Wind powered factories: history (and future) of industrial windmills

Posted by Gail the Actuary on October 29, 2009 - 10:33am

This is a guest post by Kris De Decker. It was previously published by Low-tech Magazine (a very interesting web magazine) and by Energy Bulletin.

In the 1930s and 1940s, decades after steam engines had made wind power obsolete, Dutch researchers obstinately kept improving the – already very sophisticated – traditional windmill. The results were spectacular, and there is no doubt that today an army of ecogeeks could improve them even further. Would it make sense to revive the industrial windmill and again convert kinetic energy directly into mechanical energy?

The Netherlands had 5 times more windmills in 1850 than it has wind turbines today.

More than 900 years ago, medieval Europe became the first large civilisation not to be run by human muscle power. Thousands and thousands of windmills and waterwheels, backed up by animal power, transformed industry and society radically. It was an industrial revolution entirely powered by renewable energy – something that we can (and do) only dream of today. Wind and water powered mills were in essence the first real factories in human history. They consisted of a building, a power source, machinery and employees, and out of them came a product.

Windmills and waterwheels were not new technologies – both machines appeared already in Antiquity and the ones used in the early Middle Ages were technically no different from those. However, ancient civilisations like the Greeks and the Romans hardly used them, possibly because of religious reasons and because of a large enough reservoir of human slave labour.

Water versus wind

Water powered mills were – overall – more important and numerous than windmills. This is logical since they are a simpler and more reliable technology; the flow of a river might change according to the seasons, but generally a river always contains water. Moreover, by making use of canals and sluice gates the flow of water could be precisely controlled to provide the speed or load required by the gearwork inside the factory.

The wind, on the other hand, does not always blow. When it does, wind velocity and direction can change at any moment and windmills had no efficient method to control the strength of the wind – at least not in early medieval times. Water powered mills appeared in Europe in large amounts from the end of the 11th century onwards and only 200 years later almost all available energy in rivers and streams was put to use.

However, not all regions were suited for watermills. The reasons could be that they did not have sufficient water resources (like Spain), that they were too flat and their rivers did not have enough flow (like the Netherlands and the downlands of England) or that rivers generally froze during winter (like in Scandinavia, Russia and parts of Germany). In these countries, windmills appeared in the 13th century, possibly earlier, and spread fast. Later, also regions that had abundant water resources constructed windmills, to relieve the pressure on rivers and streams.

How many windmills?

The amount of windmills in early medieval times remains unknown, because the few inventories that could be studied do not distinguish between water and wind powered mills. For instance, we know that there were between 10,000 and 12,000 mills in the UK in 1300, but we do not know how many of them were wind powered (it must have been a minority). All we have are data on individual windmills, which start to appear at the end of the 1200s. Only in the 1700s and 1800s, when windmill technology really caught on, more accurate inventories appear.

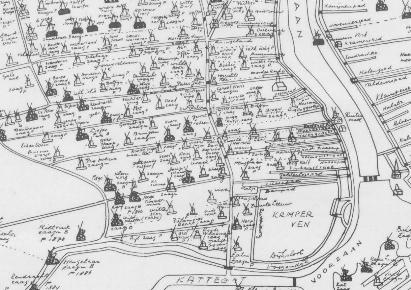

In 1750, there were 6,000 to 8,000 windmills in the Netherlands, in 1850 there were 9,000 of them. For comparison, this is almost 5 times as much as there are wind turbines in the Netherlands today (1,974 turbines as of September 2009). In the UK there were 5,000 to 10,000 windmills in 1820. France had 8,700 windmills (and 37,000 watermills) in 1847.

Germany had 18,242 windmills in 1895 (compared to around 18,000 wind turbines today) and Finland had 20,000 windmills in 1900. Portugal, Spain, several Mediterranean islands and many Eastern European and Scandinavian countries had many windmills, too. The total amount of wind powered mills in Europe was estimated to be around 200,000 (at its peak), compared to some 500,000 waterwheels. Windmills were built in the countryside and in cities, and even on the walls of castles and fortifications in order to catch more wind.

Initially, the only applications of windmills were the grinding of grain and (to a lesser extent) the pumping of water and the draining of lowland areas (for which they were connected to a waterwheel working in reverse – the scoopwheel - or to an Archimedean screw).

Around 1600, many new industrial applications of windmills appeared: saw mills, paper mills, mustard mills, tobacco mills, ...

Bread and oats were the staple diet of the Middle Ages (meat, fish and vegetables were only available to the rich) and all that grain had to be crushed or ground. It took one person with a hand mill two hours a day to grind enough flour for an average family. Corn windmills were also used to make Dutch gin and other liquors.

The grinding of grain remained the most important use of windmills - as late as 1900, the entire wheat harvest of Northern Europe was ground by windmills in the Netherlands, Denmark and Germany. However, around 1600 many new applications of windmills appeared.

New applications

Windmills were used for hulling barley and rice, grinding malt, pressing olives to olive oil, and pressing coleseed, linseed, rapeseed and hempseed for cooking and lighting. There were also cocoa mills, mustard mills and pepper mills (also used for other spices), even tobacco mills and snuff mills.

Besides food production, two other major applications of windmill technology were the production of paper (using ropes and sails from ships as a raw material) and the sawing of wood.

Windmills were also crushing chalk (to make cement), grinding mortar, draining mines, ventilating mineshafts (and even a prison), polishing glass and making gunpowder.

Textiles were another industry in which wind power came to the rescue: windmills were crushing seeds from flax (to make linen), preparing hemp fibres (to produce ropes and sailcloth), fulling cloth (to create soft wool), making paint and tanning and dying animal skins.

The Zaan district

One of the most spectacular developments of industrial wind power technology occurred in the Zaan district, a region situated just above Amsterdam in the Netherlands. Although the area is surrounded by water, the potential of water power was limited because the land is as flat as it can be and so the flow of the rivers is low. The wind, on the other hand, is strong. Many of the applications of windmills described above appeared first (and sometimes only) in the Zaan district.

It is said that the region was the world’s first industrialized area. From 1600 to 1750, when the Netherlands became an important economical power, around 1,000 windmills were built and operated here (see Fig. 6). Mills were given names, just like ships.

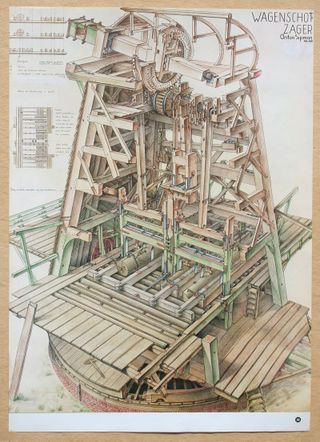

A vital element of the wind powered industry in the Zaan district was the saw mill. Wood was required to construct houses, sluices, ships and of course more windmills. Hand sawing was a very laborious task and windmills greatly reduced the time needed for the process. With hand sawing, 60 beams or trunks would take 120 working days, with wind power this only took 4 to 5 days (see Fig. 7, more here).

The first sawmill ("Het juffertje" or "The missy") was built in the town of Zaandam by Cornelis Corneliszoon in 1596. By 1630, there were 83 sawmills north of Amsterdam, of which 53 were located in the Zaan district. The peak was reached in 1731 when there were 450 sawmills in the Netherlands, 256 of them in the Zaan district. Eventually even the crane of these mills, to haul up the timber, was driven by the sails.

Another early industrial application of wind power in the Zaan district was the production of paper – this was, after all, the era in which the printing press appeared. The first papermaking windmill ("De Gans" or "The Goose") dates from 1605 and by 1740 there were 40 of them. In the middle of the 17th century, the Dutch paper mill was substantially improved, which enabled it to make whiter paper and make it faster.

One remaining example is “De Schoolmeester” ("The Teacher"), built in 1692 (see the introductory picture [Fig. 8] and the interior below). Wind powered paper mills were rare in other countries, but water powered versions already appeared in the 11th century and became quite common – in England there were 417 of them in 1800.

In saw mills, even the crane to haul up the timber was driven by the sails.

