Coal Mining Reserves - a cautious note

Posted by Heading Out on June 4, 2007 - 6:30pm

Times are changing in the coal trade, and while April marked the end of one era (the last pit pony in the UK died), on the other had we have the renewed interest, and debate over, the use of coal as a source of liquid fuels for a variety of vehicles, including aircraft. So I thought it worth trotting out some more facts that might help put the current (and future) situations in context. (Plus we haven't had a Techie talk in a bit).

The late Bob Stefanko has written that the Great Dismal Swamp is probably the best current place that represents the type of conditions under which, back in Carboniferous times (about 355 to 290 million years ago) the various vegetative fragments fall into the water, and are slowly compressing to form a layer of peat. The peat layer in the swamp is about 7 ft thick, which would convert to about 20 inches of coal. The swamp is slowly sinking, allowing the vegetative mat to continue to deepen and slowly built to a greater thickness. Back in the Carboniferous he noted that the speed at which the layers formed was likely about twice that at which the current Swamp is growing, and that, due to the different levels of pressure required to form them, it would have taken about 160 years to lay down what is now a 1 ft thick layer of lignite; 260 years for a foot of bituminous, and about 490 years for a foot of anthracite. Since it is more worthwhile to mine thicker coal, and eight-feet is a nice working height, this would have required about 2,100 years of steady growth to lay down the layer of vegetation that formed the Pittsburgh seam in Pennsylvania. The original areas over which these forests and swamps grew were vast, and the cycles of deposition grew as the land distorted, with multiple seams being deposited in some cases, and a single thick seam in others. But how has it survived? How much is really there, and how much can we actually produce?

I thought I would split those questions into two bits, with the actual numbers coming in the second post, while, with this one, I’d try and explain some of the reasons why, while oil companies often get more oil out of the ground than they anticipate, it is often the other way out when you are mining for coal.

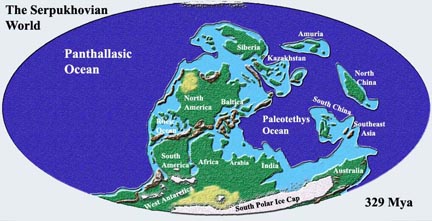

So, consider, if you will, the map from the site above, that shows back in Serpukhovian times that the planet looked a lot different than it does now.

Shape of the world at the time that the coal seams were laid down.

With all the continents together, as they were, they have had to travel a considerable distance over the past 300-odd million years to get to where they are today. Along the way they have bumped into each other, and in the process caused mountain ranges to rise, and fall, and there has been quite considerable erosion of the surface between times. And when the land fell then the seas would deposit more layers of rock, so that the coal as it was formed by the pressure of the rocks that overlay it, would change into the different types of coal that we know today.

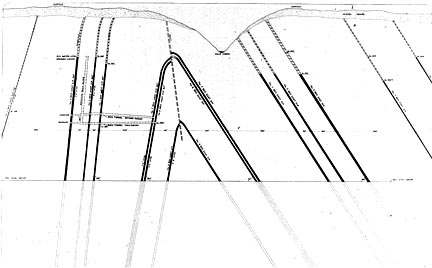

Even though the original coal material was laid down horizontally, as the continents moved these rocks became folded and tilted. Thus, for example, in Washington State beds, and in Colorado coal seams may end up lying at very steep angles. The geological way of expressing this is to talk about the dip of the seam, that being the maximum angle to the horizontal, while the strike of the seam is the line along the horizontal perpendicular to the dip. Thus beds in Washington State may dip at between 20 and 60 degrees.

Vertical slice through an area of Washington State showing the way that the coal seams dip.

There are considerable problems when the seam gets to dip more than a few degrees. Bear in mind that machines don’t easily move around slopes that are more than fifteen degrees, and you might understand why, for example, it has been very difficult to mechanize the mines of what once were the most productive in the Soviet Union, but now belong to Ukraine . These are the mines of the Donetsk Coal Basin, where

During the communist era , this region produced most of the Soviet Union's coal, and reaped the high wages and prestige that came with it. Statues of miners were erected in squares; villages were named after famous engineers.

The tide began to turn in the last 20 years of Soviet rule, when the flow of funds from Moscow dried up. After communism's fall, the mines were exposed as the money-losers they are, at the same time that economic pressures devastated their customers. In a decade, the demand for Ukrainian coal dropped 45 percent.

Now Donbass is clinging to the two-thirds of its industry that remains. Viktor Yanukovich, the regional governor, said in an interview last month that another 30 of the region's 89 mines would eventually have to close. But he said he needed at least five years to accomplish that and needed an average of $18 million per mine to provide the miners benefits, retrain them and safely close the pits. "I am not against closing down the mines," he said. "But not as it was done before."

Talk of closure is anathema to Anatoli Goncharov, the director of Gaegova mine, which is located in a bleak village outside Donetsk. His mine produces 360,000 tons of coal per year, less than half what it did in the mid-1980s. Because of the steep angle of the seam, half of coal must be extracted by hand, with hammers.

It costs the mine nearly $30 to produce a ton of coal -- $11.50 more than the coal is selling for. Even with $2.7 million in state subsidies last year, the mine failed to break even. The Ministry of Fuel and Energy has put it on a list of pits that cannot be saved, the mine director acknowledged.

(Note that the story is from 2002).

Coal seams can be mined as deep as 4,500 ft, but the methane and other problems (including keeping the roof from falling in) have made these difficult conditions to work in, so that while there is still coal in the ground, it is becoming increasingly uneconomic, under present conditions, to extract it.

So one of the first problems that the mining engineer has in determining whether to count coal as a reserve is whether or not it is either practical or economic to mine it. This means that, in general, it must be machine mineable, since the productivity of a human miner is no longer sufficient, in many countries, to cover the costs of labor and support.

The second problem is to ensure that there is enough of it. And so before deciding to mine the company will drill cores down to the coal seam over the planned area that will be mined. These don’t, at first sight, need to be that close, since the initial intent is just to see what is there and that it goes out far enough to make it worth while to sink the mining shaft (which costs several million dollars).

However, even the best attempts at accuracy with this planning do not necessarily work out. Consider for example, the case of the mine at Glenrothes in Scotland.

The primary reason for the designation of Glenrothes was to house miners who where to work at a new super coal mine. This was to be the most modern of the day and was built west of Thornton, an established village south of Glenrothes. The Super Pit was named the Rothes Colliery and it was officially opened by the Queen in 1957. Iconic photographs of the young Queen going down the Rothes Colliery in an all-white boiler suit and helmet are still regularly shown in programmes about the royal family. About 5,000 miners were to be required to produce 5,000 tonnes of coal per day, and huge railway yards were established. The pit was to have a working life of 100 years. The planned long-term benefits were to be huge, and the driver for economic regeneration for central Fife. In 1961, 4 years after opening, the huge investment was written off and the mine run down because of un-stemmable flooding.

