama Attorney General Troy King said tonight that he has told representatives of BP Plc. that they should stop circulating settlement agreements among coastal Alabamians. The agreements, King said, essentially require that people give up the right to sue in exchange for payment of up to $5,000." http://blog.al.com/live/2010/05/bp_told_to_stop_circulating_se.html

Betcha not one person with a legitimate claim represented by a lawyer will get less than $5,000. Most trial lawyers I know of work on contingency fees and certainly it would be good to get the word out to folks that they should not accept any other agreement with a lawyer.

"Contingency fee Under this arrangement, the attorney's fee is based on a percentage of what you are awarded in the case. If you lose the case, the attorney does not get a fee, although you will still have to pay expenses. The contingency fee percentage varies and some lawyers offer a sliding scale based on how far along the case is when it is settled. A one-third fee is common. Also, ask whether the lawyer will calculate the fee before or after the expenses. This can make a substantial difference, since calculating the percentage of the attorney's fee after the expenses have been deducted increases the amount of money you receive.

This type of fee is usually found in personal injury cases, accidental claims, property damage cases, or other cases where a large amount of money is in contention."

http://www.lectlaw.com/files/cos79.htm

I

I suspect that putting a lot more safety features in place would not only cost more money, but it would use more energy, so the energy return on investment (EROI) of the oil would go down.

That would mean that no matter how high prices rise, putting a lot of safety measures in place could limit how much oil we get out of offshore reservoirs.

Does anyone know--would safety systems clock up much energy in making, maintaining, and running them? Or is energy use for these not a big concern?

I suspect that putting a lot more safety features in place

http://www.opednews.com/articles/BP-Insider-Massive-Dead-Z-by-Rob-Kall-1...

Why does this crap keep getting repeated? A remote control for the BOP would have made no difference in this case as the BOP was activated from the rig.

Plus this fake news item claims that "My source reports that the pressure in the well was reported to be 135-165,000 PSi".

Who believes that?

Remember the guys that were always sleeping in math class? I think we've found them. And, they wouldn't take any classes that began with a "ph". The alternative spelling confounded them.

Remember the guys that were always sleeping in math class? I think we've found them.

Arn't they the ones in poly-sci and are now the leaders?

Why does this crap keep getting repeated? A remote control for the BOP would have made no difference in this case as the BOP was activated from the rig.

The claim is:

Perhaps back-up is actually 'return to up' as in going to up again.

But to me back-up is backup as in a redundant. Redundant shut-off valve.

Now, the nature of the leak or where it would have been placed would have made no difference in this case but 'remote control' is different than a redundant shut off, is it not?

They are talking about this type of device http://www.km.kongsberg.com/ks/web/nokbg0240.nsf/AllWeb/2A64AE2B8E9FA942...

Cameron, makers of the Deepwater Horizon BOP, describes this as "optional"

http://www.c-a-m.com/content/products/product_detail.cfm?pid=2886

So does normal rules and regs (that are claimed to have been waved) list a backup BOP? Or just backup control system to the BOP? Or was the BOP supposed to have a redundant set of valves?

If I am not mistaken the BOP stack installed on this well had multiple shear rams and a combination of mechanisms designed to seal the well as well as redundant control systems. The criticism I have heard of it is that the rams may not have been powerful enough to shear the drill pipe if there was a joint collar or tool in the ram path. It has also been mentioned that the high-strength drill and well casing being used in deep water environments puts extra strain on the rams and perhaps increases the chance of failure. Other countries has instituted regulations that require stronger designs for deep sea wells than are required by US regulations.

I don't think there is the suggestion from available evidence that an additional remote control system would have helped in this case, as the BOP was activated by people on the rig and repeated attempts were made using submersibles to use the device to achieve a better seal - stop the leak. This is my layman's view.

This BP cartoon gives a good view of the BOP on this well:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

and this link provides some schematics and technical discussion of design issues:

http://drillingcontractor.org/dcpi/dc-mayjune07/DC_May07_BOP.pdf

A Google search will provide a wealth of other links such as:

http://www.jamstec.go.jp/jamstec-e/newsletter/vol5/vol5_2.html

http://www.jamstec.go.jp/chikyu/image_files/B01.jpg

http://www.blowout-preventers.com/

etc.

This is my layman's view.

That is all I have - I'm relying on others to suss out if there was a waver, what was waved, and would the waved item(s) have helped prevent the problem.

The author of the piece is also the owner of the site. I know him. Should I reach out and encourage fixing this? Or just fact checking future pieces?

Costs associated with safety, and their negative impact (perceived) are a false economy. I went through this learning process right out of university in the go-go '80's. You know, when the Kool-Aid of free markets was widely distributed and drank in copious amounts. We were all such efficient machines of free enterprise back then. The bottom line was the only truth...

But, working in refineries and chemical plants we were under a tight regime of safety, especially in Esso (Imperial Oil, Exxon of the GWN). What I learned is integrating safety measures into the field work actually improved quality and had little negative impact on productivity. It made us plan out the work more thoroughly and thereby execute the work more efficiently. That is, we weren't running around all the time looking for a piece of test equipment or tool.

All it takes is to be around an accident where someone gets seriously injured or even killed and I guarantee one's attitude towards safety will change for the better. If it wasn't for the high resistance grounding on the pipeline system feeding Toronto from Sarnia, I would have had a co-worker splattered all over me from contact with a 2,300 V motor starter. Luckily all he got was a 2nd degree burn across his hand and the crap scared out of him.

Our safety indoctrination was conducted by an engineer previously in my position. He survived an arc flash incident that burned 80% of his body. His lesson was short and to the point, "It's not safe until you f%&king well say it is!" With larger systems, i.e. drill rigs, we rely on larger safety systems mechanical, administrative, and procedural. Some may appear onerous, but what I do is try to look beyond the paperwork and ask what are they really trying to say? What is at risk and what are the consequences?