Other remarkable windmills in the Zaan district were snuff and tobacco mills (38 in 1795), oil mills (140 in 1731), barley hulling mills (65 in 1731), dyestuff mills (21 in 1731) and hemp mills (20 in 1731). The Dutch also built hundreds of windmills in the West Indies for crushing sugar cane. Relatively few of the 1,000 surviving windmills in the Netherlands are industrial windmills - drainage and corn mills remained economically viable much longer.

Backup power: animals

In many other European countries, similar functions were mainly performed by watermills. However, not all activities powered by waterwheels could be powered by sails. The fickleness of the wind made windmills unsuited for processes that required a very steady and reliable power output, like metal making, spinning, tool-sharpening or extracting minerals from mines.

In countries where the potential of water power was insufficient, some of these activities were powered by animals, mainly horses. Horses were also used as a backup power in long periods of calm, in order to guarantee delivery. For instance, in the Netherlands in 1850, there were 1,800 windmills for the grinding of corn, but also 1,300 horsemills for the grinding of buckwheat – a grain that required a more steady power source for grinding.

Post mills and tower mills

Early medieval windmills were simple machines, derived from waterwheels. During the following centuries, however, windmills became a very sophisticated technology. Windmills are much more complicated machines than waterwheels because wind velocity and speed change continually. Earlier windmills in Iran and Afghanistan were of the horizontal (vertical-axis) type, and thus did not have to adapt to changes in wind direction. But these machines, which were much less efficient, were never used in Europe.

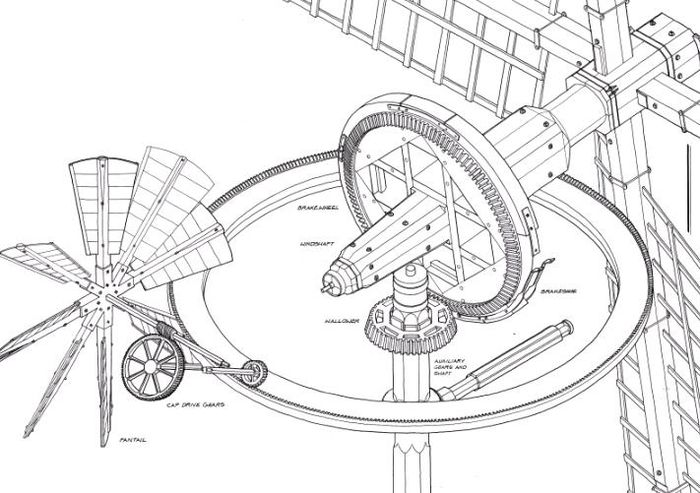

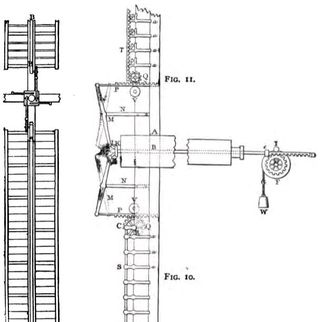

Initially, medieval millwrights solved the problem of varying wind direction by positioning the whole mill on a central spindle so that it could be turned to face the wind. This was the so-called “post mill” (see Fig. 9). Around the 1400s, a second type of windmill appeared, in which only the cap and sails rotated and the body of the mill remained stationary. This was the so-called “tower mill”, which was later perfected by the Dutch (see Fig. 10).

Tower mills were also the dominant type around the Mediterranean, but these were less efficient machines with very different sails. Because it was stationary, the main body of a tower mill could be constructed from stone or brick, and thus they were more sturdily built. Both types continued to be in use, but many post mills were replaced by tower mills from the 1600s to the 1800s.

Turning the sails into the wind

These days, wind turbines are turned into the wind automatically by means of electronic equipment. When the wind becomes too strong, the electronics turn the blades out of the wind so they are not blown to smithereens. Medieval millwrights had no microchips and so they had to find another solution.

For many centuries, windmills were turned into the wind by mere muscle power. This was done by lifting a large tailpole at the back of the mill (hooked up to the tail ladder in the case of a post mill), moving it to the required position, and fixing it again at one of the twelve anchor posts sunk into the ground in a circle around the mill.

This was not an easy task, because the body of a post mill had to be turned with the weight of all the machinery inside. Some mills were equipped with a winch at the end of the tailpole, riding on a circular track, which made the task a bit easier. The cap of tower mills was turned in a similar fashion, by means of a much longer tailpole - reaching to the ground (Fig. 11) or to the terrace in the case of a tower mill with a stage (here). Vent holes were drilled in the sides of the body of the mill – when the wind started blowing through one of these holes, the miller knew that wind direction had changed.

Adjusting the sails: a daunting task

Adapting to variations in wind velocity was even more challenging. The factory machinery inside the mill required a rather precise operating speed. For instance, corn mills worked best at 50 to 60 sail revolutions per minute. Once surpassing 80 sail revolutions per minute the grain would burn. Another risk was that when sails started turning too fast, the windmill could be destroyed.

Again, for centuries, the miller had to do this by hand. Basically, there were two ways to adjust to changing wind speeds. Minor differences in wind velocity could be absorbed inside the mill, by increasing or decreasing the load. For instance, in a corn mill, adapting to a higher wind speed could be done by widening the gap between the milling stones and adding more grain. Because the load is increased, the amount of revolutions of the sails remains more or less the same in spite of the higher wind speed.

When the changes in wind speed became too large, however, the miller had no choice but to get out of the mill and adjust the sails. Traditional windmills were not equipped with blades, but with sails – mostly a wooden framework covered with canvas (in colder climates the canvas was generally replaced by slats of wood, which were easier to handle in freezing conditions).

Reefing two or even four sails, or reducing sail area were very effective methods to adjust to higher wind speeds, but these must have been daunting tasks in high winds. At least two sails had to be brought within a vertical position and stopped so that the miller, climbing the sail, could take off the cloth. If the brake failed while the miller was in the sail, he would be in for a spectacular ride. Tying and reefing all four sails was also a standard procedure at the beginning and end of each working day.

During the second half of the eighteenth century, several complex but effective techniques were developed that made it possible for a traditional windmill to be left mostly unattended

During the second half of the eighteenth century, several complex but effective techniques were developed that made it possible for a traditional wind mill to be left mostly unattended, at least when it concerned changes in wind speed and direction. In 1745, the English blacksmith Edmund Lee invented the "self-regulating wind machine" or "winding", a device that automatically adapted the positioning of the windmill to the direction of the wind. It consisted of a fantail (two fantails for larger windmills) and a gearwork (Fig. 13).

A fantail can be described as an auxiliary windmill that is mounted behind the main sails, at a right angle to them. If the direction of the wind changes, it hits the fantail, turning the mill until the main sails are again perpendicular to the wind.

The fantail is geared down to a travelling wheel in the cap of the tower (in case of a tower mill, above) or around the building (in case of a post mill, see picture). Fantails were later used for wind-powered water pumps in the US, but because these machines were much lighter there was no need for a gearwork to turn them.

The winding not only made the handling of the mill much easier, it also augmented the power output. A substantial amount of power can get lost because of slight variations in the wind direction, but the miller did not always have the time (or the will) to turn the windmill following every minor change.

Automatic control: spring and patent sails

Around the same time as the fantail and winding were invented, mechanisms started to appear that were aimed at automatically adapting the sails to varying wind speeds. This led to the development of the so-called “spring-sail” in 1772, invented by Scottish millwright Andrew Meikle. On a spring sail, the sailcloth is replaced by dozens of shutters like those of a Venetian blind. Each shutter is controlled by a spring.

As the wind increases, it overcomes the force of the spring and the shutter will open, letting the wind through and slowing down the sails. The stronger the wind, the more the shutters will open. When the wind speed decreases, the shutters will be closed by the spring, again forming one uninterrupted surface. All of this results in having sails with a similar rotation speed at any wind velocity.

The problem with spring-sails is that the tensions of the springs (which are all connected to each other by means of a long pole) have to be adjusted beforehand depending on the expected wind speed and the power needed. Once set, it is impossible to make adjustments while the sails are turning.

