Permeability and Initial Oil Production

Posted by Heading Out on September 27, 2009 - 11:13am

This is part of Heading Out's Sunday tech talk series.

We got oil! We have put together the drill, mounted it on the derrick, circulated mud and drilled a well and used casing to line it, and a Christmas Tree to control it, and we found a layer of rock with the right porosity, and it has oil in it. Hell-lo, Beverly Hills!

Ah, but hold on a moment gentle folk, aren't we forgetting that to get the oil out of the ground, it first has to get to the well. The basics of this aren't particularly complex, but within this topic of oil well production lies a scientific reason that production goes down in an oil field as the field gets older.

I'm going to begin by making a slight correction. Last time while I talked about sandstones and carbonates, I did not explain the second group very well. And because the structure of a carbonate field is often quite different from one that occurs in sandstone, I am going to put the more generic post on production from carbonates off another week. Save only to say that the carbonates are usually limestones (including chalks) and dolomite, and that because these are very fine grained rocks, but easier to dissolve, the oil is more often found in the joints and cracks and dissolved holes in these rocks, than it is evenly spread through the rock. In contrast, with sandstone, the oil is often in the pore spaces that are spread throughout the rock, and so let's assume for now that we've got oil within a sandstone layer.

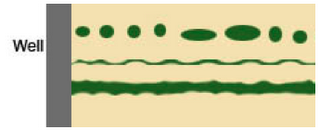

The sketch shows three different layers of oil lying next to a well. In the top case none of the little pockets of oil connects to another, nor do any reach the well. (Like the holes in a swiss cheese they can be large, but are not connected one to another.) If the entire rock were like this, even though it had porosity, and a fair bit of oil, none of it could be extracted, since none of it could flow to the well. Now we can make a path for such oil to get to the well, but this artificial stimulation of the well (through hydrofracing and its variants) is a secondary process that we will also leave until later. What we need is a clear path that connects all the oil that sits between the grains of sand to have a path to the well, similar, perhaps, to that shown by the second layer of green (for oil) in the sketch.

The existence of flow paths in the rock is known as the permeability of the rock. It is a measure of how easy it is for oil to move through the passageways that it finds in the rock. These are the interconnected spaces, and the fractures and breaks that occur in the rock.

The law describing the flow of fluid through rock is known as Darcy's Law. (I’m not actually putting the equation in the post – but it can be found at the citation, together with the terms that go into it.) However, in simple terms it says that the volume of liquid flowing through a rock is going to be a function of the area of the rock through which the flow occurs, multiplied by the pressure difference between the two faces at each end of the flow path, multiplied by a constant which is related to the ease with which the oil can flow through the rock, and divided by the length of the rock path. We’ll assume that the volume that the rock will flow through is a constant (it's the side of the well), so the area over which the flow will take place is also a constant.

When we had reached the rock just above the oil reservoir we had a break while we discussed the difference in pressure between the fluid in the well and the fluid in the rock. At the time we set the well pressure at 3,000 psi and the pore pressure, the pressure of the oil in the rock, at 5,000 psi. The difference in pressures, that 2,000 psi is the driving pressure that will push/pull the oil to move it to the well. This is the pressure drop that exists in the rock from the background pressure to the well. (As the oil flows the pressure along the path that it flows will start to drop.) The hydraulic conductivity is a phrase used to describe the resistance that the rock gives to the oil moving through it. (You might think of it as a reverse friction--in other words the higher the number the less resistance there is to flow.) A wide crack in the rock, with almost smooth sides (the third row above) has a higher conductivity than the second where the gap is narrower and more tortuous. And let us just say for now that the length is the distance from the well to the point that the oil pressure is equal to the original pressure when the drill reached the rock. (We call that the original pore pressure.)

Now you might think that with the original 2,000 psi difference, that I used above, between the pore pressure and the well pressure that the oil would really gush from the well. And yes it might - but we don't want that and so we tighten the choke to reduce the difference in pressure between the well and the pore pressure, and the flow slows down.

However, as the flow of oil starts to move towards the well, it does not flow evenly through the rock. Think of watching rain hit a pile of freshly dumped earth. At first, as the rain falls it runs evenly over the surface. But as it does it finds some layers of soil are weaker, and others have been compacted a bit more. And so the water erodes the softer, less compacted soil, and the water near those channels finds it easier to flow into them. And so after a while the water coming off the pile is no longer evenly flowing but is cutting grooves in the soil and all the water is coming out of those channels.

In many ways the rock carrying the oil acts the same way. The two channels in the top picture are in the same rock, with the same oil, but it is much easier for oil to flow through the bigger channel, and it will be at much less pressure drop than it takes to get oil to flow out of the thinner crack. And with the flow of the oil the channels in which it does flow well get bigger, reducing further the flow through the narrow channels, and trapping, or stranding the oil that is left in them.