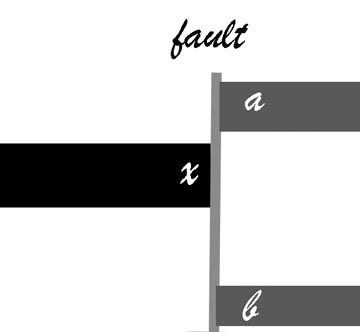

There were actually a couple of problems at the mine that could not easily have been foreseen by the drilling pattern. If you look back up at the picture of the Washington coal seams you will see the almost vertical line in the middle of the picture, with the black lines representing the coal seams vertically offset one from the other on either side of it. This is what is called a “fault”, and over the course of time the rock was moved to the point that it broke here and created this fracture in the ground. The rock then moved on one side relative to the other. (Like, on a very small scale, the movement that occurs across a major Earth fault when there is an earthquake).

You have mined to x and meet a fault, did the coal go to a or b? How do you know?

With the movement the rock that lies along the fault gets crushed, which can make it easier for water to flow through. So that if some of the rock, on either side of the coal seam, contained water, then when the mining operation reached to fault, then water could flow through the fault into the mine. There is also another problem. Say you are in charge of the driving of the tunnel that reaches the fault. Suddenly, in front of you, the coal turns into rock. You realize that you have hit a fault, but which way did the coal go – did the ground hade (move) down, or up. The rational way to find out is to drill up or down until you find where it went. Well that takes time, and money, but the worst isn’t over yet. Now you have to move the mining operation that say 20 ft that the coal has moved up. This means driving tunnels upwards, then moving the equipment up, and then recreating the mining pattern, and then moving on. All this development has been in rock, so you haven’t been earning any money from the area while this was going on. And if the difference in height is too great, then the area is abandoned for the time being.

What happened at Glenrothes was that the ground had a lot of these very small faults. They were not apparent from the initial cores, which were quite widely spaced, but over a period of four years they were found sufficiently often, and with a lot of water in them, that it became uneconomic to continue to operate the mine. The mine was estimated to have reserves of 183 million tons of coal, to be able to produce a million tons a year, and to have an operational life of 100 years. In the five years of its life it produced around 700,000 tons in total. (The full story of the mine – which had many problems that I have glossed over – can be found in The Disappearing Scottish Colliery by Robert Halliday.)

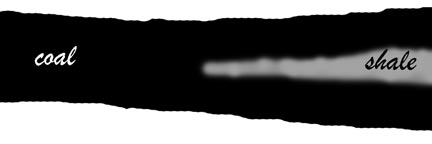

There are a couple of other problems that happened at Genrothes that are also fairly common, but that can make life miserable for the miner. Let us go back to when the coal was first still vegetation in the swamp. Swamps are not great flat growing areas that are all even. Streams work their way through, cutting channels through the peat and filling them, often with sand, or other material washed down from local hills. There are dirt hillocks and, after storms the land might be flooded with layers of silt, that can be feet thick.

Now move forward some 300 million years. The sand and silt have turned into sandstone and shale, but they did not compress as much as the vegetation. So now instead of there being a nice 8-ft thick seam which the miner has a machine to extract, the coal has a layer of rock in the middle (the silt layer) that is about a foot thick, but that wanders up and down in the seam, and then gets thicker, as it approaches an old river channel so that the two sections of the seam are now about four feet apart. The mining machine grinds off the coal with picks , but when these start to run into rock they wear away very quickly, so that mining slows down and becomes more expensive. And then the machine reaches the sandstone filled river channel and things get just a little more difficult.

When two fours are not as good as one eight.

Now the coal is still there, there are a lot of tools to help get it mined that were not around at the time of Glenrothes, and it is not really necessary in all cases that miners be physically present at the machine when it is mining. But some of the time we still haven’t got the answers that would bring some of this coal back to the point where it is considered a reserve. And there is some doubt, therefore, as to what we call a reserve and what not. But we’ll leave that discussion to another day.

Dismal Swamp sounds like a place we'll go to cheer up after reading TOD. I don't think another Carboniferous era is possible because of human interference in nature; for example the draining and firing of peat swamps in Indonesia to prepare for oil palm plantations. Then again if Fred Flintstone had fixed up his erosion gully we wouldn't have the Grand Canyon. A recent Australian ABC doco suggests a return to high CO2, poor circulation, abundant plankton 'snow' in the oceans to create more oil for future humanoids.

I'm sure coal reserves are exaggerated. There are

barrels-of-oil equivalent so maybe there should be

buckets-of-coal equivalent. This is for when coal

boosters talk of centuries of methane from thin, deep or faulted seams such as in Queensland's Bowen Basin. Burn the lot now I reckon and force the need for alternatives.

Coal reserves may be under-reported if the figures are based on estimates made before 2003. Take the example of that Ukranian mine - it wasn't worth digging up at all with a coal price below $30 per ton. Presumably there would have been other companies at the time who left a lot of coal out of their reported reserves because it wasn't economical to extract it.

Now the coal price is over $50 per ton, a lot of black gunk that could not previously justify its inclusion in reserve figures might get added in.

Of course with oil prices higher, costs will be higher too. It depends what proportion of mining costs are made up by fuel costs.

I know it's tempting to believe that coal will run out soon after oil (because it is foul polluting stuff etc) but wishing does not make it so.

If we are to believe in things we cannot see or touch, how do we tell the true belief from the false belief?

The limiting factor in coal production is the CO2 absorption capacity of the atmosphere. I want to remind everyone here that NASA climatologist James Hansen has calculated in:

Implications of "peak oil" for atmospheric CO2 and climate

http://arxiv.org/abs/0704.2782

that - if we burn all oil and gas - we must have phased out all coal - where CO2 sequestration is not done - by 2050. This is the condition to keep CO2 concentrations under 450 ppm CO2 and hence further warming under 1 degree. Remember that in the last interglacial periods temperatures were around 1 degree higher and sea levels 5-6 m higher.

Hansen writes in his latest press release (29/5/07)

"Dangerous human-made interference with climate: a GISS modelE study"

http://www.atmos-chem-phys.net/7/2287/2007/acp-7-2287-2007.pdf

The paper documenting the climate model employed in that study is available now at:

http://pubs.giss.nasa.gov/docs/notyet/inpress_Hansen_etal_1.pdf

Coal is nature's way of sequestering carbon.

Educational post on what I'm sure is just a short-list of the quandaries facing us when it comes to the implications of ramping up CTL and further coal fired electricity production...

Coal, of course, is the monster of hydrocarbon energy (when it comes to "reserves")--but it seems this comes at a great environmental cost, not to mention the sheer, physically strenuous effort needed to extract the stuff.

I look forward to more coal posts, keep 'em coming.

This is a good enough place to remind everyone that coal-to-liquids processes run at about 50% efficiency. That means that the coal only lasts half as long if you turn it all into liquid Hummer fuel and that you get (at least) twice the CO2 for every mile driven. If you try to replace a large fraction of the ENERGY being used in liquid fuel it goes away even faster.

You can't outrun the 2nd law.

You can still use coal for the carbon feedstock and use an external hydrogen source. Say you have a natural gas source nearby, you can use the excess hydrogen from that, and someday you can even talk about using nuclear or solar thermochemical hydrogen production; Not someday soon unfortunately.

You probably mean the first.