This was solved in 1789 by Stephen Hooper, who introduced blinds that could be adjusted with a manual chain from the ground without stopping the mill ("roller reefing sails", Figure 17). However, the system was too complicated. The final improvement to self-reefing sails came in 1807 when William Cubit attached counterweights to the adjustment chain of spring sails, making the control of the sails fully automatic without the complexity of the roller reefing method – these were called “patent sails” (Fig. 15).

Berton sails

The only problem left was that patent sails had a lower efficiency than normal sails, and as a result it was common to combine two patent sails with two normal sails as a compromise between handling and efficiency. In 1848, the Frenchman Berton replaced the many small shutters by fewer longitudinal shutters operating according to the same principle, an intriguing method that gave a sturdier construction and a better aerodynamic performance ("Berton Sails", see Fig. 18).

Moreover, the system could be adjusted by the miller from inside the cap of the mill. In 1860, Catchpole introduced air brakes, which were a very effective means to automatically slowing down the sails in a gale. Inside the mill, an automatic centrifugal governor replaced the manual adapting of the distance between the milling stones.

Of course, self-reefing sails and other automatic systems did not solve the problem of windless days - that is why the miller worked day and night when there was a good breeze. Millers were even exempt from Sunday's rest.

As was the case with the fantail, self-reefing sails did not only improve the handling of the windmill, but also the power output. Because there was no longer a need for the miller to stand on the ground to fix or unfurl the sails, the wind shaft could be installed much higher so that the mill could benefit from higher wind speeds (the Dutch had solved this issue before by constructing tower mills where the sails could be reefed from a stage at a higher level).

Power output of a windmill

Another important improvement was the introduction of cast iron for the manufacture of the gearwork. This happened in 1755, only ten years after the introduction of the winding, by John Smeaton. For centuries, all gears inside the mill were made of wood. This resulted in serious energy losses.

Measurements performed by the Dutch in the 1930s, on a drainage windmill constructed in 1648, showed that the mill generated around 40 horsepower at the windshaft but only 15.6 horsepower at the machines – an efficiency of only 39 percent. Almost two thirds of the generated power was lost in the transmission. Drainage mills had a slightly higher efficiency of around 50 percent.

Windmills with wood gearings had an efficiency of only 39 percent

The use of cast-iron (and later iron) did not only improve the efficiency of the gearwork, but also allowed for the construction of larger windmills. The use of wood limited the diameter of the sails to around 30 meters – already common in the 1600s.

The maximum length of a stock (more than twice the length of one sail) was around 30 metres (100 feet) because there were no larger trunks available. Only in the second half of the nineteenth century iron stocks came to be used for the sails and for the windshaft.

Innovations came too late

Unfortunately, the many important improvements of windmill technology came too late. Already at the end of the 1700s, around the same time that these innovations appeared, the first corn mill switched from wind power to steam power – and to the black smoke that came with it. Around 1850, steam powered mills became more common and the importance of windmills started to decline. To make things worse, fantails, self-reefing sails and iron stiffening were slow to catch on - in many countries and regions they were never even used.

Berton sails were only applied in France, patent sails were mainly used in England. Although iron stocks allowed for the construction of larger sails, that never happened. The highest tower mill ever constructed was made entirely out of wood. It was standing in the Netherlands and was constructed in 1899 ("De Hoop" or "The Hope" in Prinsenhagen, now the city of Breda). It stood 38 metres (125 ft) tall, with sails around 27 metres (88.5 ft) in diameter. The cap and sails were removed in 1929 but the tower is still there.

Largest windmill ever built

The two Dutch windmills with the largest sail diameter are standing in the Golden Gate Park in San Francisco, built between 1903 and 1905. The largest one, the "Murphy Windmill", stands 29 metres (95 ft) tall with sails 35 metres (114 ft) across. The stocks were cut from one single log - the US had larger trees. But its gearwork is made entirely of cast iron and that shows: the mill pumped up to 150,000 litres (40,000 gallons) of water per day to irrigate the park. The Murphy Mill was replaced by an electrical engine some years later and fell into disrepair.

The decline of the windmill was slow, especially in the Netherlands - the Dutch even preferred windmills with auxiliary steam engines over fully steam powered mills. More than 6 million wind powered waterpumps (with annular sails) would be built in the United States between the 1850s and the 1930s, but elsewhere few windmills were erected after 1900. The attention shifted to wind turbines generating electricity, and that has remained so ever since.

Impressive improvements in the 1920s and 1930s

In the 1920s and 1930s, however, when windmills had stopped working almost everywhere in Europe, the Dutch started a research program that led to the final development of the classical windmill. In 1923, the “Dutch Windmill Society” was founded, with the mission to improve the performance of windmills generating mechanical energy. Among the members were famous millwright builders like the Dekker Brothers. The results were spectacular.

The maximum power output of a windmill was doubled from 50 to 100 horsepower at the end of the 1920s.

Through the application of aeronautical principles and the use of sheet metal (basically equipping traditional windmills with sails somewhat similar to the blades of modern wind turbines) the maximum power output of a windmill was doubled from 50 to 100 horsepower at the end of the 1920s.

More than 70 windmills were equipped with the new "Dekkerized sails" during the following decade. Moreover, improvements in the gearwork slashed energy losses and allowed for windmills to generate much more power at lower wind speeds.

Doubling energy output

Tests conducted in 1939 by the “Prinsenmolen Committee” showed that an improved windmill would start to turn with a wind speed of 3.5 to 4 m/s (7.75 to 9 mph) compared to 5 to 6 m/s (11 to 13.5 mph) for the old design. At 5.5 m/s (12.5 mph) their power was found to be equal to that of a normal mill at 8 m/s (18 mph).

This meant that while a traditional windmill could be worked for around 2,671 hours per year in the Netherlands, the new streamlined design could be operated for 4,442 hours per year – more or less doubling the annual energy output.

The improved windmill had two advantages; a greater output at a given wind speed, and longer working hours by utilizing lighter winds. The gain was especially found in lower wind speeds, because with stronger winds the sails of the improved windmill had to be reefed sooner.

More improvements during the 1930s by Chris van Bussel, Kurt Bilau, G.J. Ten Have, Van Riet, P.L. Fauël (Fig. 23), Sabinin and Yurieff led to a windmill, installed in 1940 and demolished in 1960, with up to two and a half times the power output of windmills with traditional sails: 125 horsepower.

Next, the Second World War stopped further investigations and after the war, like the rest of the world, the Dutch shifted their attention to the generation of electricity.

Revert to traditional windmills?

Today, windmills and waterwheels that convert kinetic energy directly into mechanical energy are considered obsolete, and while some have survived, few of them have any commercial function in developed countries. Wind turbines now turn renewable energy into electricity, which might later be converted back to mechanical energy.

Of course it is impossible to operate a flat screen television or a laptop with mechanical energy, but many other processes could in principle still be driven in that old-fashioned way. Grain still has to be ground, wood still has to be sawn, seeds still have to be pressed, but now we use electricity to drive machines that perform the same processes. This electricity can be generated by means of modern wind turbines, or other renewable energy sources, and that is the future that everybody has in mind.

Embodied energy

However, there are some reasons that might make it interesting to revert to a direct conversion from kinetic to mechanical energy. Planting a few million high-tech wind turbines, covering deserts with solar plants and developing a smart grid and an elaborate electrical car infrastructure all sound attractive, but the most important question is whether there are enough material, energy and financial resources available to make those dreams ever come true.

Traditional windmills could be improved substantially with today’s knowledge and materials

Available data on the reserves of exotic resources required for many eco-technologies look grim, and some time ago it was heard that China (the main producer of important ecotech metals) plans to restrict the export of those metals. Windmills that convert kinetic energy directly to mechanical work could be operated without exotic materials.

High-tech traditional windmills

On a more positive note, traditional windmills could be improved substantially with today’s knowledge and fairly common materials. The gearings and sails could be made of steel or aluminum, which would seriously improve efficiency and also make windmills fireproof. Being made entirely or in large part of wood, many windmills were destroyed by fire. Of course, also the factory machinery inside the mill could be made much more efficient now.