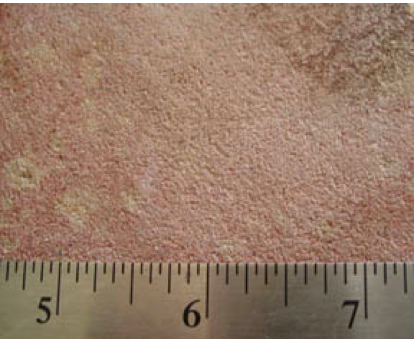

Now you might think that this has, initially to be a great difference. Well, here is a picture of a piece of sandstone I had in my office. It is at first glance made up of grains of about the same size and were it full of oil you might think that oil would flow evenly through it. (It has no oil in it--oily rock looks black and it is hard to make out the features I am talking about due to lack of contrast.)

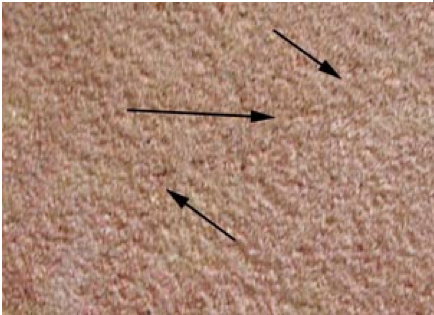

But if you look more closely (and I have zoomed in a bit on one area above the 6-inch marker) you might see a thin connected path wandering through the sandstone. (I have marked it with arrows.)

That line is one of higher permeability. I have been on a site where the ground was supposed to be as evenly sized and permeable as this sandstone, if not more. A test was being run in which my hosts had pumped some fluid into the rock. Since they did not get the result they wanted, they dyed the next batch of water a bright color and pumped it into the ground. They then dug a hole over the site, and looked down the side to see the thick colored layer that they expected to find. They needed a magnifying glass, all the fluid (hundreds of gallons) had gone into a single flaw, about the size of the one shown in the two pictures, and none anywhere else.

For those who can’t see it very well, here is a picture of a block of sandstone outside the Oil Museum in Stavanger that I took this afternoon, and you should be able to see a number of larger fractures that have been naturally recemented running through the block)

However, while we were injecting fluid in the case just above, the opposite can happen if one is not careful in drawing the oil from a well. The initial production can create flow paths through the rock, leaving isolated patches of oil that are not recovered on either side.

But hold-on you say surely if we just keep dropping the pressure (by opening the choke) then eventually we will have enough difference to move even that oil. Well, No! (You may have noticed I am becoming a relatively negative person.)

I was reading "The Color of Oil" by Michael Economides and Ronald Oligney when I first drafted this post. It is a very fast (even more so than this) spin around the world of oil, but I am going to use their numbers (page 32-33) for this next bit.

The oil inside the pores of the rock is initially assumed, for now, to be at the same pressure as the burial depth of the rock (due to geological movement this is a very, very simplifying assumption, but let's make it). But as we let the oil flow out of the rock this pressure, which is caused by the oil and rock compression will get less. While the oil can expand and flow, the rock does not, and so after a while there is no pressure difference between the oil and the fluid in the well. The oil stops moving because the differential pressure has gone away. Professor Economides

"Recovery of 3 percent or less of the initial oil in place can make the reservoir pressure equal to the pressure at the bottom of the hole. When this occurs, fluids are no linger driven into the well and 97% of the original oil is left "in place" in the reservoir. This defines primary recovery, the most elemental but generally unacceptable ending point in petroleum exploitation."

What else can we use as a driving force? Well, some posts back I mentioned the analogy of a bottle of champagne. Shake it, pop the cork, and the dissolved gas in the wine will fountain it out over the happy celebrants. But after the fizz is gone, there will still be some wine in the bottle. It is the same sort of thing that happens with the oil. Oil usually contains gas dissolved within it. As the pressure within the oil drops, this gas begins to come out of the liquid. (Slowly release the cap on a bottle of soda water and you will see the same thing.) (Note that this does not change the pressure in the well, and thus reduces the difference or driving pressure moving the fluid to the well.)

Professor Economides continues:

"A specific (lower) pressure level called the "bubble-point" pressure marks the onset of natural gas evolution, known as the solution gas. When this level is reached (the point at which this occurs depends on the specific crude), recovery can increase substantially to 15% or more."

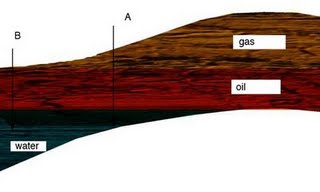

Now let's go back to our example of the two bottom layers of oil in the top sketch. The bottom one will flow oil faster and draw oil from further out, than the upper one. As the pressure in the larger channel drops, as it empties, the remaining oil in the channel will start emitting gas. While the gas will rise, overall, to give a gas layer above the oil, it will also flow more easily into the well than the oil in thinner channels. If the reservoir engineer is not careful at this point, all of a sudden he may find that all he is getting out of the well is gas. (Take a drinking straw and sucking gently move it down onto the top of water in a glass. Note that the straw has to be in the water before you can drink any. If you had machine strength suction and you don't so DO NOT TRY, you would find that if the straw was within half an inch of the water you might start to get a little, but effectively you won't get much.) So it is with the oil well. You need to be drawing from the oil zone only to keep oil production happening.