I would have thought chasing a band across a fault while problematic is not impossible to determine which direction the seam moved in.

surley test investigations of the stratigraphy above and below the seam could be easy pointers for displacement.

if the stratigraphy below the seam is present "in section" at the interface of the seam and the fault we know the seam has moved up.. and vice versa.

though i imagaine you YMRDV with this one as the degree of fault displacement may make investigating the stratigraphy above and below the seam rather problematic.

though the water flow and other logistical problems seem somewhat more of a challenge.

interesting post... up to standard

Boris

London

It is not that it can't be done, it is just that it is time consuming and expensive and when they were running longwall mining, moving the face through the fault or re-creating the face set up on the other side of the fault was not always simple.

I challenge the learned readers and posters of TOD to do something, a special favor if you will.

It's easy, it will not cost you a thing, and it will not take long. Given that many TOD readers enjoy research anyway, you should even find it fun.

Go to Google, and put these two words in the search bar: Mountaintop removal

Click on a few of the links, especially the ones that say they have photos.

That's it.

Humans have lost patience with nature, and do not wish to engage in the old fashioned "coal mining" described by Heading Out. There is a faster way.

In fact, given the demand for energy and the lack of capital and labor in the coal belt, it may be the only way to grow the coal industry.

You simply blast the region from which you intend to extract the coal to bits.

You convert the surface to splinters and cinders with massive amounts of explosives, and then go in and scrape up your coal. It makes the surface look like an area used for the testing of small nuclear devices.

This is happening NOW. It must be understandable why, for us aware Kentuckians, West Virginians, and others in the Appalachian Mountain region, we are a bit less hysterical about these "scenarios" depicting some future ecological catastrophe, and we don't blush and faint at Al Gore's astounding footage of a block of ice falling into the sea.

We have more pressing problems NOW, within a couple of hours drive of Al's old home town.

Check out the links. See what is happening to the most diverse wilderness area in North America NOW. Then come back and tell us how coal will be removed in the future. And solar and wind are all "toys" and "silver bb's" and nuclear is forbidden, while we do what we are doing to remove coal because we refuse to change. Preach to us about cause and effect.

Roger Conner Jr.

Remember, we are only one cubic mile from freedom (and freedom ain't coal)

Getting the coal from a surface mining operation is safer, cheaper and gets more of the coal out that does underground mining (rough rule used to be 50% for underground 85% for surface). Most surface mining operations are disruptive while they are going on, since they are moving large quantities of soil and rock to reach the underlying coal. Mountain top removal is one of the more controversial of these, since it does not replace the rock, as it was. However there are relatively strict regulations for the restoration of the land after mining is over. Some of this land then provides places to build things such as hospitals and schools, and has more value than it had previously. However there are some strong opinions on both sides of this issue. One rarely sees pictures, for example, of how the land looks after it is restored, generally it is shown during mining, or from areas that were extracted before the current regulations were put in place.

Is that because there are not pictures, or because an environmentalist conspiracy exists to suppress the good things about modern coal mining?

Well I thought about putting up a golf course picture (Twisted Gun Golf Course, W.Va or Stonecrest in Kentucky), but instead thought that this is a bit less controversial, it is just a farm.

From the windshield of a car, many of these "reclaimed" strip mines look fairly lush. However, if you get out on the ground and walk them, they are quite barren -- usually just a sparse cover of Kentucky 31 Tall Fescue with a little trefoil or sericea mixed in. I'd bet that most of these that are less than 5 years old have no more than a 30% ground cover. Without significant organic amendments -- yard waste, sewage sludge, what have you -- these areas will take decades to develop a healthy and productive vegetative cover.

In my opinion, the "improving the economics of the region by making flat land" argument is crapola. There isn't significant enough economic activity (for a variety of reasons that aren't likely to change) in Appalachia to make use of much of this area. But if you tell someone that you've just created a great parking lot, I guess they'll be more likely to overlook the fact that the mine spoil supports only a sickly stand of fescue.

has anyone tried reclaiming and rebuilding the soil with permaculture techniques? Is it effectively lost forever?

Seems like with some care,quite a lot could be done -- and it would be cheap land for all the millions who will be displaced from the coast with rising sea levels.

A lot more could certainly be done. But it all costs money and no one spends any more than they have to.

I worked on some coal mine reclamation projects when I was employed by one of the Southeastern Land Grant schools and I think we were able to improve some things -- particularly in the areas of topsoil salvage, spoil mixing (some rock types for reasons of texture and chemistry just naturally weather to a more desirable soil parent material), and (top)soil amendments. But it would admittedly have been much more expensive to implement all of the things that we recommended. And some of our recommendations were not politically popular (sewage sludge amendments). So, in the end, what you end up with are a lot of half-measures.

Bottom line: It's just damned hard to create a healthy vegetative cover with only bulldozed rock and a hydro-seeder. Mother Nature will eventually finish the job for you but on her own time. Meantime, you're living with a destroyed ecosystem, you've grossly increased rainfall runoff (which, in the narrow stream valleys characteristic of the Appalachian Region is just what you don't want to do) and you've created a lot of just plain ugly places.

Sure...

But why should I care?

I'm being a bit smarmy here sure, but I really dont know why I should care about mountaintops being scarred in the middle of nowhere. Isn't this just an aesthetic issue?

Well, I guess that depends on what you value. In my mind, it is rarely a question of simple aesthetics. The Appalachian corrider is, for instance, an important flyway for migratory songbirds -- songbirds that help to control insects in wood-producing forests in Appalachia or in New England or South America. It also happens that the Appalachian Highlands sit atop the sub-continental divide between the Atlantic and the Gulf and so essentially form the headwaters region for much of the freshwater runoff in the Southeastern US. So, there are water quality issues, as well.

But your question does, I think, reflect our attitude, as a society, about things that are "out of sight, out of mind." The coal-bearing portion of the Appalchians has been made, in effect, a national sacrifice zone. But that was well underway before anyone thought about Peak Oil or Climate Change and I expect that process to continue.

But why should I care?

I'm being a bit smarmy here sure,

No, you've already emotionally invested in seeing Fission Power be the "way to go", so you don't care.

in the middle of nowhere.

Your 'middle of nowhere' is someone else's somewhere.

Isn't this just an aesthetic issue?

No. Educating you on heavy metal issues is pointless however, as you have shown a desire to remain ignorant.

It's clearly different out west here in Wyoming but as we produce so darn much of the stuff (480 million tons last year) it might be interesting to compare how the land is mined. Most of the Powder River Basin is gently rolling with the largest seam, from the Fort Union formation, dipping gently to the west toward the Bighorn Mountains. On the western edge of the basin it dips much more steeply to the east and very little is economically minable. Seams are to thick to mine underground. State regs require the mining companies to set the topsoil aside, seed it and keep it separated from subsoil and subsequent overburden layers. The topsoil is to be replaced at the end of reclamation and seeded to "similar" vegetative cover. It takes over a century to create one inch of topsoil so it's clearly a precious commodity. The overburden layers are replaced in the same stratigraphic order in which they were found. Digging 100 foot seams of coal does not produce 100 foot deep holes as the overburden expands greatly while sequestered and does not seem to compact nearly as much as pre-mining. Mined areas are made to blend in topographically with surrounding land. Is it perfect? Absolutely not, but no open pits or highwalls left behind.