Now there some measures taken to the extreme which appear ridiculous. The recent "Viz-vest" is one I seriously question. At point does universal application become counter-productive? I definitely wear mine when moving about mine sites because all sorts of large vehicles are running around; but a liquor store worker taking a box out to a customer's vehicle? This is one overuse I believe will be counter-productive.

Or there was the time working in the refinery in Venezuela (Cardon for those of any interest). There was a fall accident long before I got there and now everyone had to wear a fall arrest harness if they were working over 6' or 10' (I forget) above the ground. Here we were working on a Stacker-Reclaimer unit complete with stairways and walkways - not even a ladder to contend with - and we had to have a fall arrest on. Just where did they think I was going to fall in the electrical room? That was absurd, but heaven help you if you challenged the dogma.

And maybe that's what we should be watching for. When safety becomes dogma it has lost its focus, and hence its initial purpose.

Remember Hill Street Blues? "Be safe out there."

Excellent posting! Most mature oil companies realized many years ago that it is more efficient, effective and economical to reduce all incidents and accidents through competent planning and procedures. I put BP in this category. Unfortunately its a dangerous business and stuff happens.

The safety features are expensive not because they require a lot energy to manufacture but because they are in particular no consumer goods (low production volume and high development and overhead costs).

I remember hearing costs of $500,000 for one single valve. With $500'000 you can currently buy close to 10,000 tons of coal.

costs of $500,000 for one single valve.

Getting a waver for a few of 'em at that price means a better bonus. (Assuming that the reporting is true that there was a waver issued) Assuming that a reduntant set of valves would have prevented this, that $500,000 cost per valve looks cheap now doesn't it? Wonder if there was a bonus paid on that alledged waver?

http://www.mcclatchydc.com/2010/05/07/93761/despite-spill-feds-still-giv...

But lets not worry because the regulators are doing this for our own good.

failing -- With the blow out it might not seem there isn't much attention paid to safety. Nothing could be farther from the truth. While drilling a well there are redundant systems and a large number of personnel monitoring operations. There's a very long list of safety/certified training covering dozens of different disciplines. The reason is obvious: dangerous situations are not just a possibility but a certainty. My post to Web last night offers details so I'll not repeat. Call them "near misses". But that term really refers more to the response to such dangerous situations. Appropriate response and an accident is easily avoided. A poor response and the worse case results is a blow out. But the circumstances that lead to a well kick develop often.

That's why there are redundant safety systems and constant training to deal with well kicks. I don't have any real numbers since such a database isn't reported. But to give a sense of the possibility if there were 100 wells drilling in the GOM at the same time, there could be 1 or 2 well control situations EVERY WEEK that could, if not managed properly, could lead to a blow out IMHO. Such a stat would be alarming to most but we can also take it as an indication of the resources applied to safety issues. As been said before, we can acknowledge the inherent risks, accept them and continue drilling. Or we decide to limit or ban drilling. But we shouldn’t pretend they don’t exist.

The cost of safety protocols, including expensive equipment, is already in place. Always room for improvement but I’ve previously stated my opinion that such an expansion wouldn’t reduce the potential significantly. But a great improvement could be generated by stronger enforcement of current regs and procedures. Operators have already invested heavily in safety protocols. But there is always a financial consideration behind every operation: time. Time taken to ensure as safe as possible an effort is THE cost factor. If true, why did BP’s engineer over ride the company man’s recommendation to not displace the riser with salt water and thus reduce the safety margin of that additional backpressure? Time. Time is money when ops are costing $40,000+ per hour. More time spent waiting on the cement to cure. More time spent evaluating the quality of the cement job. More time spent recementing if it were needed. More time spent reentering the well after it was abandoned had they not removed the drilling mud from below the top cement plug they had yet to set. As they were pumping mud off the rig into the boat why didn’t they monitor the mud volume that would have clearly indicated the well was coming in? Because there was a rush to get that rig contract off day rate (probably $600,000/day or more) and there was a perception that the conditions were safe. Did the folks tasked with monitoring the mud returns realize there was a conflict over procedure between the company man and the BP engineer? Probably not IMHO. Was the company man aware the mud returns weren’t being monitored? Just a guess but I would say no.

If the blow out occurred as the story indicates, how avoidable was this accident? It will come as no comfort to learn it was easily avoidable. As the mud was being pumped out of the riser it was going into a tank that is routinely monitored for volume gains. If more mud is coming out of the well then salt water was pumped down then it’s obvious the well is unloading and “coming in”. Had this been noted they would have immediately gone into “kill mode” and shut the well in. Could this have prevented the blow out? Probably. This is the core of the safety training for well control. And how high tech was this safety protocol of monitoring mud returns? All that was needed was to stop displacing the riser for 2 minutes and have a hand with a high school education looking at a pipe with mud flowing out of it. No mud coming out: all is OK. Mud flowing out: the well is coming in and a blow out could be eminent. We could spend billions of $’s improving equipment and training. And none of that would prevent this type of mistake. I can promise you with 100% certainty that if this is eventually proven to be the cause of the blow out we’ll see new regs from the Feds with regards to displacing risers in the future. But even before those regs are in place companies will issue new internal protocols along the same lines. And the new procedures will be followed religiously. For a while. And then one day a company man will get pushed to move faster and rules will be bent. But it’s not difficult to design a safeguard against this possibility as well as most others: an independent third party observing adherence to safety procedures. An insignificant increase to drilling costs. It might add $1 or $2 million per year to drilling ops on one rig that could have a cumulative cost of to drill of $500 million or more over the same time period.