However, going back to Darcy's Law (in itself an application of Newton's Law) as the well has produced the oil and the compression has come off the oil as some of it left, the pore pressure in the rock has gone down, and thus the difference in pressure between the well and the rock is less. With less of a “push” the flow of oil from the well will also get less, and with no further stimulus, the oil flow will gradually stop as the difference between the pressure in the rock and in the well reached the same level, and if this were all that happened then it would leave about 85% of the well in the ground, and sometimes that does occur.

However, if you remember from the first post where I talked about rock pressure, there can often be water under the oil.

This water can provide some pressure on the oil above it, and as the oil flows up into the well, the water can rise up into the pore spaces that the oil has left, and keep some of the pressure on the oil a little longer.

Professor Economides:

"If a large water aquifer is in contact with the petroleum reservoir, a natural drive mechanism can be provided by natural water influx. The larger the aquifer, the more effective and the more long-lived this drive mechanism tends to be. If a strong water drive is in effect, 10 to 25% of the oil in place can be recovered."

Once that is over, and with 25 - 40% of the oil recovered, then in a conventional well the oil is at the same pressure as the fluid in the bottom of the well, and no more oil will flow. To get the rest out will require some form of pumping.

And yes, one of the ways to increase the production is to pump water, under pressure, below the oil level to keep the pressure up. But to discuss that, and other steps in enhanced oil recovery are topics for another day.

But for now remember, it is not the oil in the reservoir that has been depleted, at this point, it is the force (the differential pressure between the oil and the well) that has been reduced, and finally gone away, and with it the oil production.

Unfortunately because driving pressure and permeability are so inter-twined this has been a long post. And yet I still may have glossed over some points too rapidly. So as usual if there are questions or discussion or correction, please comment.

didn't you leave out the part about viscosity ? the petroleum engineering version is :

v = k/u(dp/ds)

d'arcy's law was originally applied to water wells and since the viscosity of water is by definition 1, viscosity doesn't appear in old d'arcy's equation.

and incidentally, one of the best and most interesting spe articles i have read is a reprint of d'arcy's original work. i can't find the article right at this moment and interestingly a search of the spe elibrary or whatever they are calling it now didnt return any results for "d'arcy". what are they teaching in petroleum engineering nowadays ?

He does mention conductivity, which is the inverse of viscosity or resistivity. The underlying assumption is that it is hard to disentangle the effects of permeability -- which is the resistance due to limited porosity, and that of viscosity -- which is the resistance due to the stickiness of the liquid. That is why in the above equation, it comes out as k/u, which if grouped as such will carry through as a permeability/viscosity ratio.

I can follow the math involved in this discussion because it is fairly elemental statistical physics. D'Arcy's law or Darcy's law is essentially also known as Fick's first law of diffusion and it gets used all over the place in engineering and physics. Of course, some fields have to have their own name for the same basic mathematical construct. (Evidently, electrical engineers weren't quite so pompous and stuck with the original Fick's law name)

What I find really fascinating is HeadingOut's description of the variations in the porosity in the rock. This leads to variations in the flow rate. What I think scientists don't universally recognize is that this puts a damper on the use of Darcy's Law, or at least one needs to incorporate this variation into their solutions. In many research papers I find reference to the idea of anomalous diffusion and from there things start to get ugly. The math gets very hairy and what they try to solve is the laws of diffusion assuming erratic forms of random walk. They call it anomalous diffusion because the bottom line is that no one really understands it well, and the generally accepted math is basically unusable in practice. And again this same behavior shows up in other physics fields, where it is referred to as "dispersive transport". They call it transport because their is both a drift component and a diffusive component. Dispersion acts on both.

The basic idea is that variations in diffusivity due to changes in the underlying structure lead to very long tails in flow of material. You can thus get larger flow rates from certain paths in the rock and slower rates from other paths. IMO, working out the dispersion is actually straightforward as the laws of entropy would state that the variations in effective diffusion would be as much as the average rate. That is a maximum entropy estimator.

I believe all this has a lot of practical significance and aids in our understanding of how the lifetime of an oil well plays out. Just the fact that the so-called stripper wells can keep producing for years indicates that some real slow processes are at work, and it is likely that the long tails of the dispersive transport are at work. Of course, regular diffusion also plays a role in this, yet all the measurements from breakthrough curves suggests that you need to consider anomalous diffusion to get the time dependence right.

Heading Out has essentially given a great explanation of how this can variability and dispersion manifests itself. The idea of a homogeneous substrate is not a good assumption in practice and you need to somehow smear the effects out.

-----

I don't know what they are teaching in petroleum engineering either, having never taken classes in that field. When I was deciding on a major, I recall that the petroleum engineers were promised the highest starting salaries and I think chemical engineers were next. At the time I didn't go into that field of engineering study because it looked like all they did was memorize formulas and their was little room for creative research.