Windmills could be built much larger and thus more powerful. To give an indication; in 2005, the Dutch built another traditional windmill, that generates electricity - the "Noletmolen" in Schiedam. It stands almost 42 metres tall with sails 30 metres across, slightly less than the Murphy Mill in San Francisco. It was built for promotional purposes by a distillery (the town hosts 5 more historical mills built to produce Dutch gin). Although the mill is not really a "mill", it is built according to a traditional design, but using high-tech materials and sails (Fig. 24). The result is a power output of more than 200 horsepower at the windshaft. Take that, Energy Ball.

Ecotech treatment

Backup power for a traditional windmill could be delivered by an electrical motor instead of horses (or we could just work when the wind blows). There is no doubt that now, 70 years later, an army of ecotech geeks could still seriously improve the Dutch experiments from the 1930s. The results might not look as romantic as a traditional windmill, but very useful.

Of course, this is not a plea to eliminate electricity-generating wind turbines or even the electricity infrastructure altogether. But, some things might be more efficiently done with direct conversion of kinetic energy to mechanical energy.

We will dive deeper into the history of renewable energy in forthcoming articles.

Kris De Decker (edited by Vincent Grosjean)

Sources (in order of importance)

- "Power from Wind: A History of Windmill Technology

", Richard L. Hills, 1994.

- "Molens", Frederick Stokhuyzen, 1962 (English summary here).

- "Research inspired by the Dutch windmills: An account of an extensive programme of research and development

", The Prinsenmolen Committee, 1966 (I could not find this book but it is the source to which both books above refer to when describing the Dutch experiments in the 1930s).

- "Histoire générale des techniques", Maurice Dumas, 1964

- "Molendatabase" – pictures and descriptions (in Dutch) of windmills in the Netherlands.

- "Natural sources of power", Robert Steele Ball (1908)

- "Geschiedenis van de techniek in Nederland, de wording van een moderne samenleving 1800-1890", H.W. Lintsen, 1992

- "Gevlucht", Wikipedia Dutch

- "History of technology", "Energy conversion" and "Windmills", Encyclopedia Britannica.

- "An Encyclopedia of the History of Technology (Routledge Companion Encyclopaedias)

", Ian McNeil, 1990

- "Wind, Water, Work: Ancient And Medieval Milling Technology (Technology and Change in History)

", Adam Lucas, 2005

- "Handbook of Fluid Dynamics

", Richard W. Johnson, 1998

- "The windmill as prime mover", Alfred R. Wolff, 1885

- "An experimental enquiry concerning the natural powers of water and wind to turn mills", John Smeaton, 1760

- "Groot Volkomen Moolenboek", 1734

- "Penterbak" - pictures

- "Industriemolens" - pictures of industrial windmills in the Netherlands

- "Windmills in Sussex", Peter Hemming, 1936

- "Windmills in Holland", K. Boonenburg, 1951 (pdf)

- "Windmill sail", Wikipedia English

- "Origen y expansion de los molinos de viento en Espana”, José Ignacio Rojas Sola y Juan Manual Amezcua Ogayar, Interciencia, Vol.30, 2005

- "The windmill: a medieval steam engine?", John Langdon (pdf)

- "The Evolution of Technology (Cambridge Studies in the History of Science)

", George Basalla, 1989

- "Windkraftanlagen: grundlagen, technik, einsatz, wirtschaftlichkeit", Eric Hau, 2003

- "European Route of Industrial Heritages"

Kris,

Brilliant! I want to run outside an make one.

Good work

David

Agreed - utterly fascinating read. The SF anthology Wastelands : Stories of the Apocalypse includes "Waiting for the Zephyr," which features a sail powered landgoing vehicle - wonder if that was ever tried.

I should add, a large vehicle, not the small sail racers people tool around salt flats on.

Great article, reminds me of the not only the water-pumping windmills I still see relics of, but of the wind-powered sawmill my 80 yr old uncle recalls his uncle operating out in the US West. The US has been called the Saudi Arabia of wind, it only requires us recognizing that and acting on it.

If draft animals see a return in farming/transport, then their availability would help ameliorate any dead wind times.

Thanks Kris!

The Windmill Museum in Kendallville Indiana recently built a Dutch style windmill. It's beautiful, but I don't know if it is attached to anything like a grain grinder. Their museum has a huge number of the classic american water-pumping windmills all on towers and spinning.

Have you seen or heard much about Hydraulic Windmills? They use a hydraulic pump up in the body of the mill instead of a generator. I know that New Alchemy Institute experimented with one many years ago.

With a Hydraulic Windmill one could use the power directly in any rotating machinery without the need for combining the tower structure into the building housing the machinery.

Can hydraulic "power" be accumulated and stored for later use? Maybe in some sort of combined hydraulic/pnuematic tank like home wells use?

Might make the most sense to take wind directly (and Mechanically) to pumped Hydro for the storage medium, while of course extracting that energy also need not automatically go through electricity, if you can establish the applications near the reservoir, and just take the direct mechanical energy.

As convenience (electricity) often comes with a cost, then finding ways to live with percieved 'inconveniences' can likewise earn some benefits.

Ummm, by hydraulic I meant pressurized oil - like a hydraulic cylinder or motor uses.

Your reply sounds like you are thinking about water, but I may be reading it wrong...

Yes, you're right, I was changing fluids there. I suppose it would be conceivable to store Hydraulic pressure directly using numerous Rams that are holding up a load, etc.. but that leaves a lot of seals under constant pressure.. my thought was to use a source like stored Hydro, and release it to run a Hydraulic pump when the work is happening.

Of course there's the 'Raised weights' option may work in a smaller scale situation, or where hydro-reservoir isn't possible.. but hydraulics would chew up that potential pretty fast, I'd imagine..

No. I like Jokuhls original plan. It could be used at any hydroelectric plant. Just add some windmills that when the wind is available pump some of the water back upstream, and therefore the amount available for the hydroplant is increased. Today we here a lot of talk about doing this with electricity from the windmills, this just avoids the generator transmission line and motor. Of course these direct pump mills would have to be placed close to the dam, but perhaps they can deliver cheaper dispatchable power than more traditional methods.

I see the hydraulics, as more of a means to transmit mechanical forces than as a means to store energy.

Generally you are trying to catch the more consistent, stronger wind that is available at greater elevation. Converting it to electricity at the hub eleminates the need for long, heavy drive gear and frees the towers to be much taller. Even right at the hydro facility towers would need to be positioned as high as practical. Hard to see any advantage to direct wind powered mechanical pumps at a hydro facility that generates electricity. Wires are just a heck of a lot easier to run than long, complex drive gear. Even in your backyard well an electric submersible pump gets water a lot higher a than any mechanical system you can readily devise. Electric motors and generators can be made simple and easy to maintain.

I don't believe a couple of right-angle gears and a long drive-shaft is actually all that complicated. There are surely conveniences in Electrics, but also a great amount of materials requirements, particularly insulators and solid-state components which drive up the embedded energy in Electric systems.. I'm not against them, but we've gotten spoiled with our expectation of that convenience, while a simple, elegant bit of machine-work can be surprisingly durable and effective.

Alan's proposals about pumped storage between a couple of the Great Lakes strikes me as an ideal application for direct Wind-supported Hydro, with volumes so large that the direct impact might be quite minimal.. and you've got the Wind-Resource right near the Reservoirs, coming down the plains.

is there some way the aqueduct to Arizona can be worked into his plan, that has been talked about for even longer :-) If we are pumping that much great lake water around with 'minimal' effect (I've spent a lot of my life on their shores so I know the sort of 'minimal' effects small up and down fluctuations have on the shoreline) the tech available will be able to support efficient electric pumps. All mechanical linkages are relatively brittle in comparison. A mega project of that sort does not suggest any lack of high tech capability.

I don't really think taking hydraulic clues from a guy who lives in a city that is mostly below sea level might be the best course anyway :-) but big ideas are needed so who knows.