As a comedian once said: “You can’t fix stupid”. No, but you can pay someone to keep an eye on stupid.

Rockman - have you seen this.

http://www.rigzone.com/news/article.asp?a_id=92994

If I'm reading it right it seems to fit your scenario.

No I hadn't shelburn...thanks. Very good tech description but only for an insider. But folks should take away the point about "time". I've always been a little suspicious that they were either setting world time records moving thru this phase or they were skipping/rushing too fast. The 20-hour cement wait time always jumped out. Normally a 24-hour wait is standard. That doesn't those 4 hours caused the well to come in. Not uncommon to get the cement to set up properly in 12 hours. But sometimes it can take 30 hours. That’s why you do the various tests. I don't recall if the Rigzone report had the cement bond log (CBL) run included. The CBL does a fair jump of indicating the quality of the bond between csg and cmt. Not fool proof but useful. At the depth involved the CBL run would have taken several hours. This is where the time factor might have kicked in. In addition to the extra time the subcontractor takes to run the CBL he also has a fair bit of equipment on the rig that is typically shipped off the rig after most ops are completed. At the end of a well there's always a big rush getting equipment/personnel of the rig. I suspect you know this routine well: it's shut up - pack up - get on the boat. I also suspect that the mud logger, who monitors the returning mud for indications of hydrocarbons, might have already been shut down at this point. The basic Mother of All Screwups: if you’re “sure” you’re safe you start shutting down the various safeguards.

We still need to see the final investigation results but the story laid out just fits too well. Saving $300,000 of rig time might cost BP a few billion $’s.

RM - Thanks for the knowledge and the calming discussion of a pretty technical situation. Your assessment that this could most probably have been easily prevented are right on the mark. Fixing stupid is a constant and immense struggle. Thankfully I've only been at the site of such an event once (Blast Furnace slag explosion), was far enough away to be sent to help clean up and there was only one critical injury out of 3 or four who were "Doing Stupid".

I was watching the History Channel last week and they had a repeat of one of their Engineering Disaster programs. The four or five incidents reviewed were in completely different fields but the cause was almost universally the same - failure to follow procedures they were trained in and/or trying to save time.

The one that stood out was the "Big Blue" crane collapse when lifting a large(HUGE) section of roof for Miller stadium. The rig was so large that there were 4 operators on the crane with 2 or 3 assistant/spotters communicating with the operators by radio. The accident happened because they attempted the lift in winds of 20mph with gusts to possibly 30mph when procedures set the max at 10mph. I think the death toll was 3.

Same thing with the space shuttle disaster in '86 when they launched at temperatures below minimum and ignored the protests of several booster engineers. Stupid just keeps rearing its ugly head now and then.

All the new procedures and regulations in the world won't stop humans from cutting corners. To state the obvious, they're only effective if they're followed.

I think the safety issue here comes close to the nuclear one. Accidents have an extremely low probability of occuring but huge costs if they do. We, as a society, need to decide if the product/service is worth that cost. Educating the public then gets into what passes for news coverage t5hese days, particularly regarding technical subjects. Talk about trying to fix stupid!

All the more reason the thank those of you who toil to maintain this informative site.

I'm a retired engineer and it's educational to learn a bit about another field. What these crews can do 5 miles down, in an 8-10 inch hole, is truly amazing to me. In addition, I did not know that there was the $75 million limit on some aspect of damages. Eliminating that perk for the industry will mean at least one positive thing will come of this tragedy.

For those who may be unaware - there is a similar liability waiver for the nuclear industry. The Price Anderson Act caps liability at $500 million for a nuclear plant diasaster. That, and the fact that the nuclear industry won't build new plants without 100% government loan guarantees are things to consider when folks sing the praises of new nuclear plants. In the 50's they said nuclear power would be too che3ap to meter.

moose - you point out an important aspect of high-risk investments. Let's use nuke plants as an example. How many folks would invest or insure a nuke plant if they would be on the hook for 100% of the liability in a worse case event? Perhaps no one. So if the feds want nuke plants built they'll have to lay the max liability on the taxpayer. Same with Deep Water drilling. The feds receive many billions of $'s every year from oil/NG royalties. Put 100% of the liabilities on the companies and it might reduce drilling/royalty income. Folks can debate such policies. But more importantly it would be fair for the gov't to make it clear to the public that this is the reason for such a policy. Then folks would know what they are truly voting for. If nuke plants and Deep Water drilling depend upon public liability then so be. Then it's either build/drill or not.

Know something abt Big Blue incident.

My recall not perfect, but...

Two [3?]of union crane operators refused to do the lift because [a]wind was beyond spec limits, [b] crawler mats felt and were judged unstable, and [c]load was over-the-limit of crane set-up. They were told either fly the load or get off the job. They refused and were replaced with more other crane ops.

The laid-off 2 [3?] arranged to observe the lift from a man-basket raised by another, nearby boom.

As Big Blue raised the load, the king-pin snapped, Big Blue boom slowly swayed and toppled, taking-out the nearby man-basket and killing the observing 2 [3?] operators.

who earlier refused to perform the lift.

OSHA was on-site because of prior problems, and were videoing the lift.I saw the OSHA video during a union training class at a nuke plant.

The accident happened because they attempted the lift in winds of 20mph with gusts to possibly 30mph when procedures set the max at 10mph. I think the death toll was 3.

Same thing with the space shuttle disaster in '86 when they launched at temperatures below minimum and ignored the protests of several booster engineers. Stupid just keeps rearing its ugly head now and then.

Neither are 'stupid' - both were trying to "save some money".

And this kind of cost cutting crap is why things like fission plants should not be widespread - Man has shown Man is not able to act responsibly.