As far as research into dispersive transport of ground solutes, most of the work is being done in Israel. They have the corner on this market, since they have the consultant who originally came up with the anomalous diffusion math, the Continuous Time Random Walk (CTRW) theory. The problem is that only he understands it, see B. Berkowitz, A. Cortis, M. Dentz and H. Scher, Modeling non-Fickian transport in geological formations as a continuous time random walk, Reviews of Geophysics, 44, RG2003, doi:10.1029/2005RG000178, 2006

IMO, it is all explainable by applying dispersion to Darcy's law, and you get the same result, but much more simply. Unfortunately, I don't think these guys read The Oil Drum.

Of course I have a much longer post at http://mobjectivist.blogspot.com/2009/06/dispersive-transport.html which describes these ideas in greater detail.

we usually use transmissibiliy, kh/u.

conductivity is a term more commonly applied to wireline logging - inverse of (electical) resistivity of the bulk rock and fluid zone.

Doesn't the term h indicate the head or height of the gradient? This isn't a constant term in the normal formulation of a relationship.

The diffusion constant, D, is another name often used for this combined behavior. It takes into consideration the combined properties of the medium and the solute. It is in general difficult to separate the two effects.

Mobility is used to describe the relation between pure diffusivity and the effects of a driving field, whether it is gravity or something like an electric field for charged particles.

I think maybe the factor of the external force is what is missing from the simple Darcy's law formulation.

"h" is the height or thickness of the zone of interest.

Might be talking past one another. The dh/dS term is the "dip angle", which provides a driving gradient at the heart of any diffusion process. From this figure, you can consider it a constant for the sake of solving the partial differential equation, yet it isn't a constant in terms of a physical property.

kh/u, transmissibility, is a convenient grouping of terms for well test analysis, for example.

pressure is usually represented by p, for pressure, with gravitational effects, represented by h, ignored. h for head is a civil engineering term.

petroleum engineers, the emperors of empirical, are not always rigorous in terminology.

WHT: about twentysome years back, in my previous incarnation as supercomputing engineer, I spent a week with Mary Wheeler, and her math grad students at Rice who were working on ways to solve such problems. I think the real issue comes from the fact that the reservoir does not have an infinite extent of oil (especially in the vertical direction). If a favored channel begins to fill with a lower viscosity fluid (think of the water layer below in HOs diagram), then as some of this channel gets filled with the lower viscosity fliud (the water), its flow increases even more. Eventually it can connect to the well directly, forming a water-only bypass. So I imagine that reservoir management has to do with trying to maximize the economic output of the field while trying to avoid messing it up by creating bypasses. Of course one's knowledge of the actual state of what is happening underground is going to come from very indirect indicators, so it must be a high stakes game of educated guessing.

I find it somewhat predictable that the research centers around how best to exploit what exists. What I am describing is the basic statistics surrounding the fundamental process. If they can't get that right, they have no business working at with a supercomputer. That will only get them the wrong answer, only that much faster. :) :)

Hello Enemy of State,

Your Quote: "Eventually it can connect to the well directly, forming a water-only bypass. So I imagine that reservoir management has to do with trying to maximize the economic output of the field while trying to avoid messing it up by creating bypasses."

Yep, a major problem in Ghawar as evidenced by the Shedgum Leak area, and other Super-Ks covered in the Voelker 594-page PDF Motherlode. This is the basis of much of the waterfront override problems. Euan, SS, and F_F covered much of this back in 2007. Recall the Saudis frantically reworking their wells to reduce the overall watercut percentage.

Yes but ....

Its a constant problem and a big one for horizontal well. I do a lot of sort of random reading of the oil literature to get a feel for whats happening in the industry. Google and almost randomly follow links.

A huge issue right now is dealing with problematic horizontal wells. I'm pretty sure that almost all horizontal wells will need significant rework during their lifetime. And this is not cheap.

Not only are they expensive to drill but once they age for a bit they have a huge number of problems.

If you think about it its pretty obvious that most will suffer some form of water break through or channeling and that once it starts "fixes" are short term.

The Saudi's put in multi branched wells with cutoffs already in place putting a lot of the cost up front.

This decision instead of being advanced technology that should be lauded indicates that they are suffering water breakthrough so badly that expensive cutting edge wells where cheaper than other alternatives.

The flip side is I question the reserve calculations associated with horizontal wells given the above the actually return is a huge question and does not look that good.

As far as I can tell its really nothing more than accounting fraud.

Everything is a short term problem or small setback nothing is ever written down. It works just like banks claiming face value on junk assets since they are going to hold to maturity.

And the beauty of the game with oil is for the most part these wells show a profit and cover their initial costs early in life later on of course the net profit drops as they turn into one problem after another but you have already booked your profits at that point. And you can take your time discounting the wells and don't have to touch your reserves since its "technical problems".

In the end its just the oil version of other accounting frauds rampant today.

EDIT: Add one sample link.

http://www.ep-weatherford.com/Solutions/Consult/Horizontal_Well.htm

The exception is the rule for horizontal wells. To many ways to fail. Good old fashioned complexity problems strike back.