The pumped hydro at dams will require a lot of lift, hard to beat powerful electric pumps. Your are at an electric hydro generation station for god's sake, that implies electrical use on a larger scale, which of course implies no shortage of motors and generators.

In a later post I suggested a use for a mechanical linkage where hydraulics just look to be too messy, on a floating generator 'island' where gears track up and down the piers tethering the float. Tidal environments suit this best but they are messy. If you wanted to cover a large portion of the pumped hydro reservoir with floating generator pad/s you could greatly reduce evaporation. The costs and ERoEI of such a project are well past me, just a wild and crazy idea that really might not be in some locals.

I would rather do all sorts of stuff to the hydro power we already have before really trying to mess with the great lakes flow more than we have already.

The real draw of the mechanical linkages to wind power seems to be the implied return to that medieval 'paradise' so many here would like to see. That is more in the realm of religious beliefs, religion can trump efficiency and have no real counter argument that will make a lick of difference to the believer--that is how we are wired.

Hydraulic windmills were tried. Didn't work out, in the same way that the hydraulic logic computers that were tested in case the environment of space was hostile enough to prevent solid state chips working.

Problem 1 - how are you going to transmit the power? If you have long hydraulic hose from the nacell to the ground where you place the hydraulic to electric EQ - how do you adapt to the blades moving into the wind?

Long hydraulic lines, lots of friction loss not to mention all the mechanical issues in maintaining hydraulic integrity. I'm sure there is plenty of literature out their comparing the power transmission losses between different types of systems. Electrical resistance is of course not always a triffling consideration either. I'm sure someone around here could give us some real world numbers on power transmission efficiencies.

A 6000 MW (the power of 3000 wind-turbines), 800 kV single HVDC line loss (+ converter and S/S losses) @ full load are 6% per 1000 miles:

http://events.energetics.com/electric_transmission09/pdfs/Bahrman.pdf

(Only a pipeline can compete - if you factor in the total energy in the oil transported).

Here is info and test results on the New Alchemy Institute hydraulic windmill discussed above.

In the same document is info on how to build a sail-wing windmill for pumping water. (A small do-it-yourself windmill with "blades" made of tensioned fabric, like a sail boat)

Amazing what you can find on the internet...

Fascinating article indeed. Does that make me an ecogeek?

I saw this on the Energy Bulletin.

If small to medium size local windmills make a comeback, as I believe they will eventually,building them will be much easier in a powered down , resuorce deprived economy will be a lot easier than one might think-unless we export all of our scrap to China!

There will be many thousands of heavy duty trucks sitting around and the drive line components are admirably suited to recycling into windmills.

The rear differential and axle assembly for instance is designed to carry ten ton loads at high speed over rough roads for a million miles while transmitting up to five hundred horsepower or even more to the rear wheelseven at first gear speeds-the torque loads are enormous but they seldom fail.It converts rotary motion at a right angle to boot!It already has a built in brake system ,and a steel wheel that bolts right onto it would make an admirable hub for the airfoils with some modification.

The drive shafts on such trucks can be coupled end to end easily to get power from the top of the tower to the ground level.

The gears and bearings in these truck components are very efficient-this is not an area that relates to repairs and maintainence directly so I could be wrong but I'm thinking that power losses are less than two percent in modern truck transmissions and another two percent in the rear differential gears.

My guess is that a windmill built fron such salvaged truck parts would last for generations-considering the light loadsand low operating speed- as long as the operator makes sure the lubricants don't leak out.

Furthermore the frame rails are already jioned in a ladder layout-the frames from four trucks would suffice for the tower of a square mill tower up to forty eight feet(the length of the longest truck trailers that are very common) high with two rails in each wall. Such a tower would be very easy to build in comparision to a masonry or wooden tower, and extending its hieght to eighty eight feet would not be that hard.

Getting any higher could be quite a job without a big crane but it could be done with sufficient man power and time.

oldfarmermac -

Your post is truly a coincidence!

I happened to have missed the series 'Jericho' when it was on TV several years ago, so I borrowed the DVDs of the first season from our public library. The series is about a small remote Kansas town trying to cope with the chaos resulting from several nuclear blasts wiping out about a dozen major cities (so far, it's unclear who did it, possibly an inside job).

In the episode I was watching last night, the townspeople were running out of fuel for their emergency generators, and they decided to try to build some wind turbines. They were scrounging for parts and trying to figure out a way to make moderate size wind turbines. After watching the show I sat down to try to figure out a way of making wind turbines literally out of junk.

Then the exact same idea dawned on me: why not take a truck rear end, situate its axis horizontally, attach a homemade blade to the steel wheel rim, and then transmit power vertically through the downward pointing drive shaft. If you want to get some additional increase in rotational speed, you could even leave the (manual) transmission attached, so that when it's in first gear (and with say a about a 3.00 axle ratio) you'd have something like an 11:1 overall speed ratio, which would be good for turning a generator or alternator. These could also be gotten from junk. You could rig up, via an arrangement of fan belts, several alternators in parallel, which would give a decent current, albeit only at 12 volts. If you want more voltage, you could perhaps scrounge a transformer from somewhere. Crude, at least you'd have some juice for vital functions, such as running a clinic.

The blades could either be welded up out of scrap sheet steel using a template to give the proper twist, or alternatively, they could be fashioned out of wood, just like the old airplane propellers.

I'm not sure how long such a homemade windmill would last, but it would be a fun project that would demonstrate what can be done in a pinch if one exercises some imagination and resourcefulness.

Got an old truck you'd like to donate?

How about some of those "clunkers"? Aren't SUV's officially trucks?

18-wheelers usually have 24 volt alternators. There are ways to convert auto alternators to produce higher voltages.

The problem with using the differential with a drive shaft hanging below it is that the lubricant will easily flow out of the end seals. Differentials are made with the idea that most of the oil will lay in a pool in the bottom of the case which allows for a lower resistance seal to be used. Seals which would prevent leakage would increase friction and lower efficiency.

Of course the main piece you need is simply a hefty load-bearing bearing for your rotor, maybe a second one for Yaw.. and so a great many of these ( http://www.otherpower.com/trips1.html ) have been built using merely a wheel bearing from a passenger car.. Volvos in this case.

I have read articles about taking an ordinary ac motor and a 200 mgd capacitor and a method to start a magnetic field, either fixed or coils, and turning that into a simple generator. Never tried it but seen it working.

Also. Alternators produce ac current at a higher voltage. The voltage in a car or truck is 12 volts dc but that is because of the voltage regulating system.

Sorry, don't know where you are in the world, but in the US, all 18 wheelers are 12 volt. Back in the 60's there were some "start on 24-run on 12" systems, but they went away pretty quickly after alot of battery blowup explosions when joe sixpack tried to jump start in cold weather. Good idea, bad execution....so to speak.

And while I'm at it, you need to put the torque to a rear drive unit thru the pinion gear (driveshaft end), in the correct direction, otherwise it will want to walk over the ring gear due to the way they are cut. They are built to go well over a million miles today, but designed to take torque in one direction for max wear. Arvin Meritor makes the vast majority of class 8 stuff in this country. Check out their site for more info than you will ever want.

www.arvinmeritor.com

If it gets to the point in this country that you, or anyone else is using truck parts for windmills, drivetrain lash will be the least of your worries....hahahahahahah.

nukendukem -

Well, you obviously know your truck axles and truck electrical systems!

I didn't think of the differential lube oozing out due to a vertical configuration, but I suspect that there is a way around it (even if it means having someone collecting the leaking lube and pouring it back it.) Hey, during hard times one does stuff like this. One does what one can to keep things running.

Still, I think you must admit that a horizontally placed truck axle has great potential for being the drive mechanism for a crude home-built wind turbine. (?)

One other nice thing is that if you leave the brake lines in place, along with the master cylinder and some semblance of a brake pedal, you could slow down or completely stop the blades from turning during periods of excessively high winds, thereby preventing the blades from self-destructing.

When I'm on this subject, I look to the Cubans for inspiration. Since the early 1960s then have managed to keep their vintage American cars up and running (more or less) through sheer will, ingenuity, and persistence.