I have personally seen some decent reclamation done on pits opened in the early 80s. One big problem has been reestablishing native shrubs such as sagebrush ( Artemisia tridentata). A lot of experimenting was taking place in the mid-80s with direct planting of sage seedlings. At least reclamation today doesn't simply consist of seeding crested wheatgrass (Agropyron cristatum)as was done along hundreds of miles of highways in Wyoming and some of the oldest mine pits in the region. It's a great vegetative cover but pure stands lack diversity of plant species and it has low value as wildlife forage. Plus, any monoculture is not desirable for long term ecosystem stability. I don't know if companies have gone that extra mile including shrubs as it was more expensive than just drilling seed with machines. Still, so much of that land is/was good pronghorn habitat it made sense to try. It has been a number of years since I worked directly with the federal coal program there but it's quite a different world out here in the dry west. Areas that are seeded are irrigated with water produced on site from pit de-watering. Acid mine leaching is not a problem in the Powder River Basin as there is so little sulfur in the coal and not nearly the precip to carry acids off site.

This is not meaning to imply mountain top mining back east is environmentally acceptable. The sulfur/acid leaching and poisoning of fresh water streams draining old mines is inexcusable. Many of my kin still live in those hollers and towns in the region. Don't want to see their homeland destroyed in the name of efficiency and economy.

jbunt

It will take "decades" to recover. Wow!!!! How long is that relative to the age of the earth? 50%? We cannot wait decades.

Thanks. Are there more? All I hear is stories about destroyed environments and displaced people and ruined rives. It's good to see that isn't always the case

Heading Out said,

Mountain top removal is one of the more controversial of these, since it does not replace the rock, as it was. However there are relatively strict regulations for the restoration of the land after mining is over. Some of this land then provides places to build things such as hospitals and schools, and has more value than it had previously.

Sadly, by reading the words of Heading Out and others, I have failed terribly in my effort to gain any concern about the blasting of the Appalachian region.

While concern is great about the ecological damage befalling the 18 to 30 sqaure miles of Alberta, an area with (and I do not want to make it a contest, it is simply true) far less ecological diversity than the Appalachian Region, we will get a place to build buildings, as Heading Out points out, and so there is considered no great loss in the American South....

Let's look at just a small sample of what is being lost, as the mining regions of Appalachia have become the biggest North American market for explosives:

http://zeeman.ehc.edu/envs/Hopp/resources.html

http://www.dlia.org/

http://www.dlia.org/atbi/species/index.shtml

We will for the moment use the Smoky Mountains as an example of Appalachia, although there are many "micro environments" in Appalachia containing even greater variety of species:

If we take the catagory of “flowering plants, we get:

Arales

Calamus, Arum, Duckweed

Commelinales

Spiderwort, Yellow-eyed Grass

Cyperales

Sedge, Grass

Juncales

Rush

Liliales

Century-plant, Yam, Iris, Lily, Catbrier

Najadales

Pondweed

Orchidales

Orchid

Typhales

Bur-reed, Cat-tail

Magnoliopsida

(Dicotyledons)

Apiales

Carrot, Ginseng, Birthwort

Asterales

Aster

Callitrichales

Water-starwort

Campanulales

Bellflower

Capparales

Mustard, Caper

Caryophyllales

Amaranth, Pink, Goosefoot, Carpet-weed, Four o'clock, Pokeweed, Purslane

Celastrales

Holly, Bittersweet

Cornales

Dogwood

Diapensiales

Diapensia

Dipsacales

Honeysuckle, Teasel, Valerian

Ebenales

Ebony, Sweetleaf

Ericales

Clethra, Heath, Indian Pipe, Shinleaf

Euphorbiales

Boxwood, Spurge

Fabales

Pea

Fagales

Birch, Beech

Gentianales

Dogbane, Milkweed, Gentian, Logania

Geraniales

Touch-me-not, Geranium, Wood-Sorrel

Haloragales

Water Milfoil

Hamamelidales

Witch-hazel, Plane-tree

Juglandales

Walnut

Lamiales

Borage, Mint, Verbena

Laurales

Strawberry-shrub, Laurel

Linales

Flax

Magnoliales

Custard-apple, Magnolia

Malvales

Mallow, Linden

Myrtales

Loosestrife, Melastome, Evening Primrose, Mezereum

Nepenthales

Sundew

Nymphaeales

Water-lily

Papaverales

Fumitory, Poppy

Plantaginales

Plantain

Podostemales

River-weed

Polygalales

Milkwort

Polygonales

Buckwheat

Primulales

Primrose

Ranunculales

Barberry, Moonseed, Buttercup

Rhamnales

Oleaster, Buckthorn, Grape

Rosales

Stonecrop, Currant, Rose, Saxifrage, Storax

Rubiales

Madder

Salicales

Willow

Santalales

Sandalwood, Christmas Mistletoe

Sapindales

MapleSumac, Horse-chestnut, Rue, Quassia, Bladdernut

Scrophulariales

Acanthus, Trumpet-creeper, Butterfly-bush, Olive, Broom-rape, Figwort

Solanales

Morning-glory, Dodder, Waterleaf, Phlox, Potato

Theales

Mangosteen, Tea

Urticales

Hemp, Mulberry, Elm, Nettle

Violales

Rock-rose, Cucumber, Passion-flower, Violet

Or how about some mosses?

Bartramiaceae

Bryaceae

Mniaceae

Buxbaumiales

Buxbaumiaceae

Dicranales

Bruchiaceae

Dicranaceae

Ditrichaceae

Leucobryaceae

Fissidentales

Fissidentaceae

Funariales

Ephemeraceae

Funariaceae

Grimmiales

Grimmiaceae

Ptychomitriaceae

Hookeriales

Hookeriaceae

Hypnales

Amblystegiaceae

Brachytheciaceae

Entodontaceae

Fabroniaceae

Hylocomiaceae

Hypnaceae

Leskeaceae

Myriniaceae

Plagiotheciaceae

Pterigynandraceae

Sematophyllaceae

Thamnobryaceae

Theliaceae

Thuidiaceae

Isobryales

Fontinalaceae

Leucodontales

Anomodontaceae

Climaciaceae

Cryphaeaceae

Hedwigiaceae

Leptodontaceae

Leucodontaceae

Neckeraceae

Orthotrichales

Orthotrichaceae

Polytrichales

Polytrichaceae

Pottiales

Pottiaceae

Seligerales

Seligeriaceae

Tetraphidales

Tetraphidaceae

Or Liverworts, Hepatophyta

Order

Family

Jungermanniales

Acrobolbaceae

Calypogeiaceae

Cephaloziaceae

Geocalycaceae

Gymnomitriaceae

Herbertaceae

Jubulaceae

Jungermanniaceae

Lejeuneaceae

Lepidoziaceae

Plagiochilaceae

Porellaceae

Pseudolepicoleaceae

Radulaceae

Scapaniaceae

Trichocoleaceae

Marchantiales

Aytoniaceae

Conocephalaceae

Marchantiaceae

Ricciaceae

Metzgeriales

Aneuraceae

Blasiaceae

Fossombroniaceae

Metzgeriaceae

Pallaviciniaceae

Pelliaceae

Of over 11,000 moth and butterfly varieties in North America, there are more than one thousand in the Great Smoky Mountains alone, much less the entire of Appalachia

