Carbonates, Chalk and Oilfield Subsidence

Posted by Heading Out on October 11, 2009 - 10:33am

This is a part of the continuing series of technical talks that I post on Sundays, and which can be found by clicking on the tech talk link at the top of the main page. Gradually these are getting a little more technical, so I would suggest if you are new to these that you start at the beginning and work your way up.

Having recently written about sandstones and permeability, and then about water flooding, I want to go on, this time to talk about carbonate rocks, as the general topic and secondary porosity, with some comments at the end on formations in chalk and the problems that this can bring to places such as Ekofisk. (Added for clarity - when I talk about carbonates I mean calcium carbonate and the related rocks such as limestone, chalk and dolomite, to name but three.) I again want to emphasize that, life being what it is, the true situation is often a bit more complex than I describe in this simplistic overview, and that I am very grateful when folk give more specific information about some of their experiences in the field.

When I wrote about sandstones, I mentioned that (as a general rule) carbonates are different to the conditions found with sandstone. For a start the rock itself is much finer grained than a typical sandstone. Even if there were oil in the body of the rock it would be more difficult to get out. Most of the oil is found in what is called secondary porosity. This is the network of fractures and bedding planes that are formed in the rock as it is compressed and moved after it has first been formed. The rock is largely limestone, though it may also be dolomite or related rocks. The rock is usually not a massive, solid rock (such as you might want to build a house or cathedral with).

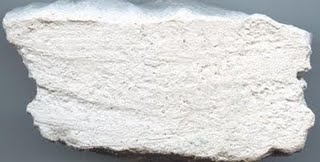

Rather oil will collect where there are spaces in the rock. These can be where there was a coral reef, or a lot of change in rock structure. You can see that sort of thing in some new road cuts

such as this one.

It is easier to explain some of the problems of getting the oil out, if one looks at a road cut that has weathered a bit

You can see how the passage of water has opened the joints and dissolved small holes (or vugs) in the rock. These provide the spaces in the rock into which the oil can move and collect and be trapped. Perhaps it might be easier if I used a simpler sketch of a section through the rock to make the next point.

With the oil painted green, as it fills one crack system, but not them all, the well is just a little bit too far to the left to tap into the major fissure system and get all the oil. If only we could reach out a few feet and hit those cracks! And we can and do.

This is part of the reason that we send down the small explosive shaped charges that not only penetrate through the well case and the concrete, but also extend a hole out into the rock. By driving these perforations out into the crack system in the rock a path can be created from the oil-filled cracks to the well. Those cracks can also be cleaned up a bit (since they often have very small particles of carbonate filling them in the zone around the well) by having an acid pumped down into the completion zone. This acid will also open up some of the finer fissures in the rock so that a free path will develop from the well to the oil-filled cracks.

And so we can begin to produce oil. However after a while, for one of several reasons, the flow from the well will begin to decline. I mentioned last time that the underlying reason will be that the pressure in the reservoir will drop as the oil is withdrawn. But there are other reasons.

If the oil is removed too quickly we can generate, before we need to, a gas cap in the well. Fine rock can be carried through the cracks towards the well, and block the passages. Some of the oil contents, such as the waxes, can settle out of the oil, and fill the holes in the well casing. As the oil flows to the well, underlying water can follow it and cut-off blocks of oil in the rock. And the pressure difference between the oil further away from the well, and the well itself might not be enough to move that more distant oil towards the well. (Are you really sure you want to make this investment?)

Before I leave Carbonates let me go back to the other kind, where there is a reasonable amount of primary porosity, and where the oil is spread through the rock. This can happen when, for example, the rock is a chalk (another form of calcium carbonate or limestone).

Chalk poses some different problems in production. Let me illustrate them with an abbreviated history of the Ekofisk field. The field was found in 1969, and started production in 1971. It produced from a fractured chalk that has “high porosity but low permeability.” When it was originally produced the driving force to move the oil to the wells was through pressure depletion of the oil, and in this way they were able to recover between 17 and 18% of the oil in place. In the process, however, there was a relatively unexpected problem.

To explain it let me make a very, very simple illustrative example.

Now in the original condition the pressure of the oil in the pores (holes) in the rock above is equal to a significant portion of the pressure of the overlying rock. At Ekofisk the pore pressure was 7,135 psia at a depth of 10,400 ft. Porosity can be as high as 48%.

But as the oil is drawn off through the well that pressure reduces, and the load transfers to the rock columns that are one either side of the circular pores. (The well pressure was reduced to below 5,000 psi). When the load on these columns becomes higher than the strength of the rock then the pillars will collapse. This helps a little to squeeze some of the oil out, but it also (when it happens over a large enough volume) compresses the entire volume of the rock holding the oil. This can close some of the passage ways to the well (permeability), and make it harder to get the oil out, though that does not appear to have happened. But it also lowers the sea bed, on which some of the recovery oil platforms were standing. That subsidence has been up to 30 ft in places. (The platforms were elevated in 1987) but new platforms were ultimately required that would allow a subsidence of up to 66 ft. (20 meters).