The SPE literature dealing with the Saudis use of maximum reservoir contact wells (MRC) coupled with SMART completion technology seems to demonstrate that they have effectively licked some of the major problems associated with water break through. According to most of the literature the water breakthrough in Ghawar was largely along fractures and high permeability streaks. Using 4D seismic Aramco was able to determine the location of the main breakthrough zones and fracture zones which would almost certainly result in by-passing if intersected with a horizontal section. An important point that wasn't discussed in the above article is that mobility ratio of the phases in question are quite important. Water tends to be more mobile than oil and has a higher apparent permeability associated. Hence you intersect water with a horizontal borehole and no matter what sort of pressure differential you produce at you will produce more water at the expense of less oil. With the MRC wells Aramco has been able to avoid the potential trouble zones and in the eventuality that they do experience break through in one of the laterals they can shut it off downhole using the SMART technology. They can then go and drill a new lateral in the main hole and use expandable liner to insure the production isn't tubing constrained. Actually a pretty amazing story. The papers seem to be adamant that the recovery factor will get as high as 65% - 75% from these carbonates based on laboratory wettability experiments.

Give them some time. Seriously these solutions seem to be temporary and one of the concerns is that your constantly have to reenter and rework the wells. Exactly as you pointed out. This is not a good thing tm.

There are in my opinion very expensive wells with maintenance costs potentially equal to the original drilling costs over time.

Ok what happens when the shut off a fracture and continue under water drive ?

The water is going to go somewhere else my best guess assuming you have one major fracture you have intersected on one branch and you block that branch the water is going to get driven into the smaller fractures eventually what you probably will see is water cut starting to rise quickly in several of the laterals. Thats a guess I'd argue and a reasonable guess. Assuming you have had significant water encroachment in the local fracture networks simply drilling new laterals can't solve the problem.

If I had to guess assuming the above is true the right answer is probably to choke the watered out section but not block it completely.

A well known example where similar things happen is when you build a pond blocking a stream very often existing springs increase in flow and new springs form as the pond charges the ground water system.

The water continues to flow somewhere and generally its forced to take a more tortuous route. Underground fractures are similar in many ways to above ground water courses so I don't think I'm all wet in what I'm saying :)

Time will tell but I've read enough to conclude that horizontal wells are not the silver bullets they claim to be they just seem to kick the can down the road for a bit leading to even more serious water problems at a later date. The more you try to avoid it the worse the eventual outcome.

They have now been deployed long enough that if I'm right we should start seeing tons of problems with them cropping up each time more serious than the last.

Horizontal wells seem to be somewhat akin to extracting from coal veins. Lots of effort for a very short term gain. So the effect is the same as mountain top removal; they will suck everything out that they can, however they can.

Sorry, I have some experience in this end of things and it isn't the doom and gloom you predict, far from it. There are several decent papers published in SPE that demonstrate the effectiveness of the horizontal wells. The fact that you have much higher Kh means you can produce at lower drawdown which also means less chance of coning either gas or bottom water. The reservoirs in SA are not fractured ubiqitously. Seismic and drilling results have demonstrated the fractured zones are discrete and as long as the laterals are drilled to avoid them you end up with a fairly steady state water front advance. The matrix permeability of the Arab carbonates is very high so injected water will not preferentially charge through micro cracks that will have K often less than the matrix. Of course injected water will preferentially course through the macro fractures but as long as they are not open to the bore hole you will produce hydrocarbons from the matrix. Note that the water does go somewhere....it along with swept hydrocarbon are produced at the wellbore. Remember that even under ideal conditions here your water cut is still going to be relatively high at steady state production. In Ghawar most of the MRC wells are producing from behind the water flood front...water cut is high but you are still producing oil. As long as it is cost effective to produce at high water cut you are good to go. Many fields in the world produce at up to as high as 90% water cut.

Horizontal wells work for a number of reasons....firstly they allow you to have better standoff from an overlying gas cap and an underlying aquifer which means your chance of preferentially coning either at the expense of high % hydrocarbon production is lower. They also increase Kh or the amount of effective pay in the well bore which equates to production rate and the ability to have lower drawdown and again lower chance of coning of either gas or water. As well they allow for better sweep of anisotropic reservoirs, increasing your chances of connecting into sweet spots. Of course horizontals are also used to connect up the maximum number of fractures in unconventional reservoirs. Tight gas charged carbonates are a good example as are fractured basement plays which are quite prolific in places like Vietnam. They do become problematic when there is a strong water drive associated but SMART completions actually work pretty well.

There is a lot of data collected over the years on horizontals, the problems you speak to were encountered in a lot of the earlier wells but new advances are allowing for better controls.

The oil actually came before the movie stars in Beverly Hills or what then known as "Morocco". After the Civil War it was explored by wildcatters and roughnecks, who drilled their oil wells whereever they found that Black Gold.

In 1900, Burton Green, along with several partners, bought the leases and eventually formed the Amalgamated Oil Company and commissioned a new round of oil exploration.

After drilling many unproductive wells, they reorganized as the Rodeo Land and Water Company in 1906. Eventually Edward Doheny bought up the leases and proceeded to further explore the area.

Union Oil Company of California drilled the oil well on the campus of Beverly Hills High School, with all the appropriate permits, back in early 1960. It was the first oil well of its kind to be masked making it look like a building including floral decorations to fit in with the rest of the school. Royalties are being paid to Beverly Hills and their school district under a long term arrangement.