The leaks can be easily(in relation to the overall job) dealt with without serious power losses.

Small windmills could probably be used to drive a bank of 24 volt alternators to good effect but larger ones will be used to drive much larger generators or to drive pumps or grinding mills or other machines that can be driven directly.

Joule,

Not a big one.

I am very interested in windmills as a part of the overall energy picture but even though I live in the mountians the wind resource on our property is close to zero-we are in a sort of cup on a lower slope so I have never considered building one.

But if I am still able to get around when my family duties are over I may invite a few people to come visit who are interested in such things-I have a good shop and considerable mechanical expertise.

Or maybe I can load up my tools and hit the road and go someplace where people are building waterwheels and windmills and solar collectors.

Joule/oldfarmermack

You hit the nail on the head.Truck back axles are built to take up to 20,000 flbs torque and 500hp and never realy fail. Remember any 3 phase motor will also work as a generator when driven. The amount of perfectly good gearing bearings that get dumped is criminal. The materials will be avalible for a lot of years all that will be needed is forward thinking people Otherwise known as Bodgers to make use of all the scrap. The results may not look the best but it will work.

Even a single-phase induction motor can supply electric power when driven over synchronous speed. This can be done without complex equipment.

Here is an account of building and running an induction generator.

Here is an induction-generator controller using a dump load to manage excess power.

The biggest issue with using a scheme like this to run a factory is going to be managing the load to match the power supply, or vice versa. Having either a secondary load (or set of loads) which can be varied with the wind and changing power demand or a secondary generator (ditto) will be a huge help in a system like this.

The rear-axle trick has been around for a long time; it was referred to in "The Handbook of Homemade Power" in the 70's IIRC, which is a collection of stuff from "Mother Earth News" even earlier. Leaking lube is an issue, and one suggestion is to point the drive shaft UP. Putting a generator up on the tower is much simpler mechanically than running long shafts; there is a reason that the fractional-horsepower motor revolutionized industrial machinery.

Edit: it might be feasible to use storage batteries as an energy buffer for an AC system. I would not be surprised if common electronics, such as lamp dimmers, could be adapted into polyphase inverters to prop up the power of an AC system when generation sagged; simple rectifiers would suffice to dump excess power to the batteries when there was a surplus, although SCRs would also allow some control of power factor.

I was thinking on a small homestead scale farm a mobile windmill of a few hp with a PTO type shaft mounted on a wagon frame may be useful. When the winds blow you move it around to maybe a dragsaw, a grain mill or thresher, haybaler, wood shop or water pump.

My add-on to this has been the idea of over-building part of the tower to support a number of sliding weights on winch or chain assemblies, so that I can carry some stored energy that way. Put your shop tools in a shed right nearby (with a very sturdy roof!), and you engage your tools through the weights, not the windmill.

I devised a continuous-loop system that would allow the wind to be lifting weights independent of a user extracting energy from them descending. (On Paper, anyway)

Another variation, a bit more outrageous would be to tow a tracked vehicle up a hill with a similar winch/release system.. could be a couple spare funicular TrainCars on conveniently abandoned Tracks, or an old Ambulance, OilTruck or Schoolbus with wheelguides, ruts, etc.. Only do this if you KNOW you can make your kids listen to your explicit orders.

Wow, look at those prices climb! Are we going over a waterfall - and me with no barrel?

Something I've ciphered over is using the energy stored in hoisted weights to run a window fan at night. Haven't come up with anything I would consider practical though.

If you got several sturdy youngsters, a treadwheel crane may be useful for hoisting weights.

barret -- ages ago when I was doing field work in Mexico I saw such a contraption used to power a small fan. I can't recall much detail but it was essentially powered by some metal (lead?) plates. This Indian farmer would lift the plates (6 or 7?) one at a time and hang it on some kind of bracket arrangement. The weights dropped very slowly (maybe over a couple of hours). Had some sort of pulley arrangement such that a small vertical drop of the weight equated to a high rmp at the fan. This was in a dirt floor hut with no electricity. They let us sit inside to avoid a very rare rain shower. I'm sure one of mechanical types at TOD can offer a design.

Multiply the mass in kg by ten by the number of meters you lift it, then divide by 3600 to get the number of watt-hours you get. If you are running a fan, the device can be made self-regulating by sizing your pulley and fan blades to match your weight or using a block and tackle, although that would hurt efficiency. Note that lifting 1000 kg 10 meters only yields 27 watt hours of storage, and in practice more like 20 watt hours because of inefficiencies in the equipment needed to do that.

Although the round trip efficiency of lifting a mass even with basic equipment is probably the highest round trip efficiency possible with only low-tech parts, a more practical application would be pumped storage using a windmill to pump water uphill. That has a low round trip efficiency but has much better storage potential (assuming you have a hill and a pool to store water in) than lifting a mass on pulleys.

I am not saying it can't be done, but energy storage schemes involving lifting weights other than water (and that assumes you have a suitable pump and a suitable waterwheel or turbine) are limited to small applications like small fan. To use a favorite phrase on this site: Can it scale? Not without late 19th-early 20th century technology.

The KE stored by pumping water uphill is the same as you get from solid weights and requires an appropriate reservoir. Additionally there are leakage and evaporation losses from pumped hydro.

With the right gearing you could do a staged weight setup which could be built in locations without appropriate reservoirs for pumped hydro. This sort of system can use the heaviest weights the local tech can deal with, and scaling is done by simply adding another weight to the chain. The tricky part is setting up a coupling+brake system that only allows one weight to be engaged with the system at a time.

I suspect that an appropriate design exists for use in mechanical-gravity drive clocks, the tricky part is scaling it to a useful power capacity for light industrial applications.

as added trick I have often wondered about having a large floating 'island' mounted on hydraulically plumbed pilings. The hydraulic flow would power generator/s on the 'island' as it went up and down when the water level changed. I more envisioned this as tidal thing. I just see so many issues in the seal system on the piling plumbing. But if you are talking big offshore islands, that could support wind farms and desalinization plants (some ERoEI issues there)... Actually what I first envisioned was some way to capture the tidal energy that moves boat docks up and down, but it is such a messy environment. Now that I think about it a mechanical drive with a gear turning as it tracked up and down the pilings might be something that could be worked out. Space on a already crowded dock would be an issue but more flotation allows more resistance to be overcome thus a bigger generator to run.

Consider the 'Island' being a retired SuperTanker or Three..

Then, you can use various energy forms, Solar, Wind, Wave and Tide, and even the rocking of the boat as dispersed sources with which to pump water OUT of the Tanks, while Turbines are running with INrushing water. The mass of the boat VS bouancy is the actual storage medium.

The supertankers will be corroded and sinking within 20 years.

The marine environment is much less forgiving than many who have not spent time around it imagine, that is for sure. Any idea how much energy could be harnessed by floating docks (supply and a range of masses that seems reasonable to you) that have an average up and down movement of ten feet per tide? Lots small of ports and habors with that much tide in some regions.

Maybe 20 years would still be a profitable stretch to Run that Hull into the ground.. if the fittings needed on the ship itself weren't too involved.. There are a lot of them out there.

Gotta love the engineers who just say why things won't work.

This kind of ideas tend to give me a headache.

I can see the big island idea causing headaches, the covered hydro reservoir maybe, but trying to get some juice out of floating docks where the tide manages at least a ten feet up and down average does not seem that far fetched to me. The pilings are there, the tides are more or less constant (within a range), the mass and flotation can be adjusted and the power is needed at the port--often smaller ones are not all that handy to the grid. Again marine environments are hostile, so this isn't something that could be plopped on a dock and expected to work, but we build a lot of floating docks around the world all the time, the idea seems at least worth invesitgating.

Oops didn't follow the thread right, you weren't replying to me.

Instead of lifting a fixed weight some places pump water up into a resevoir for storage. Then let is flow back down, through the pump and convert the energy back into a usable state.

Yes, that is a very valid question. We need [fossil] energy to build up alternative energy systems. But we are now gobbling up the last easy oil for convenience purposes.