Its one thing to cost cut on making a broom - where the outcomes for failure is low. Quite another where your point of failure is 1 mile under the water.

Probably true in this context, but don't forget "save some face".

The Challenger had as much to do with meeting predicted launch deadlines

(after many delays) as saving dollars.

My dad was a combat engineer in Germany (60's) levelling a hill for

a parade ground (or soccer field or whatever) - his CO (NOT an engineer)

wanted to show progress when the colonel came to inspect, so he ordered my dad

to ignore drainage. so my dad did. Colonel Wallace (who WAS an engineer) asked my dad

"What are you making Sarge, a lake?".

My dad refused to cover for the Lt. -- which may explain wny he retired

as an E-7 and not higher.

Heard a general say once "when victory is near, tighten your chinstrap"

Thanks for laying it out so clearly.

As you have said many times already--the human factor is a wild card.

Anecdotally, last time I was on the slope just doing a plain old more or less ordinary foundation the relatively young superintendent with a light commercial rather than heavy construction background devised an unapproved short cut around a problem, and then as that problem recurred used that procedure on almost 50% of the like components with the same problem. The inspector never had a clue what was happening because it wasn't his field. Nothing will fall down until long after very notable problems develop so there is very little chance the shortcuts will endanger anyone but they probably will cause problems that will require expensive fixes in order to avoid foundation failure at some point.

What did I do? I let the company owner know what was done wrong and that it was the very worst piece of work I had ever been a part of and flew home. Why didn't I do more? No one else up the chain wanted to hear about any problem, the job was on schedule. If they weren't going to make it right, I decided I didn't need their money, so I made enough stink about it to make sure they sent me home.

Why was the ill-advised shortcut used. The season was late, properly sized components were 400 long truck miles away and the superintendent wanted to get off the slope and home on his preordained schedule.

Certainly a deep sea oil rig has far more scrutiny than the little job I was on, but the people doing the work in each case are still very much human.

shelburn -

Very clear and nicely done technical overview of the situation, though the issues surrounding why things went wrong and could they have been prevented is far less clear at this point.

Technical question: When reference is made to a downhole pressure of over 5,000 psi, is that gauge pressure with respect to atmospheric pressure, or is that the actual pressure differential between the inside and outside of the blowout preventer? If it is the latter, then with 5,000 ft of seawater on top of the BOP the atmospheric gauge pressure inside the BOP would be more like 7,300 psi. So which is it? Either way, that's a lot of umph!

downhole pressure of over 5,000 psi

http://www.opednews.com/articles/BP-Insider-Massive-Dead-Z-by-Rob-Kall-1...

This part is what bothers me:

"source reports that the pressure in the well was reported to be 135-165,000 PSi."

This is bunk, BS, misinformation.

Steel of very high strength (like ASTM A-514) has a maximum yield point of around 130,000 psi, so how could any steel contain this pressure?

Heading Out has stated in several posts that pressure increases about 0.5 psi for every foot of drill depth, thus the 18,000 foot depth would equate to 9000psi max (relative to the pressure on the bottom of the ocean). So the claim of 135-165,000 psi is wrong.

If my math is right, these pressures are not physically possible in the subsurface. The average sediment density here is probably less than 2.3 g/cc; 5000' of water + 13,000' of 2.3 g/cc sediment gives a maximum overburden pressure of about 15,000 psi. If it were more than that the fluid would have frac'd its way out.

If someone can find out the mudweight used to drill the well, we can estimate the downhole fluid pressures. For example, wells in this area might be drilled with 14-15# mud or 13,000-14,000 psi at 18,000'

If you look at the figure here:

http://www.rigzone.com/news/image_detail.asp?img_id=6778&a_id=92994

as posted above the mud weight was 14 ppg

I'm not a downhole expert but I believe the well pressures are usually measured in relation to atmospheric pressure. So to determine the pressure differential between the BOP and the surrounding seawater you would subtract 2,215 psi from the well pressure assuming the well was at exactly 5,000 feet.

In this case there have been a lot of numbers thrown around. The lowest I have heard for well pressure is about 6,000 psi, but conventional wisdom seems to think 10,000 psi is a better number. Based on the depth of 5,000 feet of water and 18,000 feet of drilled depth the theoretical pressure could be over 20,000 psi and unsubstantiated reports say that the blowout registered over 30,000 psi.

I almost have to believe the 30,000 psi could only result from a surge but 10,000 psi or more seems reasonable leaving about over 7,000 psi driving force behind the leak less any reduction due to the leak itself reducing the pressure.

This schematic suggests that the well depth was figured from sea-level:

http://www.rigzone.com/news/image_detail.asp?img_id=6778&a_id=92994

It is associated with the following piece posted on "Rigzone":

http://www.rigzone.com/news/article.asp?a_id=92994

that discusses the work-flow sequence that should have been occurring prior to the accident.

Another question - is it possible from the descriptions/accounts of the accident available to make an educated guess about when the BOP was activated? Most likely after the well kick/gas explosion but prior to the abandonment (I recall that was at least 20 min). The reason for the question - is there some information in what was observed that can say whether the kink in the riser is restricting the flow or the incompletely sealed BOP, that is can the pictures of the fire and sustained burning that occurred allow a conclusion that the BOP did operate and partially close the well - or does the level of burning suggest an uncontrolled well that was only restricted when the rig sank and the riser kinked?

The following is today appearing in articles about the cause:

"While investigators have yet to finalize the cause, the possible source of the blast emerged in interviews between rig workers and University of California at Berkeley Prof. Robert Bea, who shared them with the Associated Press. Bea is an engineering professor on a National Academy of Engineering panel on oil safety and worked for BP as a risk consultant in the 1990s.