Bombycoidea

Bombycidae

Silkworm moths

Saturniidae

Emperor moths

Sphingidae

Hawk moths

Choreutoidea

Choreutidae

Metalmark Moths

Cossoidea

Cossidae

Carpenterworm Moths

Drepanoidea

Drepanidae

Hooktip Moths

Thyrididae

Picture-Winged Leaf Moths

Gelechioidea

Amphisbatidae

Moths

Autostichidae

Moths

Coleophoridae

Casebearer Moths

Cosmopterigidae

Cosmet Moths

Deoclonidae

Moths

Elachistidae

Grass Miner Moths

Gelechiidae

Twirler Moths

Glyphidoceridae

Moths

Oecophoridae

Concealer Moths

Xyloryctidae

Moths

Geometroidea

Geometridae

Geometer Moths

Uraniidae

Swallowtail Moths

Gracillarioidea

Bucculatricidae

Moths

Gracillariidae

Leafminer Moths

Hepialoidea

Hepialidae

Ghost Moths

Hesperioidea

Hesperiidae

Skippers

Incurvarioidea

Adelidae

Longhorned Fairy Moths

Incurvariidae

Leafcutter Moths

Prodoxidae

Yucca Moths

Lasiocampoidea

Lasiocampidae

Lappet Moths

Mimallonoidea

Mimallonidae

Sackbearer Moths

Nepticuloidea

Opostegidae

White Eye-Cap Moths

Noctuoidea

Arctiidae

Footman and tiger Moths

Lymantriidae

Tussock Moths

Noctuidae

Owlet Moths

Nolidae

Nolid moths

Notodontidae

Prominent Moths

Papilionoidea

Lycaenidae

Gossamer-winged butterflies, and blues and coppers

Nymphalidae

Browns, fritillaries, admirals, and monarchs

Papilionidae

Swallowtail butterflies

Pieridae

Yellow-white butterflies and sulphurs

Pterophoroidea

Pterophoridae

Plume Moths

Pyraloidea

Crambidae

Snout moths

Pyralidae

Snout Moths

Schreckensteinioidea

Schreckensteiniidae

Bristle-Legged Moths

Sesioidea

Sesiidae

Clearwing Moths

Tineoidea

Acrolophidae

Tube Moths

Psychidae

Bagworm Moths

Tineidae

Fungus Moths

Tischerioidea

Tischeriidae

Trumpet Leafminer Moths

Tortricoidea

Tortricidae

Leafroller Moths

Yponomeutoidea

Acrolepiidae

False Diamondback Moths

Glyphipterigidae

Sedge Moths

Lyonetiidae

Lyonet Moths

Yponomeutidae

Ermine Moths

Zygaenoidea

Limacodidae

Slug Caterpillar Moths

Megalopygidae

Flannel Moths

Zygaenidae

The people who preach environmentalism and "localism" are now so far removed from their own nation that they are not capable of even seeing the real damage for the smokescreens.

My apology for interrupting the important discussions, thank you though for your time in reading and looking.

Roger Conner Jr.

Roger:

A thought: Why not let the people who actually live in the area -- the people that are effectively the "caretakers" of that local environment, and are the ones that actually have to live with the consequences -- why not let THEM be the ones that get to decide whether, and to what extent, such coal mining takes place? Who else would be in a better position to decide whether the benefits outweigh the costs?

What we have right now are big, non-local corporations funded by big, non-local investors making decisions approved by big, non-local governments to exploit this resource, and then telling the local people that the jobs from the mining and the restoration work afterwards will be to "their benefit". I don't see much evidence that the local people are actually consulted about any of this.

WNC, if I can butt in here, the mineral rights, as you would expect, are often owned by large corporate enitities that are often located many miles away. That is part of the ongoing tragedy of Appalachia (though, the region is in no way unique in this regard; it just happens to have been the focus of a lot of attention, historically).

Coal (as in "King Coal") is the entire economy in much of the coal-producing Appalachians. This owes to the fact that the land is poorly suited for larger scale ag and is geographically remote (and difficult to traverse). Hence, it is relatively sparsely settled. Coal mining, when things are booming, can provide a decent wage, but as you would expect, when the entire economy is dependent upon a single industry, when things go bad, everyone suffers.

When you talk to the local population, you find that they have a love-hate relationship with coal. They like the money but hate what mining does to their health and their environment. There is also a tendency among long-timers to be a bit fatalistic, having been through many economic downturns, seen the health of their loved ones (particularly earlier generations) deteriorate and having had to live with decisions that are made by rich, powerful men in far-away places, for so many years.

I hear what you are saying, but this isn't the way that the extractive industries work.

Part of the problem is an interpretation of the law of mineral rights that allows more than minimal disturbance of the land surface in order to extract minerals under the surface. I would define a "minimal" amount of disturbance to be that caused by typical oil drilling or deep shaft mining operations. Those have enough of an impact on the land as it is.

I am not saying that open pit mining should be totally prohibited, just that subjecting it to a higher level of regulation is not an unjustified violation of property rights.

Roger,

No need to for me to Google mountaintop removal, since I have seen it with my own eyes.

I used to have a mountain chalet in WV. While traveling on some back winding road, I came across a huge clearing I could see in the distance. I'd say about 700 acres.

The landscape looked artificially flat amongst the mountains and obviously devoid of any trees.

Operating in this "flat spots with steps" was maybe a dozen pieces of very heavy diesel powered equipment spewing clouds of black smoke easily visible from a distance. Aside from the obvious environmental destruction, it certainly put many things into perspective, and raises so many questions that it starts to boggle the mind.

It takes energy to get energy.

How much energy did it take to make the awesome earth digging and moving equipment? How much energy does it take to make a ton of high quality steel? How did they move this huge equipment from a Caterpillar factory to the middle of nowhere? What kind of maintenance does this equipment need, how long does it last, and how much does it cost?

How much diesel is this operation burning in a day? There were no visible train tracks (or cars), so how far were they trucking it? How do those asphalt roads hold up to such tonnage, day in and day out? (The tandem dump trucks were lined up)

If CTL is implemented to make diesel, how much would they have to dig to power themselves, and how much would be leftover for electric power generation? Hey much energy does the CTL process use to make a gallon of liquid fuel? What is the value of this coal if it is used to make liquid fuels as well as electricity? (Law of Receding Horizons, HeIsSoFly?) What is the scalability of CTL?

How many acres of Palm Oil trees will be needed to power this single operation every day using biodiesel? How much used frying oil?

I guess it comes down to ERoEI. How does all of this compare (BTU wise) to a single well bore on the Arabian peninsula that has been flowing for years?

Conclusion:

One barrel of oil contains an awesome amount of energy and replacing any portion of it with coal will not be easy or cheap, and certainly will not be easy on the environment.

Sandor:

You're right on the money about the energy economics of coal. When oil replaced coal in the early 20th century in the US, it did so because of cost. Spindletop in Jefferson County, Texas is considered the beginning of the modern oil age in Texas. The well blew in at 100,000 barrels per day, and the well was so prolific that the operator put up an earthen dam to contain the oil.