So it seems that the oil was there and people moved in afterwards.

Internet Archive Search: oil. Heaps of vintage texts to peruse. These words from Oil-field practice (1921) are more than familiar:

You get a sense of why the Yergins and Lynches are so gung ho about oil's prospects reading this book. Syria and Arabia are listed as countries that might have oil; much more prospective regions included the Argentine or Peru. A 1919 USGS estimate for the US was 8 BBO, "not enough to last us 15 years at the present rate of consumption." A footnote ups that figure to 9.15 BBO as of 1922.

Excellent approach to point out the variations in the structure of the rock. It's not something everyone wants to discuss because assuming homogeneity generally makes the analysis easier. But then you get to thinking about what causes the huge variation in the sizes of oil reservoirs and fields in the first place. IMO, it is likely due to the same process as Heading Out has described. The bigger fields have the spurious inhomogeneity in porosity that has allowed more oil to accumulate in a portion of the capture regions than in other fields that are more slowly accumulating.

In fact, by solving a drift equation where the flow velocities are distributed as a damped exponential k*exp(-kv) over a span of time, you can derive the cumulative distribution of reservoir sizes that goes as N ~ 1/(Volume+C). This says that there are only a few really large reservoirs and many more smaller reservoirs.

So, the same mechanisms that prevent us from extracting oil at a uniform, predictable rate were also responsible for creating the large inhomogeneities in size in the first place. After all, if all rock was homogeneous, then the variations in flow rate and of the faults that the oil collects around would not exist. All that oil would have slowly diffused upward without every getting trapped or would have migrated slowly into a uniform mush.

Thanks, Dave! There are just a lot more details involved in this than most of us would ever have imagined. Before your discussion, I hadn't really figured out the difference between permeability and porosity.

It seems like unconventional production at least sometimes is at the outer edges of permeability and porosity. “Tight gas reservoirs” have very low permeability and porosity. I am told they are usually defined to refer to formations having a permeability of 0.1 millidarcy (mD) or less. Fracking or other stimulation is required to get the gas out.

I can see why these sites would be by-passed initially. With extra work and cost, the gas can be extracted. The question is whether the selling price will be high enough to cover these costs.

I think what people mostly miss is that unless we understand how the oil moves around when we are not around, we are at that much of a loss to understand how easily it can get extracted.

The relentless forces of entropy tend to disperse the oil as much as possible, and trying to reverse the course of that entropy takes loads of energy. So we are playing the equation of entropy multiplied by the coarse of geological time against the brute force of energy expended over a short human time scale.

Who ends up winning that battle?

I think one of the issues is the extent to which all of the fracking really increases gas production, rather than just moving it forward (at great energy cost). At some point, wells become too expensive to continue to produce (especially if more expensive fracking is needed). When gas prices are as low as they are today, that point isn't very many years out.

Creating artificial fractures, superflow zones, high permiability areas by multi-stage fracing is increasing chances of recovering oil in old fields that was thought to be locked in the rock till the end of time. The very recent technological advancement has rapidly improved initial flow rates in both oil and gas wells:

http://www.nickles.com/ntm/extra.asp?article=NTM2009_SN0000.html

Just wanted to say thanks to Heading Out for this excellent series. I've spent most of today reading them all, mostly in reverse order. (Started with this one, then part way through realized I really needed context from the previous week, went back to read that and repeated the same experience, so at this point I've read about half of each article in the series...)

Yes, these are the best. Unfortunately, the technical nature keeps the subjective gloom and doom out of the discussion and consequently we don't get quite as lively a comment section.

Perhaps the title of this post should have been:

Darcy's Law : Proof that we are doomed

HeadingOut. Thankyou for this series of very informative posts. They are easy to read and offer the rank and file such as myself an increased libriary from which to draw. Please continue to post these valuable lessons.

WebHubbleTelescope. So you know. I have been reading your work every since the shock model introduction(07?) and I scan for your posts on a daily basis. I consider your comments very reasoned. I especially like your contributions concerning the knowable and the probable/possible and the likelyhood of an elephant discovery postponing a peak. Of course the math backing this up is not boring either.

Regards TG80 sends

Thanks. In some ways this is more interesting than my real work.

The Dude posted some links to Petroleum Engineering message boards and the discussion is fascinating. It looks like much of the discussion is about passing around cracking codes for analysis software. I might be be misreading the context, but the engineers on the board appear desperate to try anything that will give them some sort of edge in figuring out where the oil is.

Take a look at this post on the Petroleum Community Forum where engineers are asking for activation codes for a piece of GIS software:

http://www.egpet.net/vb/t6129-5.html

Who are these people and why can't their company afford this software?

Or are these just Chinese software pirates hoping that someone on the offhand chance will reveal the codes?

Trying to figure out the oil industry is as inscrutable as ever.

WebHubbleTelescope.