Just prior to the accident, members of BP management were on board the Deepwater Horizon rig, which BP leased from Transocean to celebrate its safety record, according to the interviews. The rig had struck oil and BP officials planned to convert the well from exploration to production.

Bea told the AP he believes a chemical reaction caused by setting cement created heat and a gas bubble which destroyed the seal.

"A small bubble becomes a really big bubble," told the AP. "So the expanding bubble becomes like a cannon shooting the gas into your face."

Where is there a more detailed explanation of this? Did someone make a big mistake?

First - yes a bubble of gas down in the well under high pressure expands greatly when the pressure is reduced.

For example a bubble of gas leaking out of the BOP 5,000 feet down where the pressure is 2,215 psia will expand about 150 times in size by the time it reaches the surface. Gas in the well is under much greater pressure so will expand even more.

Second -

This article is exactly the type of highly irresponsible reporting that upsets me.

I believe the original article was from AP and it has been picked up and distributed as gospel by the worldwide media.

I have read the AP article several times and tried to dissect exactly what data and facts led to this conclusion.

I’m not saying the conclusion is wrong but I think it is premature and based on very limited data. Here is what I found in the article.

A 73 year old, emotional, professor at U of Cal Berkley is being quoted as the ultimate authority. Is the fact that he is 73 and emotional a factor – probably not. Are his credentials good – up to a point.

He has a solid background as a civil engineer in offshore structures and pipelines; in fact I think we may have crossed paths back in the late 70s, early 80s. But in his resume at U of Cal there is no indication of downhole experience or expertise. In fact, his educational background and offshore experience parallel mine but he was at better schools and more cerebral with less grunt work.

http://www.ce.berkeley.edu/~bea/about.html

I certainly don’t have the background to make authoritative statements about what happened to the well.

As near as I can follow from the AP article his entire source of information was “portions” of three interviews from people who were on the rig which “were described in detail”. There is NO indication that he had any access to well data. It does not identify who these interviewees are, their job descriptions or even the thrust of the interviews. They could have been cooks or consulting geologists.

That he did not even have access to the original interviews is also disturbing.

It seems quite a reach to go from descriptions of “portions” of 3 interviews to a definitive statement about the cause of the blowout.

I also get the feeling that he is focused on methane hydrates. My experience is that methane hydrate people fall in two groups. (1) Those who believe that methane hydrates are like the Bakken shale and if TPTB would just give us access it would solve all American energy needs within 6 months, and (2) those who believe that methane hydrates will cause deepwater blowouts.

I shouldn’t lump those two categories together as the second group is at least working from a scientific basis.

It is possible that methane hydrates are the root of the problem but I think it is MUCH too early to make that assumption based on the minimal information available.

And I believe the media is irresponsible to do so.

At the risk of pissing off civil engineers and just being rude, we called them "snivels" because they didn't want to take the tough math classes. "Our stuff doesn't move", they contended, "So why do we have to take dynamic systems?". Whereas over in e-world everything is dynamic and we ate Laplace Transforms with our Cheerios for breakfast.

Anyway, I would put a lot more credence in Shelburn's analysis than a university professor. Aren't these the same guys that designed the university library building and forgot to include the weight of the books?

Now now, I didn't even quite make it to civil - General with Ocean Engineering option (structures).

Little did I know that ocean structures move, and dynamics and fatigue life completely of the existing charts became remedial work

I didn't even quite make it to civil - Little did I know that ocean structures move,

Guess what - Civil 'things' move too. You just HOPE they stay 'mostly static'. The upside to a very dynamic building is they become a static (rubble) problem again.

At least the rig is now a statics problem and no longer a fatigue problem eh?

Thank you Shelburn, for your thoughtful insights. I can only add that the media misinformation is a result of misidentification of the situation from Day One, the root, has a lot to do with the nonsense floating around. This is not a spill allowing the minds of readers and watchers to unconsciously recreate the Exxon Valdez incident, a true spill. A better call would be something direct and simple along the lines of the Deepwater Horizon Accident or Deepwater Disaster. The portable rig exploded in flames, eleven lives lost, the unit sank and lies within feet of the geyser, the leak. Where in this is a "spill"? When we let the media freely get away with coining their own phases, all truth concerning Deepwater's disaster becomes off-topic, exaggerated and unproductive hearsay. I would rather read your humble/admirable statements "We don't know - yet" than converse about a ficticious "spill" which cannot be addressed or resolved effectively without getting into the reality of BOP, wellhead, ROV, flaps, pressure, methane bubble, charts, weather, etc., etc.

To publicly, globally and repeatedly call something what it is not is what lies behind a great deal of westerners' indolence and definitely leads to ineffectual results and exponentially greater disasters.

ok, not technically a "spill". what is it ? a spew ?

as in: spew baby spew ?

This has been bugging me as well, nina. There's a simple, accurate, effective word for the whole situation: a blowout. Conjures up explosions and stuff pouring out at the same time.

"Spill." @#$%!!! This wasn't a d*** spill, with a limited amount of oil that could be released into the environment, then it stops and volunteers clean the beaches. This was a blowout that won't stop until the guys in the oil patch can make it stop.

Thanks for responding waterplanner. Blowout is excellent.

Making it stop is obviously more important to some than others who are obsessed with getting the oil aboard processing ships as well as continuing deepwater drilling. Logic says the hemorrhaging must stop asap to abate the ongoing environmental destruction, but including the grab for the treasure prevents a real, sustainable solution. The problem appears to be that both objectives cannot be met, at least not now, possibly never, if we continue as we are with regulators that cannot possibly comprehend the situation exactly as is happening simultaneously with all TBTF industries requiring strict regulation.