Petroleum can be piped, petroleum can be pumped. So its a lot less expensive to use than coal which must be shoveled. Oil has very little waste compared to coal, which produces a lot of ash and smoke. And in modern operations the ash must be disposed of and the smoke cleaned up.

The labor differential cost is why the world rapidly converted to oil from coal. And in a post peak world labor is going to get a lot cheaper if we want to maintain an energy intensive lifestyle for many people. And there's not going to be enough money around to support many of the rich. And, I think that's what peak oil is all about.

The cornucopians are right that we will never run out of oil. There's lots of places where you can complete a well and make a couple of barrels a day of oil seeping into the well bore from depleted sands and limes. Oil production started in Texas at Nacodotches in a lignite area producing out of 50-100 ft wells. In Milam County there is a field, Minerva-Rockdale, which used to be produced by rednecks with vacuum trucks sucking out a barrel or two a day of seepage, and in Fayette County at Cistern and Muldoon an operator used to produce using windmills. My father told me that in Humble a guy used to just lower a bucket in old wells and pull the oil up by hand. And those kinds of places are all over the world. The Sumerians used to produce seeps for tar to use on mud brick, the Chinese out of wells with bamboo casing, the indians of Mexico out of seeps for canoe caulking.

My thoughts exactly. I have been toying with the idea that somehow, someone seeing grass being turned into bio-diesel to be used in a tractor must consider at one point to simply use a horse and feed that off the biodiesel field.

Suppose peakoil will initially will turn out to be a major economic problem, we might see an enormous increase in unemployment. That same farmer could consider hiring, for very small pay, people to remove weeds, or other heavy farmwork that nowadays is being done the mechanised way.

P:

A man with a horse can plow about 10 acres a day, a guy with a shovel can spade up about 1/8-1/4th of an acre a day. Either way, the draft animal/person has to be fed 12 months a year, and a horse or mule eats about 15 lbs. of oats a day. Its not pretty, just brutal, hard peasant work-subsistance agriculture. Not many people are going to be able to afford boutique organic food prices at the local farmer's market when its brought in on a wagon.

That's why Alan's electric rail plan is so important-we need efficient transportation, and to save our petroleum for useful purposes if we expect a modern lifestyle. In the US around 100 years ago we had 25% of the population as farmers, and many of them were "dirt poor". Now we have about 1/2 of 1 percent producing food for the rest of us, most rural people work off the farm and are long distance commuters in the US.

A team of horses on good well plowed land might just manage

10 acres a day. One horse on unbroken land will be lucky

to plow 2 acres a day.How many gallons of bi-diesel can be

made from an acre of rapeseed?

How many gallons dose tractor use to harvest and plant an

acre?

Can an acre of crops produce enough fule for a tractor to

do the work of a horse for a year?

The future isn't production of rapeseed, or anything else, to run tractors.

A lot has been learned about agriculture that produces more food with less labor and less chemical input-- http://en.wikipedia.org/wiki/Permaculture for starters.

Trouble is, such approaches aren't really designed to develop the surpluses necessary to build an advanced industrial culture, and I doubt they can be.

In the future, human beings may be reduced to living with each other in groups, talking and telling stories and making music for amusement-- how we will miss the atomic bombs and fighter planes and tanks! And you will actually have to look at those you call your enemy before you kill them.

Napper:

Bi-diesel- where can I find it, on an internet porn site?

Bad jokes aside, I'm not a subsistance farmer, my gardening experience is limited to a kitchen garden. I've never owned a horse or mule, but I expect the price of biodiesel to vary with the distance the oil crop has to be hauled and the distance from the press/refinery, plus the size of the farm equipment. All kinds of variables.

A round trip from farm to factory and back hurts the equation considerably, but is not really necessary. People have been pressing oil from oilseeds for millennia, there are small scale appropriate technologies to do it right on the farm. The original diesel engine ran on peanut oil, it was designed specifically to be used and fueled right on the farm. The veg oils will not work below 0C (neither will factory-produced transesterfied B100), but how much agricultural activity takes place at those temps?

Sunflowers are easy to grow, I have grown them myself. They can be grown on a small scale of a few acres, which is all most farms would need. I don't have any experience with rapeseed; it yields higher, but I can't assess how easy it would be to grow and process on the farm.

I'm more concerned about the energy required to process the food and transport it. The BoWash corridor is home to some 70 million people, over 20% of the US population. None of those states are, IIRC, anywhere close to self-sufficient in food, nor likely to become so. The food to feed those people is going to have to be transported hundreds of miles. How many gallons of bio-diesel to move a ton of food from Indiana to Manhattan?

How many gallons of bio-diesel to move a ton of food from Indiana to Manhattan ?

A drop or so of lubricant once you get the food to a railhead (electrified).

Best Hopes,

Alan

Actually, I'm not sure about the relative merits & costs of electrified freight train, midwest to NE corridor vs. barge down the Ohio & Mississipi, around Fla. and up the coast. Water has traditionally been a pretty inexpensive way to move heavy bulk goods. Your rail is probably the way to go for perishable produce (though much of that could be produced locally at truck farms, greenhouses, & community gardens), but water might possibly work out to be the better strategy for moving the grain.

WRT grain, see my post below in reply to Alan per water transport of bulk quantities of grain. The big question is not how you are going to get the grain supplies, but what you are going to produce to send on the return trip in payment?

The BoWash corridor used to get most of its produce from local truck farms. These have diminished (but not entirely gone away) due to competition from produce that could be grown and transported cheaply from California, Florida, Mexico, etc. When transport costs go up high enough, truck farming will again become profitable in the area. Community gardens can also be established on vacant lots; some of this is already happening, it just needs to be scaled up. For the less dense neighborhoods where houses actually have yards, people can grow their own gardens; when food prices get high enough they will do this. There is a lot of acreage in lawn grass that could go to produce a lot of potatoes and beans -- that's what Switzerland did to feed its population during WWII.

Many of the dairy products consumed in the corridor actually do not come from all that far away - there is an arc of dairy farms from New England through upstate NY, PA, MD and VA that supply most of the milk for the region. You do get some cheese and other processed dairy products from Wisconsin and other midwest states, and higher transport costs will drive the price of those up quite a bit.

Meat? Well, I suggest that you start shopping for cookbooks with lots of recipies for beans (and maybe lay in a lifetime hoard of Beano). Meat of all types is going to become pretty expensive, especially in that part of the country. Poultry products should be reasonably available at high but not impossible prices; chickens and turkeys can be produced in quantity just outside the cities (and even in city backyards if the zoning boards are hogtied and thrown in the dungeon). The ocean fisheries are dying, but there should still be some trash fish available. Pork will be an expensive but available luxury, eaten just occasionally; salt cured country ham transports slowly & without refrigeration, so people might need to relearn to use it. Beef will become the new caviar.

In general its a win situation for small tractors. But I'd like to add that tractors are a good target for SOFC solid oxide fuel cells coupled with electric motors and of course such a tractor could also run off of batteries or external supplies with a bit more work super capacitors might even be viable for a tractor. The SOFC itself could be on the tractor or brought nearby esp if you have viable super capacitors.