I think this is http://www.theoildrum.com/story/2006/6/13/214337/916 what they need. By Mr. Sam Foucher AKA Khebab. I really admire how he lays this stuff out.... (note the scientific use of the term "stuff")

regards TG80 sends

This angle definitely does not get covered in any Petroleum Engineering reference books.

Instead this passes for analysis, from:

The Petroleum Engineering Handbook: Sustainable Operations, by M. Ibrahim Khan M. Ibrahim Khan

Sustainable development of petroleum operations? That is definitely misinterpreting our common understanding of what the term sustainability means. At best, they should call it "milking of petroleum operations".

Thanks for the post H.O. I was curious, do the fancy 3-D renderings of seismic data now being generated shed a lot more light on permeability or does most of the real data on that still come from the holes drilled and how they do or don't perform? From the above discussions it seem the mathematical models have a fog factor. A lot of trial and error still looks to be in play when we try to look through the earth. It certainly does seem that trying to get the oil out too fast will in the end just get us less oil.

Luke -- How well 3d seismic can shed more light on reservoir dynamics depends as much on the nature of the reservoir and the contained fluids as the seis data itself. The ability of the seis to image the pores in the rock depends greatly on the NG content. From a velocity stand point oil with little dissolved NG appears very similar to water. At the other end of the spectrum in some 100% NG reservoir the seis can actually "see" the NG. Directly imaging this NG is a proxy to imaging the pores. But not in all rock in all areas. Lets set those complexities aside and go forward. Any effort to map actual permeability paths the hydrocarbons follow as they are produced are best achieved by "4d" seismic. Before production begins a sesi survey is shot. Some time down the road a duplicate survey is shot with the same parameters. Comparing the changes in the two surveys allows some inferences to be made. One can try to calculate absolute values from the seis but doing so is about as difficult as it gets. Comparing changes is easier but the interpretation is still as much art as science IMO.

To add on to the point others like WHT and others have made above: I've been doing reservoir engineering for over 30 years and have yet to see PROOF of any reservoir acting like the nice neat pictures in an Reservoir Engineering 101 text book. Lots of assumtions that some reservoirs have preformed that way but no confirming proof. On the other hand, I've seen many cases where reality doesn't come close to the simple models. I've made a good portion of my living exploiting these situations. Bottom line for me today: I always assume any reservoir's dynamics are far from "normal". Today I start with the premise that normal has to be proven. Until then any assumptions that the oil is moving through the reservoir in a conventional manner are ill advised IMO.

Rockman, Does this imply that there is no hope in understanding this stuff?

Yesterday I got hold of the 2006 Petroleum Engineering Handbook by L.W.Lake. This tome is just packed with partial differential equations, and has no explanatory material; for example, it refers to Darcy's Law with no context .. only that it is used in reservoir simulations. Then it shows real data of porosity versus permeability and describes this as a purely empirical relationship. So much for the partial differential equations... I have no idea how anyone could use such a handbook.

I have seen reference books in other fields, like Electrical Engineering, and most every equation or formula referenced stems from some fundamental understanding and typically works well as applied.

Are many of the petroleum engineers ignoring the fundamentals and just blindly using these pricey simulators and plugging in parameters without really understanding what is going on?

I know this sounds like a rhetorical question.

No...good question WHT. I might not be the best person to ask though. Unlike you, HO and others I'm not that strong math wise. As a result I tend to view matters almost always from an empirical perspective. The theoretical aspects of reservoir dynamics are well founded. For me the real problem is Mother Earth. She abhors arrogance. Just when you got that last differential equation worked out she changes the rules. Can't argue the basis for many of the calculations other than their accuracy depends to large degree on the accuracy of the initial conditions as assumed. As I said earlier much many of my successes have arisen as a result of original conditions not being as assumed.

But you have to start somewhere and the theoretical is that starting point IMO. But you then have to refine those with empirical realities. From my very beginnings I developed a very bad opinion of the "certainties" of others. On my first offshore GOM development project my first 5 wells were dry holes. I drilled on the exploration mapping. The two discovery wells found the only hydrocarbons in the field.

Since that time I've drilled two "sure shot...can't miss" wells. And they both were dry holes. Thus my poor attitude towards anyone's projection of future discoveries out there just waiting to save us from PO. As I said, Mother abhors arrogance.

In some sense, what we probably observe is a smearing out of all the possible underlying physical processes at work. These are distributed randomly with respect to the characteristic parameters. This means that it really becomes a hit-or-miss proposal, since no one seems to use an appropriate stochastic formulation, ala dispersing the results, to describe this effect. And that is the angle I work.

It's probably not hard to understand why they don't do it the latter way. The engineers work their butts off doing the partial differential equations and are exhausted by the time someone suggests that they randomize the effects. Sunk costs at work.

Excellent point Hub. I can't guess how many time one of those engineers has told me "well...this is how the model said it would produce". The implication being, of course, the geologic mapping was wrong. And in many cases the geologist did miss the mark. But I've drilled many wells where the same engineers said the models didn't support the idea yet the well worked. I don't really fault them too strongly. The answer they're hunting for is very elusive. In some cases completely unobtainable. The biggest fights I've ever gotten into was often based on the inability to admit we didn't really know the answer and never would short of drilling the well. I've been kicked off more the one project for refusing to map the unmappable. In my youth I learned the harsh lesson of not putting down on paper that which can not be later justified.