Someone please explain why the well/pipes cannot be sealed/capped and be done with for now. Certainly they have other pressing projects to attend to. Are we in such dire straits today that this one spectacular blowout be allowed to run rampant through the Gulf Stream and destroy every ecosystem in its path? If I am correct about what can and cannot be done, BP might as well be attempting to "tent" the desperation, i.e.; the truth about peak is getting out there regardless.

I said "Someone please explain why the well/pipes cannot be sealed/capped and be done with for now."

Because if it truly cannot be done, we have absolutely no business out there anyway. Too far, too deep, too much potential for disaster. Period. That is the thing about the sea serious mariners know all too well: You can survive the sea, but you cannot control it.

"A 73 year old, emotional, professor at U of Cal Berkley is being quoted as the ultimate authority. Is the fact that he is 73 and emotional a factor – probably not. Are his credentials good – up to a point."

if his age and emotional status are relevant, may we say the same about yours?

"I also get the feeling that he is focused on methane hydrates."

that sounds like you're building up a straw man to knock down, eh? arriving at conclusions without complete information as well, exactly what you accuse him of. attack the information, not the messenger, and i'll give your reply more credence.

shelburn -- What do you mean by that crack "cooks or consulting geologists"? Some would find it insulting to be lumped together like that. I'm talking about the cooks, of course. Actually I've known some old cooks who understood the signs of potential well control situations. But wouldn't use them as expert witnesses, of course.

The media is certainly incompetent but I am detecting a certain confidence('hubris') in your response.

Can you as an expert assure the public that billions of barrels of oil can be safely extracted at extreme depths by the Deep Horizon technology?

The methane bubble could have been released by

warm oil moving up thru a bed of methane hydrates, melting them.

Was this possibility considered by BP in drilling this well?

Almost certainly not, because if true this could make a huge number of superdeep offshore wells undrillable.

"Can you as an expert assure the public that billions of barrels of oil can be safely extracted at extreme depths by the Deep Horizon technology?"

Absolutely not. As an engineer, what I can tell you is that the track record is way over 99% safe. The last blowout in US offshore waters that resulted in a large oil spill was in 1969, over 40 years ago. Since that time I think there have been well over 10,000 wells drilled offshore, which would give a 99.99% safety record.

But that's the problem isn't it. It that 1/100th of 1% that results in a complete disaster with 11 men killed, (and it could have been many more), more injured, a potentially massive environmental disaster and billions of dollars wasted. In fact the miracle here is that over 100 men got off the rig alive.

"The methane bubble could have been released by warm oil moving up thru a bed of methane hydrates, melting them."

If, repeat if, it was a methane bubble that caused the blowout oil would not have been the cause of it melting as the oil was being held down by the drilling mud. The heat source would probably been from the cementing process as cement gives off heat as it cures.

"Was this possibility considered by BP in drilling this well?"

Absolutely. I am no expert on downhole so will leave any technical explanation for others but I have been aware for 20 years that drillers considered methane hydrates as one of the hazards they have to prepare for in deepwater drilling.

"Almost certainly not, because if true this could make a huge number of superdeep offshore wells undrillable."

See above.

Well, you sound like a typical manager.

Here's presentation showing offshore gas hydrate dangers.

http://www.netl.doe.gov/kmd/cds/disk10/labelle.pdf

Deepwater petroleum, the Holy Grail of the Drill-Baby-Drill crowd, may be far riskier than your 99.9% confidence would lead the public to believe.

When I heard managers complaining that 'nothing is 100% safe', and that 'the public is being unreasonable', I conclude that they are contaminated with groupthink and CYA.

The oil industry is among the least safe.

But offshore oil drilling is certainly a risky occupation. Since 2001, 69 oil workers have been killed on the job, with more than 1,300 injuries and around 800 fires.

http://www.latimes.com/news/nationworld/nation/la-na-oil-rig-explosion-2...

That may contribute to a certain fatalism

and carelessness.

It may be that the whole operation was another ill-conceived gamble by an industry eager to prove it can supply the US oil addiction at Peak Oil.

maj -- I might disagree with some your assertions but not the tone. BTW,if hydrates are going to hurt you it would happen at the beginning of the ops and not at the end.

But let's just keep it simple: the physical conditions which attributed to the blow out have been encoutered repeatedly for decades in the GOM...on the shelf and in the Deep Water. Forget about the stats. Those same conditions will continue to be encountered. The public and gov't need to understand that and decide to drill or not drill. It's really just that simple.

And shelburn a "typical manager". Ohhh...those are fightin' words in Texas. Let the blood sport begin!!!

ROCKMAN,

Then you think the decision to drill a well in what seems to be a bed of gas hydrates was reasonable and 'no big deal'?

Why am I not reassured?

I may sound harsh but we are shutting down the Space Shuttle program on account of some o-rings and some insulating tiles.

Perhaps super deepwater oil development will

continue evolve from Colonel Edwin Drake's stovepipe hat or maybe it's a technological dead end.

maj -- I've seen no data indicating they did drill thru hydrates. But if they did it wouldn't be a big deal with respect to the accident. Those hydrates would have been behind multiple strings of casing long before the well blew out. But there are other shallow situations which are known to be very dangerous: shallow NG sands. That's why special seismic surveys are required by the feds before you get a drill permit. So you move your location to avoid them. And if they can't be avoided they design a casing program to deal with the problem.