So if you consider fuel cell power for tractors and even better the use of some of the waste organic material straw etc for the power instead of the edible part you have a clear winner.

And of course the ash can be recycled back into the field.

People do post routinely about how farmers in third world countries don't find it economic to use tractors. But I think the argument if flawed.

1.) Most third world farmers own small plots of land often scattered because of inheritance.

2.) They generally don't have capitol and also the local currency is kept artificially low vs the dollar for exports

so they don't have buying power for imports. And they are fairly competitive so co-ops tend to be rare and are probably not that useful for such small plots.

3.) They have an abundance of cheap labor.

4.) They have their own pork barrel politics surrounding food production that tends to distort pricing from the free market.

5.) A lot of the poor countries are tropical or semi-tropical and irrigated rice is the major grain crop.

The economics of rice farming and mechanization are different from other grains. And I'd say in general hand labor is more competitive.

6.) In many cases the draft animals are used for a variety of purposes not just plowing the field so assigning all the energy used by a horse or water buffalo to just plowing is not correct.

None of these conditions apply to western farmers so its a completely different situation so it makes no sense to compare third world farming directly to how western farms might operate as peak oil continues. I see no reason for farms not to continue to be mechanized to a high degree albeit with more efficient equipment. The most important factor in choosing mechanization over hand labor is in my opinion the size of the farm once its over about 100 acres mechanization probably wins. So I don't see people moving back to the farm in the US simply because it won't be worthwhile for the farmer to feed them for their labor much less pay them.

If you don't find that statement disturbing you should. Since post peak with our overshoot condition in I suspect many people will find that their labor is not worth the food to feed them.

Wikipedia

127 U.S. Gallons per acre for rapeseed oil

Colorado state university 1.68 gallons per acre to plough a field

you could run a 150 acre farm with 2 good horses and use

no more than 3acres to feed them.

A tractor will need 2 acres just to plough the land, then

it needs to be sowed, and harvested. anthor 2acres.

So it is more land efficient to use horses, and of course

they can have a foal to replace them. I have never come

across a tractor that will not break down.

Napper-

I don't understand; It takes 1.68 gallons to plow a field. And we can get 400 gallons of corn ethanol (a figure that will rise with crop yields, which have risen 40 percent in the last 20 years, and are still climbing). In tropical climes, we might get 1000 gallons of jatropha oil.

According to USDA, inputs are declining for farming, as productivity rises each year.

Do farmers really use that much fertilizer, that it amounts to hundreds of gallons an acre? (Of course, fertilizer comes from natural gas, although I was surprised watching an old war show, that during WWI fertilizer was made at hydropower plants.)

Seems like biofuels will be coming on strong.

Coal is filthy dirty to burn, and destructive to mine. But, as a 30-year stopgap, maybe we have to use it. I cringe at the thought of wiping out mountaintops.

Surely PHEVs and biofuels can help us use as little of the coal as possible

Have you paid vet bills etc etc.

Horses need care. Also as I said in my first post.

Gasification of the waste straw will work for tractors

you don't need to use any farmland.

Nothing against horses I still don't see them as a sure fire win post peak in the technically advanced countries. If they were as cost effective as you say I'd think they would have significantly more use now since your claiming they are effectively free. I'm sure a lot of farmers would be willing to fore go the costs of tractors fuel etc etc and go with horses now.

So what you need to do is a total cost analysis not just the

fuel costs. Also 3 acres is a bit tight for 2 horses.

http://www.newrider.com/Library/Misc_Tips/land_horse.html

I'd go 4-5 in general since you also need land for oats.

And finally technically you don't have to calculate land use. Assume 10 dollars a gallon for diesel as a maximum price you can buy it for less now in bulk.

150*10*1.68 = 2,520 dollars.

Vet bills.

http://www.horsechitchat.com/equineforums/showthread.php?t=347

180 dollars to 2,200 dollars per horse.

Assuming a good horse is 4 grand you would max at somewhat less than that say 3 grand.

And ten a gallon is a maximum so say its 5 dollars a gallon

in farm country and your at 1260 for the fuel for the tractor. And you have 360 for vet bills alone assuming no problems. I don't think horses are cheaper overall than a tractor. If you think back to when tractors first came around if they really where so much more expensive you would have had to think that we would still have competitive farms using horses now. I can't see the difference in price for fuel vs horses as enough to change the equation a what I consider the highest price possible which is the cost of new food grade sunflower oil in a individual container.

So I don't buy into the concept of farming going back to horses on any large scale its not going to happen.

And neither will we have a lot of people move back into agriculture.

What will happen is we will continue farming similar to how we do it now but probably with more organic inputs if fertilizer costs increase too much.

As I said before the overall situation indicates that 25-50% of the population of the US is not needed and not even worth the price of food to feed them. Next considering the skill set I doubt they can make it as dirt poor subsistence farmers. This underlying extreme poverty will drop wages to almost nothing and cause effective slavery as in China.

Sorry I was not clear . I am only thinking in land use.

You can feed two good horses on less land than you would

need to use to grow biodiesel for a tractor.

I am sure that given the choice I would use the extra land

needed to keep my tractor going.

I grew up in and around small 100-200 acre mixed family

farms in southen England,early sixties we all used small

tractors,most still had horses for fun, and did not need

that much land to keep. They were not draft horses which

are bigger and will need more grain if worked hard, ie

ploughing.

I can remember talking to some of the old family retainers

who used to work on the farms before the 2nd world war and after and the number of people need to run a small farm

only useing horses and manpower is 6 or more during harvest

Today it will be only 1

The other main advantage of tractors is speed. If the

weather changes you can get a lot of crops in or planted

useing one compared to useing a pair of horese, so in the

long term you will get better yields.

I was surprised at the amount of land one would need to

plant to run a tractor for a year probably nere 10% for

a mixed farm. still much more economical than horses.

It should be pointed out that there are not exactly huge numbers of the draft horse breeds that would be needed in large quantities were agriculture to become de-mechanized. It would require many, many generations to breed sufficient numbers to replace all the tractors -- probably far more time than we really have available.

Ah, but then there are the oxen. You see, dairy farms need to produce calves because cows need to calve in order for their milk production to remain. The females are offcourse to be used for milk production and the overshoot is slaughtered for meat. The males are all slaughtered for meat, yet in the old days some were castrated and used as draft animals. Very strong animals.

Yes, good point. The retired oxen were eaten, too. I am actually old enough to have experienced an ox roast in the small town in which I grew up. Something you would have a very hard time finding anywhere in the US today.

127 U.S. Gallons per acre for rapeseed oil

*3 = 381 gallons. 381/1.68 = 226 acres...using your numbers.

you could run a 150 acre farm with 2 good horses and use

no more than 3acres to feed them.

Source? What I was understanding the 'rule of thumb' was 25% of the acres have to be set aside for draft animals.

So it is more land efficient to use horses,

Oh really? I've used your numbers, I don't see that.

What is really land efficient is to put up PV and wind turbines, then use electric machinery to do the work. (feel free to refute)

Your numbers show no cost of human time to deal with the horses VS the machinery nor the feed value of seed cake VS the ponies.