As far as I can tell the results of these seismic surveys plays a big part in determining there reserve size.

Given the number of grains of salt required to accept modern reserve estimates the oil industry should team up with the salt industry. One of the two is going to make a killing in the future.

Combine the possibility of overestimating OIP to include the entire oil bearing structure i.e you may overestimate the amount of oil actually present to be equal to the visualized trap region with known long term performance problems with horizontal wells and the chances of the numbers being right are slim.

And of course all most all the error terms are positive modern oil technology by its nature tends to lead to over assuming the real situation.

While in the field it seems from my reading and from what ROCKMAN is saying the truth is quit different.

Thats not to say you don't get better or worse than predicted but for how long and why has little bearing on results which are used for reserve calculations. And of course with horizontal wells bisect a few kill fractures and produce well above expectations and you of course need to up your reserve estimates right ?

Have poor performance and its a technical glitch no reason to lower your reserve estimates the next well or a rework of this well will "fix" things.

Bottom line is using reserve estimates esp the later ones when we literally have too much information and are less dependent on well logging and what its telling us is using suspect data. Even well log data for horizontal wells is not as useful as verticals as the performance varies dramatically over the lifetime of the well while vertical performance was a better measure of the reservoir dynamics.

The reason in my opinion is fairly simple most long horizontal wells effect enough of the reservoir that the well itself has a substantial impact on the future fluid dynamics in the reservoir while for vertical wells the distribution of effects from the well did not extend that far into the bulk of the reserve and where generally pressure effects.

You don't have a well crossing thousands of fracture regions for a km's or miles. The overall fluid flow is far more complex for a horizontal well than for a vertical well and far more likely to result in large pools of bypassed oil except in the perfect textbook case.

And we don't even have a good understanding of the simple vertical case much less the longer flow dynamics around a horizontal well.

However even a basic understanding of water wells will tell you that the future is not as bright as predicted. Natural springs which generally have very good flow rates are very similar to horizontal wells since they exist because they connect a large fracture region. While a man made water well unless it gets lucky has low but steady flow rates. During a drought natural springs in general rapidly dry up as they drain their fracture region while man made wells tend to last until the overall water table drops below the bottom of the well. Everything I read indicates that horizontal vs vertical wells has similar dynamics.

Horizontal well performance is based on draining the fracture network with slow oil movement into the fracture region while vertical wells which have limited intersection with fracture regions tends to allow far more oil to move out of the pores and into the fracture regions. Thus the tendency is for horizontals to have a high initial flow rate but as the fracture regions are drained movement of oil out of the pores and into the fractures for drainage is difficult to achieve at best. Resting the well for a significant amount of time for example may be required to actually produce any oil at all or mechanical pumping.

Regardless both are not well understood and it should be obvious that the intrinsic dynamics are different just like they are for natural water springs and man made vertical wells.

There are several problems with 3D seismic for reservoir dynamics. The first is that seismic measurements tell us nothing directly about permeability. What we do learn, in a very indirect manner, is the P-wave velocity, the S-wave velocity, and the density of the reservoir.

There are a number of limitations with what we can do with seismic information:

The result is that 3D seismic exploration becomes more expensive and less effective as the area of a prospect gets smaller, as the target gets deeper, and as the porosity decreases.

We've already found all the big, shallow, high porosity fields. Now we're looking for fields that are deep, small or low porosity (or all three).

ROCK

Thanks for the comeback, you and those responding to your post have shed a lot of light in a most compact fashion.

Heading Out, thank you for such an informative post. I am not an engineer, far from it, but i continue to learn, and my daughter graduates this december from University of Texas with a degree in geology. not sure where she got those smarts from. anyway, i'd like to talk about the haynesville shale, specifically horizontal wells. a seismic was recently conducted on my land, and the geologist look at that seismic data to determine where to drill. when the spot has been chosen, which it has, they plan to drill about 4 miles in length. i think that was the # given. it might be more like 4800 ft long. anyway, i am aware that the hydraulic fracturing process includes lots (millions of gallons)of water, but the haynesville shale has been giving a very high first year depletion rate, somewhere in the range of 80% plus or minus 10 the first year. Question: why can't the drillers stop after 3 or 4 months when the flow rate drops and re-frac or set small charges along the length of the well line to capture the other trapped oil/gas in the rock around the length of the well? I am not sure if they do anymore fracing after the initial frac job to start the flow. would it be detrimental to the well casing if they did that?

The easiest time to work on a well is when it is first put in, and all the equipment and access are readily available. One of the technical breakthroughs that I will write about as the series continues relates to horizontal wells, and the multiple fracing tools that are now available.

Frac spacing and the lengths achieved and performance are all going to be controlled by the circumstance at that particular well.

On the other hand wells are worked over after production, if the perceived result covers the cost of the treatment, but again it comes down to return on investment.

thank you for your input, i look forward to seeing more of your posts.