It appears rather obvious to me that the source of the blow out was 18,000' down.

i think what rockman is trying to say is that caltrates occur below the ocean floor and to a limited depth. so once the shallow sea floor is drilled, cased and cemented, the hydrates are sealed behind casing.

http://en.wikipedia.org/wiki/Methane_clathrate

assuming the ocean floor is at 32 deg f and the temperature gradient is 0.006 deg f per foot (0.6 deg f per 100 ft., a low temp gradient) the hydrates couldnt exist below about 5300 ft (18 deg c or64 deg f). this section is behind casing and a cement sheath.

no need to look for anything as exotic as hydrates to explain the existance of methane gas on the rig floor or methane hydrates in the dome, methane had to come from the miocene. hydrates would form readily at 32 deg f.

i assume we are in for a round of "blame hydrates" here now.

i think what rockman is trying to say is that caltrates occur below the ocean floor and to a limited depth.

He stated that the change in pressure is (perhaps) the issue. (I only hedge as there could be caltrates on the floor there - I do not know)

The Gas is under pressure and as it leaves the higher pressure of the well to the lower pressure of the ocean it will have a drop in temp (Boyles law as I remember). That low pressure, now cold, gas then mixes with water (already at 1 deg C) and gets trapped in an ice matrix.

majoran

North Korea's oil consumption reportedly dropped more 71% in 2003.

The previous major drop in 1990/1991 with drought caused a massive famine with some 2 to 3.5 million people dieing.

You want an income and retirement too? How do you propose to achieve those after killing the economy by cutting off oil? - or not keeping up with the decline after Peak Oil?

You are welcome to switch back to coal and oxcarts! e.g.

Total Number of Coal Mining Fatalities from 1900 through 2009: 104,674

massive famine with some 2 to 3.5 million people dieing.

Plenty of people are gonna die on the downslope of the end of oil.

Energy per person = energy / number of people

If the amount of energy goes down and the energy per person is desired to be the same, what way do you think "management" is going to try to balance the equation?

You want an income and retirement too? How do you propose to achieve those after killing the economy by cutting off oil?

Perhaps the idea of 'income' and 'retirement' is as unrealistic as 'the economy' needing to be 'saved'. Or even that 'economy' actually means what is claimed by many.

But I'll let another frame the issue not by oil but with a different 'thing' and with a different group.

http://www.ratical.com/co-globalize/solariRising.html

I wouldn't have a clue what caused the problem, but this BBC article tells us that the box is sitting on the seabed next to the well while they figure out what to do about "flammable gas hydrates" which have formed inside the box.

I love corporate-speak :) "opportunities to overcome this challenge" instead of "figure out how to fix this mess" :D

There is a quote attributed to Herbert Spencer. "There is a principle which is a bar against all information, which is proof against all arguments and which cannot fail to keep a man in everlasting ignorance—that principle is contempt prior to investigation.

As shelburn has so competently explained above, many of "the media, the politicians, and the bloggers" have once again managed to prove Herbert Spencer correct.

Funny, we are all experts in one area or another and have all seen first hand how non-experts in our particular area of expertise get it wrong simply because they fall prey to that fundamental temptation of the human species to claim the right to an opinion without working for it first. By that I mean taking the time to study the facts, seek out the real experts, and refrain from forming an opinion until you have the understanding to back it up. We see others doing it all the time, it is the rare person that can see it in themselves and resist the urge. It is all to easy to makeup or regurgitate incorrect information simply because it massages your mental pleasure center.

I am fortunate that there are so many exceptional people contributing their hard work and time to enlighten me here on the Oil Drum.

By the way, MSNBC is just quoting an AP report that "documents show a methane bubble" caused the oil rig explosion.

Thanks for a nice overview Shelburn!

One question about the "fire department": You basically state that the response to the spill has been adequate, and that the contingency plans have worked. As a layman, I do keep wondering though: If this tailor-made dome is going to save the day, why is there no "generic" dome (or a couple of different versions) sitting at the gulf coastline for such an emergency case? Is it that noone thought they could be useful, or is it that such a dome has to be tailor-made for each specific accident site, and having one ready might not help because it would have to be rebuilt anyway for the specific accident site?

From the reports I read it seems that 10 days or so were lost by having to construct this dome, and the cost of cleaning up the mess made during those 10 days would seem to outweigh the "insurance cost" of having a few domes ready by a few orders of magnitude. Or am I missing something here?

I can't say I think the spill response was "adequate". Adequate would be cleaning up all the oil and that is certainly not happening yet.

I think the spill response was substantial but we have a spill that is clearly more than substantial.

How much standby response is enough is a question I'm sure will be debated for months and I am also sure the end result will be to increase the level of readiness.

The dome itself has to be custom made for the situation. If this one works and they deploy a second dome don't be surprised if it has a different configuration to this one.

There are a lot of technical problems, many discussed on this board, that will be solved assuming this dome works. In a way this is like a R&D project and all that knowledge will be available for future use.

Even though the dome itself will probably have to be custom made to meet any future leak there is a lot of the system above the dome that could probably be kept on standby. I don't think the fabrication of the dome itself has been the delaying factor. I think the critical path is probably somewhere else in the system - engineering, vessel procurement, drill string/riser modification, etc.

If, God forbid, this happens again the response will be better and quicker due to lessons learned here.

The dome itself has to be custom made for the situation

Is not this dome a modified coffer dam that was once used in shallow water?

I'm guessing there just is not diagram out there better than the one you posted here. You might note that when I posted it yesterday a I fiddled with the width and height of the jpg a little to bring the drawing a little closer to a proportional representation ?- )

Thanks for the recap, nice job of consolidating a transitioning between the replies you made to HOs key post.

I should mention that this week's episode of This Week in Energy (Episode 23) features interviews on the Oil Spill. One is with Arthur Berman, of our staff. The other is with Dr. Kiki Sanford, who talks more about the environmental impacts.