In order to stop the collapse, and also to increase the flow of oil to the wells, a program using water injection at pressure was started in 1987, by injecting 820,000 barrels of water a day, it was anticipated that the field would allow the recovery of about 36% of the oil, and provide an additional 300 million barrels of oil. Current estimates are that it will increase overall recovery to 50% of the oil in place.

There are, however, now some concerns about the dissolution of some of the chalk by the water that is being used for the injection, weakening it further. One of the problems in analysis, as it turns out, has been in disregarding the temperatures at which the extraction is occurring. (For those who go to the reference the exchange rate is roughly 5 kr to the dollar.)

From which you will see that there is still lots to talk about. But, as before, if I have glossed over stuff, just ask a question and I (or others who contribute) will be glad to give an answer.

"a program using water injection at pressure was started in 1987, by injecting 820,000 barrels of water a day, it was anticipated that the field would allow the recovery of about 36% of the oil, and provide an additional 300 million barrels of oil."

I presume this is seawater, not fresh water. I don't know anything about offshore drilling. The water in itself dissolves the chalk, but do the other substances in the seawater cause chemical reactions?

The reference that I used for the comment on "weakening it further" goes to a University of Stavanger site where they are studying the problems.

If I recall seawater injection on the North Slope introduced enough micro organisms into the system to eventually cause significant corrosion problems in oil delivery network. Is this a regular headache the industry has to deal with?

Hello HO,

Thxs so much for this Tech series. If any TOD newbies are now 'mentally permeable' to sink their teeth well into a more advanced discussion, I recommend the Joe Voelker 540-page PDF Motherlode on Ghawar, plus reading the outstanding TOD keyposts and comments back in 2007. Recall that Stuart Staniford presented his results at a prior ASPO Conference. You can't go wrong by reading Simmons' book either [or re-reading it for a refresher].

http://pangea.stanford.edu/~jcaers/theses/thesisJoeVoelker.pdf

-----------------------

A RESERVOIR CHARACTERIZATION OF ARAB-D SUPER-K AS A DISCRETE FRACTURE NETWORK FLOW SYSTEM, GHAWAR FIELD, SAUDI ARABIA

-----------------------

This TOD-link has many embedded links to help further any newbie research projects:

http://www.theoildrum.com/node/2462

-----------------------

GHAWAR: an estimate of remaining oil reserves and production decline (Part 1 - background and methodology)

Posted by Euan Mearns on April 25, 2007 - 6:50pm

----------------------

Bob Shaw in Phx,Az Are Humans Smarter than Yeast?

Here's a page about Man-made Subsidence, one example being that caused by the Wilmington field in LA. This pdf, published ca. 1965, is more detailed: A LINEAR RELATIONSHIP BETWEEN LIQUID PRODUCTION AND. OILFIELD SUiBSIDENCE. Analysis of various LA and Venezuelan fields. Also this pdf: Symposium on Land Subsidence. Hmm, two of the strata in Wilmington were named "Union Pacific" and "Ford." The damage caused by the subsidence was more than offset by the petroleum revenue. Mushy siltstones did the job here instead of chalk, sediments on top are post-Pleistocene. ROCK told us about the rapid deposition in the GOM creating a shallower pressure gradient, thus BP drilling 35k feet down for oil in Tiber; I wonder if that applies to the LA basin too.

How common is it for subsidence to cause problems with roads , water and sewer lines, houses ,etc?

There are several different types of subsidence. Those that are man-made and those that are natural. In areas of the world where the rock can be dissolved by water underground caves can form along underground water passages. These can, over time, grow large enough to work their way up to the surface, where suddenly, one morning, you go outside the house and there is a hole that may be 60-ft deep or more. (These are generally restricted to depths of about 100 ft).

Then there is the deliberate subsidence caused when a mine uses a longwall method to extract the coal. If done correctly it may leave little damage to the surface, but occurs as the coal is mined. Sometimes that can be put to good effect. The town of Duisburg in Germany had the mine extract coal from under the harbor to lower it 2 meters so that the quays, which had become too high over the Ruhr River (which joins the Rhine there), would be low enough to work again. They lowered an oil farm without the owner knowing. (It is all relative). Sadly it was in the days before the Internet, so though I have the paper I don't have an electronic reference.

Then there is the unplanned subsidence which can occur at unexpected times.

This page from the USGS describes a variety of subsidence problems associated various extraction activities: water, oil and gas, coal. The section on Houston provides examples of road flooding, damaged houses, and changes to the coastline. The Long Beach harbor area required construction of levees in order to protect oil/gas wells and harbor facilities.

There are probably a limited number of cases where extraction occurred directly under an urban/suburban area where damage would be more likely to occur.