Still, we'll have little choice. The global warming awareness in Australia seems to be higher than in the US. We just had these articles on sea level rises:

High tide for housing

http://www.smh.com.au/environment/high-tide-for-housing-20091018-h2xz.html

Make evacuation plans

http://www.smh.com.au/environment/make-evacuation-plans-20091026-hgpe.html

Go on my web site www.crudeoilpeak.com and use the external links on sea level rises. At the same time you can read about my reminder on OPEC's overstated oil reserves. My worst case scenario is that by the time the world has really understood what global warming means and goes massively into renewable energy projects, everything will get stuck in diesel shortages. I already talked 3 times with the Australian Climate Change Minister Penny Wong about it, but our politicians just don't get it. Possibly never did Physics 1A at Uni to appreciate what energy is.

Would the mass-production of wind-farms (not cars) be the only good and justifiable reason to print money?

"Yes, that is a very valid question. We need [fossil] energy to build up alternative energy systems. But we are now gobbling up the last easy oil for convenience purposes."

Most of the European wind and water mills described in the article were designed and build before industrialization therefore fossil fuels will not be nessesary for future construction. As long as we have raw materials and competent builders they can be rebuilt.

Grautr,

Agreed-Actually building them now will be a lot easier-except perhaps for some lost skills.There will be a lot of new modern materials that can be incorporated even in a mostly collapsed economy.

Some of these materials will be as commonplace as standardized nuts and bolts,dimensioned lumber, and better cement.

And it will be a long long time before fuel is so scarce that an excavator can't be used to dig the foundations , etc.There will be lots of heavy machines in running order too if bau collapses-a bulldozer kept in a shed will run just fine after being properly stored for many years-you might have to repair a few leaks is about the only real problem.Maybe put the acid back in the batteries and recharge them.

Really High value jobs will be done with machinery-at least the ones that can't be done by hand- for four or five decades at least after tshtf unless a war wipes out the oil industry beyond the point of getting it restarted.

You have no idea about the magnitude of the job to replace all of our coal fired power plants, our much higher population, the standard of living to be defended and the fights about dwindling oil supplies.

Actually with the $180 billion spent on AIG to save Wallstreets bonuses, one could have financed 600 Oerlikon highly automated thinfilm photovoltaic factories, which produce 96 GW per year. So in only 4 years these photovoltaic factories have produced more capacity than all the coal power capacity in the US combined.

http://www.oerlikon.com/ecomaXL/index.php?site=SOLAR_EN_press_releases_d...

By the way, the photovoltaic factories in Germany pay more taxes than what they indirectly receive in feed-in tariffs - not to mention that they reduced the German unemployment rate (granted that unemployed people are not quite as costly as banksters but they DO cost).

http://lohnsteuer-kompakt.de/redaktion/steuereinnahmen-der-solarindustri...

Unfortunately, building thin-film PV plants requires real physical assets such as sophisticated equipment. Bailing out the banksters just needed some numbers in a computer (which is all that fiat currencies are these days).

Unfortunately, building thin-film PV plants requires real physical assets such as sophisticated equipment.

Fortunately, these companies accept cash.

Unfortunately, these companies had to lay off many thousands of people willing to produce that sophisticated equipment but weren't as fortunate as the bankers.

Actually they wouldn't have to lay off all these people if they just had access to cheap credit from the national bank as the banks did, but unfortunately they did not and suffered from the fact that the banks increased the interest rates of the credits they were given before the recession hit, because their stock price dropped and subsequently were forced to come up with drastic measures to please the banks.

http://www.neurope.eu/articles/Oerlikon-CEO-gets-the-boot--with-2500-oth...

And unfortunately the unemployed also have to be paid for by us and not the bankers.

But what would we do without world-economy harming derivative-bankers?

After all, they developed democracy and the rule of law.

After all, they developed medicine and health care.

After all, they developed modern agriculture.

After all, they created all the literature, music and film.

After all, they developed clean water distribution.

After all, they developed any means for transportation including ships, trains, cars, aircraft's, bridges and tunnels.

After all, they developed electricity and artificial lighting.

After all, they developed the telephone, radio, TV, computer, satellites and the internet.

After all, they developed efficiency and renewable energy.

After all, they freed the world from the Nazis and got rid off all evil-doers singlehandedly.

And of course, it was the derivate-bankers who were the first on the moon.

And that's why they deserve record bonuses even when they generate record losses.

We agree on this. Before the first bailout I wrote Bush and my Congressmen that I would not vote for anybody who voted for the bailout. If everybody sent such a note we would be better off.

Of course I probably would not have voted for them anyhow, so it was a bit of an empty threat.

Matt ,I don't expect enough small to medium windmills to be built to replace more than a small fraction of our current energy use-probably such mills will not approach five or ten percent of our cureent electricity output even after several decades-but otoh, every kwh that comes out of them will most likely be put to a very high value use-I don't think any juice will be wasted on big flashy signs at convenience stores or lighting up empty buildings for a couple of janitors.

But I do believe that it is still possible - but not at all LIKELY- for us to make the transition to renewables and nukes.

All that is lacking is the committment.It would be very hard- but not nearly as hard as facing the consequences of failing to do it.

We are not supposed to be able to afford a hundred billion for a hvdc grid?Bullshit!That is about four hundred dollars per person -one time!We could afford that easily out of our fast food habit or our beer habit or our cosmetics and flashy clothes habit.

And I don't think it would take very long to recover our money as a result of the savings in buyimg coal to burn for juice-coal is getting expensive too.

It's not just the AVIODED coal PURCHASE money we would save-a major reduction in the use of coal would depress the price of coal across the board. There is no need to even consider the envoronmental savings -except as a bonus.

It will happen if we get a Pearl Harbor scale wake up call and we are lucky enough to avoid WWIII.

We spent somewhere in the nieghborhood of five billion dollars to supply coal to our electric utilities last year-not to mention all the stranded environmental costs associated with mining and burning it.

My personal wag is that we could save at least two billion a year in direct expenses by getting a robust wind system in place nationally.If that could be financed and leveraged at five percent we would have enough money to put in a serviceable super grid-or at least the skeleton of one.

Of course given the political realities we must first experience some sort of knocked on our butts mugging by an energy crisis before we will act-at that point operating under emergency decrees the problems involved in routing the lines and other political considerations will be solved in a hurry.

Incidentally the major coal players seem to believe that coal prices are going to go up quite a bit over the next few years.

Would the mass-production of wind-farms (not cars) be the only good and justifiable reason to print money?

It would be, but unfortunately the wind turbine production rate in the US has gone down by 38% while money is being printed to increase Wall Streets bonuses. (Ironically more wind turbines were added during the Bush administration than during the Obama administration which is supposedly all about renewable energy and job creation.)

AWEA reported that wind turbine manufacturing still lags below 2008 levels, in both production and new announcements.

Bankers bonuses are more important than sustainable jobs and energy independence.

Politicians (in particular) don't [i]want[/i] to fix 'the problem'. By fixing it, they remove the need for their job description.

Maybe I'm just being cynical today...

This is a really great article. It does TOD proud.

What I find fascinating is the link between energy and economic output in a society.

In this case technical mastery "know how" combined with geographical serendipity (good wind and water conditions) leads to economic prosperity - in the Netherlands.

There is a new book out that looks at the Industrial Revolution in England - why did it blossom in England when many other countries had the necessary preconditions - financial system, legal system, technical expertise, good labor force etc. and the suggestion is - England had abundant and cheap coal. More so than any other country in 1800. England was a significant energy exporter.

And England dominated the 19th century economically.

The analogy I make is to the US in 1900. The US had abundant and cheap oil. The US was a significant oil exporter in 1900, and had a good run for the next 100 years.

So where does that leave us in 2010?

The British Industrial Revolution in Global Perspective (New Approaches to Economic and Social History) (Hardcover)2009 Robert C Allen

Kris told me he is a regular Oil Drum reader. Hopefully, he will be able to make some comments today.

Oil has a few more years, as does coal. Wind and Geothermal and Biomass and Solar will all play a part.

I think that France with nuclear power plants and electric rail and trolleys might be the better place to survive the next few years.