Speaking as a retired chemical engineer, all I can say is that if oil people have a problem with bad publicity on the causes of the disaster they should have made damn sure it never happened. Saying we don't know yet doesn't cut it, because that fact is self-evident on the face of it. Just the way things are, and blaming the media is irrelevant.

As retired licensed therapist, I can say I have massive problems with the mass media that continually spouts off on subjects in which they have little, or no, knowledge or expertise. Mass media is entertainment. In addition, I have zero expectation for any industry or occupation to deal with all problems at all times in all situations regardless of conditions. I've made far to many mistakes in my own professional life to think that way.

I really appreciate the Oil Drum and articles such as this that are written by knowledgable people. Without sources such as this I would be left with the "entertainment".

Thank you.

I'm not commenting on the bad publicity, bad publicity is a given in this situation.

I'm disgusted with the misinformation from the media and also the lack of factual information both from the media and BP.

We, the people on this board, "don't know yet" because we don't have the required information and are being fed a lot half truths and untruths by the media.

It is possible that BP already know exactly what happened and it is also possible they won't know until the BOP is recovered - which is at least 3 months in the future.

BP, as the operator, is ultimately accountable and they will be paying in many ways for many years, including the bad publicity.

There is a root cause and responsibility for this accident and hopefully there will be proper accountability for the mistakes or failures that caused the accident. Even more important is to understand what happened so safety can be improved and hopefully keep it from happening in the future.

But there is still no excuse for the media to do such a poor job of explaining what happened and what is going on.

All judgments aside, I agree with that tactic. Obviously the BOP is one the root cause factors, so wait until it can be recovered and analyzed. Until that time, "work the problem in front of you" (I watched Apollo 13 the other night).

Once again Boyle's Law proves true; a gas will expand to fill a vacuum. Here the vacuum is lack of knowledge to meet inquiry and expectations and the gas is poor information.

Thanks Shelburn and Rockman for providing insights into the complexities of very high rapid pressure transients and high uncertainties of unknown gas bubbles.

TJ

Are you claiming omniscience with an immaculate record in all projects?

We all seek to emulate the Deacon's Masterpiece in constructing his One Horse Shay.

However, we actually experience:

To Engineer is Human, the Role of Failure in Successful Design

Henry Petroski, ISBN 0-679-73416-3

Nope. I'm claiming impatience with the media after you've caused a disaster and have no better explanations is fruitless.

Right now I'm watching CNN and the dome effort has failed, apparently because of hydrate formation.

"Gas and oil rushed up the riser; there was little wind, and a gas cloud got all over the rig. When the main inductions of the engines got a whiff, they ran away and exploded. Blew them right off the rig. This set everything on fire. A similar explosion in the mud pit / mud pump room blew the mud pumps overboard. Another in the mud sack storage room, sited most unfortunately right next to the living quarters, took out all the interior walls where everyone was hanging out having - I am not making this up - a party to celebrate 7 years of accident free work on this rig. 7 BP bigwigs were there visiting from town."

http://gcaptain.com/forum/offshore/4805-deepwater-horizon-transocean-oil...

Great post Shelburn. In talking about the media distortions, let's not forget about Fox News, which is trying to blame the spill on Obama and his staff.

Actually it was a North Korean mini-sub that used a torpedo to set the rig on fire and two days later blew itself up in a suicide mission directly under the rig to sink it.

Believe it or not - that is from an actual "news article" floating around the internet attributed to the Russian Navy - and 2/3 of the comments were from people who believe the report and were belittling the comments saying it was horsepuky!

I'm selling tin foil hats a wholesale prices.

So it wasn't Dr. Evil with his (air quotes) Laser installation on the moon? Geez, I didn't see that one coming...

"A number of years ago, a small tanker with a full load of fuel broke up on the Scottish coast during a North Sea winter storm......... But after the storm abated, there was almost no sign of the oil. The power of the storm had effectively dispersed all the oil and cleaned the rock beaches and cliffs."

Because the oil was not found on the beaches it was probably on the bottom of the ocean, after coagulating into tar balls and sinking. Light oil can evaporate if exposed to higher temps (sunlight), but this would probably not happen in a storm.

My concern would be the damage to the environment from the oil at the ocean bottom, such as in the GOM where crabs, other shellfish, and scanvenger fish reside and lay eggs. Until the oil is broken down by microbes, the oil is still adversely affecting the aquatic environment. Just because you can't see the oil on the beach doesn't mean that it does no harm. In fact it is still doing great harm to the ocean's creatures at the bottom, beside killing the fishing and shellfish business for years.

Mark S. Bucol

Engineering Consultant, BSME

My concern would be the damage to the environment from the oil at the ocean bottom,

http://members.greenpeace.org/blog/greenpeaceusa_blog/2010/05/05/bp_work...

I'm sure many are reflecting on this incident in the larger context as I was yesterday and it occurred to me Tolkien warned us of the consequences of Peak Oil before Hubbard.

Saruman: "Moria... You fear to go into those mines. The dwarves delved too greedily and too deep. You know what they awoke in the darkness of Khazad-dum... shadow and flame."

This oil disaster may be our Balrog.

Maybe if Hirsch used this analogy instead of the 0,10, and 20 year planning horizons more people would have readily accepted the recommended plans of action. Nothing like some scary monsters with flames and whips to get people motivated!

Just something to ponder as we appear to up against the limits of our technology...

Tolkien is a very apt prophet for peak oil. We share the fate of Middle Earth... after all, it is us... and we grapple daily with events similar to those which disturbed the Shire and launched the voyage to the Mountain of Doom.

Tolkien writes of the hope of those who face uncertainty, danger and change - none of which is our choosing - but face we must.

With foes ahead, behind us dread,

Beneath the sky shall be our bed,