Dude -- I'm not familiar with the details of the depositional history of the west coast basin but I suspect they haven't been as dramatic as the GOM. But they also contain compressional forces (the "big" lateral fault systems) we don't have down here. Predicting pressure gradients is generally very site specific. There's an onshore area just a couple of hours from Houston where the pressures at 4000' are greater then those at 34,000' at Tiber. Has to do with the way the rocks are layered there. Quit a shock to the drillers when they started there many decades ago. Even worse it was very difficult to detect those pressure until it was too late so lots of burned rigs and lost hands.

Is the observation of subsidence with the simultaneous observation of linear production a cause or an effect relationship?

just a quick question: Why is nitrogen used for injections into wells? I have heard that it's done, but don't understand the return on investment using nitrogen.

Nitrogen injection compensates for declining well pressure to keep the oil flowing.

Ok, thank you . is it necessary for nitrogen to be injected often? or is it a one time deal?

gee -- Consider Cantarell Field in Mexico. As the oi is produced the pressure goes down...just like slowly letting the air out of a tire. And the lower the air pressure the slower the remaining air comes out until it's so low none of the remaining air will flow out. But it you had a second valve stem that was putting air into the tire as you let it out the other valve you could have a steady flow indefinately. Now imagine the same tire filled with water under pressure. Open the valve and it flows out until the pressure gets to low to flow anymore. But now start pumping in air as you flow the water at a constant non-declining rate. Every thing looks fine and the water appears it will never stop flowing. Until, of course, the injected air (or nitrogen) completely replaces the water. Then, quit suddenly, no more water and a big blow of air. This is apparently why Cantarell has shown such a rapid decline. As the injected nitrogen reaches the producing wells they "gas out" (as opposed to "water out" in a different type of reservoir drive situation) and you suddenly (a few months perhaps) you lose the oil stream. As you now see the injection is a continuous process in such applications.

Man, what a brilliant explanation. i can see clearly now. thanks. i keep hearing these peak oil nay sayers spouting on about enhanced recovery techniques, they make it sound so "shangra la" but they never give you the backside of the story. it's all spin.

on a side note, i would imagine the cost of using nitrogen is very expensive when the decision has to be made to use it.

Thank You!

Rockman

gee -- I've never seen an estimate of the cost to generate the N2. I'm guessing they use NG from the field to power the system so the ops cost might not be huge. But the cost of the initial plant could be huge. The N2 generating plant at Cantarell is the largest in the world.

Not that there haven't been improvements to enhanced oil recovery techniques over the decades but the basic methods have been applied to appropriate reservoirs since the 1950s and earlier. The US is the third largest oil producer in the world. Texas is a big oil producer. The west Texas oil fields are a large percentage of our production. Just a WAG on my part but I would guess more then 90% of those fields have been subjected to EOR operations for more than 40 years and continue to produce under this condition today. Of course, many foreign fields haven't benefited from such efforts. And, unfortunately, the national oil companies that control most of these fields have a rather poor record when it comes to EOR. The only real step change in EOR has been the use of horizontal well bores. But this is a very expensive approach. While it can increase ultimate recovery the typical reason for using such redrills is to increase flow rate and not improve ult recovery. The down side: while increasing flow rates and recovery it obviously also shortens field life. So the concept that EOR will delay or lessen PO's effects isn't that much of a cornucopian life boat IMO.

At what point in the production level does the company decide to use nitrogen to extract the oil? is it a percentage drop in production? and what is that percentage drop?

Air has 21% oxygen. Oil+oxygen+heat= bye bye oil

Rgds

WeekendPeak

Thanks, I think that was the real question, why go to the expense of obtaining nitrogen, air if free? My not so educated guess is that the temps are too low for the oxygen to combine with the hydrocarbons (although the reaction rate probably goes a up at something the pressure squared), for this to be too much of a problem. Of course if you burn some of it, it might begin to resemble THAI. I would think partial combustion equals much higher temperature equals much lower viscosity. Might be good for flow rates?

EOS -- Air (or pue oxygen) injection has been used as an EOR method since the early 1960's. Proper name is in situ combustion. Common name: fire flood. Typically about 10 to 15% of the oil in place is burned. Primary goal is to use the increase volume of combustion gases in the reservoir to increase reservoir pressure. Side benefits are the increased mobility of the heavier oils via temp increases and CO2 solution. Probably one of the most efficient (but most complicated) EOR techniques for such reservoirs. I've pitched the idea to a few operators and they've been too intimidate to give it a try. Injecting non-combustable gases is easier. And you're right about spontaneous combustion. If reservoir temps are below 160 degrees F or so you have to light the fire. Temps above that and it ignites spontaneously. Back in the 90's Amaco injected air into a reservoir anticipating the air cap would push down the NG cap which would, in turn, push the oil out of the down dip well. They didn't take into account the the NG cap also contained a small amount of oil. A 7500' the oxygen spont. combusted with this oil and began an unexpected fire flood. This actually pushed the oil out much faster then they had modeled. One of those situations where the plan was very wrong and worked quit well.