Actually, almost 90% of the French energy consumption is not provided by nuclear power according to the International Atomic Energy Agency:

French energy consumption: 54'785.84 kWh/capita

http://www.iaea.org/inisnkm/nkm/aws/eedrb/data/FR-encc.html

French electricity consumption: 7'366.00 kWh/capita

http://www.iaea.org/inisnkm/nkm/aws/eedrb/data/FR-elcc.html

French nuclear electricity consumption: 5745 kWh/capita (78% nuclear power):

http://www.iaea.org/inisnkm/nkm/aws/eedrb/data/FR-elpn.html

The first number is gross thermal energy, so you should compare with thermal reactor power, a factor of three higher, so 30% nuclear overall.

More importantly, most fossil applications can be converted to electric power and factory mass produced nuclear plants can be built as needed.

Besides that oil, coal and gas heaters and hot water boilers have close to 100% and not just 30% efficiency.

And besides that uranium powered heaters, air-crafts, commercial ships, trucks and cars are not commercially available, that's irrelevant.

Fact is that France still depends heavily on foreign oil and foreign gas even if you ignore the fact that their uranium also needs to be imported.

The American manufacturing experience — which used more waterpower more than coal until 1870 — suggests that the Industrial Revolution was actually finance-led. The social preceded the geological or technical. I don't deny that energy plays a big role in development, but it's not the only lever, even if it is the one I'm most interested in.

The U.S. was so anomalous in so many respects after the Civil War, that it's hard to chalk it all up to the presence of abundant oil. We were bigger — amount of land, number of people, size of corporations — than any single European country, but we inherited their economic institutions and goals.

Scale is what makes China scary for Americans, regardless of their energy resources/desires.

Thanks for that excellent in depth paper. I was aware that Dutch engineers had drained the lowlands and areas of England (Fens and Isle of Dogs) using windmills but had no idea of the full scope of other uses they had.

I'm looking fowards to the forthcomming articles.

Thanks for the intersting history of the windmills, they are impressive engineering structures.

I am a little skeptical of your final conclusions though. I would be surprised if it were ever more efficient to build a large windmill rather than a small modern wind turbine with a generator and wire going to an induction motor to drive your factory machinery. Especially if as suggested at the end a backup electrical motor is required anyway. The thick tower you need to transmit the kinetic energy introduces shadowing, drag and probably turbulance into the equation and the many mechanical linkages will have losses which will reduce efficiency.

having the wind turbine produce electricity also allows us the flexibility to move our factory equipment around as we feel like it, as we just need a longer wire. The mechanical linkages will also require maintenance and eventually replacement, this will always be the case but if the machinery is housed elsewhere it's easier to get at and maintain. It would also be easier to decouple the link between the turbine and the equipment for maintenance (i.e. just unplug the motor), and you can still sell excess electricity produced to the grid while the machinery's out of action.

Brilliant article, and a welcome alternative to only high tech answers.

While a modern turbine may be more efficient, direct mechanical power like this could be reproduced with much much less embodied energy, exotic materials and little if any fossil fuels.

I think that's the main selling point here, is high tech eco technology really a sustainable option if it's continuing to rely on high energy extraction of materials from around the world?

I think there's room for both, having lived in Holland, i can say these are really beautiful machines - though a lot of them are just houses now..

I think that converting the wind's KE directly into useful work is not really worth it; you would get higher efficiencies in most cases using a motor/generator pair.

Which cases would you say would be most promising for this kind of direct use of the KE? I would have thought that the loss of energy in each conversion (KE > EE > KE) would reduce the efficiency considerably. But this is not my area of expertise by a long shot.

Sometimes (and in the times to come, I fear).. there are MANY other considerations besides simply efficiency. Availability of motor/generator materials comes to mind, and also the use of wind in simple systems like water-pumping which are likely cheaper to make and possibly less-prone to being scrapped for precious parts.

It's not an Either/Or proposition anyway, just reminding us that there are many ways to apply the power in the wind. It's easy to get Homogenized into expecting electricity out of the deal. Windpower for direct ventilation, for simple mechanical processes can make a very handy backup, and would in all likelihood be working in ADDITION to Electric Wind Turbines.

The best uses for the KE straight from the wind would be grinding grain or operating machine tools. Although you won't get a CNC machine working after TSHTF, a smaller one that uses screws (not the chain drive or rack and pinion type) could be converted to a manual mill just by taking off the stepper motors and attaching cranks to them, assuming you can run the spindle via a PTO. Tool wear would be the biggest issue, but if you have good tools and primarily use them to mill wood, a lathe or a mill could turn out some very nice wooden components for things and the tools will not wear that fast.

Electric motors are very reliable, they will be around for a long time after TSHTF and they can be recycled into new electric motors with some care and the ability to re-insulate the wires. Efficiency and performance will not be as high as a factory-wound motor, but it can be done. Unless every single book on the subject is burnt for warmth and every electrical engineer (or in developing countries, motor repair person) dies. They do this (completely strip down and rebuild) old electrical motors in most of the world already, BTW. It's a cottage industry, although I imagine they have slaves doing it in China in a factory somewhere.

Jokuhl has it right though, it would be foolish to expect only KE from the wind or only electricity from the wind.

Actually most wind turbine's today use a DFIG, a fancy form of induction machine (although this probably won't be allowed for much longer for grid reliability reasons). We've had these for about 100 years now and they do not require anything much fancier than iron and copper wire. It is a myth that rare-earth PM synchronous generators are in wide use yet in wind turbines.

The advantages of electricity over direct mechanical power were so overwhelming that factories were some of the first users of electric motors. The labor savings and efficiency of converting to electricity were enormous, sometimes causing a ten fold increase in output per worker hour. A good example is the Ball glass plant described in "Electrifying America: Social Meanings of a New Technology"

http://www.amazon.com/Electrifying-America-Meanings-Technology-1880-1940...

Factory electrification took place mostly between 1900 and 1920.

Electricity can be efficiently generated without rare earth elements used in magnets of generators, and I cannot think of any limiting factors to wind power (other than intermittency) except the availability of good locations. Also, the rare earth element industry suffers from lack of capital investment rather than a shortage of ores. One US REE mine is in the process of reopening and another deposit remains undeveloped.

Electromagnets were used in generators and motors before high tech permanent magnets. Many if not most generators still use electromagnets and almost all motors use them also. Permanent magnet motors are more efficient in certain applications, like small motors. I assume permanent magnet motors are smaller and lightweight compared to elcetromagnets motors.

Mediocre productivity may be better than outstanding productivity.

Hang on there having lived in a Woolen Mill that was water powered and toured the mill museums.

The biggest problem was the belts they only had leather back then and you had a lot of losses in the belt drives.

Plus the belts themselves where very dangerous with numerous accidents. Not that I think they cared much for the worker at the time but having your best friend git his/her arm ripped off tends to cause problems with productivity.

Also of course location location location. With water power there are only a few viable sites for factories electricity of course meant the factory could be placed anywhere. In New England at least the best sites for hydro power had been developed for a long time even as technology improved so these where not towns which meant expensive land if you expanded.

Electricity from the grid solved these problems.

Now as far as electricity vs mechanical power drives I'd argue thats debatable each has its strengths and weaknesses.

And of course my favorite air motors where not really used until after electricity was well entrenched so they never really got a chance to compete on a level playing field. Although air power is widespread in factories.

For the most part air motors are actually smaller and more robust than electrical motors. And modern toothed belts that don't have the play of old leather belts can be enclosed in safety covers.

The one disadvantage that cannot be overcome readily is of course location your going to have certain places suitable for the mechanical solutions. However if your talking about a society that has moved to limit its need for manufactured parts then the demand could easily be low enough to be met with existing locations amendable to mechanical solutions. When not if our population decreases the location issue will become less and less of a problem.

Having worked with both machanical and electrical drives I can tell you that electrical has overwhelming advantages over mechanical, a few being:

Push button start and stop

Simpler variable speed control

Automation

Factory layout independent of lineshaft location

Safety

Low maintenance