My guess is you've never worked 150 acres, with either a tractor or horses. I know of no one who works 150 acres with 2 or 3 horses.

To grow a crop you have to do a lot more than just plough

the land; ie sow spray harvest

So you use much more than 1.68 gallons to plough.More like

3.5 gallons per acre. The Colorado state uni site gives

a breakdown for each type of useage for a tractor.

I live in Warwickshire UK 100 miles north of London,

we do not get a lot of good sunshine,or much wind, though

nice mild climate.I would love to use PV or wind power,

but have not yet come acress battry powered tractors.

I AGREE WITH YOU THAT THE SKILL AND THE TIME NEEDED TO

USE HORSES IS A BIG PROBLEM.

If things get realy bad 20 to 30 years time a farmer

will most likley find it hard to make new PV panels or turbies or tractors,but will most likley be able to breed

horses.

I hope we never need to go back to useing just muscle power.

Ever had a horse the is never sick or injured? The care and feeding of a tractor is simple compared to the complexity of properly caring for a horse.

I know a European farmer that uses horses. Not because of neccessity, or for economic reason, but just because he likes the idea. He found the sale of foals was a suprisingly nice source of income. He said it suprised him to find that horses actually made more economic sense than most suspected.

A little over 100 gal/acre for sunflowers, a little over 120 gal/acres for rapeseed. Thoses yields are for industrial technology processing -- simple small-scal, low tech pressing on the farm would yield somewhat lower quantities.

The figures I have seen for common mechanized agricultural operations suggest that for most crops farm diesel usage is around 2.5-5 gal/acre. Thus, we are looking at farms needing to devote around 2.5-5% of their acreage to oilseeds to produce enough biodiesel to fuel their own operations.

Back in the horse era farms would typically have to dedicate a considerably higher percentage of their acreage for food & fodder for their horses.

And you could rotate rapeseed with wheat, as already is currently practice among farmers.

I'm not saying that farmers will switch back massively on human labour or draft animals. Actually I'm just toying with a thought. Anyhow, Life on a farm is far more complicated. But you just might find more use for draft animals, as well as biodiesel fueled tractors.

By the way, where did you get the info about former percentage of acreage for food and fodder?

My daughter, the horse expert, says that it takes about three of those acres to feed the horse, depending on the size of the critter.

Hi Roger,

Thanks, out of that mountain of information I mined this little black nugget:

Buck must have had the tough luck to be a buck short of rangerhood. Oh the heartbreak of it all.

ThatsItImout,

Thanks for reminding us. One thing that I just found is the Martin County Coal Slurry Spill which was an environmental disaster so large it made the Exxon Valdez spill look minor by comparison.

And we've never heard about it. Thanks to effective work at the top levels of our government.

On a separate topic, why would anyone think that it's a good idea to take down a bunch of mountains - host to a functioning and varied ecosystem - and turn them into a bunch of gravel parking lots that produce contaminated water and can hardly grow anything? Oh I know, it's in the bible:

"Every valley shall be exalted, the crooked shall be made straight, and the rough places plain".

And isn't there also something in the bible about "go forth and multiply thy profits to the detriment of all my living creatures"?

Just wondering.

This is why I love geology.

Good article

Im not sure if TOD has done a piece on the changing EROI of coal.

It would be very interesting to see the extent of the upward shift in the supply demand curve intersection, and make some speculative projections on where that is going.

(note I am assuming upward shift like oil - with coal I'm not sure)

Today when you take the major industrial metals - aluminum, copper, nickel, zinc, lead, the price in 2006 was 315B. Total world economy was 45T

so these metals were less than 1% of world economy. This after 3X - 5X increase in price of these metals over the past 4 years.

These metals are essential to modern life,

yet all these metals are very energy intensive to produce.

That energy (primarily) comes from coal as electricity (question: what is % of oil vs coal in production?)

I would suggest these metals are at the base of the energy "food chain" that is, cost increases here will have a multiplier effect as you get closer to end user products and services.

These economic ripples and feedback loops have a long way to play out

Very helpful article. Helps explain a lot about why the high reserve numbers we see may not result in the expected level of production.

One question that I have wondered about for quite a while -- why are China's coal reserves as low as they are? As I recall, China produces quite a bit more coal than the US, yet has only a small fraction of the coal reserves. Do you (or any reader) have any insight as to what is going on?

My first thought is that they are more conservative in the way they count their reserves.

A couple of Chinese peasants producing coal with a pick, shovel and wheel barrows at $2 a day make a skinny coal seam economic. Welcome to the post-peak economic scenario!

I don't have an immediate answer - I'll check with some of my colleagues and see if I can put it in the next post, which will deal more with national reserves.

China used to classify reserves based on the old Soviet model, and thus what they called "proven reserves" was larger than what it would be by general international practice. They have gradually moved closer to international practice, particularly for oil and natural gas.

China is currently nearing completion on its third national resource survey (first in 1987, second in 1994). Although the official results for coal have not yet been released, in 2004 China estimated they had total reserves of 1.018 trillion tonnes, but exploitable reserves were 114.5 billion tonnes. This is in essence the WEC number from the early 1990s. I expect this figure to rise with this assessment.

Why do they produce so much coal? Basically, because they have it, it's plentiful and cheap. Oil wasn't discovered in China in large quantities (Daqing field) until 1959, and output didn't exceed the low level of domestic consumption until the late 1960s. By then, China's industrialization was well under way, built on coal.

Since 2000, China's coal consumption has more than doubled to 2.3 billion tonnes. Back in 2000, the R/P number that China always touted was "150 years of coal". That same R/P number today would be 50.

Recently a number of studies from China have even predicted that China will reach peak coal production around 2020 or shortly thereafter. Indeed, if you look at the IEA WEO 2006 forecast of coal consumption (which is half the current rate of growth and doesn't include their insane CTL plans), China would be halfway through their known recoverable reserves by 2019. So even with a higher reserve number, peak is unlikely to be much farther off, especially if you factor in CTL plans. Only half of China's coal is bituminous--the balance mostly subbituminous along with some lignite--so peak coal BTUs could happen before then.

A decent book on the subject:

Coal: A Human History by Barbara Freese

http://www.amazon.com/Coal-Human-History-Barbara-Freese/dp/B000LMPL5G/re...

I read it and found it informative, particularly as it highlights the poor image that the industry has in society. It was reviewed, along with Big Coal, some time ago on this site.

"Coal: A Human History by Barbara Freese"

Fun book.

Thunder basin was fun trip too.

Thanks, Heading Out,

In your next installment, are you going to get into EROI questions? It seems that the EROI of mountaintop removal must be low, particularly once you factor in the "reclamation" cost (presuming it's done right).

Also, are you aware of Heinberg's piece on the possiblity that coal production may peak much sooner than most of us expect?

Fantastic stuff HO - love your clear explanations. Looking forward to part II, and hope you'll pass judgement on the various "peak coal is near" essays that have been floating around lately.

The last link I posted did not work but this one should. It is a coal peaking article.

http://analyst.energy.googlepages.com/TERNumber5.pdf

Larson Thane